Patents

Literature

314results about How to "Reduce assembly requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

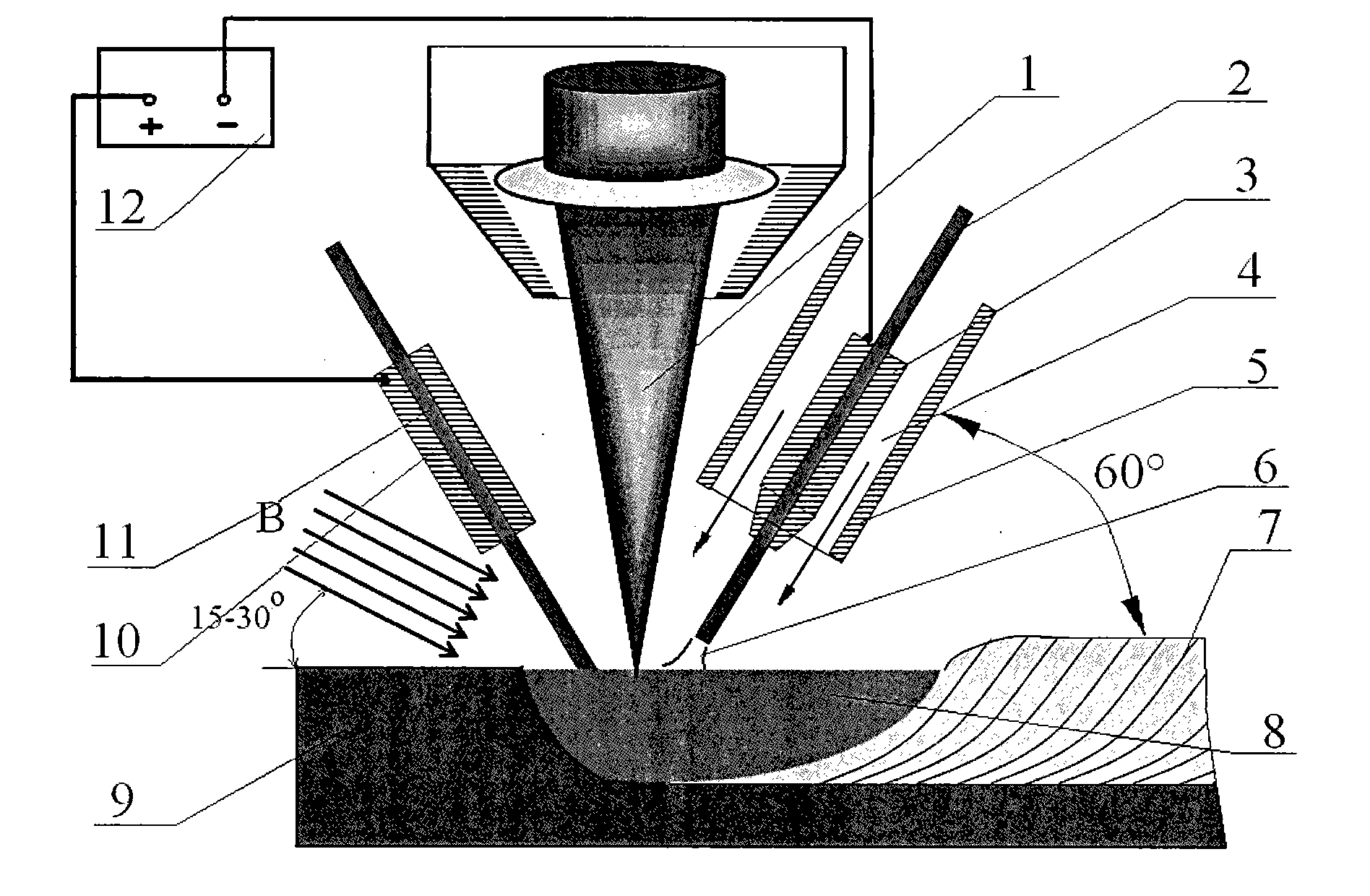

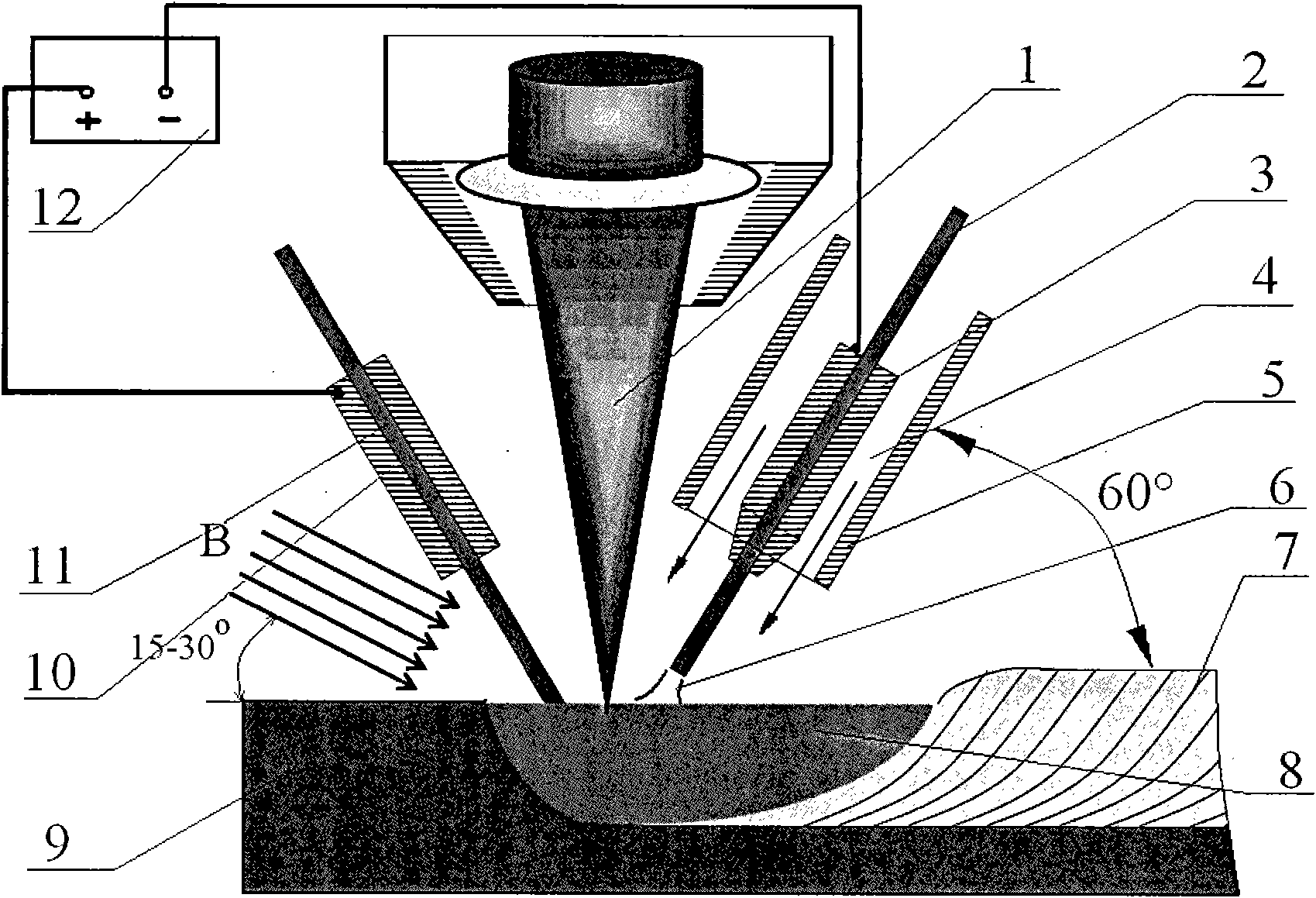

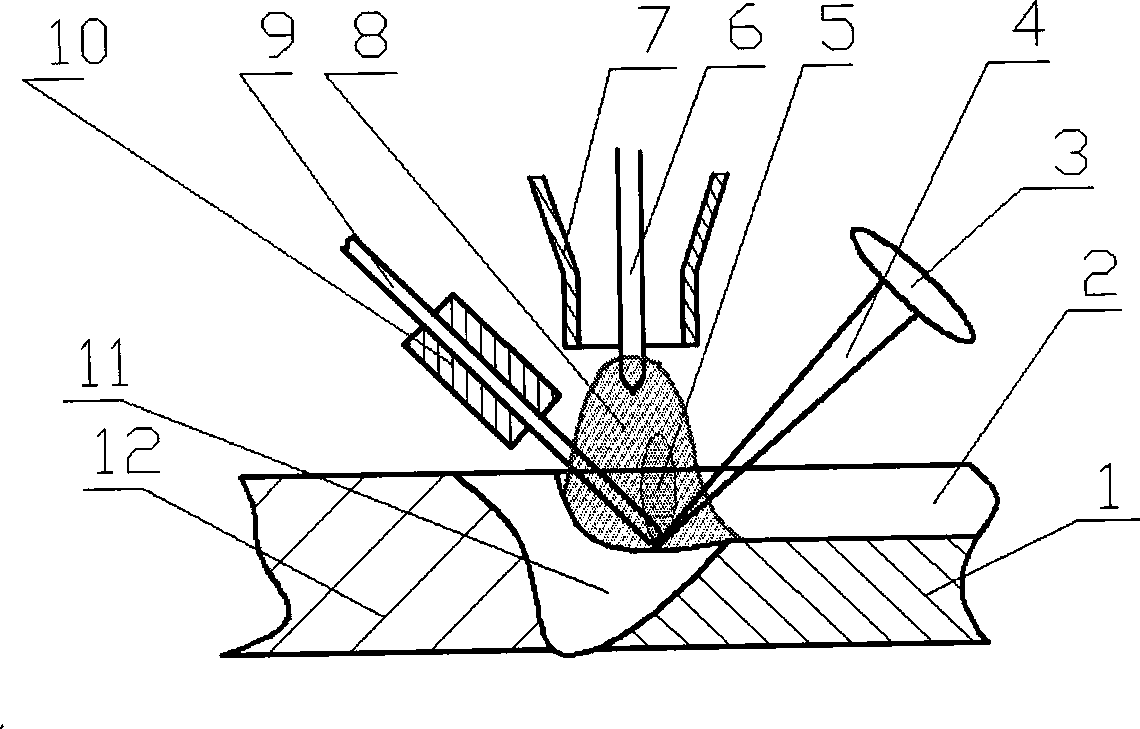

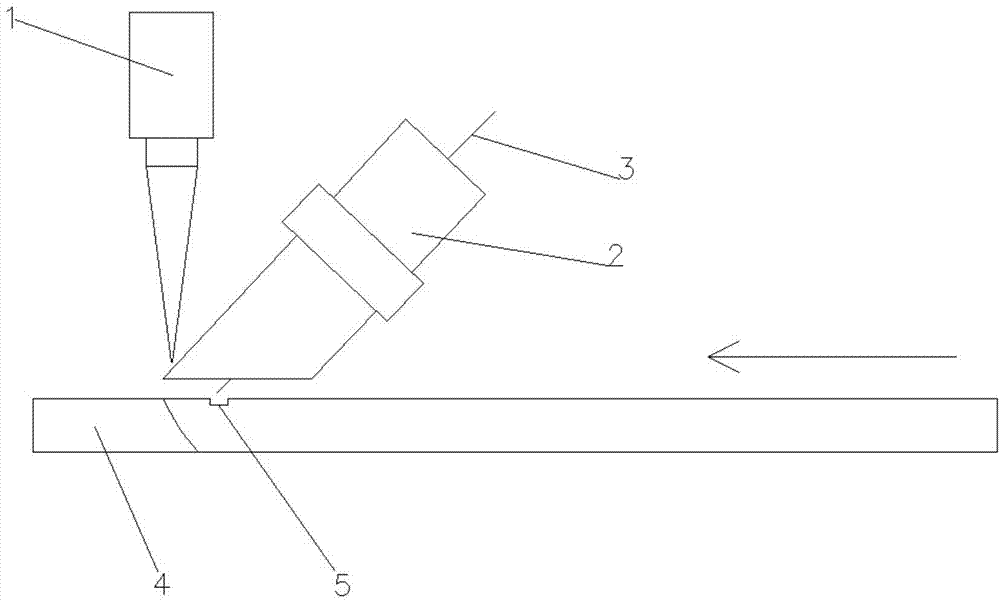

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

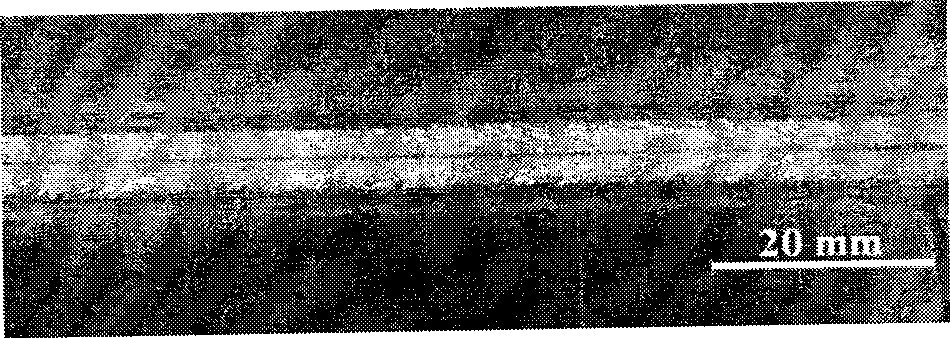

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

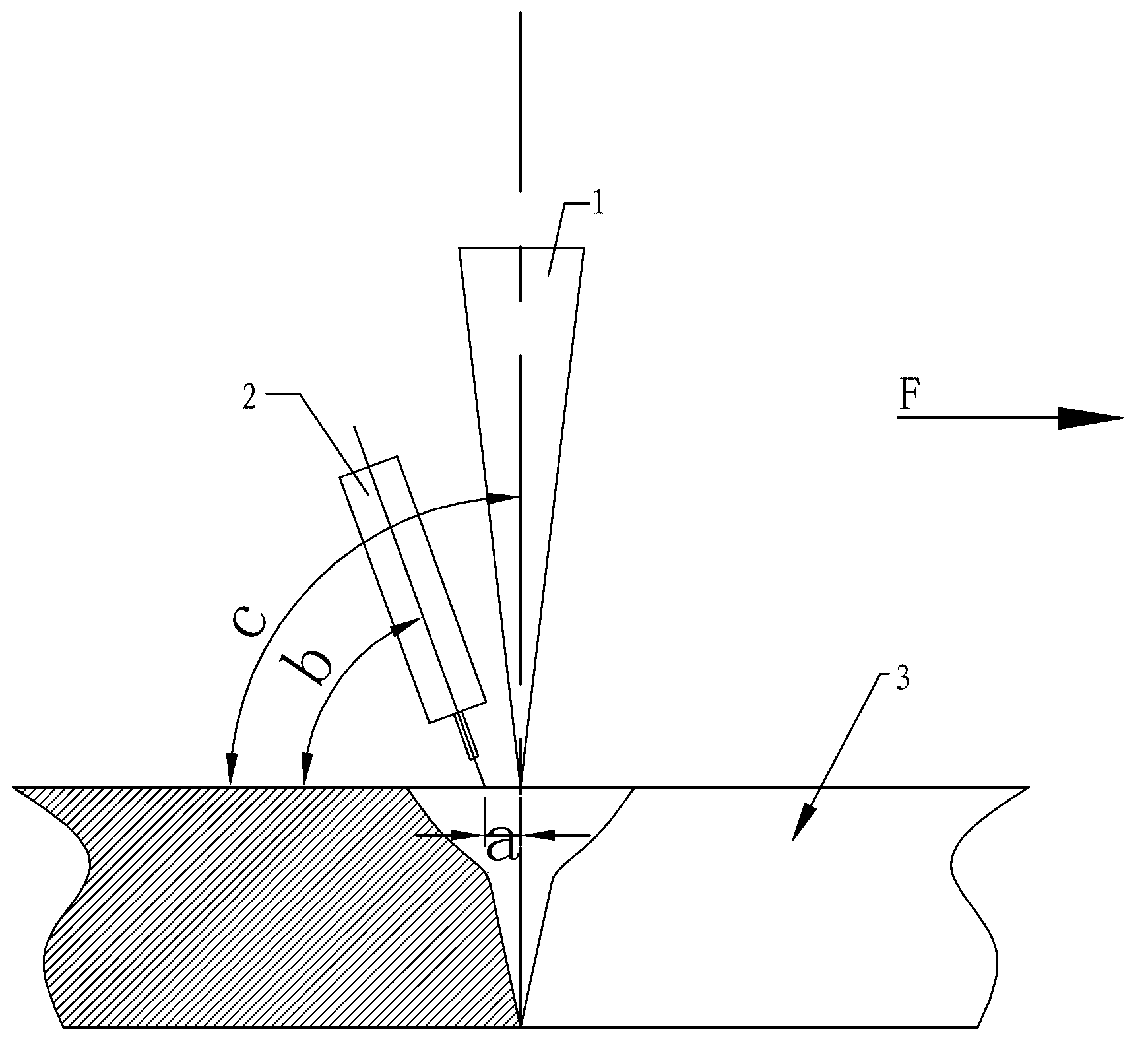

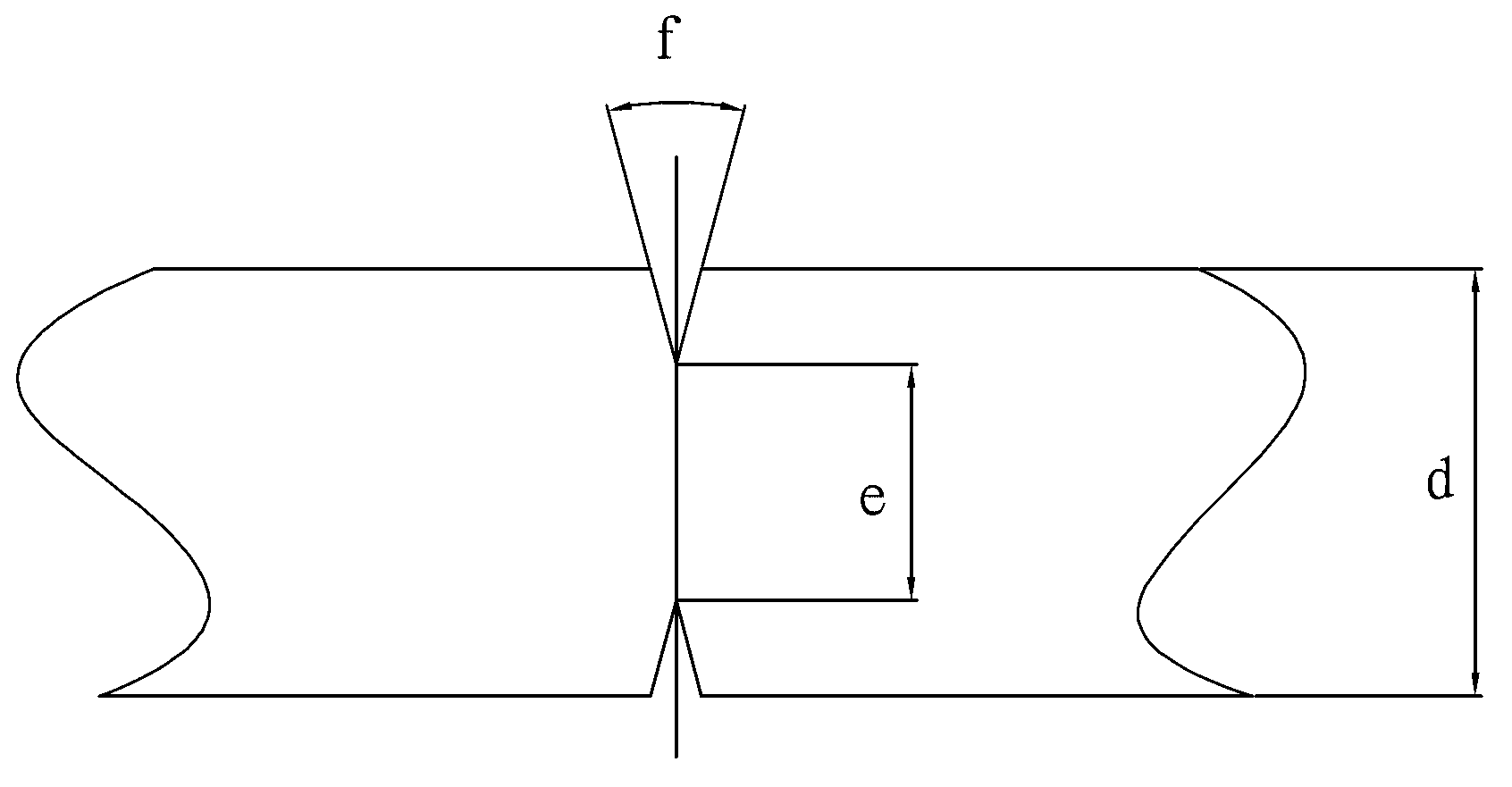

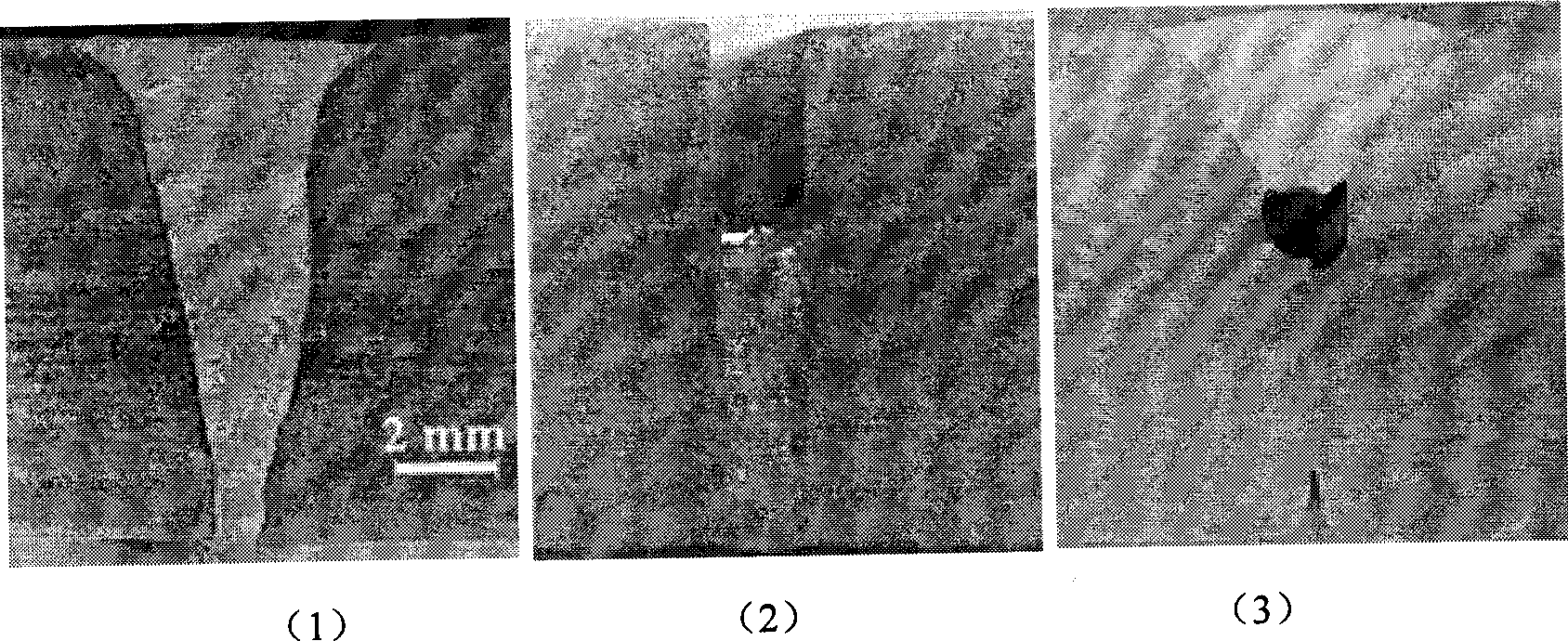

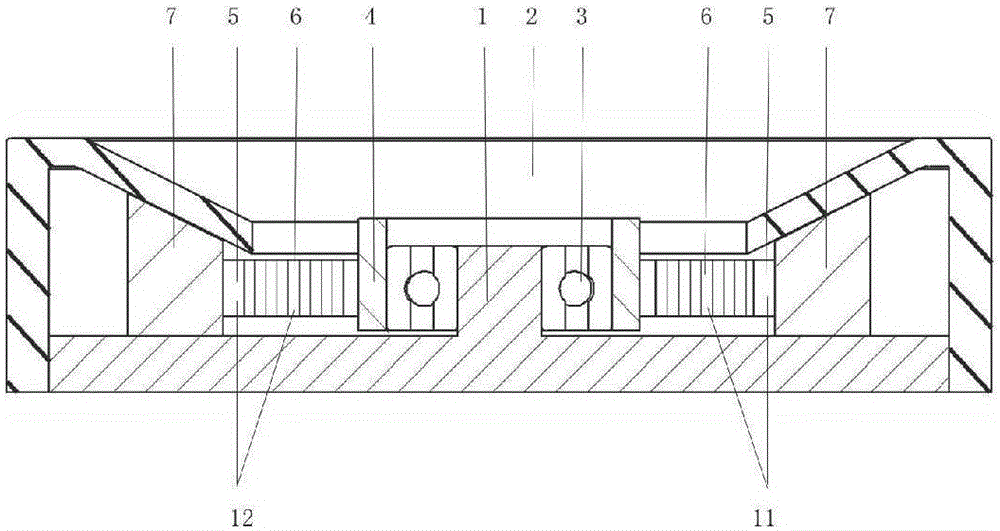

Narrow gap laser-arc hybrid welding method using filler wire

InactiveCN101474726AImprove welding efficiencySimple welding processLaser beam welding apparatusHigh power lasersEngineering

The invention relates to a narrow gap laser-arc composite welding method adopting a filler wire, belonging to the technical field of laser materials processing. The method adopts a high-power laser and an laser arc hybrid, and the arrangement mode thereof is that a laser bean and a welding wire are arranged in opposite directions corresponding to an electric arc, wherein the laser bean enters slantwise from the front part of the electric arc, and the welding wire is led into a divided edge gap from the rear of the electric arc, and after fusing the welding wire, a composite thermal source fills the gap, thereby realizing the single pass welding shaping of a work piece. The method fully utilizes the penetration fusion property of the laser and the high filling efficiency of the electric arc; and under the mutual actions of laser and arc, the stability of a welding process is improved, and the welding efficiency is increased.

