Optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt

A technology of intelligent bolts and fiber gratings, which is applied in the direction of transmitting sensing components, measuring devices, instruments, etc., by using optical devices, can solve the problems of inability to demodulate signals to distinguish strain and temperature changes, increase the complexity of the test system, etc., and achieve structural Smart, low cost, accident prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be described in detail below with reference to the drawings and specific embodiments.

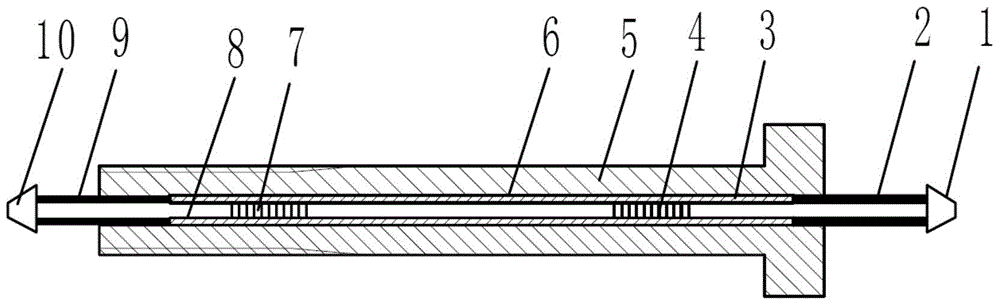

[0020] The temperature compensation smart bolt in this embodiment has a structure such as figure 1 As shown, it includes: a first fiber optic ferrule 2, a second fiber optic ferrule 9, a first fiber optic connector 1, a second fiber optic connector 10, a bolt body 5, an optical fiber 8, and a first fiber grating engraved on the same optical fiber 8 sensor 4 and a second fiber grating sensor 7.

[0021] The first FBG sensor 4 senses both temperature and strain, and the second FBG sensor 7 only senses temperature. The sensitive parts of the first FBG sensor 4 and the second FBG sensor 7 are fiber Bragg gratings, which are gratings with a length of 10 mm and a diameter of 125 μm formed on an ordinary single-mode fiber by laser marking.

[0022] The bolt body 5 has an axial sensor embedding hole 6 passing through the bolt body 5 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com