Ultrahigh strain sensor based on fiber bragg grating

A technology of strain sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problem that the negative strain measurement range cannot be improved, and can be measured, and achieves the effects of low cost, simple working principle, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below with reference to the drawings and examples.

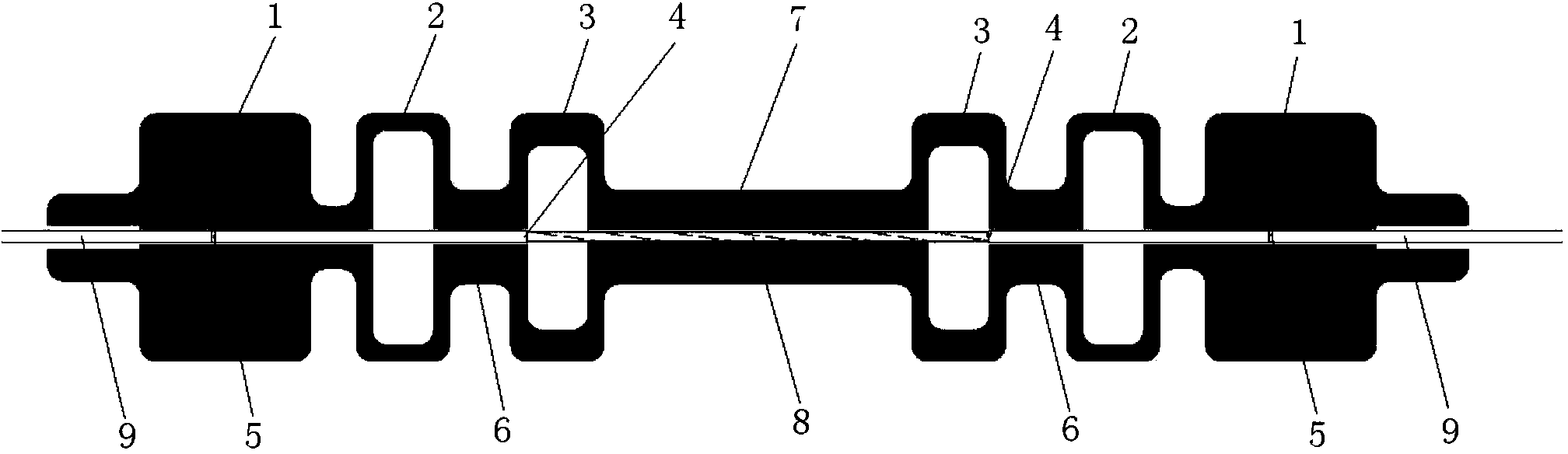

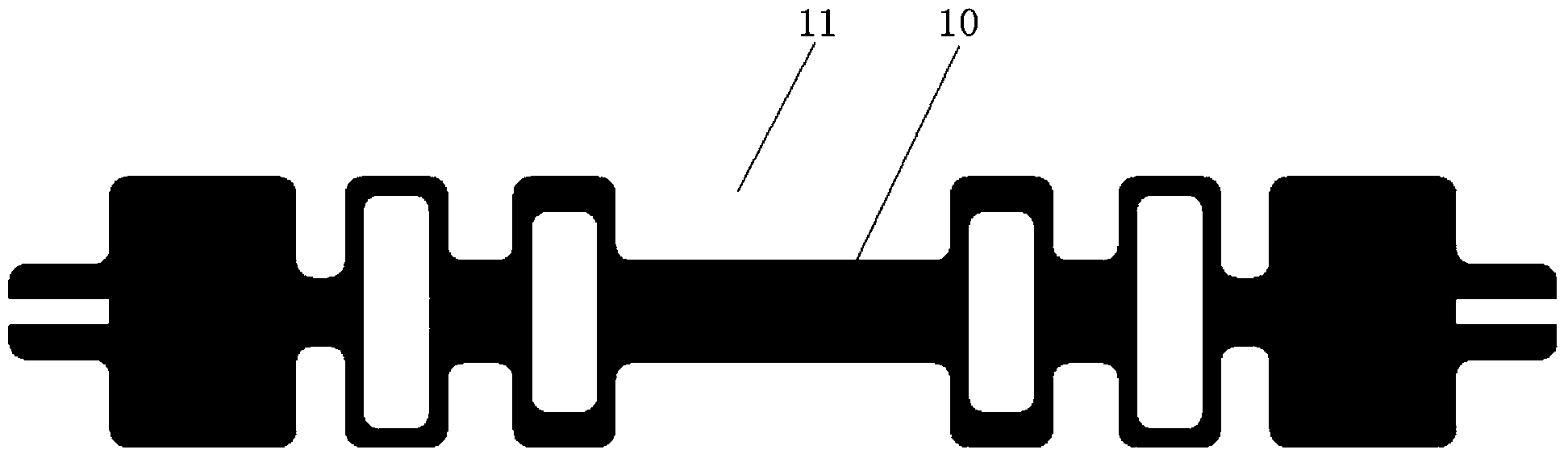

[0017] as attached figure 1 Shown, a kind of ultra-large strain sensor based on fiber grating provided by the present invention comprises substrate (11) and the optical fiber (9) that has fiber grating (8), and wherein fiber grating (8) selects the grating that grating length is 10mm for use, The base (11) is composed of a connection area (7) from the center to both ends, an inner elastic structure (3) positioned at both ends of the connection area (7), an outer elastic structure (2) and a base fixing area (1), and the connection area (7) ) is directly connected to the inner elastic structure (3) at both ends, and the U-shaped transition section ( 6) Connection, each component is processed by an integrated structure, and its U-shaped transition section (6) can also be arc-shaped or other shapes, as long as it can meet the effect of preventing exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com