Owner:BEIJING UNIV OF TECH

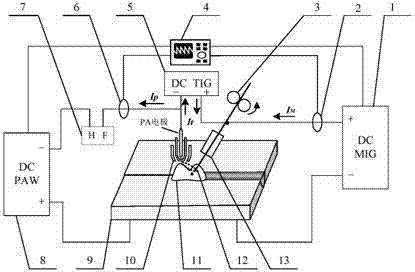

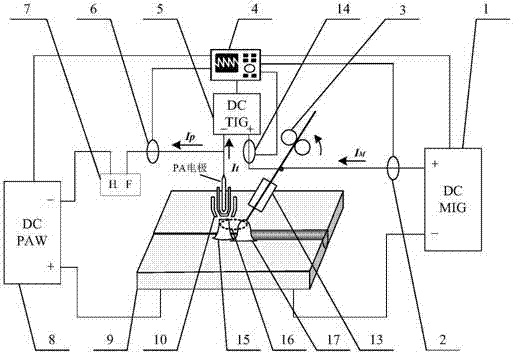

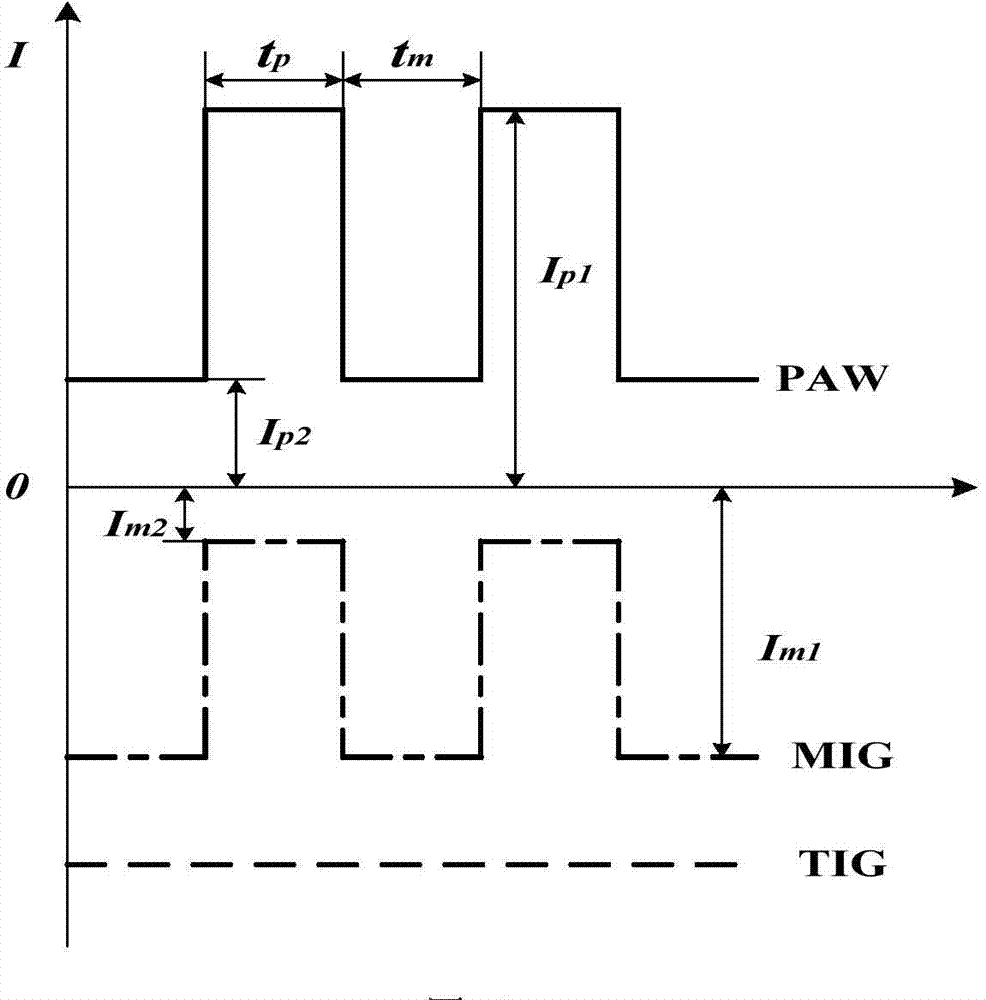

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

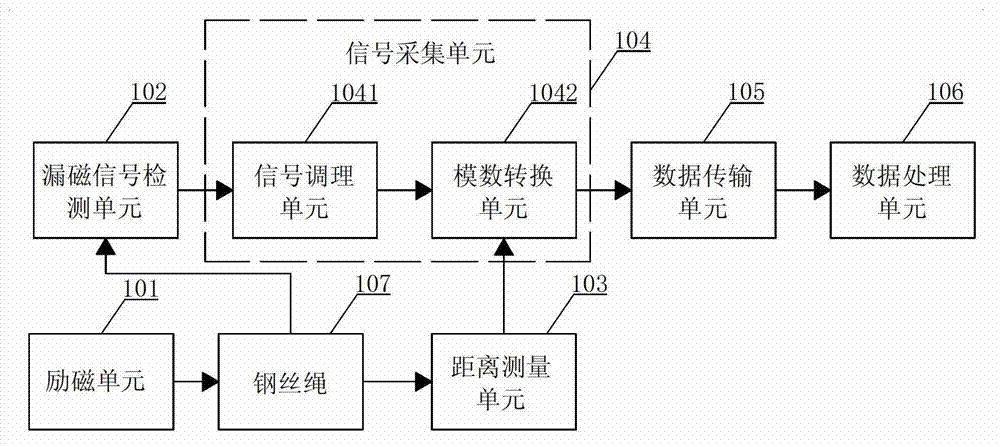

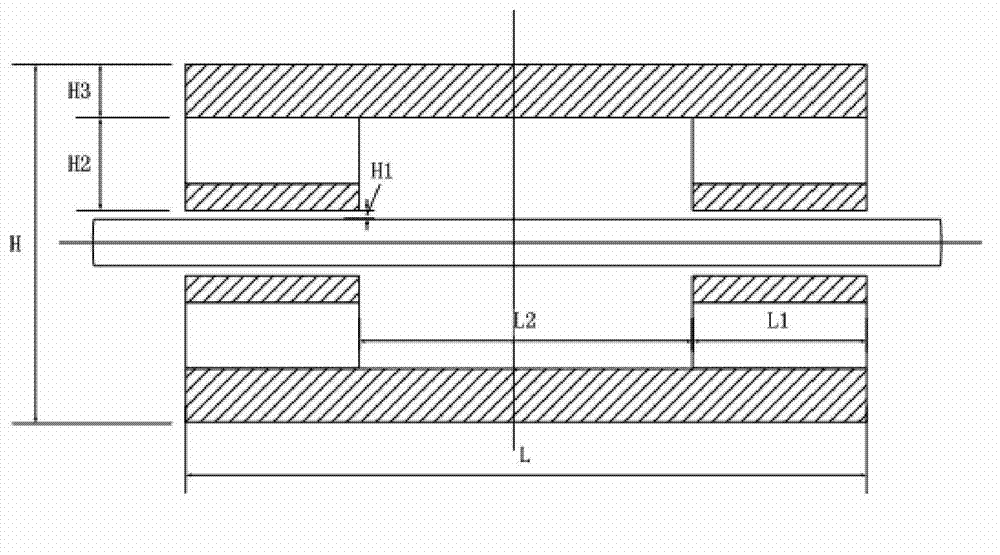

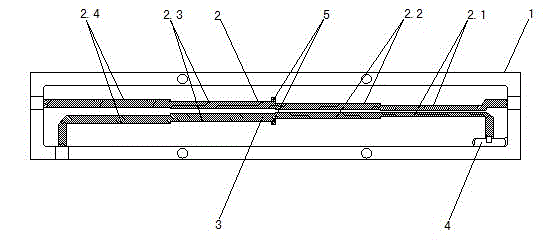

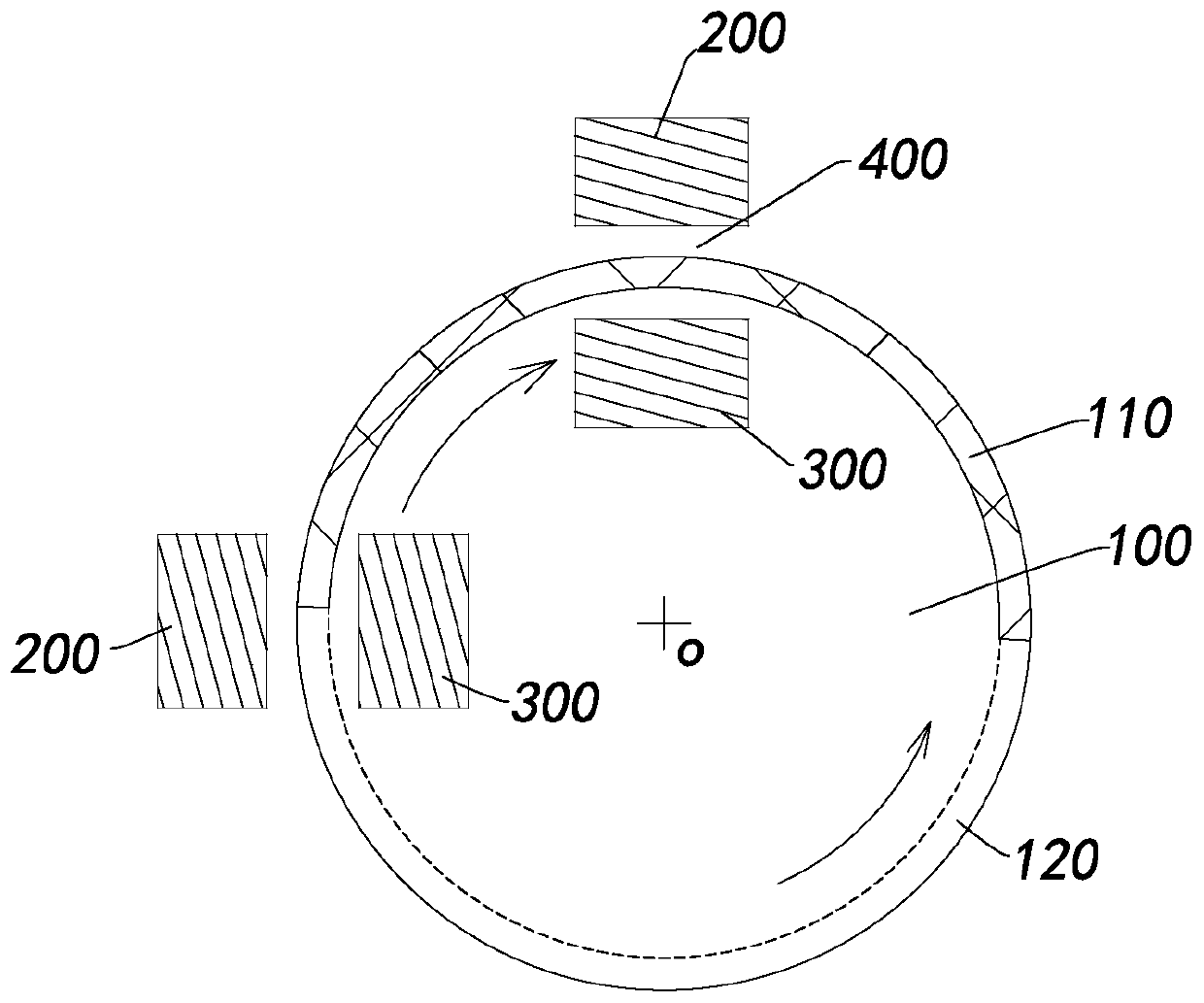

Defect detecting system for steel wire rope

InactiveCN102879460AReduce in quantityReduce assembly requirementsMaterial magnetic variablesMeasurement pointEngineering

The invention discloses a defect detecting system for a steel wire rope. Twist numbers of magneto-dependent sensors are uniformly arranged along the radial direction of the steel wire rope and in a position at the middle part of an excitation unit close to the surface of the steel wire rope with a certain distance; and then, magnetic flux leakage signals detected by the various magneto-dependent sensors are combined into one path to be output to a signal acquisition unit through a certain weight. The signal acquisition unit converts the combined magnetic flux leakage signal into a figure signal, and a data transmission unit transmits the figure signal to a data processing unit. The data processing unit obtains a difference signal by subtracting the figure signal and figure signals of N measuring points before the measuring point, and judges whether wire fracture exists in the steel wire rope or not according to the difference signal. Compared with the conventional defect detecting system for the steel wire rope, the defect detecting system for the steel wire rope, disclosed by the invention, efficiently reduces a strand wave signal, enables detection and quantization of broken wires to be more convenient, rapid and accurate, and moreover, can realize defect positioning for the steel wire rope, quantitative analysis and report generation of the detection result, and meets the requirement of modern safety production.

Owner:SHENXI MACHINERY

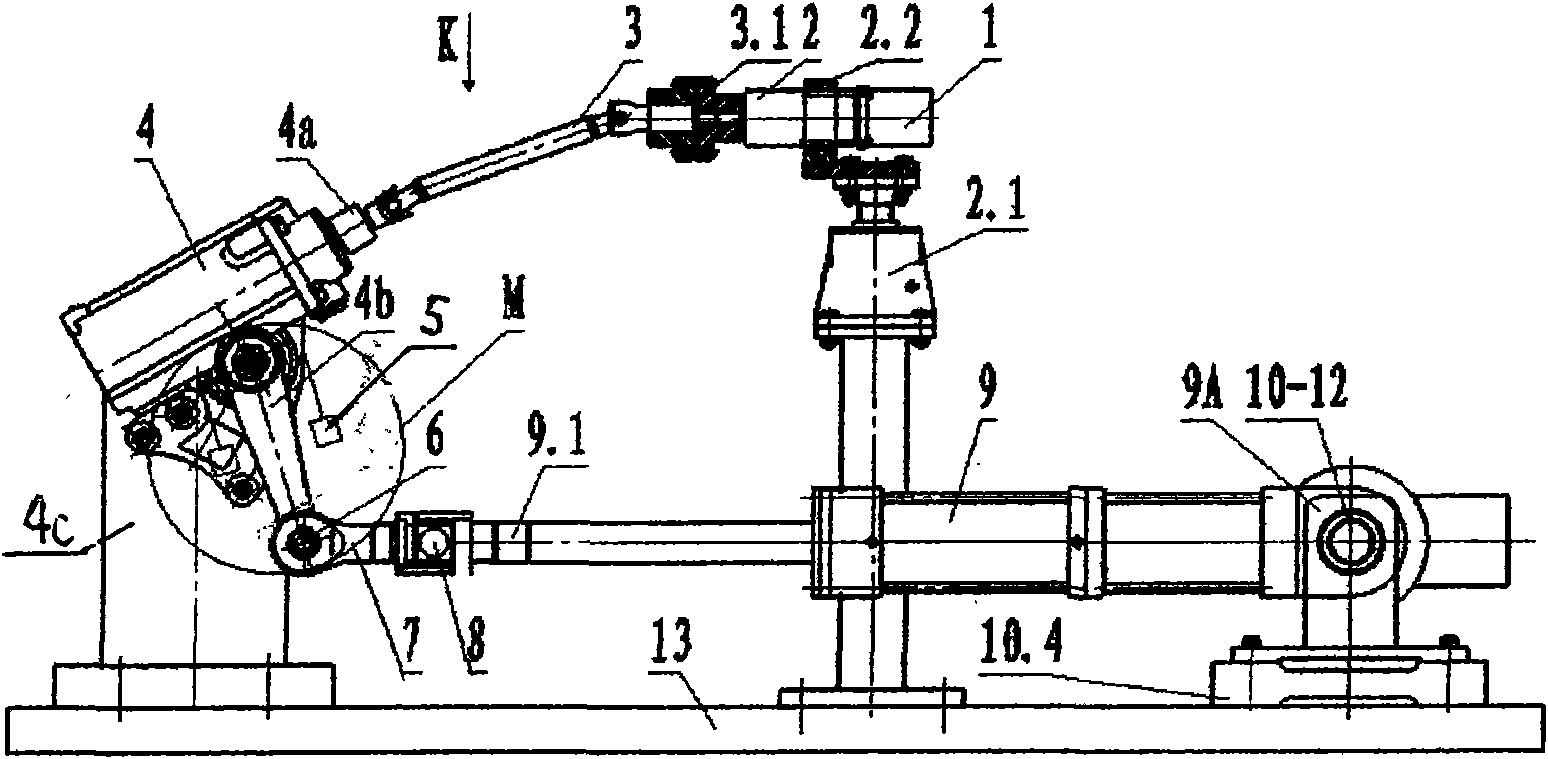

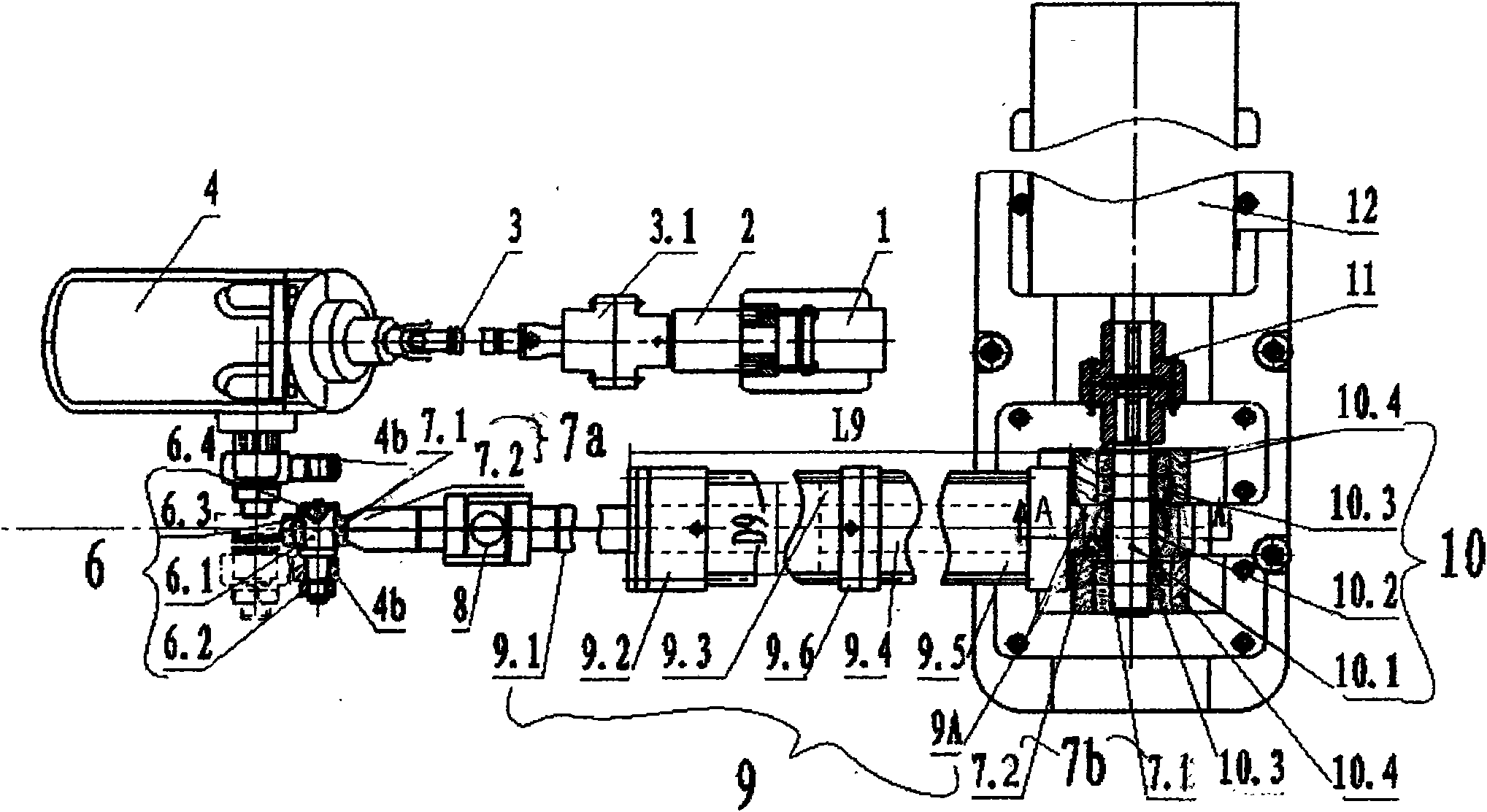

Automobile hydraulic electric power steering reliability test bench and program control test method

InactiveCN101608973ASmall footprintCompact footprintVehicle steering/rolling behaviourElectric machinerySystem stability

The invention relates to an automobile hydraulic electric power steering reliability test bench and program control test method. An input system comprises a servo motor, a reducer and a universal joint connected with the input end of a steering gear; an output system comprises a linear hydraulic cylinder with two functions of driving and load simulation, the front pole of a hydraulic cylinder piston is provided with a pressure sensor and connected with the rocker arm of the output end of the steering gear by a coupler with a joint bearing. An eccentric shaft, an eccentric bushing and a variable frequency motor are arranged at the inner bore of the rear lug of the hydraulic cylinder to form an automobile vibration simulation system, so as to simulate real vibration of rugged road surface. The hydraulic cylinder is compact and simple in structure, system integration is high and usable range is wide. The joint bearing causes the installation to be convenient. The hydraulic loop includes a throttle valve, thus speeding up oil-taking. An industrial personal computer, a motion control card and a data acquisition card are used, so that system stability is high, measurement accuracy is high, and response speed is fast. Curves and process control can be displayed in real time, and automatic save, plotting and printing can be realized. The test bench set can complete all reliability tests of fatigue, wear, forced steering, inverse overload and overpressure.

Owner:SICHUAN UNIV

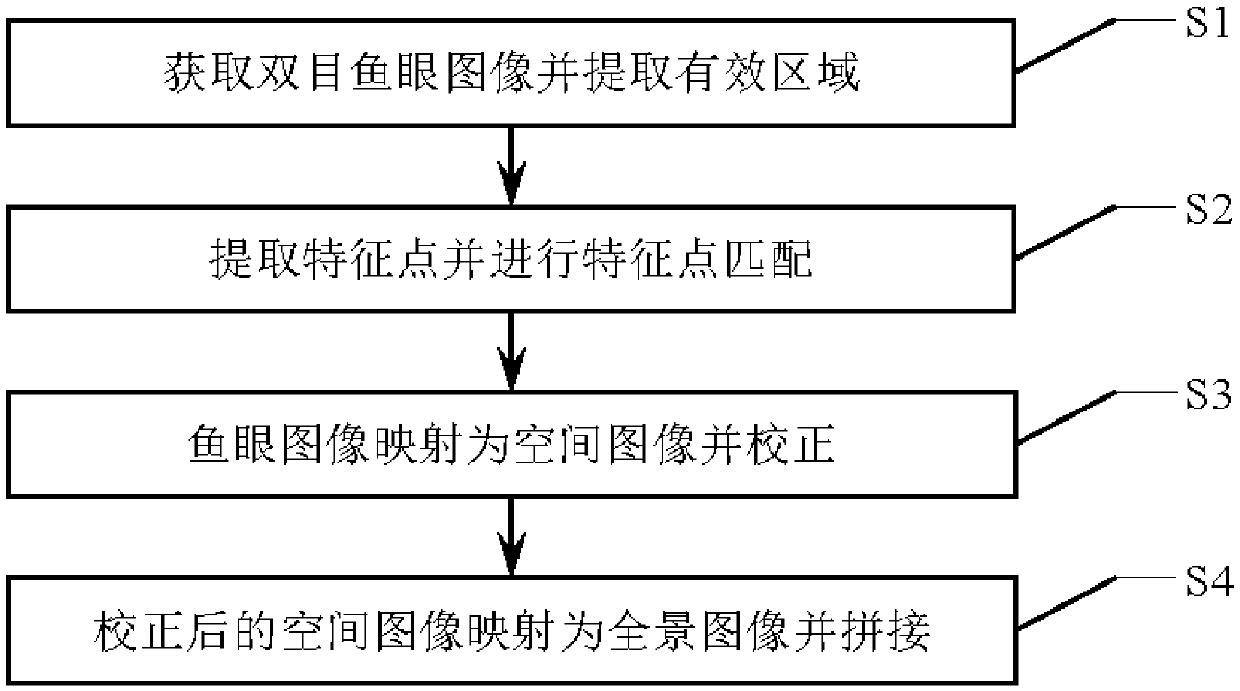

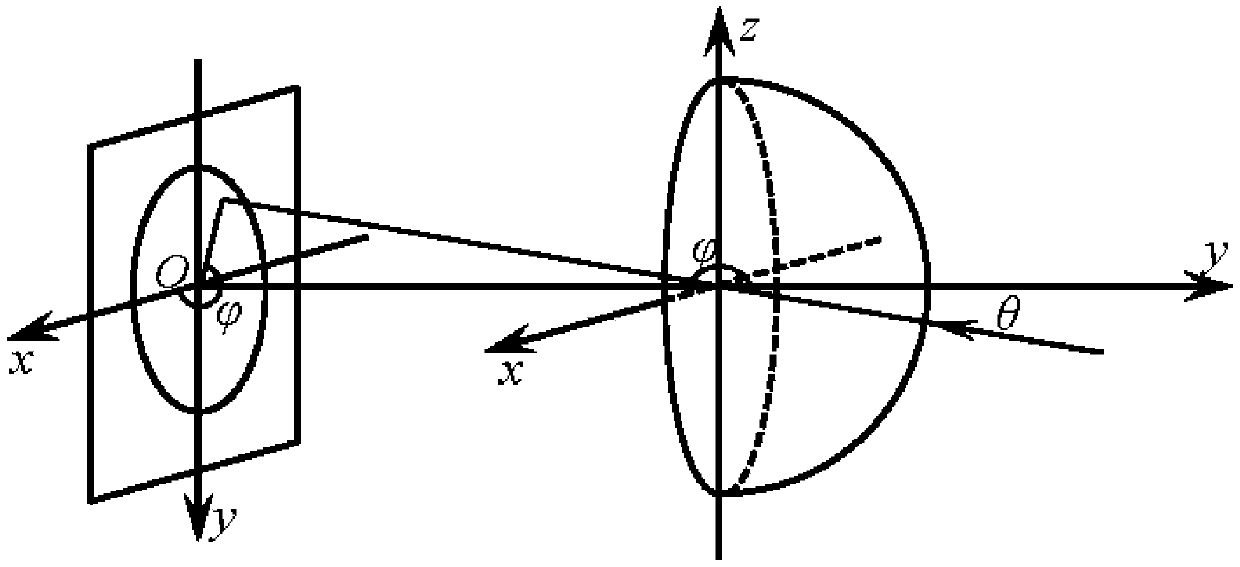

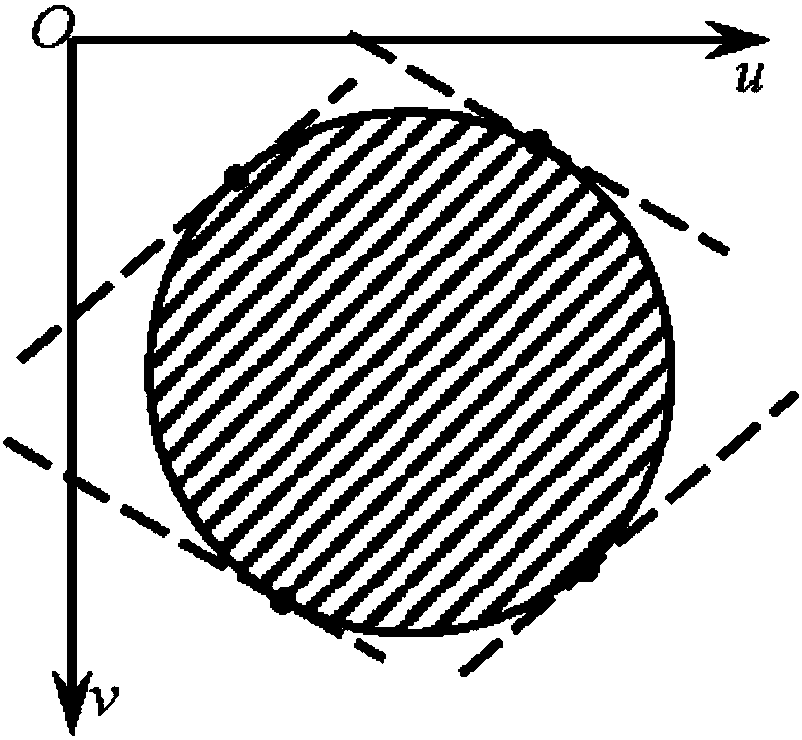

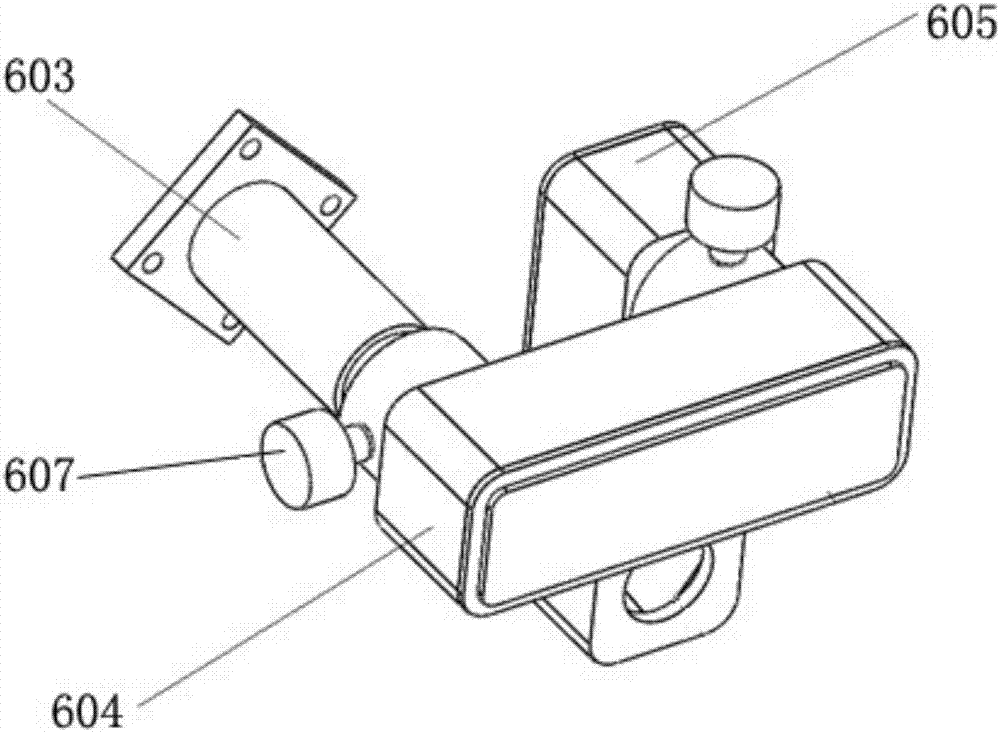

Method and system for binocular fish-eye image splicing and unfolding correction

ActiveCN107705252AReduce assembly requirementsEasy splicingImage enhancementImage analysisSingular value decompositionThree-dimensional space

The invention relates to a method and system for binocular fish-eye image splicing and unfolding correction. The method for binocular fish-eye image splicing and unfolding correction includes the steps: utilizing a binocular fish-eye camera to obtain an original binocular fish-eye image, and extracting the left and right two effective circular imaging areas from the original binocular fish-eye image; extracting the characteristic points of the overlapped part in the two effective areas, and matching the characteristic points in pairs; respectively mapping the two effective area images to obtain two space coordinate unit spherical surface images, performing matrix singular value decomposition on the three dimensional space spherical surface, obtaining the rotation relation, that is, the rotation matrix, between the two images through calculation, and correcting one of the space coordinate unit spherical surface images through the rotation matrix; and finally respectively mapping the twospace coordinate unit spherical surface images to obtain two panoramic coordinate images, and splicing the two panoramic coordinate images into a complete 360 DEG panoramic image. The method and system for binocular fish-eye image splicing and unfolding correction can solve the problem that the fish-eye imaging sensors are not in parallel during the assembling process, thus causing errors, and have the advantages of being good in the splicing effect after correction, being high in processing timeliness, and being easy to implement.

