Gasket based on force-induced color change coating

A color-induced and electrochromic technology, applied in the field of gaskets based on mechanochromic coatings, can solve problems such as loss, pre-tightening force reduction, fatigue damage of connectors, etc., to achieve simple working principle, smart structure, and accident prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, please refer to Figure 1 to Figure 2 .

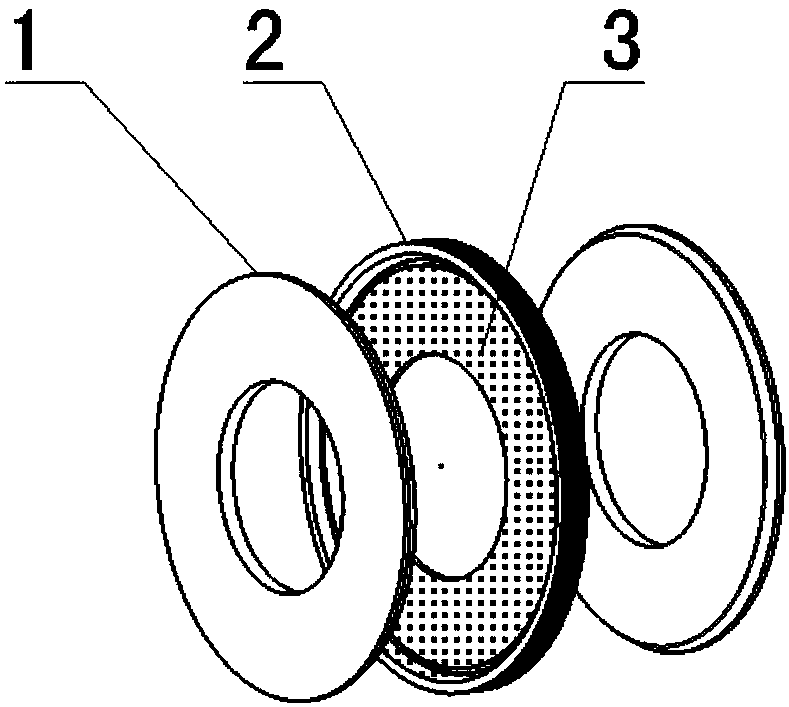

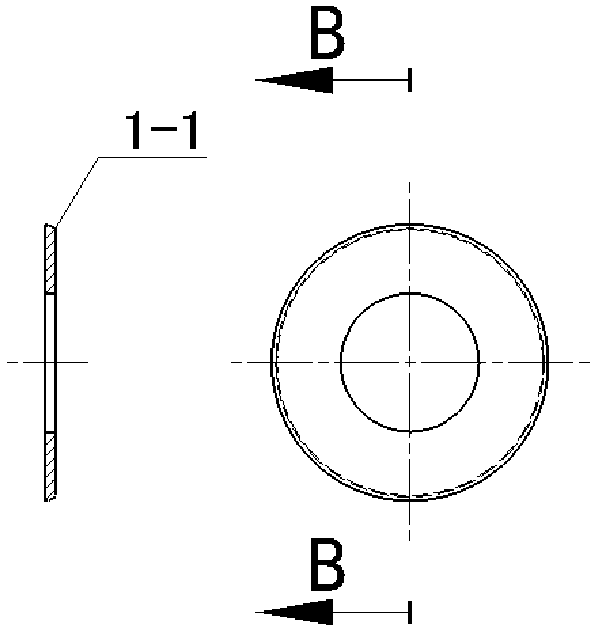

[0018] Such as figure 1 As shown, a gasket based on a mechanochromic coating, including a press gasket (1), an electrochromic coating (2), and a piezoelectric ceramic gasket (3); the surface of the piezoelectric ceramic gasket (3) is supplemented with an electric For the electrochromic coating (2), the pre-tightening force on the pressure washer (1) caused by the tightening of the bolts causes the piezoelectric material on the piezoelectric ceramic gasket (3) to generate a voltage, realizing the electrochromic coating (2) under the action of voltage. Colorize down to the specified color.

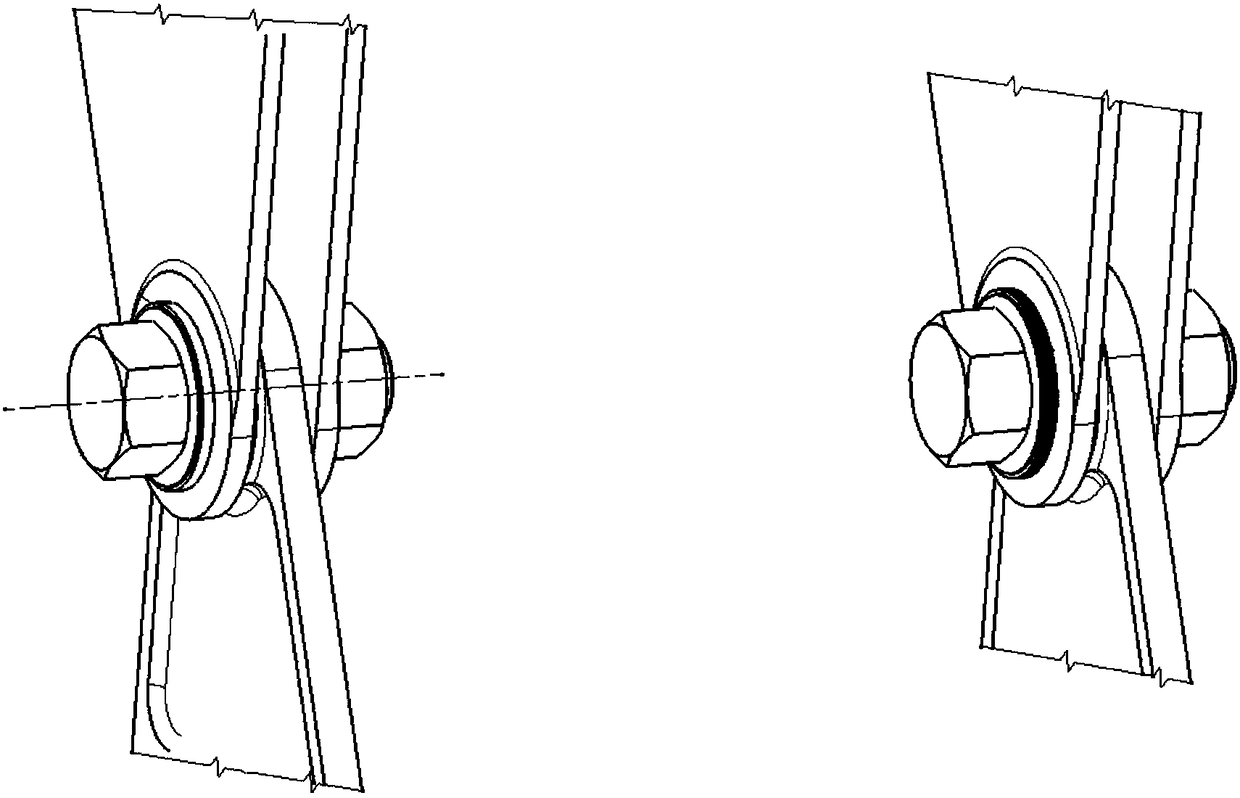

[0019] Bolt tightening is achieved by a color change, as the color disappears to indicate a loose or broken bolt.

[0020] Such as figure 2 As shown, the washer based on the mechanochromic coating changes color under preload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com