Owner:EAST CHINA UNIV OF SCI & TECH

Laser and MIG electric arc compound welding method for high-strength steel butt joints

InactiveCN103831541AReduced assembly requirementsReduce distortionWelding/soldering/cutting articlesLaser beam welding apparatusSand blastingButt joint

The invention discloses a laser and MIG electric arc compound welding method for high-strength steel butt joints. The laser and MIG electric arc compound welding method comprises the specific steps that (1) high-strength steel butt joints to be welded are machined to be provided with I-shaped grooves, wherein the high-strength steel butt joints are of a butt joint form; (2) the high-strength steel butt joints to be welded are assembled, and the size of an assembly gap between the high-strength steel butt joints is controlled to be smaller than or equal to 0.1delta; (3) welding wires are selected according to the materials of the high-strength steel butt joints to be welded, and pre-welding treatment such as oil removal, acid pickling, drying and sand blasting is carried out on the high-strength steel butt joints to be welded and the welding wires; (4) a laser source and an MIG thermal source are arranged, wherein a laser beam is perpendicularly incident from the position which is one to three millimeters away from the front portion of the MIG thermal source, the welding wires are fed into the upper surface of the high-strength steel butt joints to be welded through an MIG muzzle, and the angle between each welding wire and the horizontal plane ranges from 30 degrees to 60 degrees; (5) laser beam and MIG compound welding is carried out, and in an initial period, the maintenance time of lasers and the maintenance time of an electric arc range from 0 s to 0.5 s. The laser and MIG electric arc compound welding method for the high-strength steel butt joints, welding penetration is improved, the requirement for assembly conditions is reduced, welding quality is improved, and high welding performance is achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

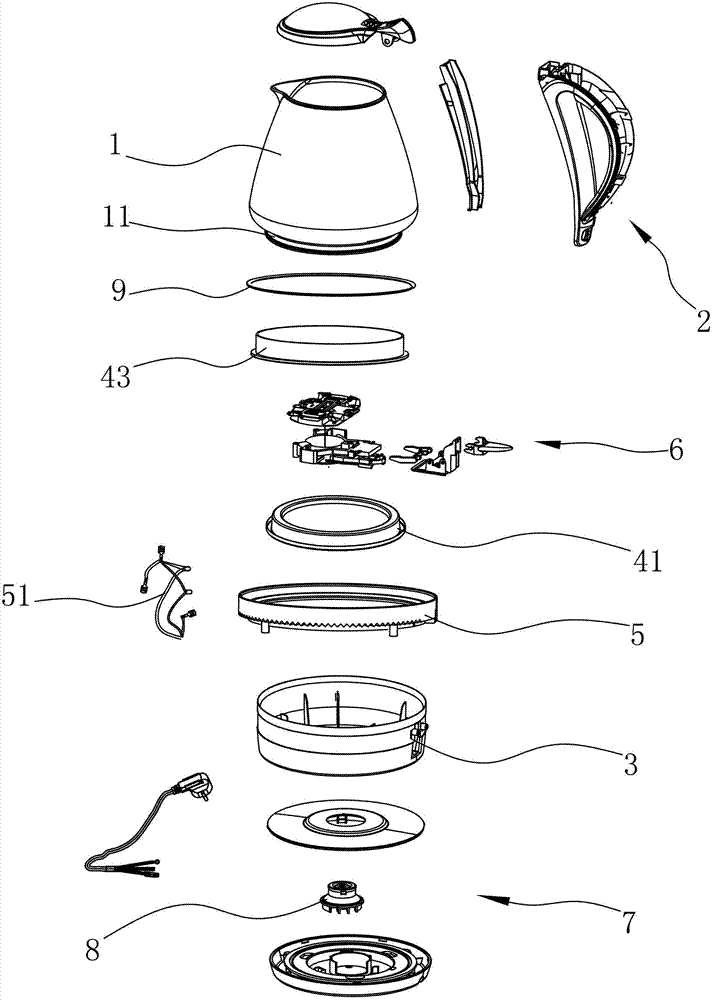

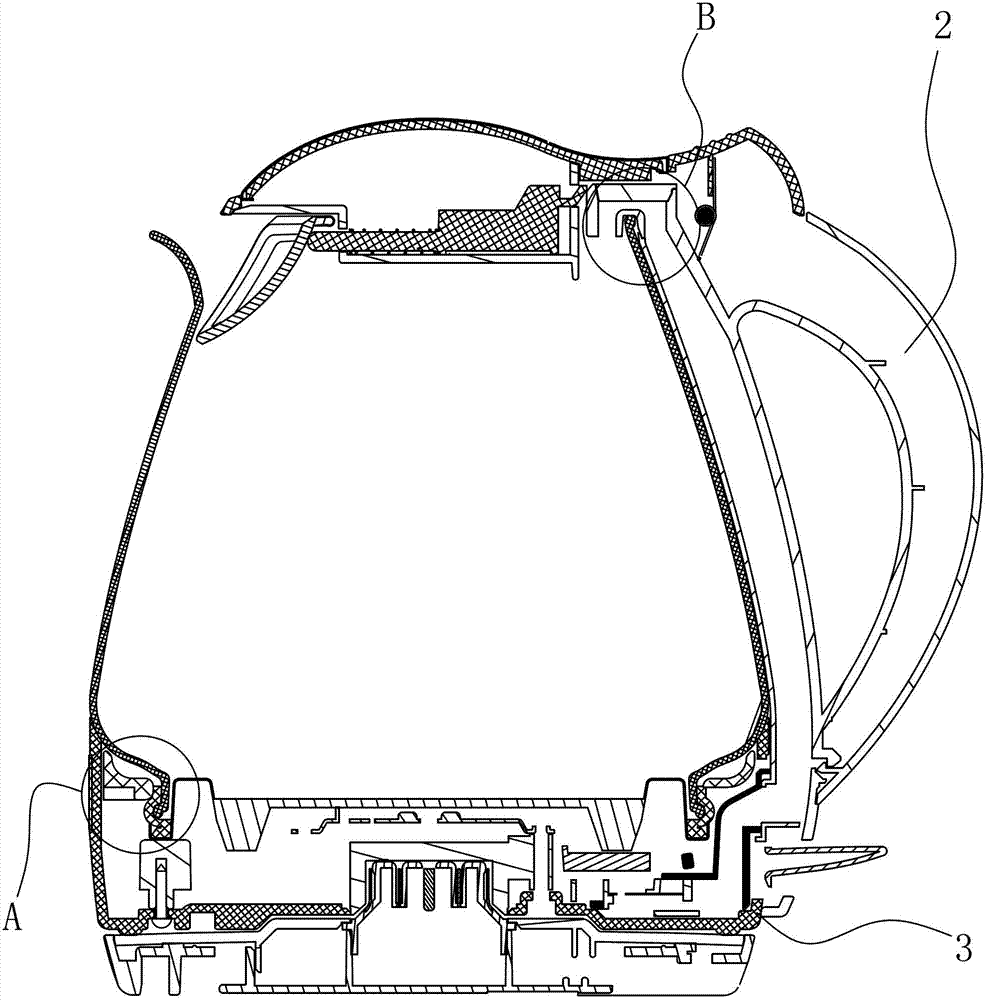

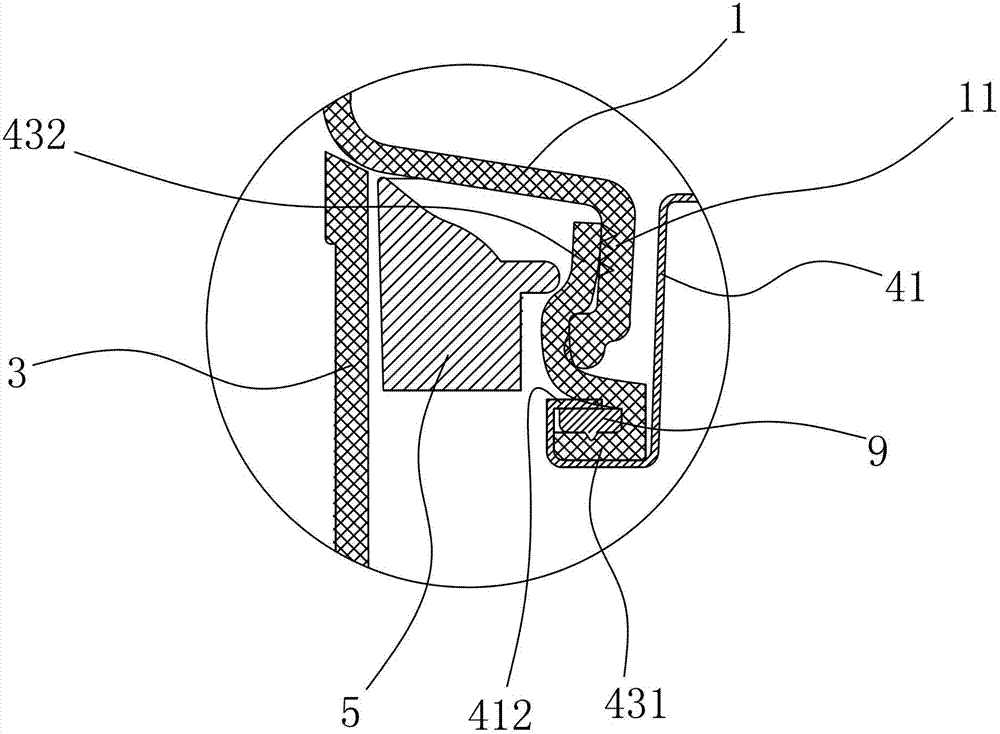

Electric heating glass kettle

ActiveCN103110348AGuaranteed sealing performanceGuaranteed airtight connectionOhmic-resistance waterproof/air-tight sealsWater-boiling vesselsEngineeringSilica gel

Provided is an electric heating glass kettle. The electric heating glass kettle comprises a glass cup body, a handle and a bottom cover, wherein the handle and the bottom cover are arranged on the cup body. The bottom of the cup body is provided with a heating disc. The heating disc comprises a body, a heating element, and a silicon ring, wherein the heating element and the silicon ring are arranged on the body, a neck portion is formed at the bottom of the cup body, the silicon ring and the body are fixedly connected in a sealing mode and wrap the neck portion, the neck portion is provided with a fastening ring, the bottom cover is connected with the fastening ring, and the handle is directly or indirectly connected with the fastening ring. Compared with the prior art, the electric heating glass kettle has the advantages that an embedded portion of the silicon ring and the body of the heating disc are fixedly sealed into one, then an elastic wrapping portion of the silicon ring is used for wrapping the neck portion of the cup body, and therefore flexible sealing connection between the heating disc and the cup body is achieved. The sealing between the heating disc and the cup body is guaranteed, structural uniformity of the cup body, the handle and the bottom cover is guaranteed, meanwhile, technological requirements on the cup body are reduced greatly, and assembly efficiency of products is improved.

Owner:NINGBO KECHENG ELECTRIC MANUFACTURE CO LTD

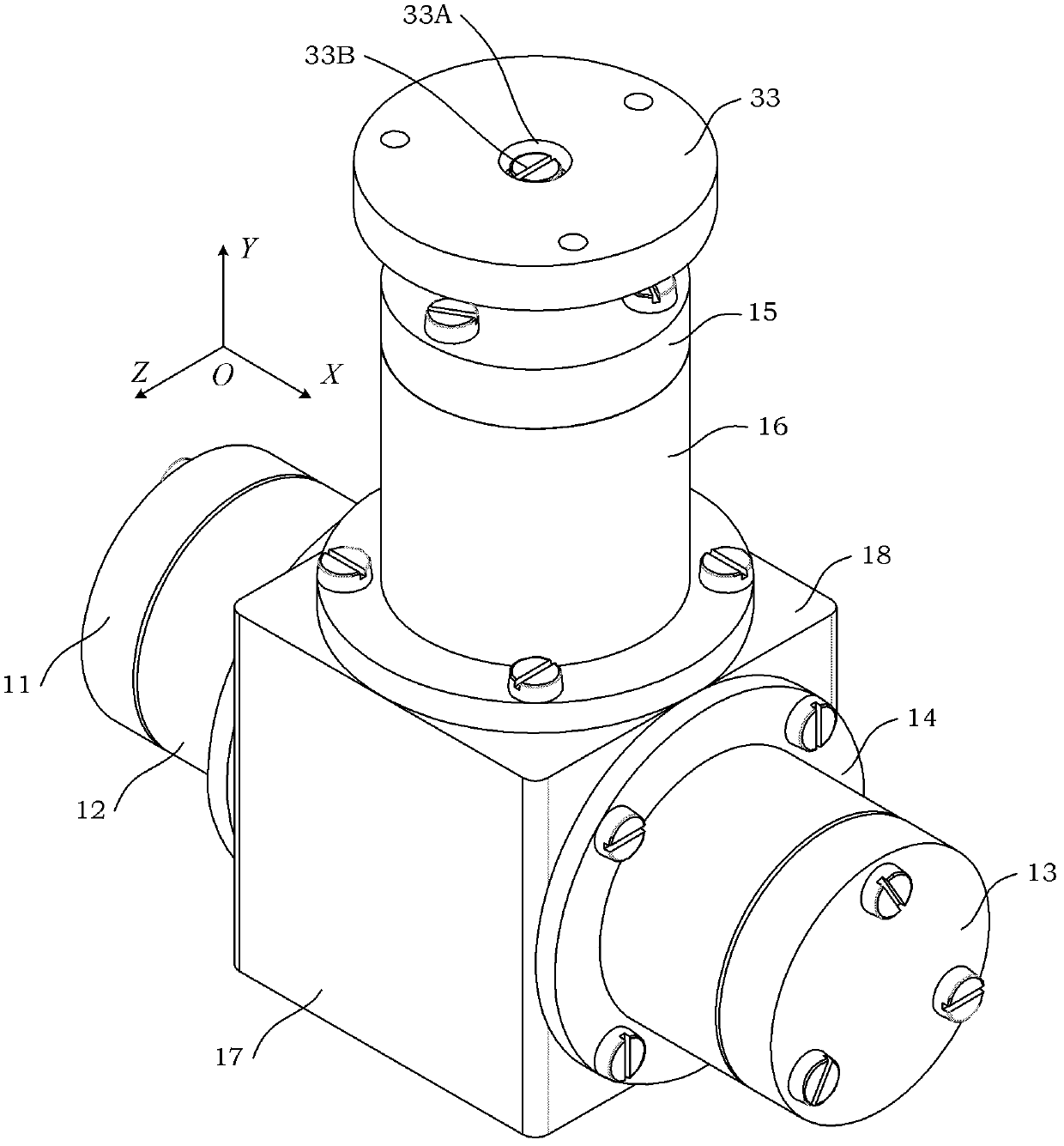

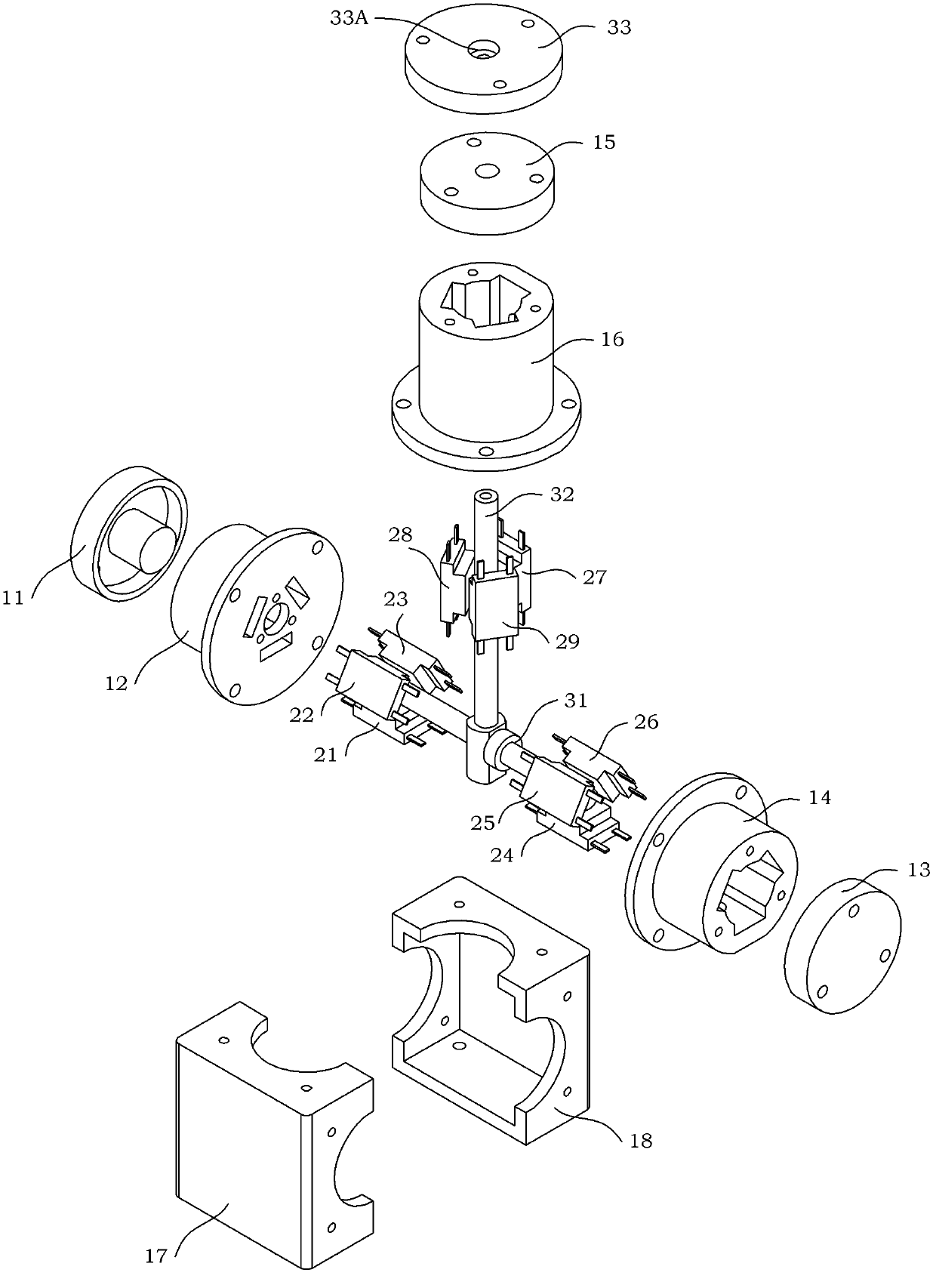

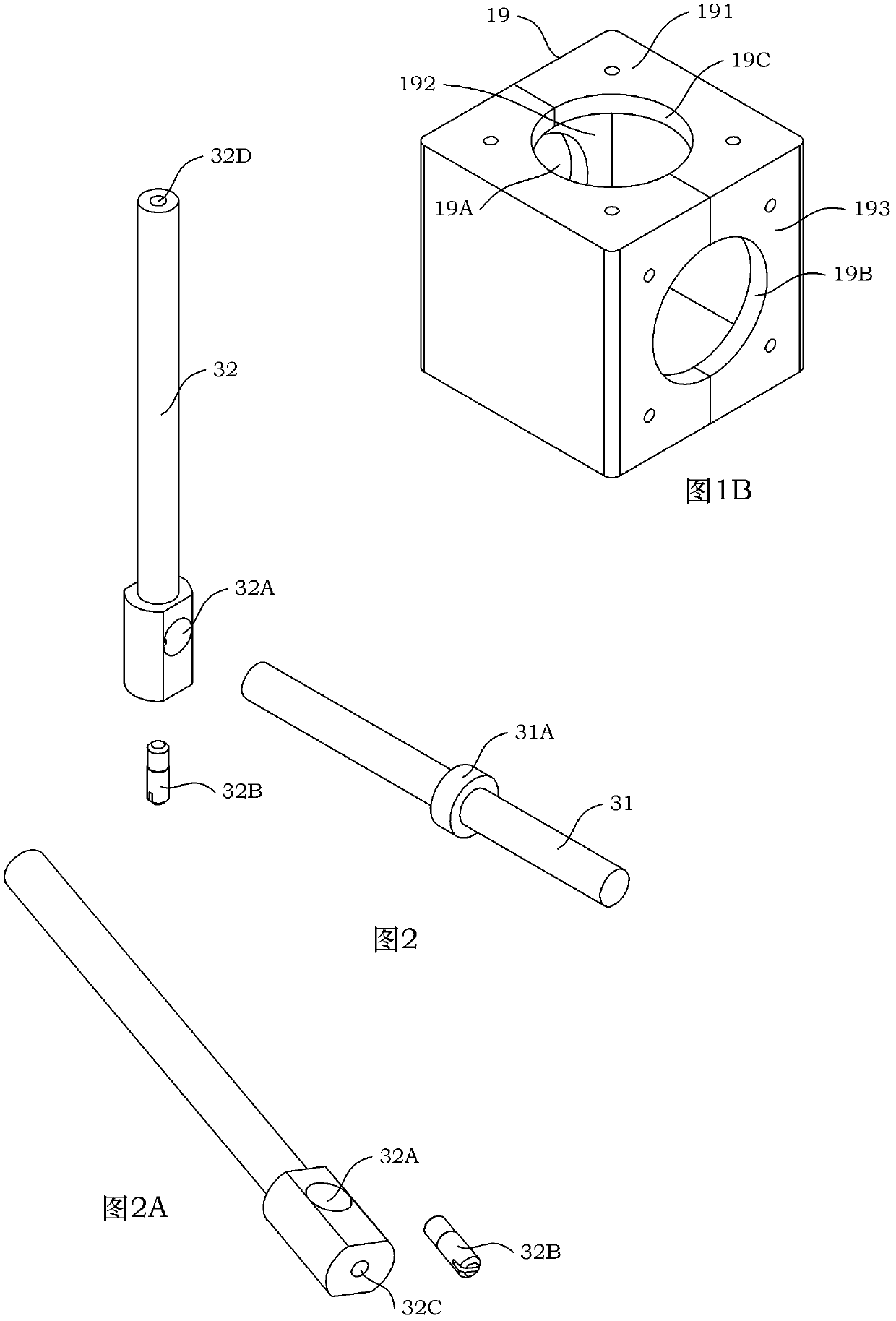

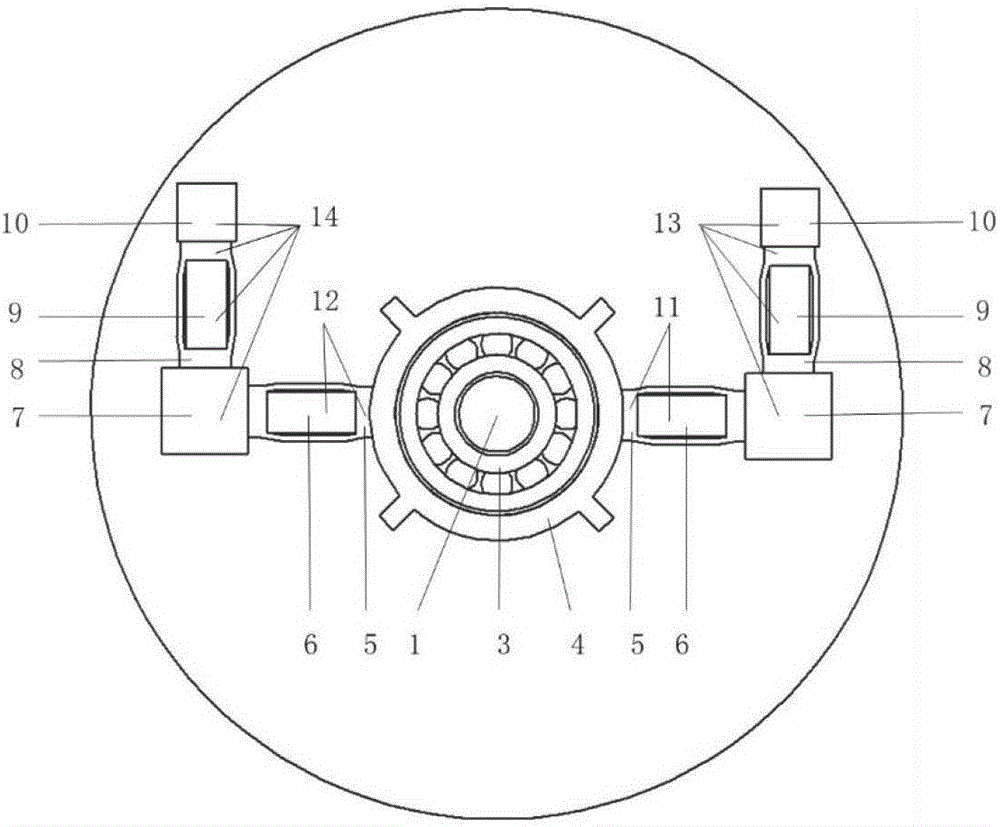

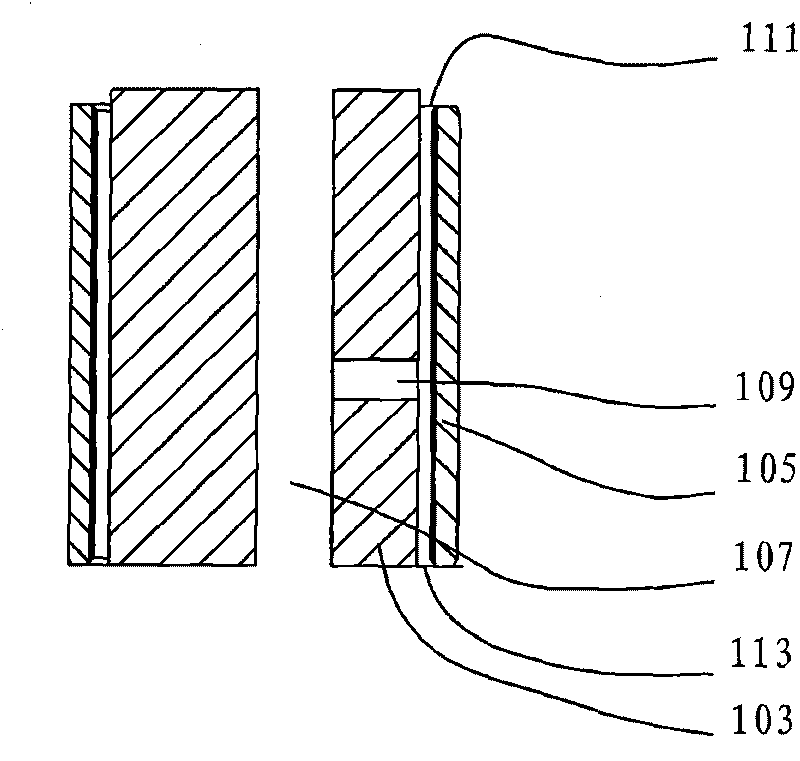

Torque sensor capable of measuring six-dimensional non-coplanar force

ActiveCN102353482ALow costHigh measurement accuracyWork measurementForce measurement using piezo-resistive materialsTorque sensorEngineering

The invention discloses a torque sensor capable of measuring six-dimensional non-coplanar force. In the torque sensor, nine sensors are arranged on three installation bases in three groups respectively; the end parts of the installation bases are connected with end covers; the two ends of an X-axis connecting rod are arranged in through holes of two installation bases respectively; and a Y-axis connecting rod is arranged in a through hole of a third installation base. The torque sensor designed by the invention is arranged on a carrier by using a loading flange. When pressure is applied to the upper end of Y-axis connecting rod, nine one-dimensional sensors which are connected with a T-shaped connecting rod are subjected to force of different magnitudes and have different outputs under the actions of six-dimensional non-coplanar force and three-dimensionalal non-coplanar orthogonal torque. Analysis on the force structure according to the theoretical mechanics indicates that the relation between the output force information of the nine one-dimensional sensors and the applied six-dimensional non-coplanar force is: the magnitude of the six-dimensional non-coplanar force can be obtained by only measuring the output numerical values of the nine one-dimensional sensors.

Owner:BEIHANG UNIV

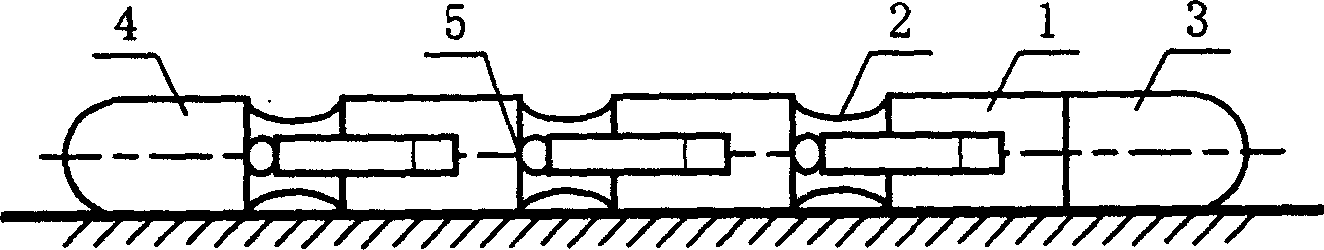

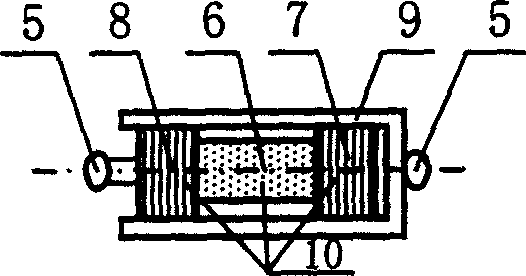

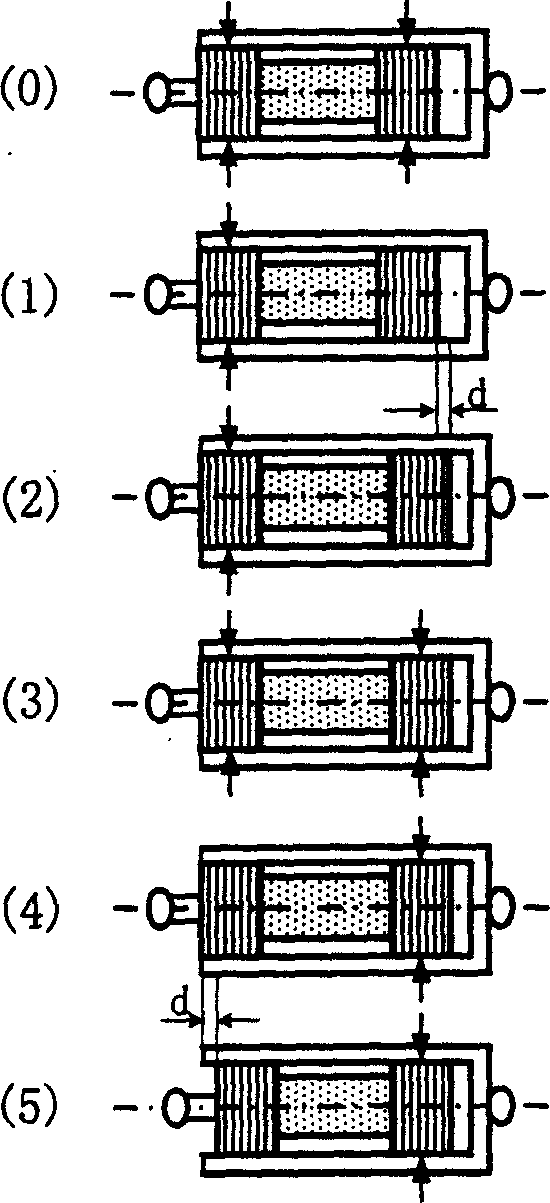

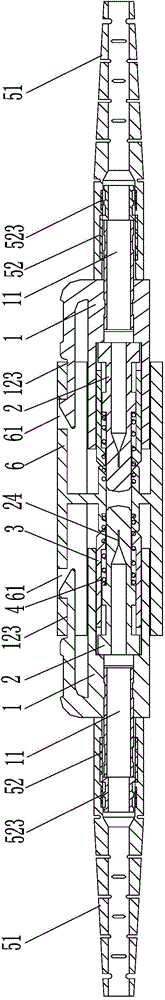

Minitype multi-articulation electromagnetic and piezoelectric creeping motion robot system

InactiveCN1544208AChange direction of motionDifferent drive speedsMicromanipulatorPiezoelectric/electrostriction/magnetostriction machinesElectricityRobotic systems

The invention is a micro-type multistage electromagnetic and piezoelectric peristaltic robot system, including: driving unit, elastic sealing film, front cabin, back cabin and cardan joint. The driving unit is composed of piezoelectric body, the first electromagnet, the second electromagnet and tube, the two ends of the piezoelectric body are stationarily bond with the two electromagnets, respectively to form a driver for the driving unit. The driving unit has a simple structure, and the key components only include piezoelectric device and electromagnetic coil and have very small size, the displacement transfer mainly depends on absorption force of electromagnets and tube, the requirements of cooperation, processing precision and assembly are reduced, the control is reliable, the displacement can be regulated by voltage waveform, amplitude and frequency applied on the piezoelectric body, moving direction can be changed with the control time sequence of the two electromagnets, convenient to control time sequence; the unit driver can reliably move on the interface of the ferromagnetic material, too.

Owner:SHANGHAI JIAO TONG UNIV

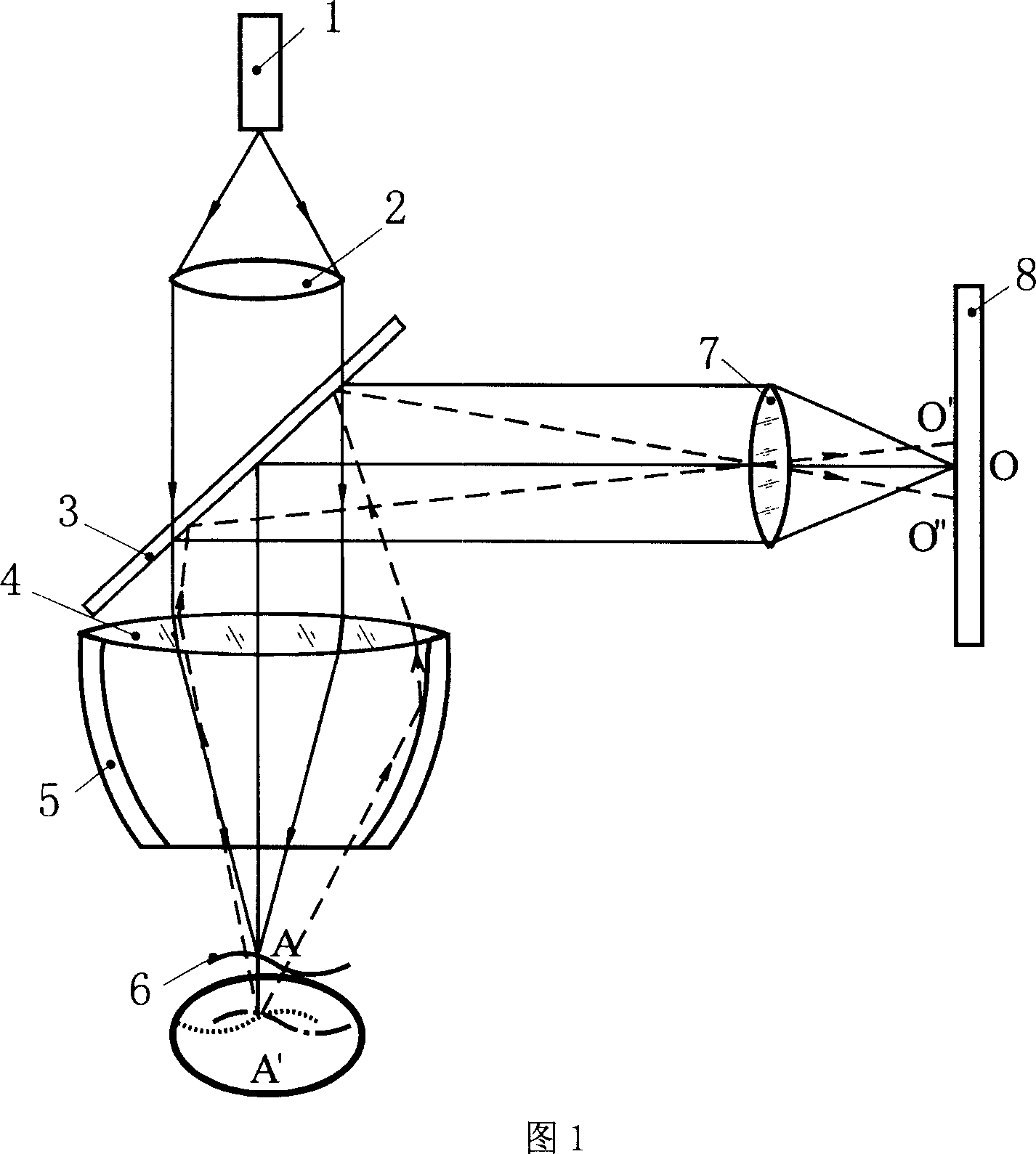

Single-photodetector confocal laser triangulation device

InactiveCN1995908AEasy to achieve focus overlapReduce assembly requirementsUsing optical meansPhotodetectorPlane mirror

The invention relates to single photo detector cofocal laser triangulation. It provides authentic three dimensional data, solves the issues resulted from the oblique angle of the inspected surfaces. It comprises laser, collimation lens, half reflective half transparent lens, aspheric lens, ring type inner reflector, inspected surface, image forming lens, and side photo detector, with the collimation right in front of the laser beam, the included angle of the half reflective and half transparent lens optical axis and the collimation lens optical axis in 45 degree clockwise. The aspheric lens and the collimation lens share the same optical axis. The center of sphere of the ring reflector shares the same optical axis with the single beam released by the symmetrical axis and the laser, collimation lens and the aspheric lens. The optical axis of the image forming lens is perpendicular with the light beam of the laser. The photo detector is set at the focal position of the imaging lens.

Owner:XIAMEN UNIV

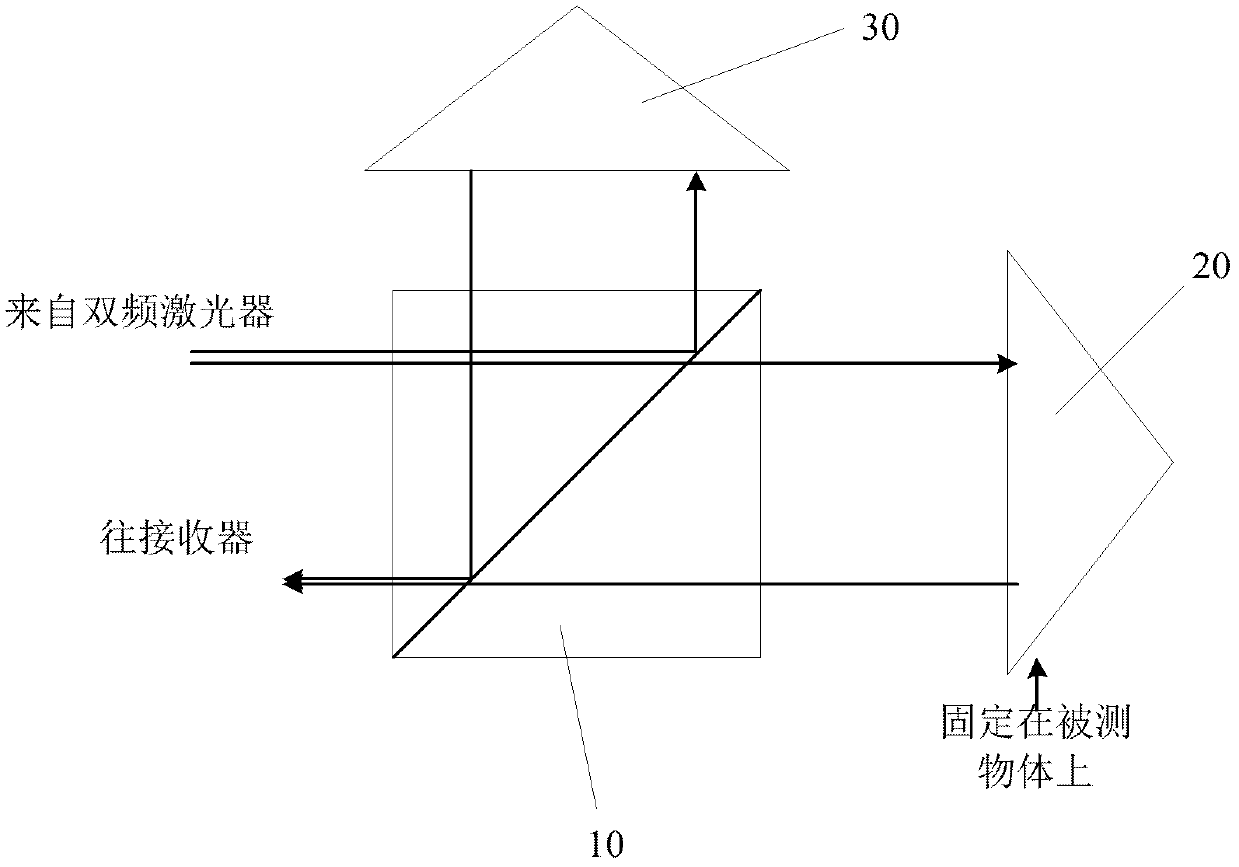

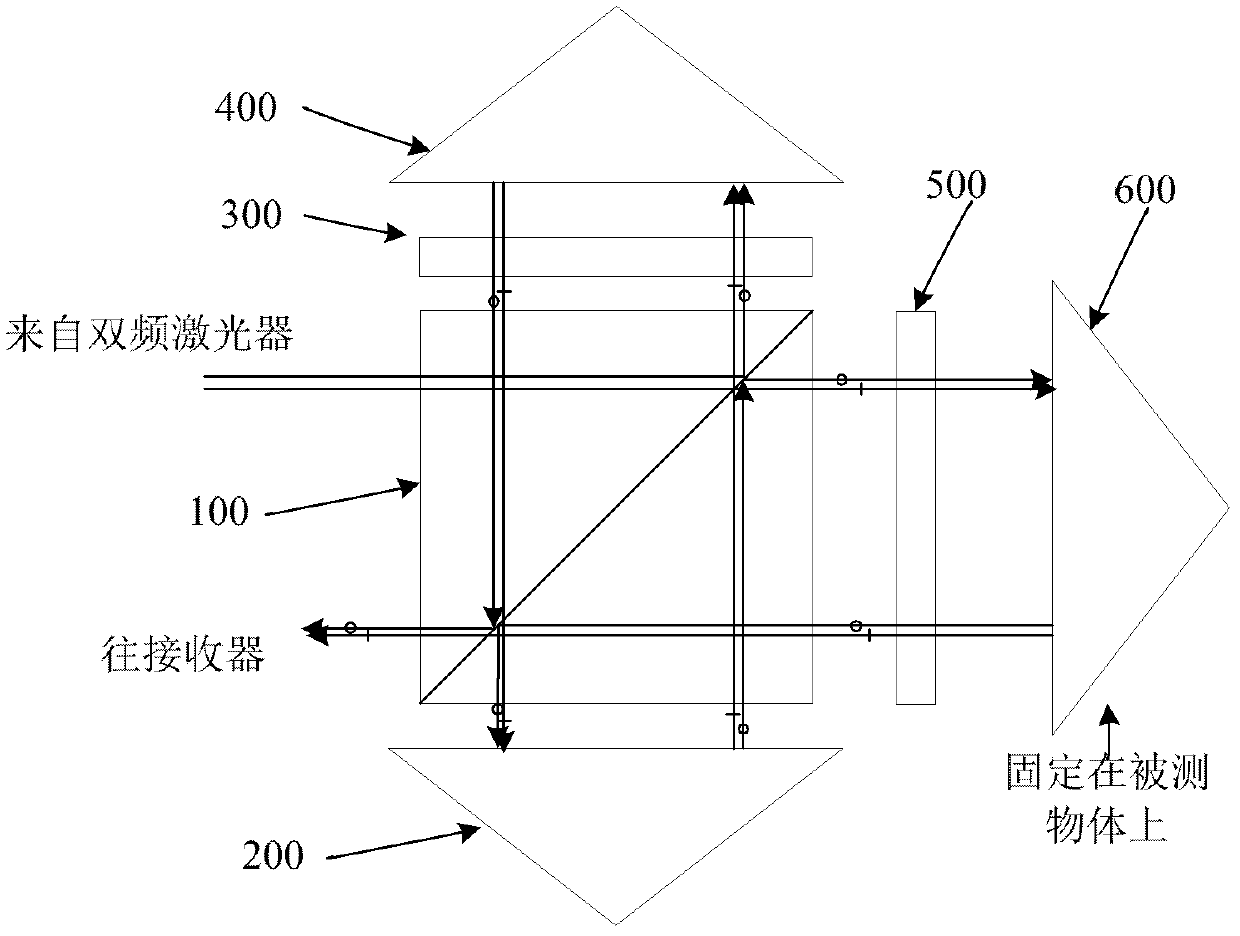

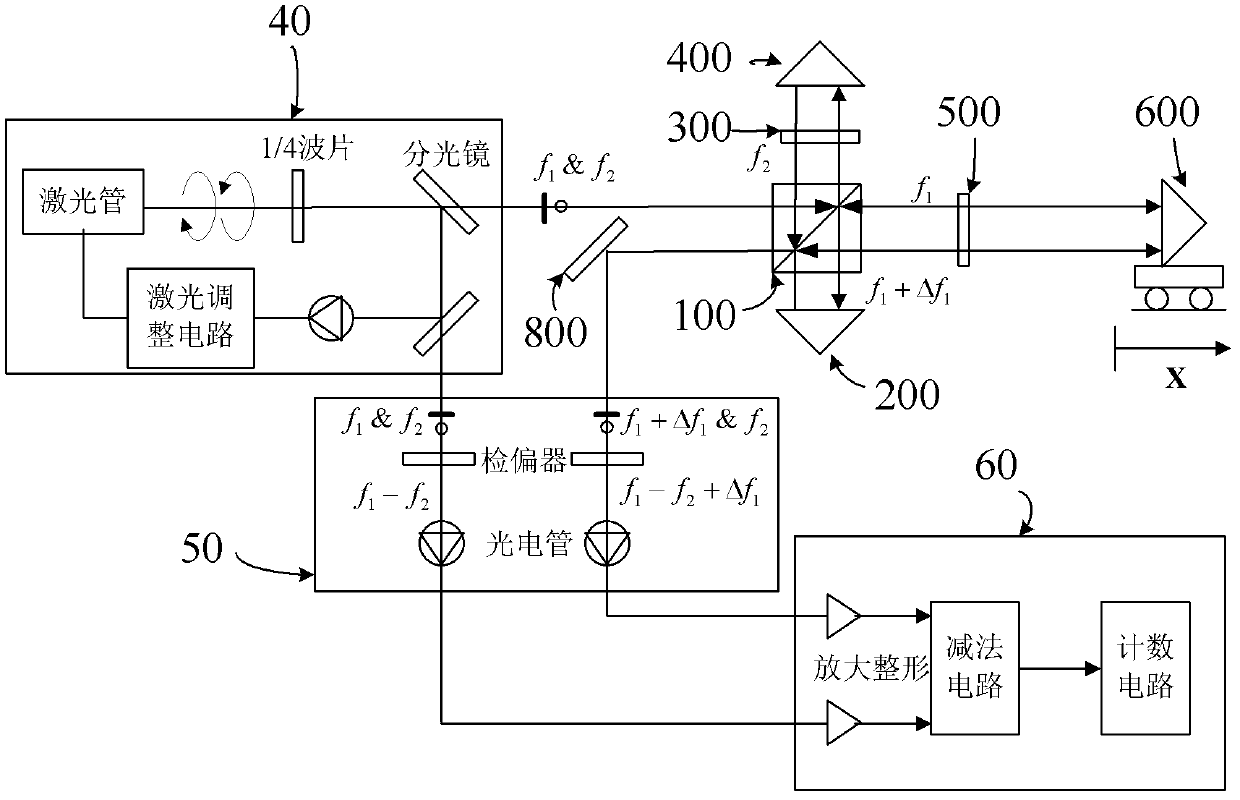

High-resolution linear interferometer

InactiveCN103376055AReduce assembly requirementsEasy to usePolarising elementsUsing optical meansImage resolutionOptoelectronics

The invention provides a high-resolution linear interferometer. The high-resolution linear interferometer comprises a polarization splitting prism, a transmission arm cube-corner prism and a reflection arm cube-corner prism and further comprises a transmission arm quarter-wave plate, a reflection arm quarter-wave plate and a common cube-corner prism, wherein the common cube-corner prism and the reflection arm quarter-wave plate are arranged on the two opposite side faces of the polarization splitting prism respectively, the transmission arm quarter-wave plate is arranged on a third side face, opposite to an incidence laser light source, of the polarization splitting prism, the transmission arm quarter-wave plate is arranged between the polarization splitting prism and the transmission arm cube-corner prism, and the reflection arm quarter-wave plate is arranged between the polarization splitting prism and the reflection arm cube-corner prism. The high-resolution linear interferometer still takes a cube-corner prism as an object to be tested, and adjustment requirements are not high when the interferometer is used. Through being additionally provided with the quarter-wave plates, the high-resolution linear interferometer has the advantage of four-times optical fine division and enables the optical resolution to be promoted to lambda / 4.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

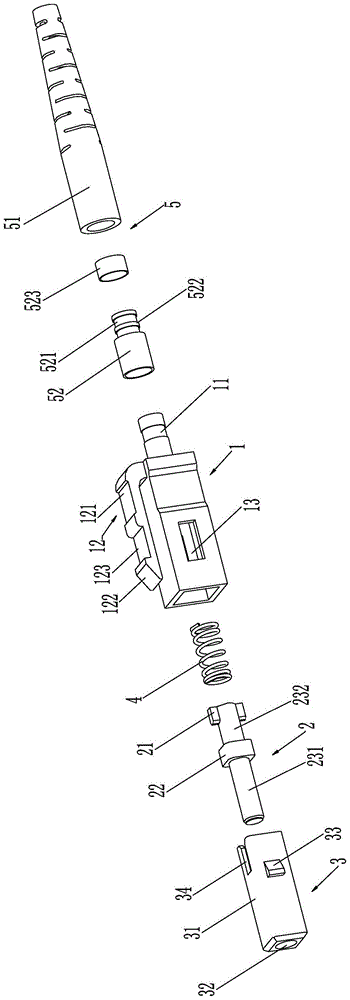

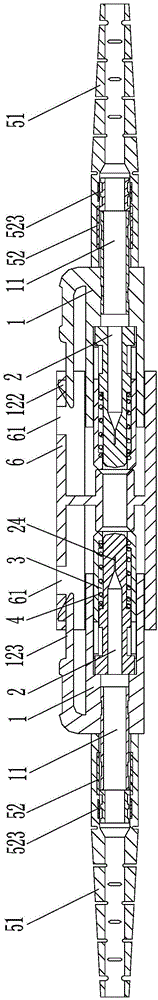

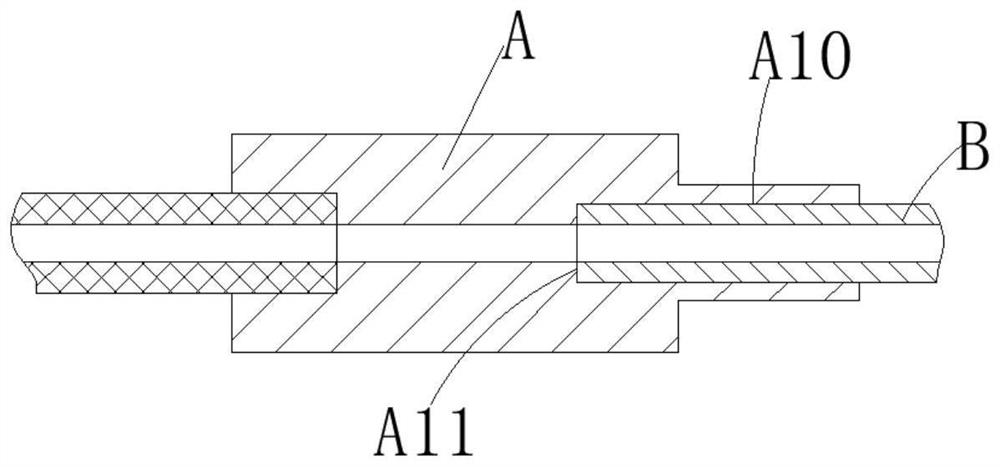

Optical fiber connector and manufacturing method thereof

ActiveCN104965262AReduce assembly requirementsLow matching accuracy requirementsCoupling light guidesFiberElastic component

The invention relates to an optical fiber connector and a manufacturing method thereof. The optical fiber connector comprises a housing and a fiber insertion core arranged in the housing. The end surface of the fiber insertion core is provided with at least one lens. The cavity at one end of the housing is equipped with an insertion core protection structure for protecting the end surface of the insertion core so as to prevent the lens surface at the end surface of the fiber insertion core from being damaged or scraped. The insertion core protection structure is internally provided with the fiber insertion core and an elastic component sleeved on a fiber insertion core tubular body to ensure free telescoping of the insertion core protection structure. The other end of the housing is provided with an extension pipe. The extension pipe is connected with a tail sheath assembly which carries out bending protecting on an optical cable and guarantees that the optical fiber connector can transmit optical signals normally under the bending pressure condition. An elastic buckle structure for enabling the optical fiber connector to be buckled to a corresponding insertion hole of an adapter is integrated to the outer wall of the housing.

Owner:SHENZHEN EPLU SCI TECH

Basic mode jaw self locking speed differential gear

InactiveCN101118005ACircumferential degrees of freedom constantEliminate impact wearDifferential gearingsControl devicesSelf limitingSelf locking

The present invention relates to a basic jaw type self-locking differential, which has the characteristics of no collision, high reliability, and long service life. The present invention is characterized in that a force transmission tooth and separating teeth and an accessory blocking tooth which are positioned on driven rings are connected as a whole; a self-limiting type blocking embedding mechanism is embedded by two embedding mechanisms of a force transmission embedding mechanism and a separation embedding mechanism under the differential condition, and axially positioned in the two mechanisms and radially positioned in the two mechanisms, between the two mechanisms or outside the two mechanisms, a lift angle of both sides blocking the working surface is formed to enough ensure the friction self-locking collided on the both sides and the stability of the blocking operating condition, in order that the lift angle has the capabilities that the adaptive axle base changes and the abrasion is automatically compensated, and the slipping mode of no collision is unvaryingly maintained between the separating teeth in the operating condition, two processes of the self-separating block process and the embedding return process are absolutely reliable, and has no relation to the stability of the spring parameter compacted by the driven rings, hence the problem that the driven rings on the both sides are synchronously separated is not a problem any longer. The processing of the differential is obviously improved, the difficulty of the assembly is largely reduced, and the performance, the service life, and the interchangeability, etc. are remarkably improved.

Owner:洪涛

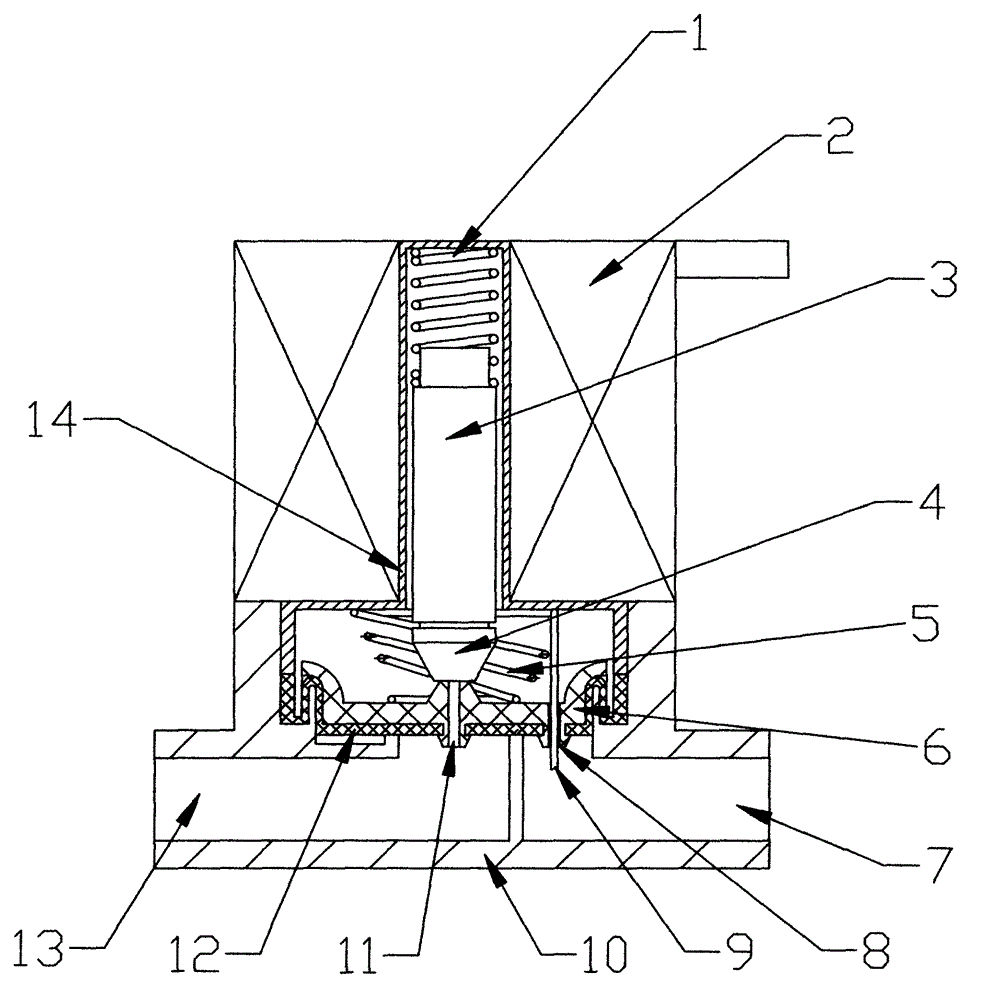

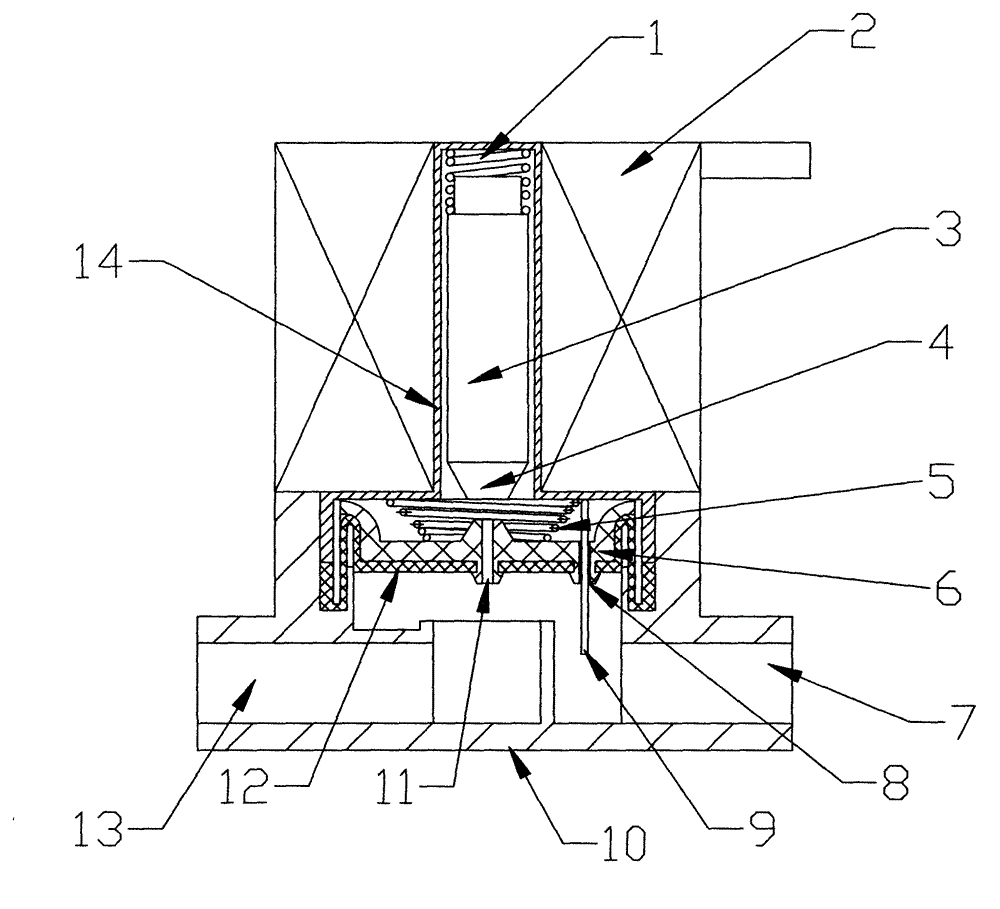

Magnetic valve with compact structure, good tightness and high reliability

InactiveCN102943896ACompact structureImprove sealingDiaphragm valvesOperating means/releasing devices for valvesMagnetic valveEngineering

The invention discloses a magnetic valve with a compact structure, good tightness and a high reliability. The magnetic valve comprises a body, the body comprises a valve seat, a coil arranged on the valve seat and a valve element sleeve arranged in the coil and a valve element arranged in the valve element sleeve, a valve water inlet is arranged on the right side on the lower portion of the valve seat, a valve water outlet is arranged on the left side on the lower portion of the valve seat, a plastic diaphragm and a rubber diaphragm are arranged between the coil and the valve seat and on the lower portion of the valve element sleeve, the plastic diaphragm is arranged on the upper portion of the rubber diaphragm, the plastic diaphragm and the rubber diaphragm are fixed together, a rubber seal head is arranged on the lower portion of the valve element, a valve element reset spring is arranged on the upper portion of the valve element, a pressure control cavity water inlet is arranged on the right portion of the plastic diaphragm, a pressure control cavity water outlet is arranged in the middle of the plastic diaphragm, the pressure control cavity water inlet is opposite to the pressure control cavity water outlet, and a tower-shaped with an unclogging pin is arranged between the plastic diaphragm and the valve element sleeve.

Owner:李志红

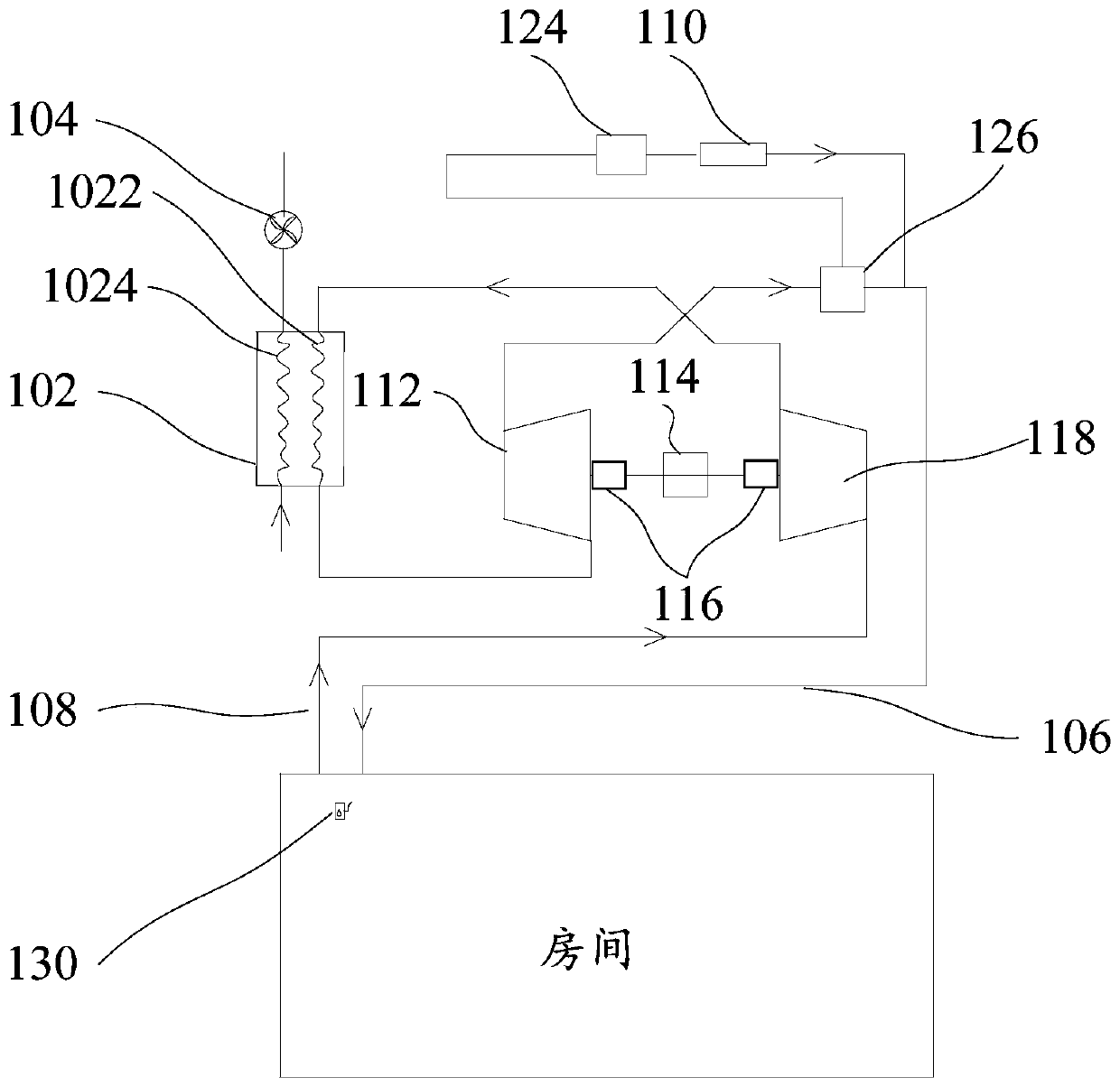

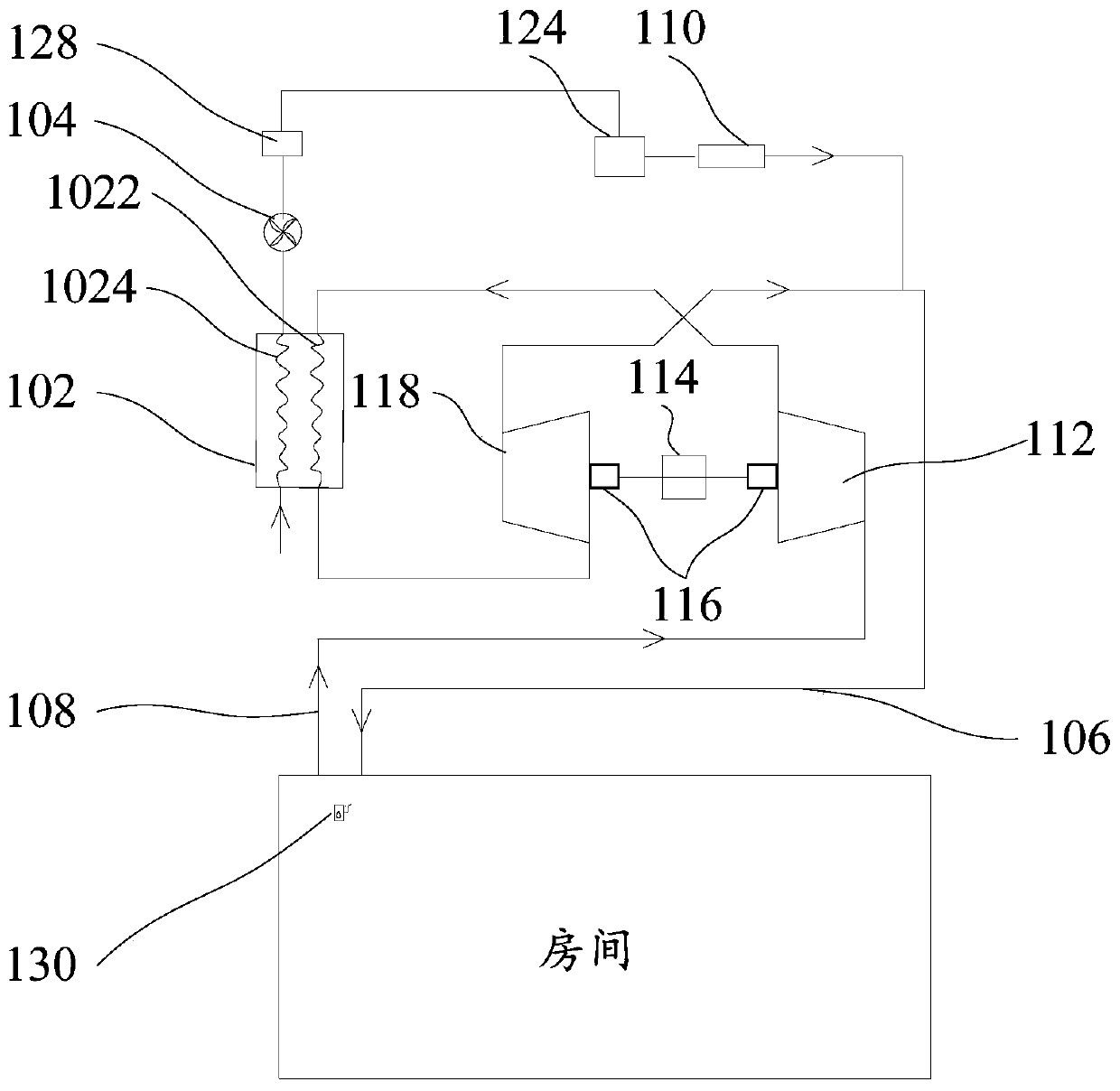

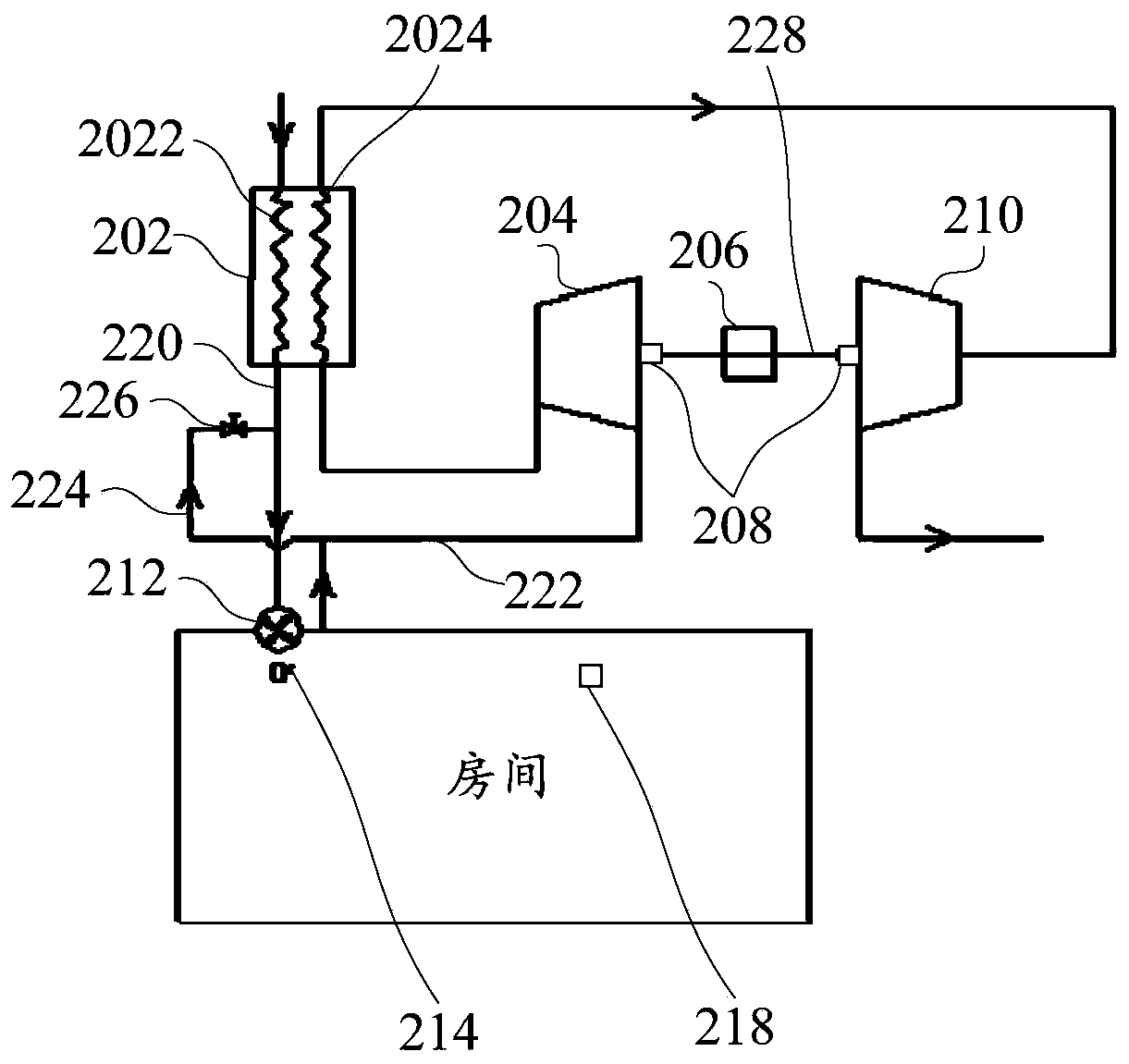

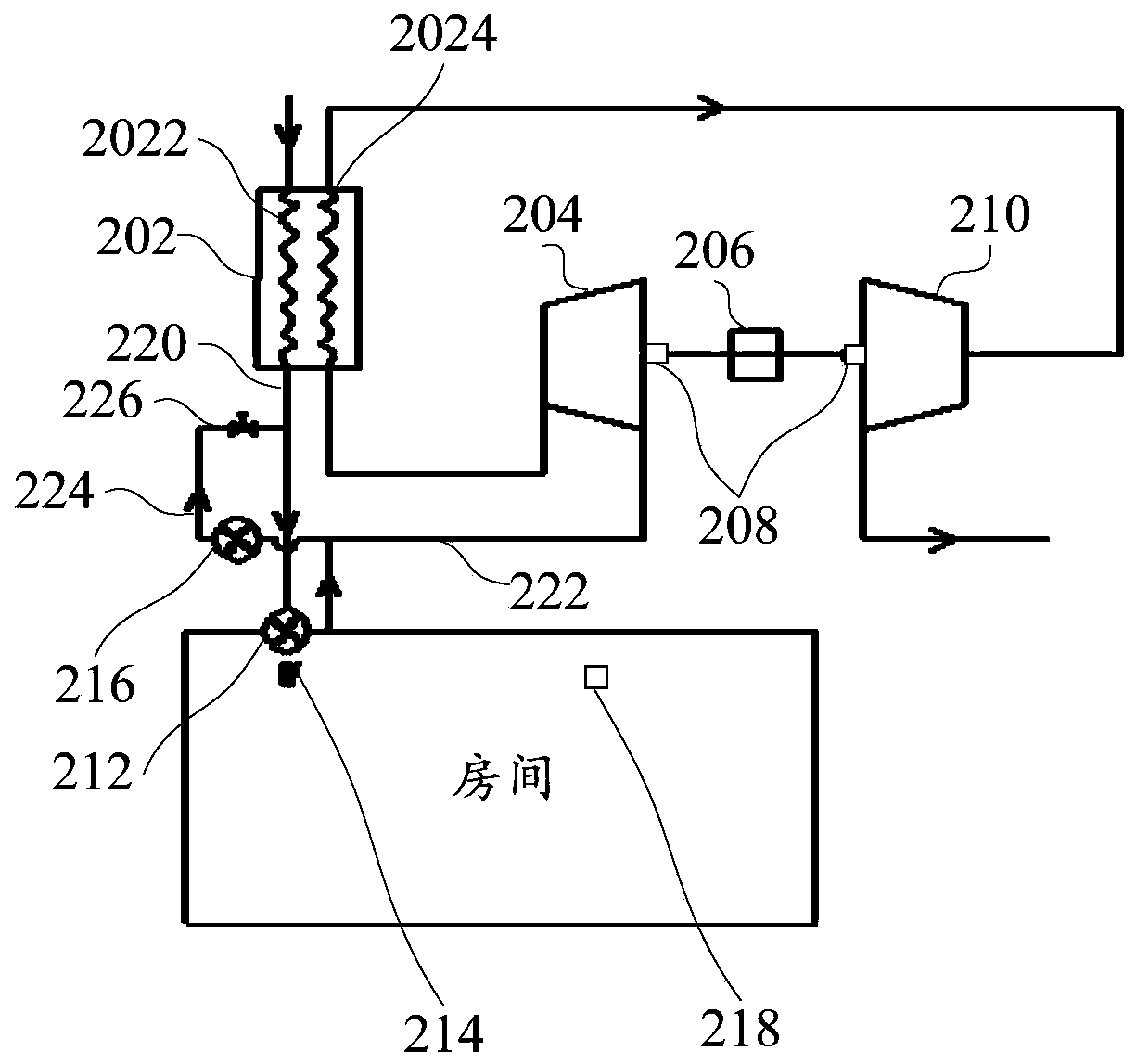

Compressed air heat exchange system

PendingCN110715479AReduce setup costsHarm reductionMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigerant

The invention provides a compressed air heat exchange system. The compressed air heat exchange system comprises a heat exchanger, a draught fan, a boosting expansion assembly and a humidifying module,wherein the heat exchanger comprises an outer circulation flow passage and an inner circulation flow passage; the two ends of the outer circulation flow passage communicate with the outdoor; the draught fan is arranged on the outer circulation flow passage, electrically connected with a processor and used for driving outdoor air to flow through the outer circulation flow passage; the boosting expansion assembly is electrically connected with the processor and can communicate with the inner circulation flow passage; an air outlet flow passage and an air return flow passage are further arrangedbetween the boosting expansion assembly and the indoor, so that the boosting expansion assembly receives indoor air through the air return flow passage and conducts heating or cooling on the indoor through the air outlet flow passage; the humidifying module is electrically connected with the processor and can communicate with the air outlet flow passage; and the processor is further used for executing computer instructions so as to implement the following steps of controlling the humidifying module to operate to conduct humidification on the indoor through the air outlet flow passage. Throughimplementation of the technical scheme, the air is adopted as a coolant to replace a compound cooling agent adopted in the correlation technology, and harm to the environment is reduced through combined operation of a compressor and an expansion machine.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

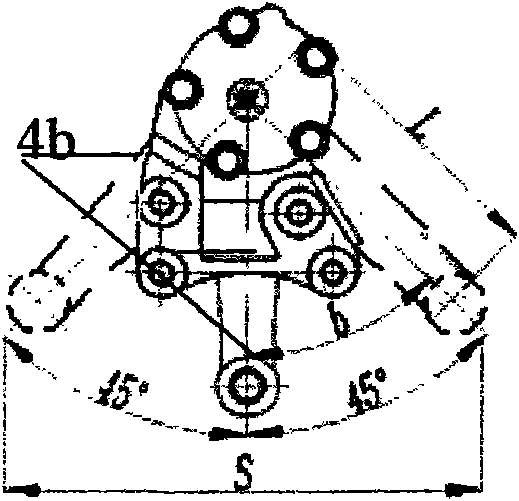

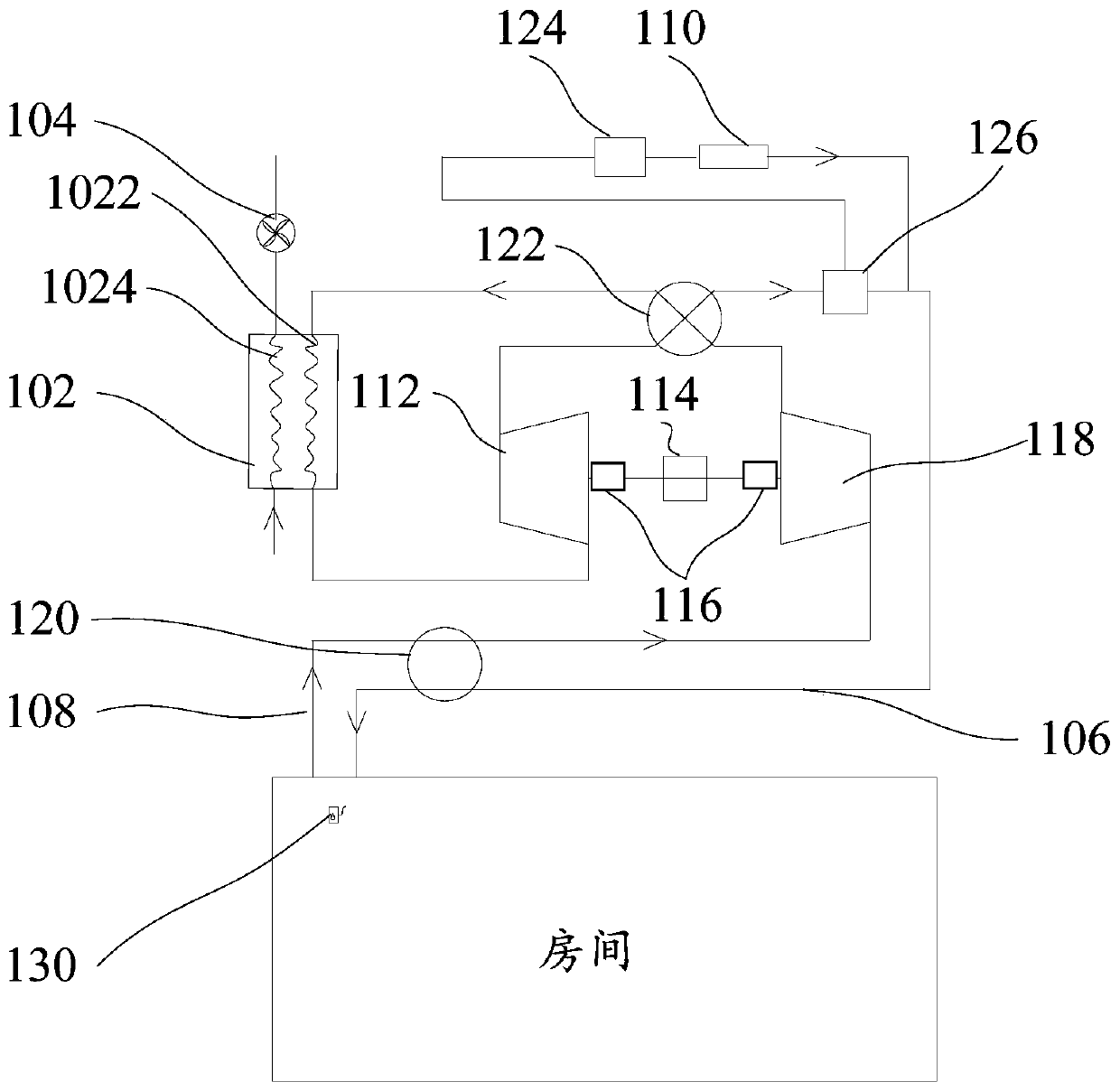

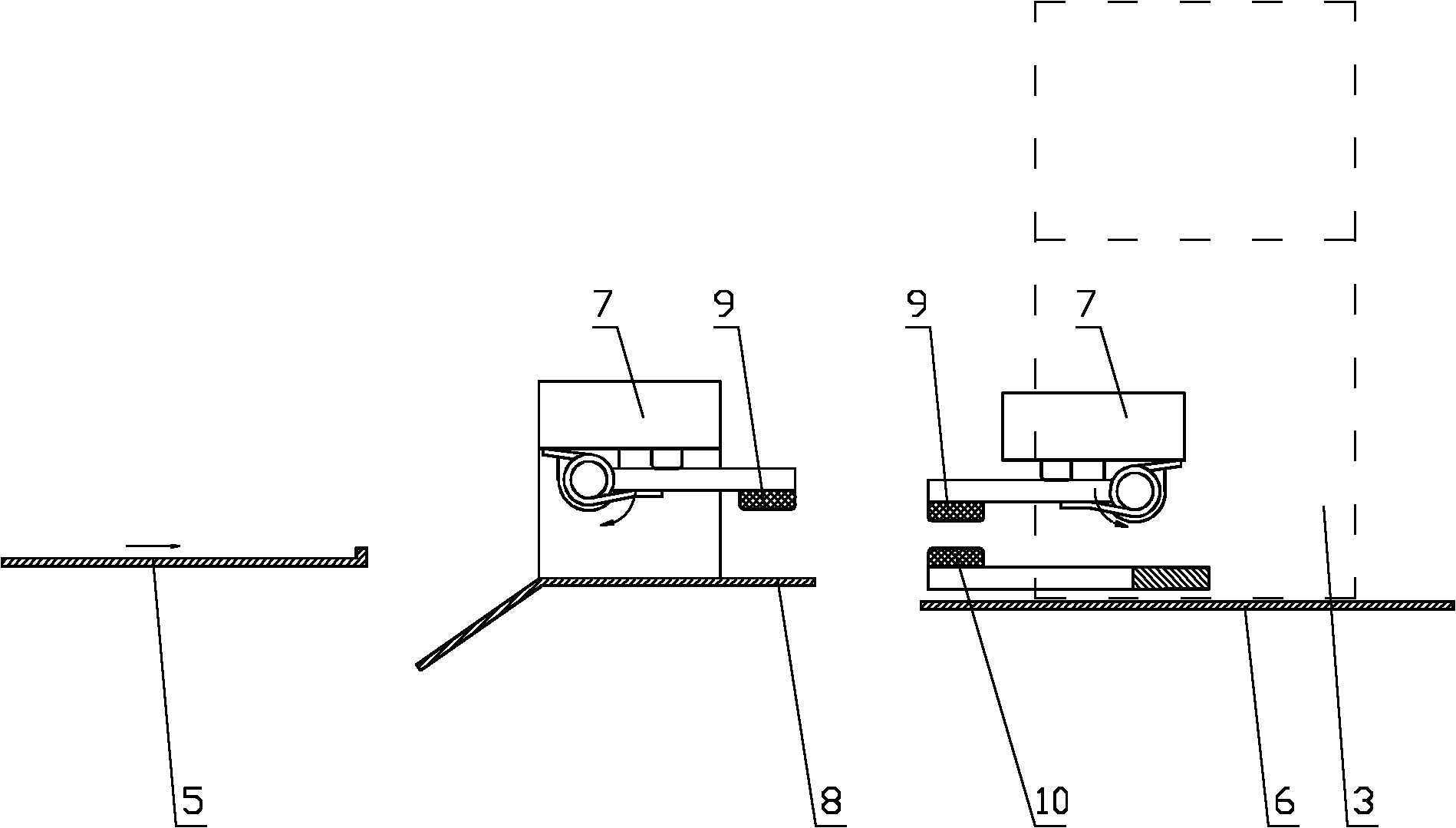

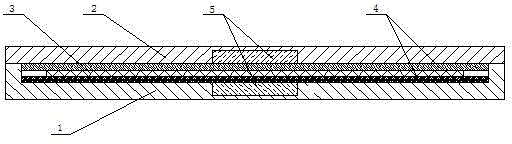

Improved buttonholing machine tool

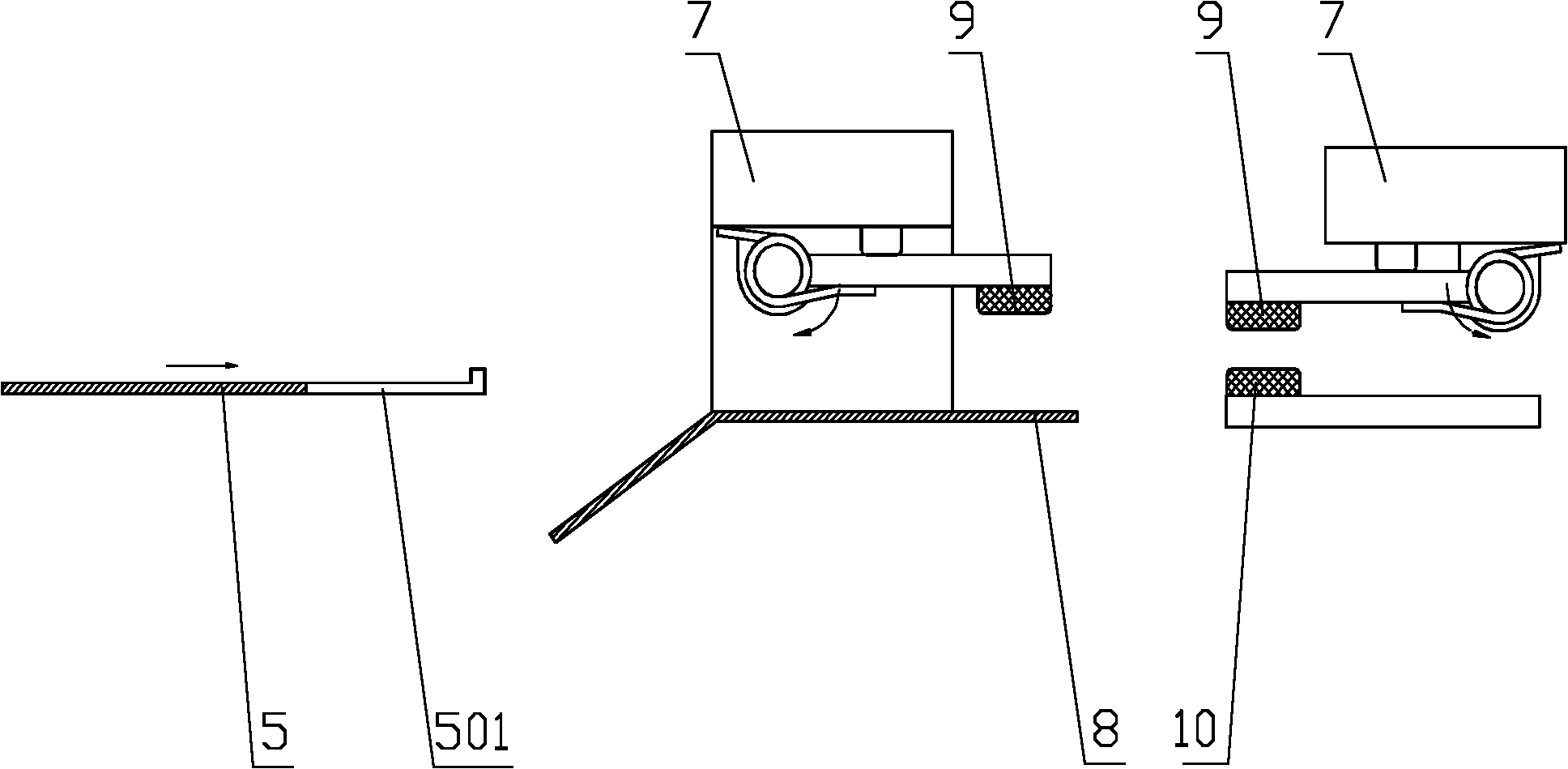

ActiveCN102304824ALow costReduce assembly requirementsSewing-machine control devicesPressersMechanical constructionEngineering

The invention discloses an improved buttonholing machine tool. The improved buttonholing machine tool comprises a horizontally arranged rectangular feeding plate and a compaction feeding assembly which is positioned on the rear side of the rectangular feeding plate; a main compaction assembly and a buttonholing machine are parallelly arranged on the rear side of the compaction feeding assembly left and right; a machine head compaction assembly is distributed on the rear side of the head of the buttonholing machine; the compaction feeding assembly comprises upper compaction pins and a lower material supporting plate which are arranged vertically; the upper compaction pins and the lower material supporting plate can be opened or closed; the main compaction assembly and the machine head compaction assembly comprise a plurality of pairs of upper and lower compaction pins which are arranged along the length direction at intervals respectively; and the upper compaction pins and the lower compaction pins can be opened or closed; and the upper compaction pins of three sets of compaction positioning assemblies are driven by an air cylinder to vertically lift. A clamping positioning structure which is vertically pressed improves straightness of a button hole of a front fly of shirts, and guarantees the aesthetic feeling of the front fly of shirts; the mechanical structure is greatly simplified, the assembly difficulty and debugging difficulty are reduced, and the mechanical assembly efficiency and the maintenance cost of a customer are improved conveniently; and the buttonholing machine tool guarantees that the stress surface is full when fabric is compacted and has a better compaction effect.

Owner:SHANGHAI WEISHI MACHINERY

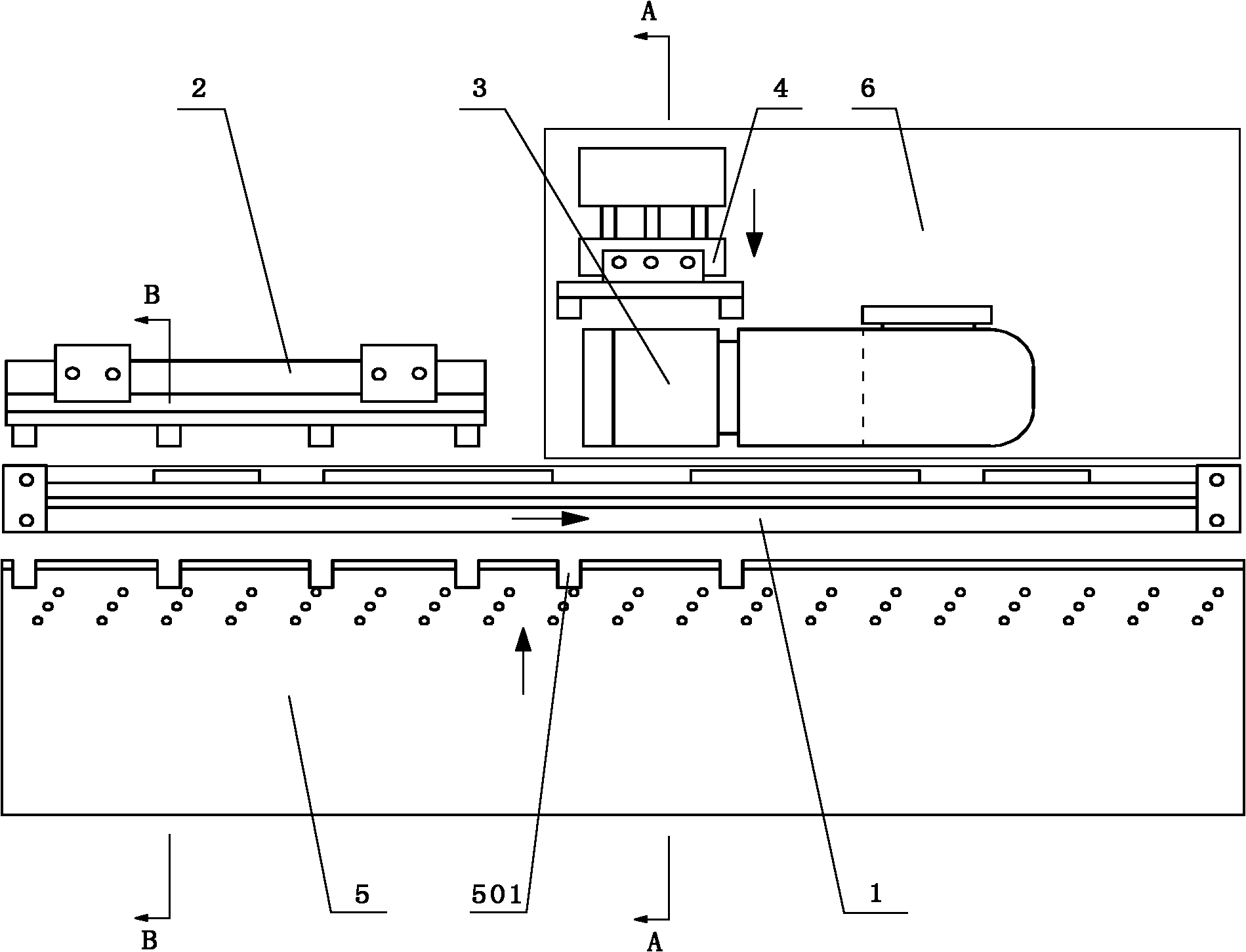

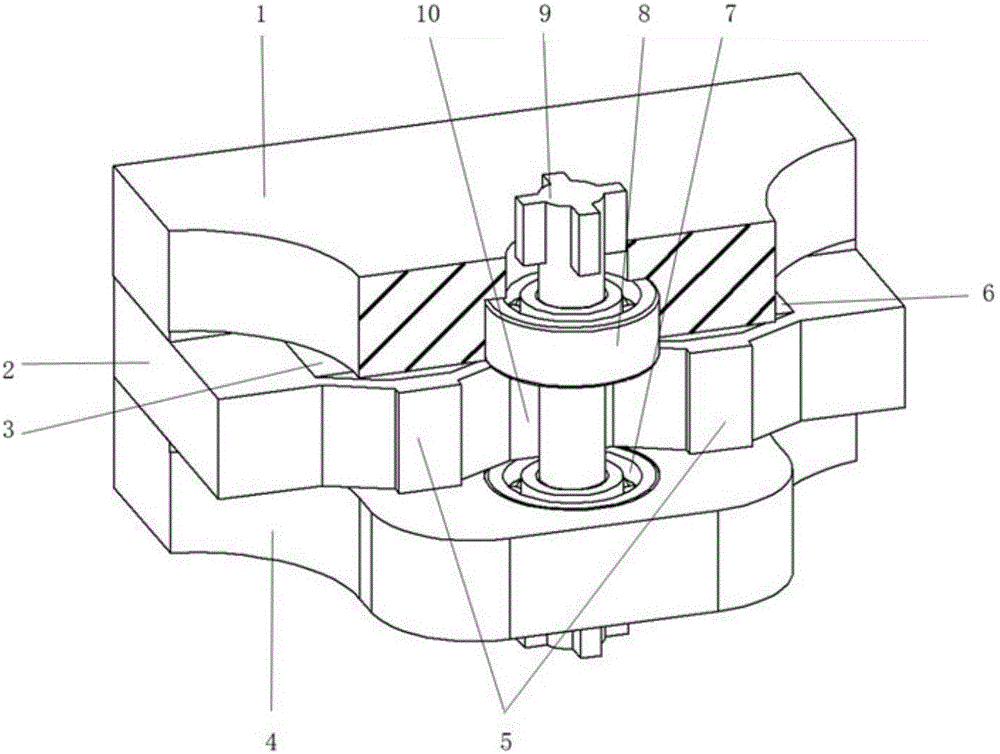

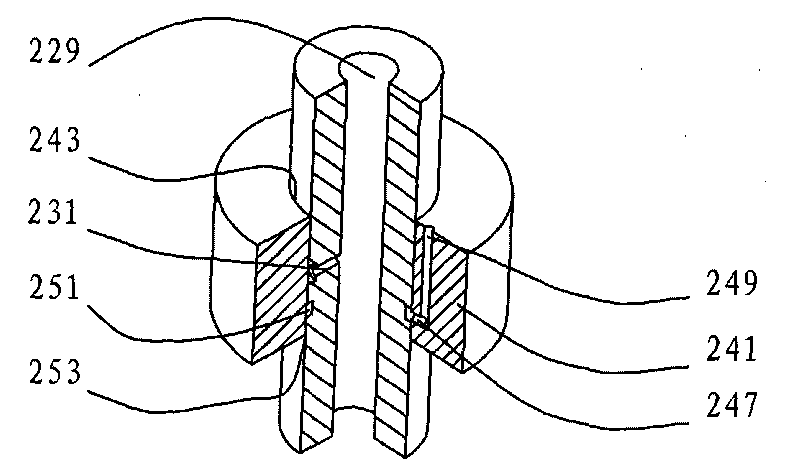

Rotatory inertia piezoelectric actuator comprising dual-rhombic series driving mechanism and actuation method

ActiveCN106208806AReduce processing and assembly difficultyReasonable use of internal spacePiezoelectric/electrostriction/magnetostriction machinesMoment of inertiaPiezoelectric actuators

The invention discloses a rotatory inertia piezoelectric actuator comprising a dual-rhombic series driving mechanism and an actuation method. The actuator consists of an upper baffle, a lower baffle, a bearing, a rotary output shaft, the dual-rhombic series driving mechanism and piezoelectric stacks, wherein the dual-rhombic series driving mechanism comprises series dual-rhombic rings; the piezoelectric stacks are in interference fit inside the series dual-rhombic rings; a friction block is arranged at a series joint of the piezoelectric stacks; the rotary output shaft of the actuator is connected with the upper baffle and the lower baffle through the bearing respectively; and the dual-rhombic series driving mechanism is fixedly assembled between the upper baffle and the lower baffle. After finish of assembly, a side face of the friction block is in close contact with the rotary output shaft, and the actuator can drive a load to output bidirectional rotary motion by control of voltage time sequences and amplitudes of the piezoelectric stacks. The rotatory inertia piezoelectric actuator has the characteristics of easiness in assembly, quick response and accurate action.

Owner:XI AN JIAOTONG UNIV

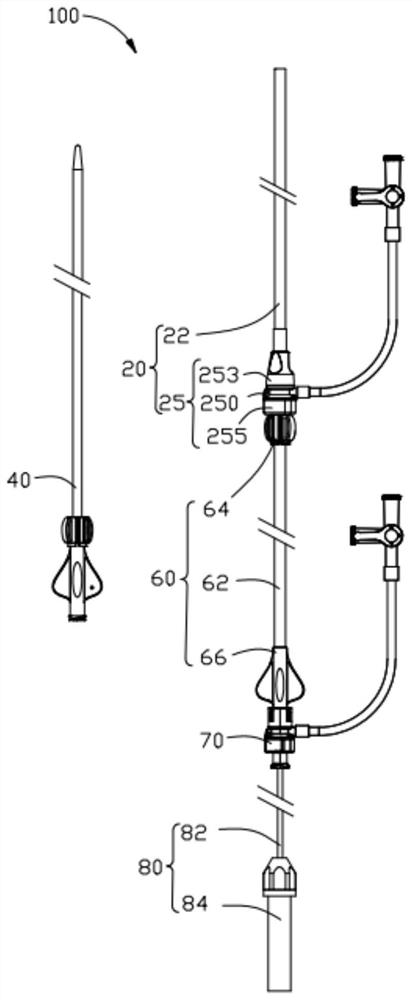

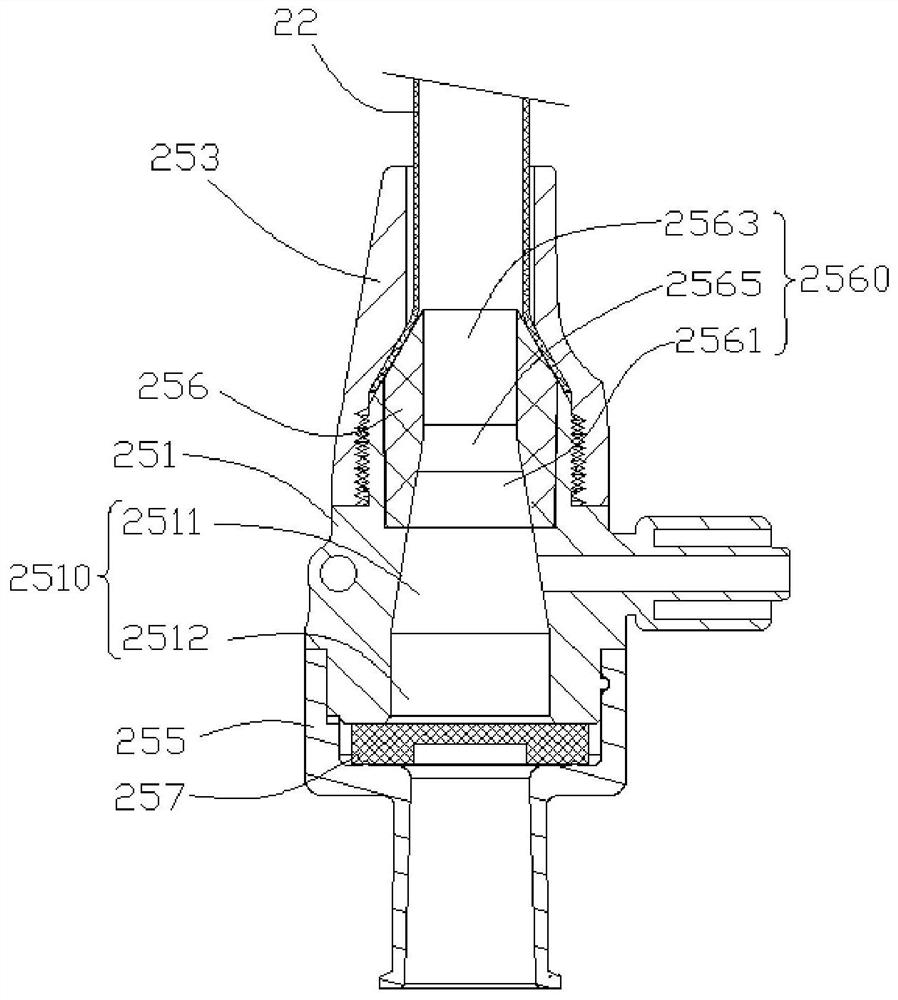

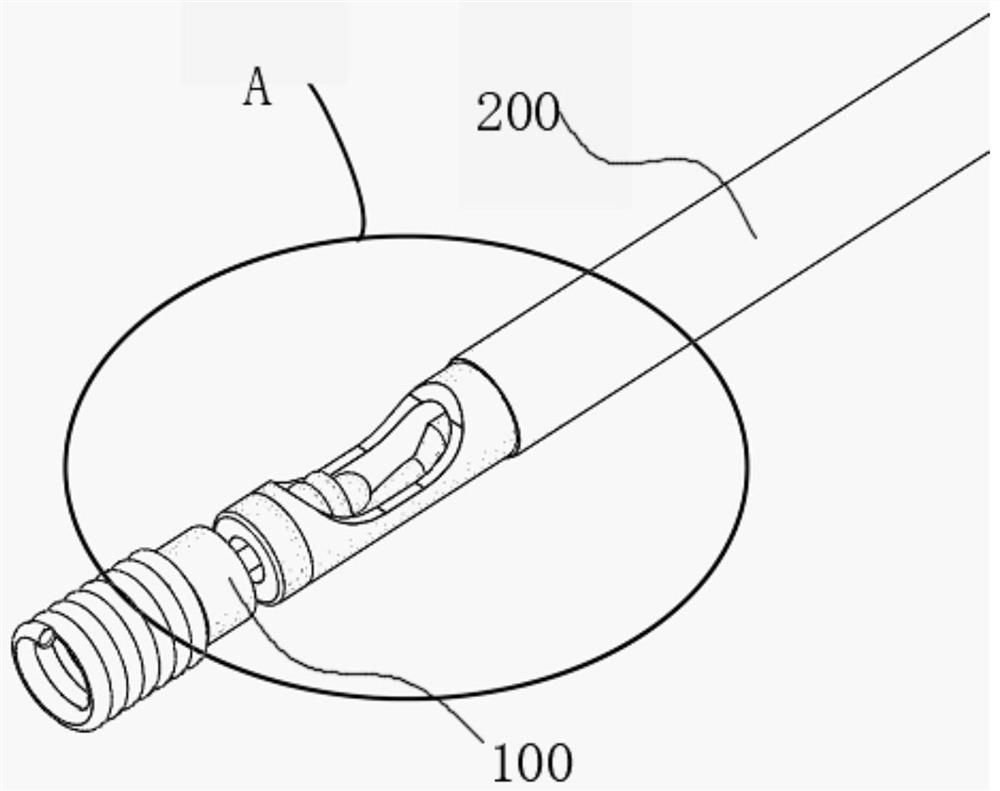

Interventional medical instrument conveying system smooth in conveying

PendingCN111803169AReduce assembly requirementsStable deliveryOcculdersEngineeringApparatus instruments

The invention provides an interventional medical instrument conveying system smooth in conveying. The system comprises a conveyor and a loader; the conveyor comprises a conveying sheath tube and a sheath tube seat connected to the near end of the conveying sheath tube; the loader comprises a loading tube, the far end of the loading tube is detachably connected with the sheath tube seat, and a connecting through hole extending in the axial direction of the sheath tube seat is formed in the sheath tube seat so as to achieving communicating between the loading tube with the conveying sheath tube,the connecting through hole comprises a reducing hole section, the hole diameter of the reducing hole section is gradually reduced from the near end to the far end, and the far end face of the loading tube extends into the reducing hole section from the near end of the connecting through hole; and a radial gap is formed between the far end face of the loading tube and the corresponding part of the reducing hole section. The interventional medical instrument conveying system can convey interventional medical instruments smoothly, and the requirement for assembling the loading tube and the sheath tube seat in the system is reduced.

Owner:HANGZHOU NUOMAO MEDTECH CO LTD

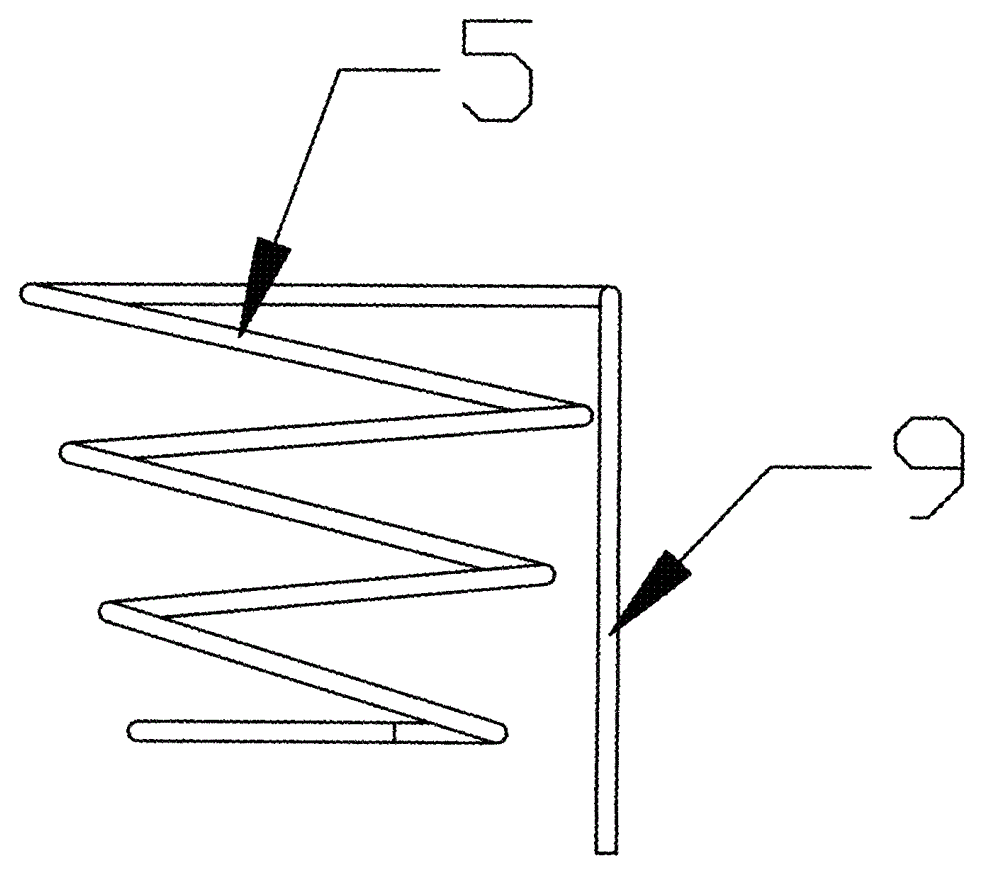

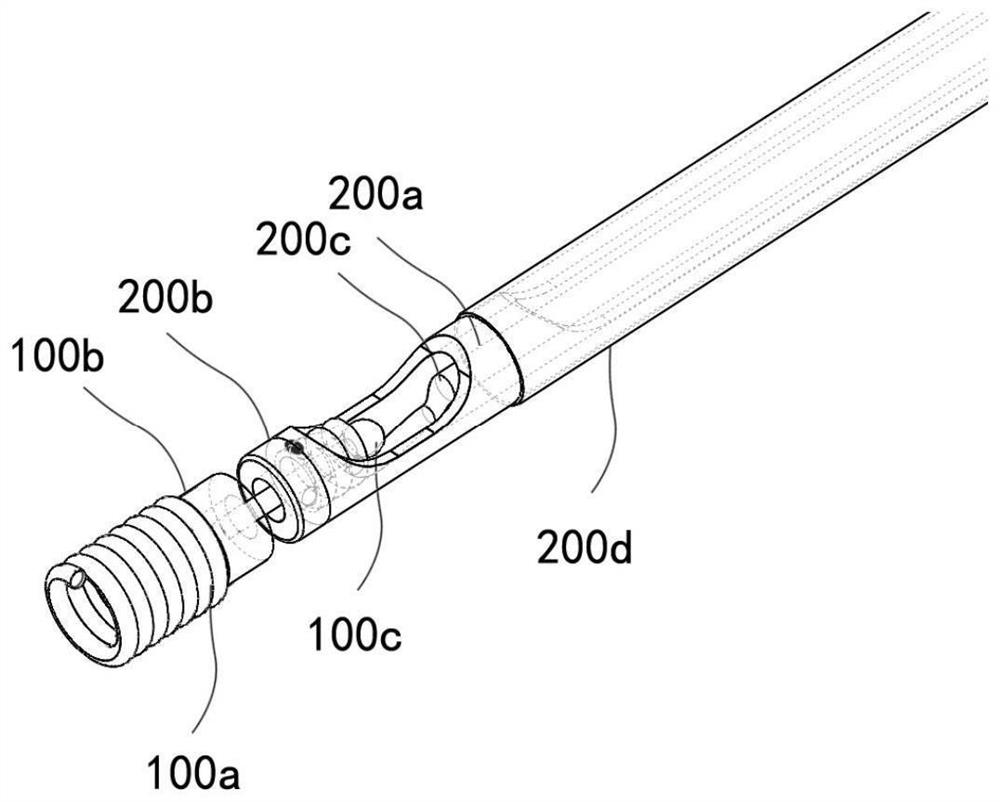

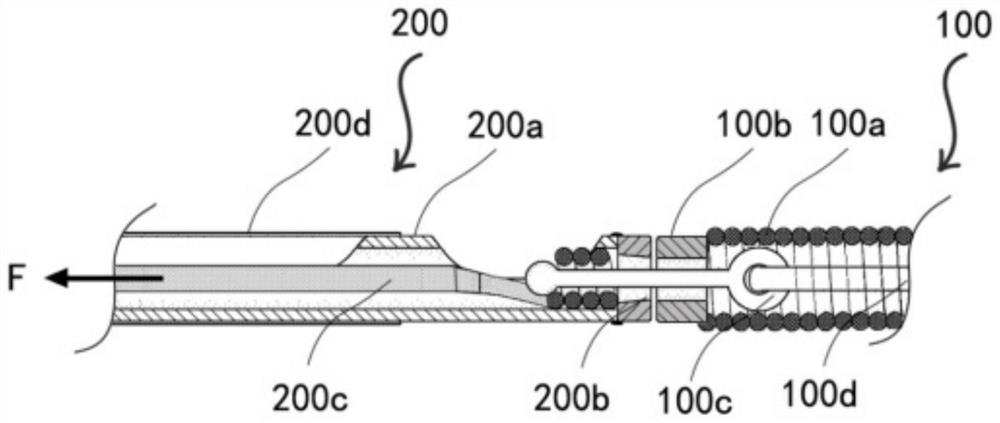

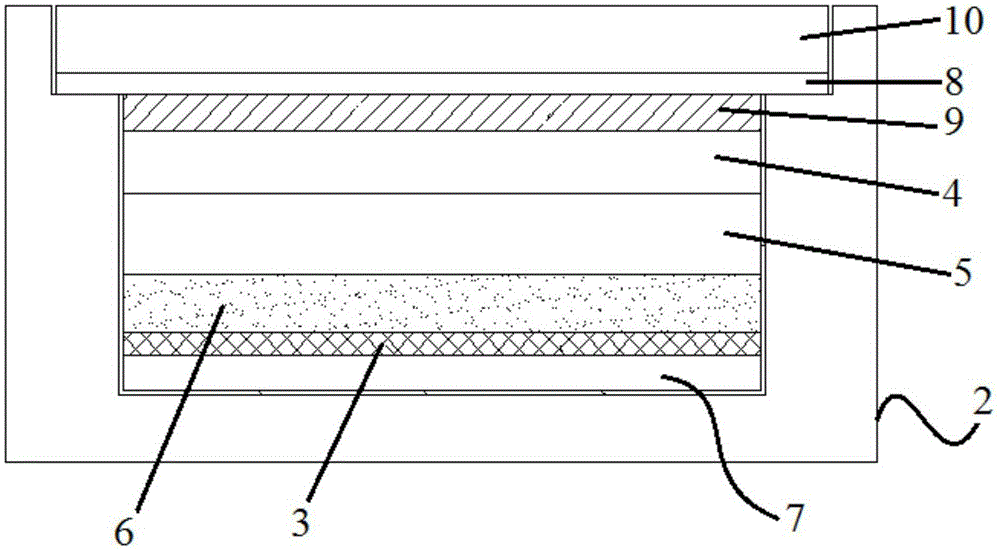

Embolism spring ring conveying system

PendingCN114469231ALow machining accuracy requirementsReduce assembly requirementsOcculdersEngineeringApparatus instruments

The invention discloses an embolism spring ring conveying system, and belongs to the technical field of medical instruments, the embolism spring ring conveying system comprises an implant, the implant comprises a release assembly, and one end, extending out of the implant, of a rod-shaped part of the release assembly is provided with a spherical head; the pushing system comprises a releasing wire, and the end, close to the implant, of the releasing wire is wound around the releasing assembly so that the releasing wire can be detachably installed on the releasing assembly through the spherical head; and the breaking and releasing mechanism is located at the end, far away from the implant, of the pushing system, and the releasing wire far away from the spherical head extends into the breaking and releasing mechanism and is used for breaking to achieve separation of the implant. According to the novel mechanical release structure, the release wire at the far end is detachably connected with the release assembly through the spiral spring-shaped structure, the machining precision and the assembly requirement of parts are lowered, and the release reliability is improved.

Owner:南京思脉德医疗科技有限公司

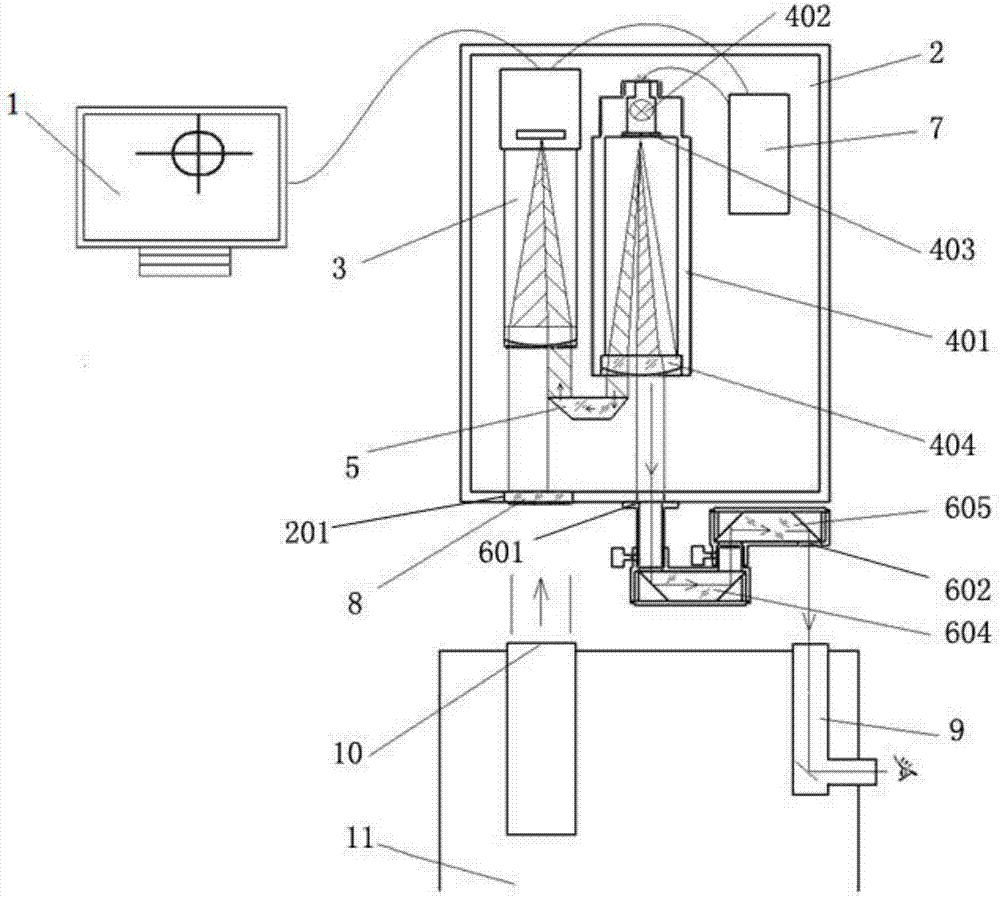

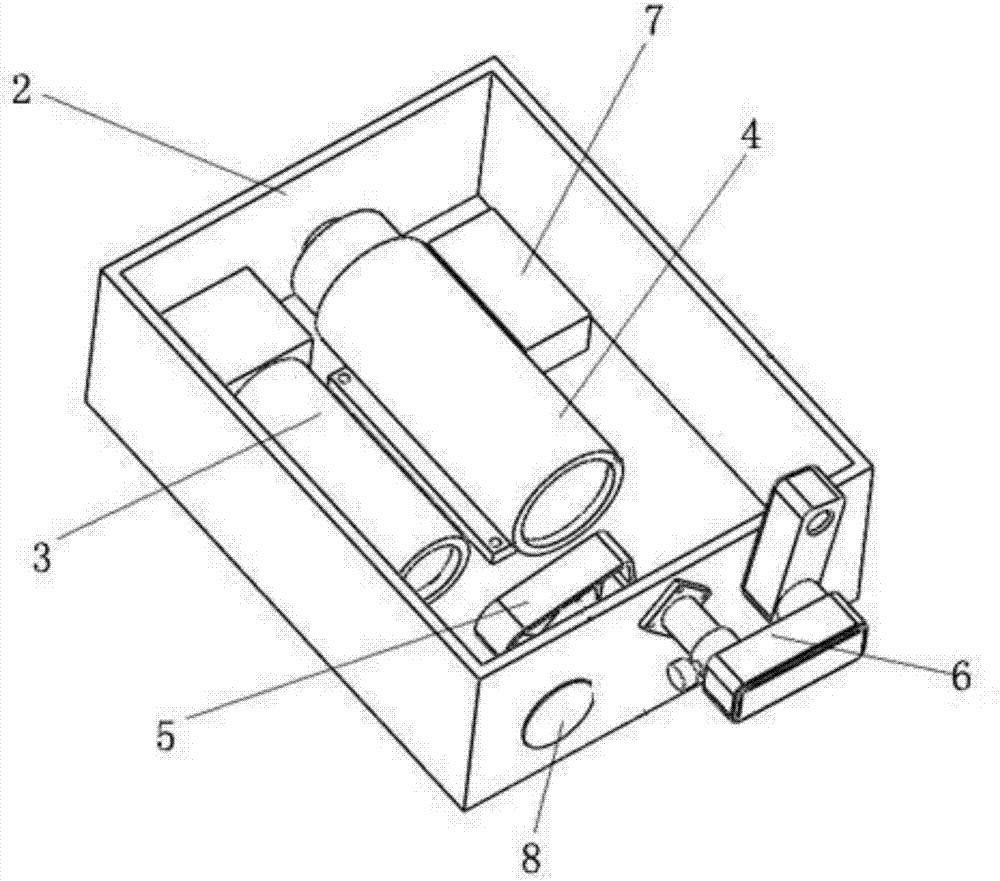

Prismatic reflection type calibrator and calibration method thereof

PendingCN107238355AImprove calibration accuracySimple structureUsing optical meansOptical axisLight beam

The invention discloses a prismatic reflection type calibrator and relates to the technical field of inspection of parallelism of optical axes. The prismatic reflection type calibrator comprises a display and further comprises a box, wherein a camera and a collimator are arranged in the box in parallel; the camera is connected with the display; the collimator can generate bright cross division lines under a dark background; a first triple prism is arranged in the box and comprises three reflectors perpendicular to one another; one end of the first triple prism can receive light beams of the collimator projected from the right upper side, and the other end of the first triple prism can reflect the light beams into the camera in parallel; a laser incidence window is formed in a position, which faces the camera, of the box; a reflecting prism group is arranged outside the box and comprises an entrance port and an exit port; and the entrance port is aligned with the collimator. The prismatic reflection type calibrator disclosed by the invention is high in complete calibration accuracy, convenient to adjust and operate and reliable; and moreover, illumination and size requirements of the environment and site are not needed, and the production efficiency is greatly improved.

Owner:NANJING RES INST ON SIMULATION TECHN

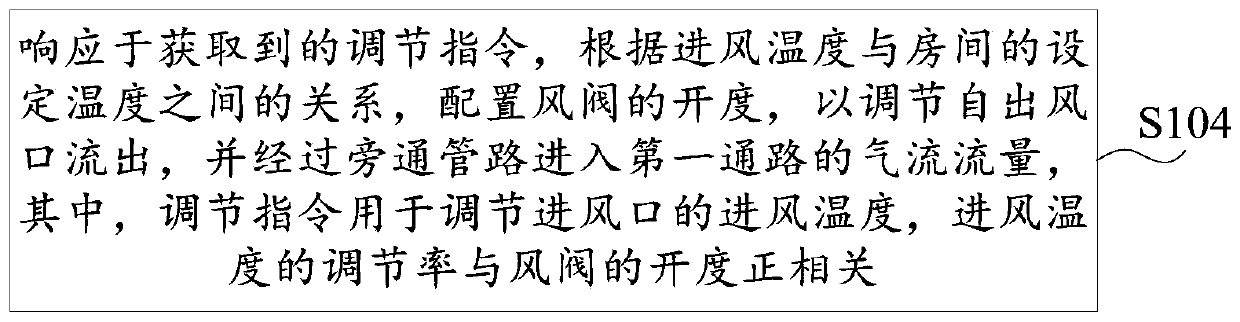

Operation control method, compressed air heat exchange system and storage medium

ActiveCN110715475ALow costReduce pollutionMechanical apparatusSpace heating and ventilation safety systemsFresh airRoomba

The invention provides an operation control method, a compressed air heat exchange system and a readable storage medium. The operation control method of the compressed air heat exchange system comprises the steps of responding to an obtained regulating instruction, and configuring the opening degree of an air valve according to the relationship between the air inlet temperature and the set temperature of a room to regulate the flow of airflow flowing out from an air outlet and entering a first channel through a bypass pipeline, wherein the regulating instruction is used for regulating the airinlet temperature of the air inlet, and the regulating rate of the air inlet temperature is positively correlated to the opening degree of the air valve. By executing the technical scheme, on one hand, the air blowing discomfort caused by excessively-low and excessively-high air inlet temperature to a user can be lowered; on the other hand, fresh air supply is achieved, and on the premise of the high outdoor air quality, the quality of air inside a room is improved; on the other hand, circulation of air inside the room can be facilitated, and therefore a temperature field is more uniform.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Multifunctional coupler

InactiveCN104900973AImprove isolationLittle change in standing waveCoupling devicesEngineeringResistor

The utility model discloses a multifunctional coupler, relating to the technical field of couplers. The multifunctional coupler comprises a housing, a coupling straight bar, a coupling curved bar, a resistor and a debugging block, wherein the coupling straight bar and the coupling curved bar are arranged in a cavity of the housing, the two ends of the coupling straight bar are connected with the outside through the housing, one end of the coupling curved bar is connected with the outside through the housing, and the other end of the coupling curved bar is connected with the resistor. The four-stage strip line cavity directional coupler disclosed by the utility model adopts a coupling strip line four-stage design and can not only meet the requirements of an ordinary cylindrical coupler for covering bandwidth, but also reduce the precision, assembly requirements and production cost which are required by processing during production processes.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

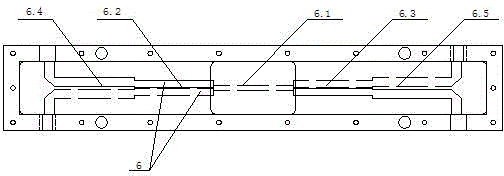

Five-stage microstrip line bridge

InactiveCN104900966AMeet coverage bandwidth requirementsReduce the precision of processing requirementsCoupling devicesEngineeringExternal connection

The invention provides a five-stage microstrip line bridge, and relates to the technical field of bridges. The five-stage microstrip line bridge comprises a cavity, a cover board, a circuit board, dielectric boards and additional dielectric boards, wherein the cover board is mounted above the cavity; the circuit board is arranged in the cavity; the upper surface and the lower surface of the circuit board are respectively provided with a microstrip line; four ends of each microstrip line can be respectively connected with the outside through the cavity; the dielectric boards are respectively arranged on and under the circuit board; and the additional dielectric boards are respectively arranged outside the dielectric boards. According to the invention, the symmetrical design of the five-stage microstrip lines of coupled strip lines is adopted, so that the requirements of a common columnar coupled rod bridge for coverage bandwidth can be met; meanwhile, the situations that the rigidity can not be ensured and a strip line is easy to deform in case of an over-long length are changed; and the processing required accuracy, assembling requirement and production cost in the production process are lowered.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

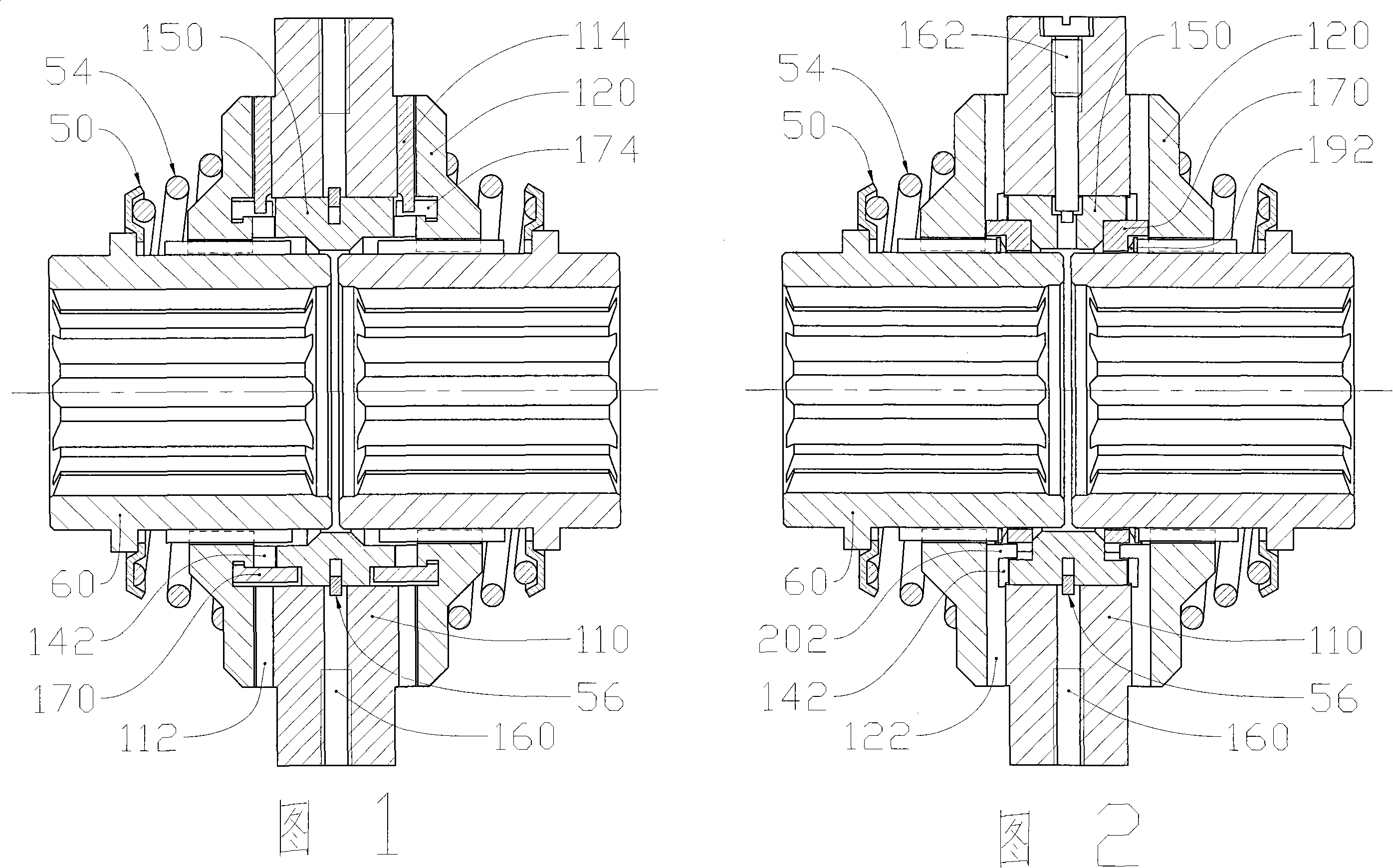

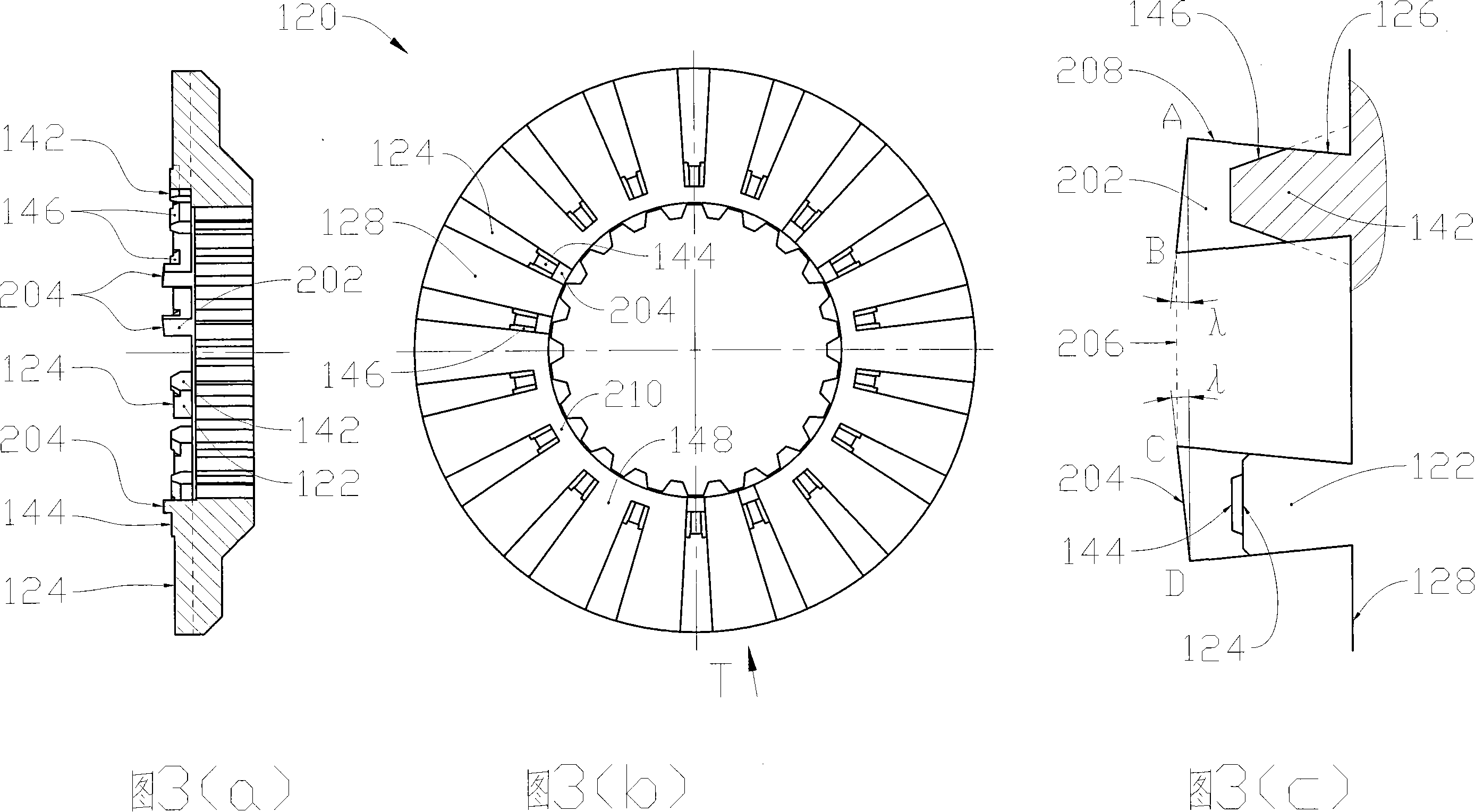

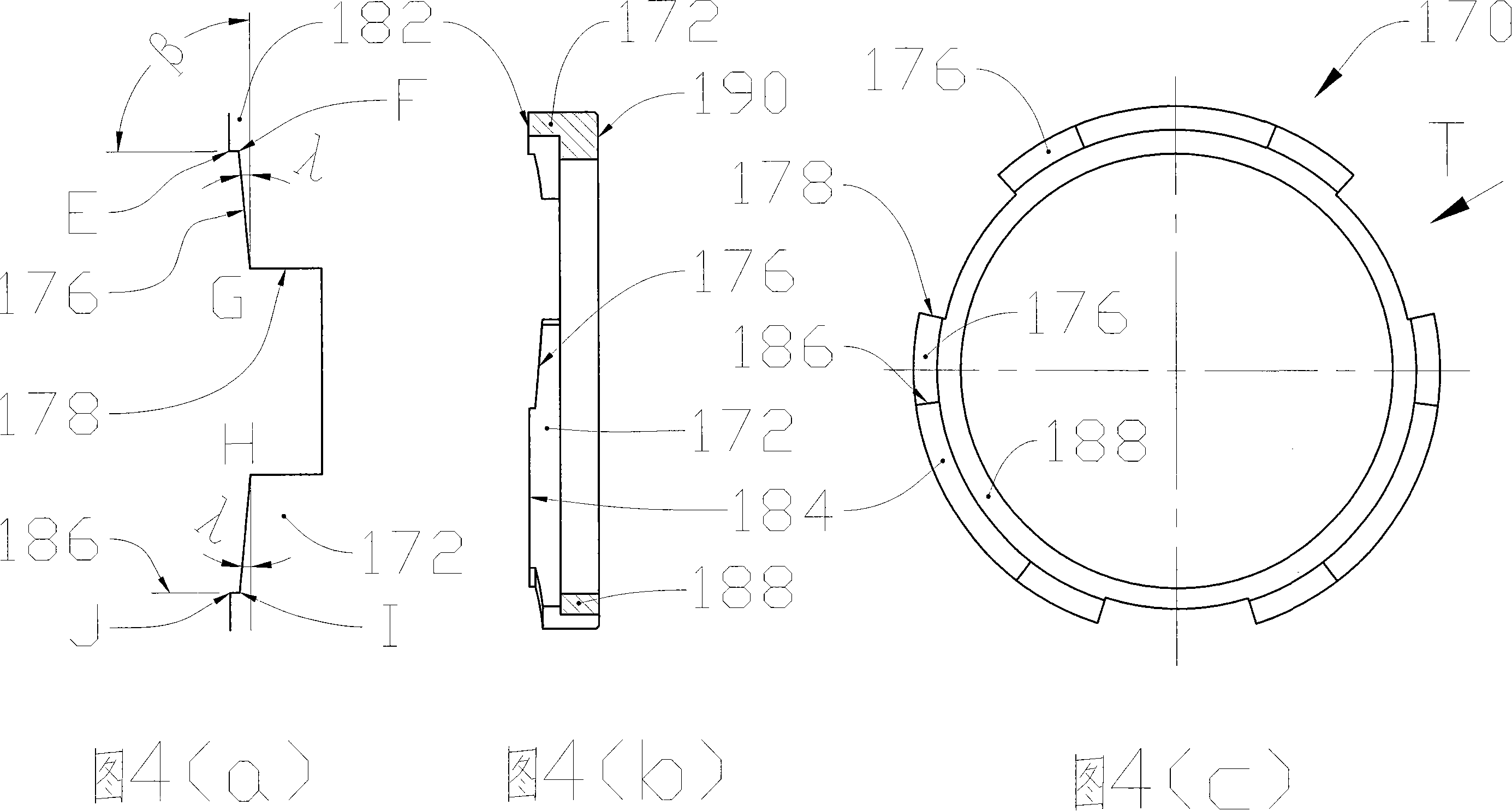

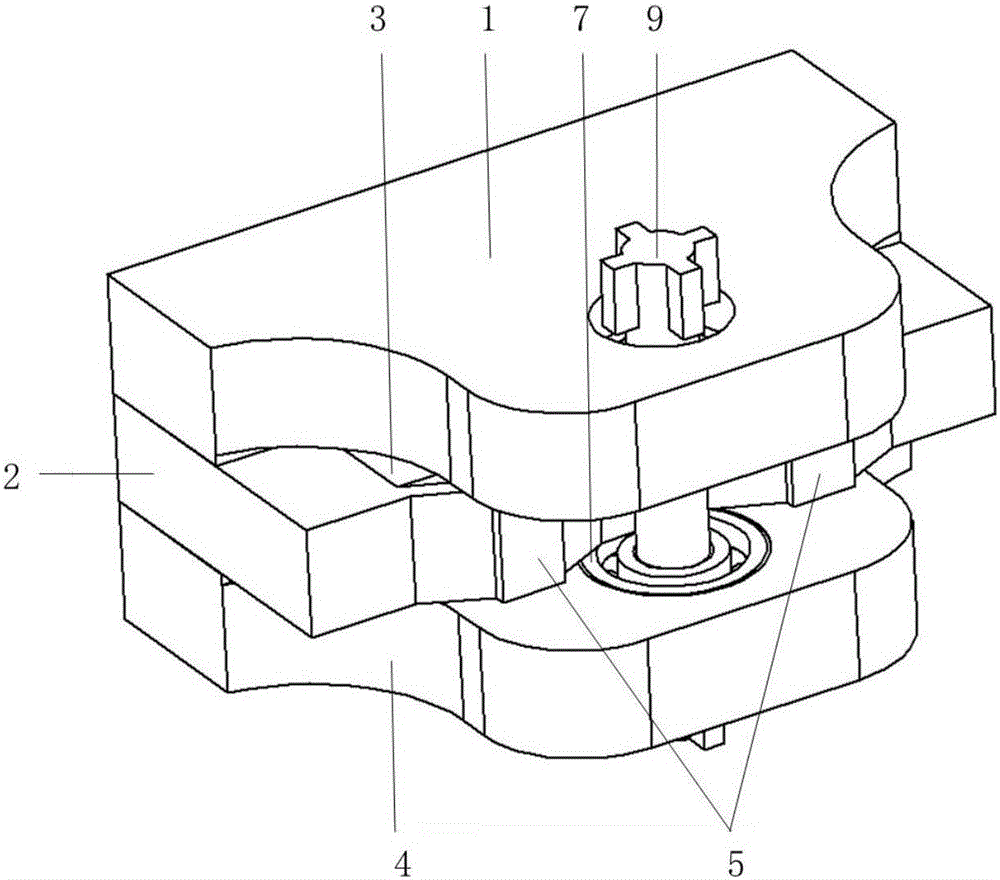

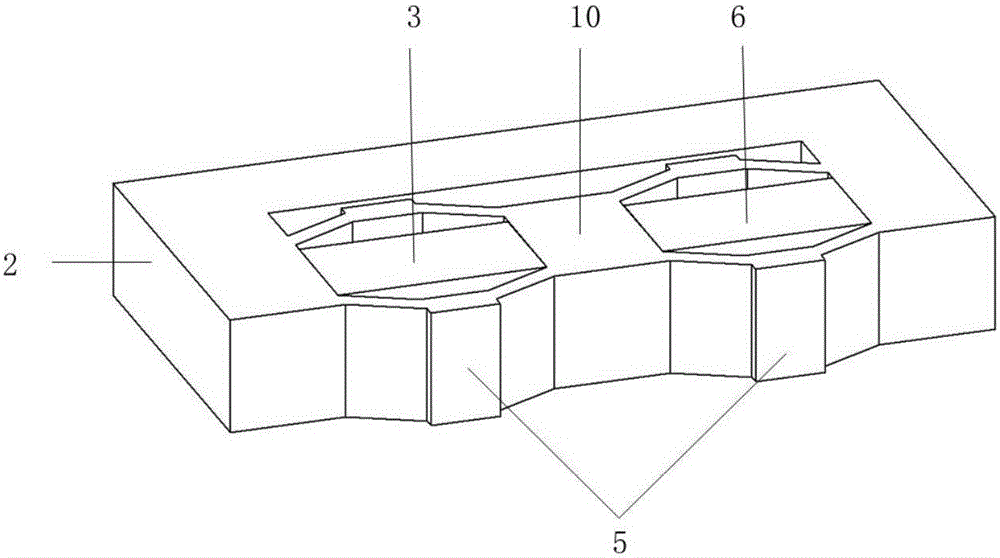

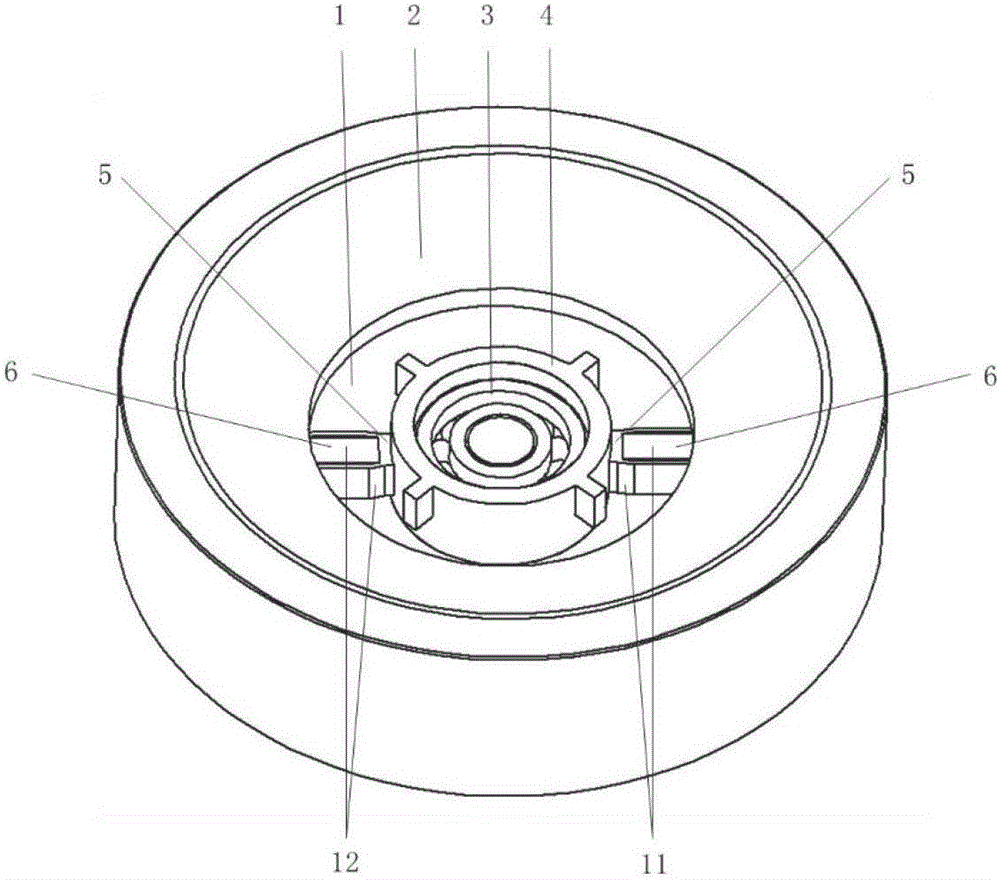

Clamping controllable disc-shaped rotary type inertia piezoelectric actuator and actuation method

ActiveCN106059386AAvoid lossImprove actuation efficiency and response speedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

The invention discloses a clamping controllable disc-shaped rotary type inertia piezoelectric actuator and an actuation method. The actuator is composed of a base, a clamping housing, a bearing, an output ring, clamping rhombic rings, clamping piezoelectric stacks, main movement blocks, mass blocks, driving rhombic rings and driving piezoelectric stacks, and the whole actuator is structurally symmetrical; the clamping rhombic rings and the driving rhombic rings are internally respectively in interference fit with the clamping piezoelectric stacks and the driving piezoelectric stacks, the mass blocks and the aforementioned parts are not in contact with the base, and mass centers are disposed in the same plane parallel to the base; and the output ring is connected with a fixation shaft at the center of the base through the bearing, the two clamping rhombic rings whose end surfaces are fixedly connected with the outer ring surface of the output ring are radially arranged at the two sides of the same diameter, axes of the clamping rhombic rings and the driving rhombic rings are vertical to each other, the two are connected through adjacent side surfaces of the main movement blocks placed on a plane of the base, the side surfaces of the mass blocks are fixedly connected with the driving rhombic rings, and other surfaces of the mass blocks are suspended above the base. The structure is novel, clamping is reliable, and bidirectional rotation can be realized.

Owner:XI AN JIAOTONG UNIV

Mobile terminal and pressure sensing device thereof

InactiveCN105426016AAvoid stackingLower requirementInput/output processes for data processingHigh volume manufacturingMetallic materials

The invention discloses a mobile terminal and a pressure sensing device thereof. The mobile terminal comprises a display module and a middle frame. The pressure sensing device is characterized by comprising a pressure sensor arranged at the bottom of the middle frame and attached to the lower surface of the display module. The pressure sensor is attached to the lower surface of the display module, a whole pressure sensing layer is prevented from being stacked on the middle frame of the complete machine, the middle frame is not required to be made of a metal material and grounded, so that the requirement for the middle frame of the complete machine is reduced, the assembly requirement for the complete machine during assembly is reduced, and the pressure sensing device and the mobile terminal have conditions of mass production.

Owner:HUAQIN TECH CO LTD

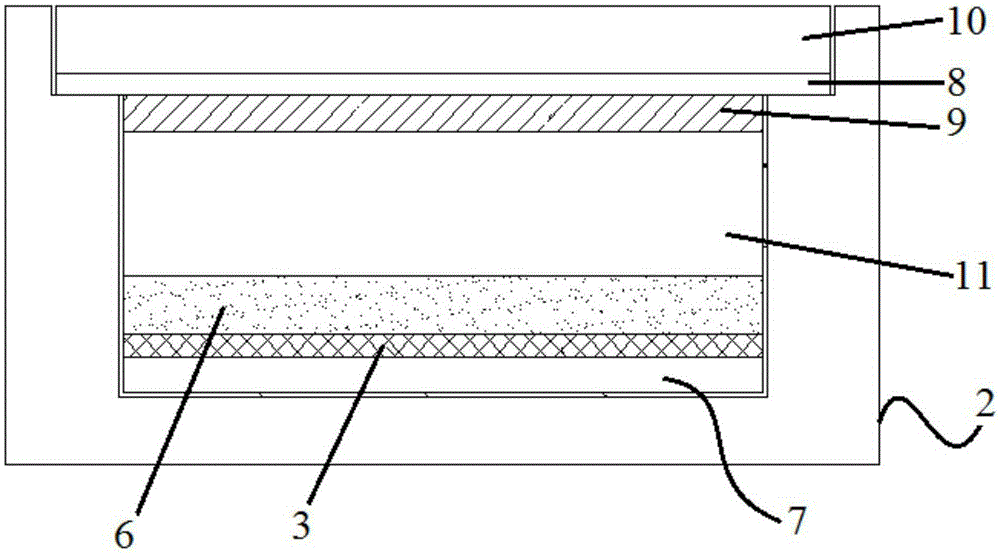

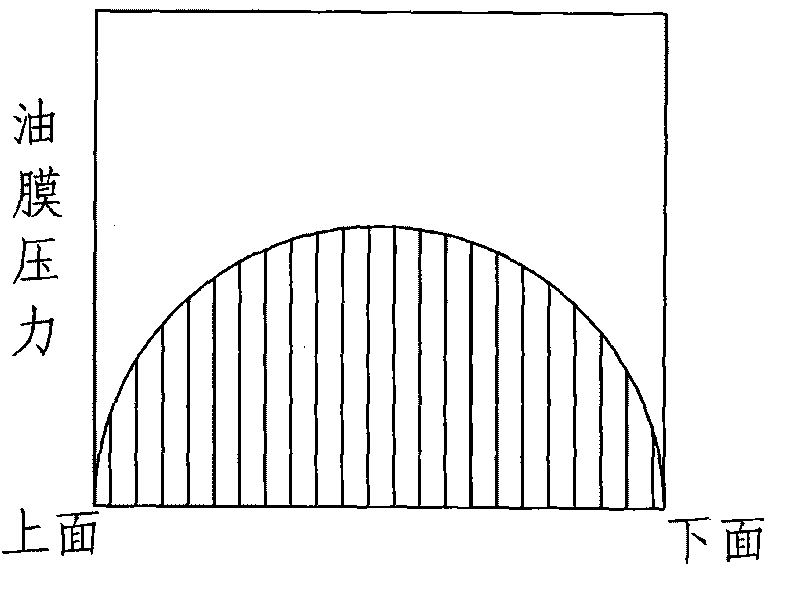

Main shaft neck part oil return mechanism of driving shaft of scroll compressor

InactiveCN101749246AReduce processing costsReduce assembly requirementsRotary piston pumpsRotary piston liquid enginesMain bearingEngineering

The invention relates to a main shaft neck part oil return mechanism of a driving shaft of a scroll compressor. The scroll compressor comprises a compression mechanism part and a motor part which are arranged in a sealing container, wherein the compression mechanism part comprises a movable eddy disc and a machine frame, the movable eddy disc is connected with a static eddy disc, the machine frame is used for supporting the movable eddy disc and the driving shaft, the back side of the movable eddy disc is provided with a driving part, the driving shaft is connected with the driving part of the movable eddy disc through a driving bearing, the driving shaft is connected with the machine frame through a main bearing, the upper end surface of the machine frame and the back side of the eddy disc form a space for accommodating the driving part of the movable eddy disc, the space is also simultaneously used as an oil recovery cavity for lubricating oil from the driving bearing and the main bearing, an annular oil groove is formed at one end of the main shaft neck part of the driving shaft far away from the movable eddy disc, an oil path is arranged on the outer wall of the main shaft neck part, and the oil path is communicated with the annular oil groove and the oil recovery cavity. The invention has the characteristics that the manufacture cost is low, the sufficient oil return at the main shaft neck part can be ensured, and the discharge of the lubricating oil along with the high-pressure gas can be reduced.

Owner:MIDEA GRP CO LTD

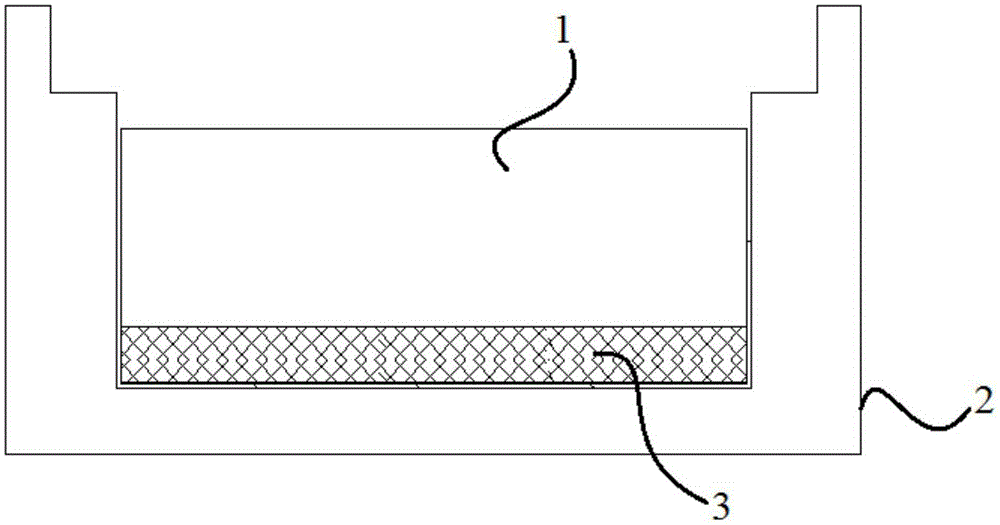

Meter, and photoelectric sampling device and the photoelectric sampling method of same

InactiveCN111121890ADifference maximizationObvious contrastVolume/mass flow by electric/magnetic effectsVolume indication and recording devicesEngineeringLight signal

The invention discloses a meter and a photoelectric sampling device and a photoelectric sampling method of the meter, which belong to the technical field of flow measurement, and solve the problem oflight interference caused by the fact that an existing meter adopts reflection type optical signal sampling. The photoelectric sampling device of the meter comprises a light emitter, a light receiverand a rotary disc, wherein the light receiver and the light emitter are oppositely arranged, and a light correlation region is formed between the light receiver and the light emitter; and the rotary disc is driven by means of a base meter of the meter to rotate, a shading part and a light-transmitting part are arranged on the rotary disc, and the shading part and the light-transmitting part alternately pass through the light correlation region through the rotating motion of the rotary disc. According to the photoelectric sampling device and the photoelectric sampling method, correlation optical signal sampling is carried out, the problem that light is easily interfered by external light in reflection-type optical signal sampling is solved, the identification difficulty of sampled signals is reduced, and the manufacturing process requirement and the assembly requirement of product parts are reduced.

Owner:GOLDCARD HIGH TECH

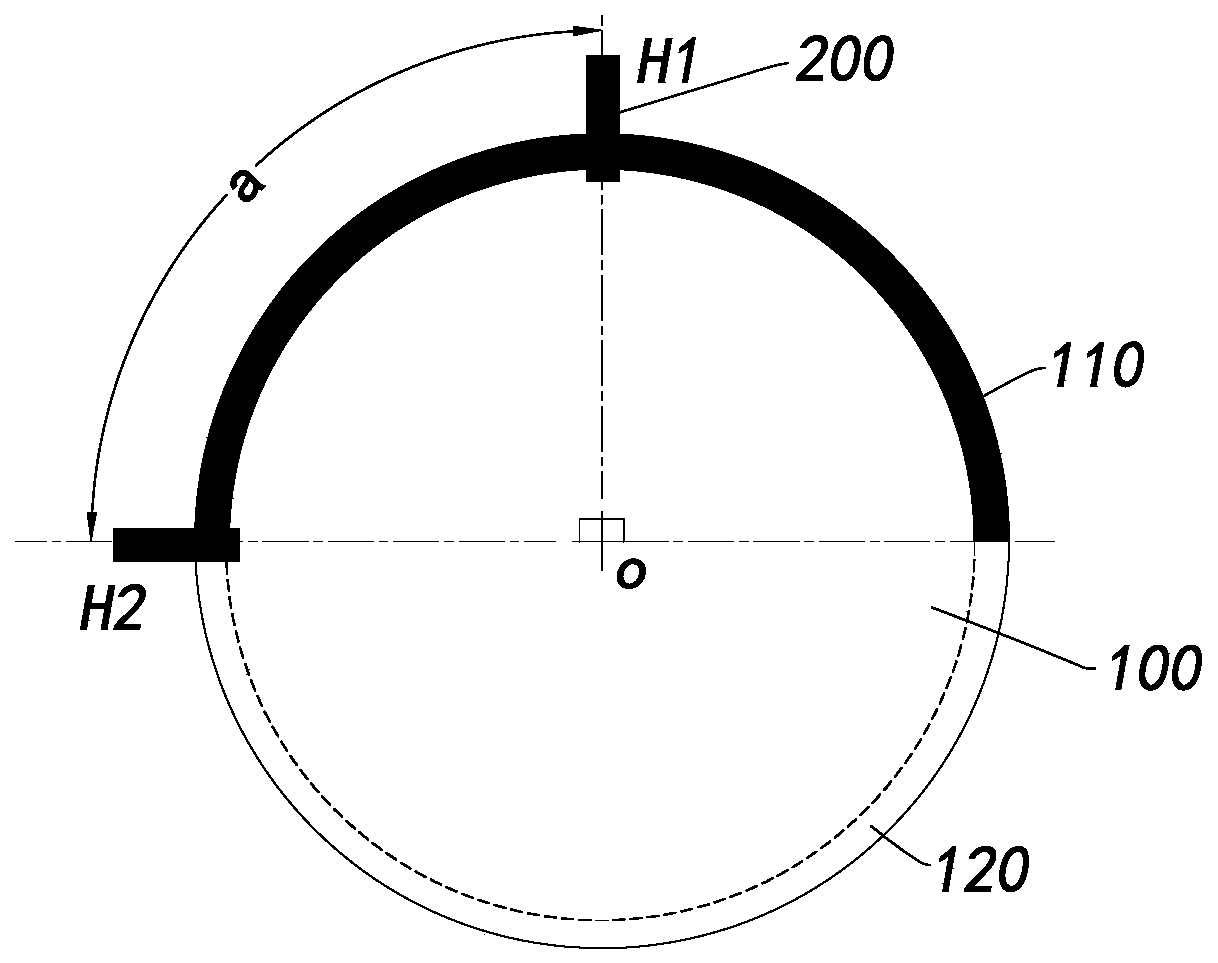

High-precision ultra-large-stroke painting robot telescopic arm adopting statically indeterminate structure

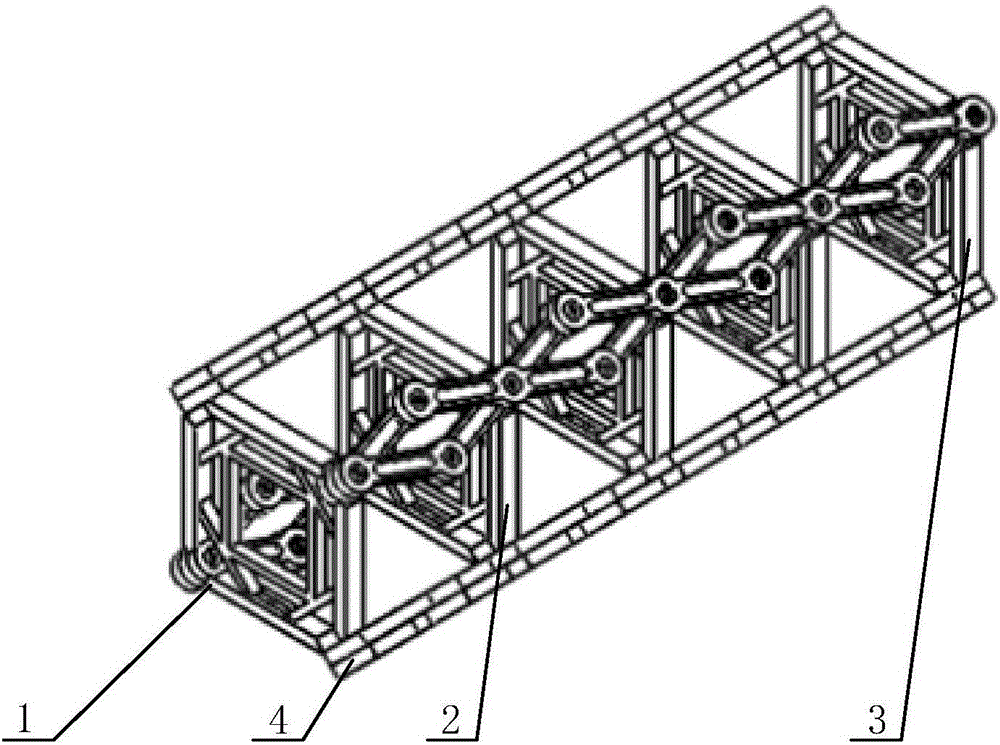

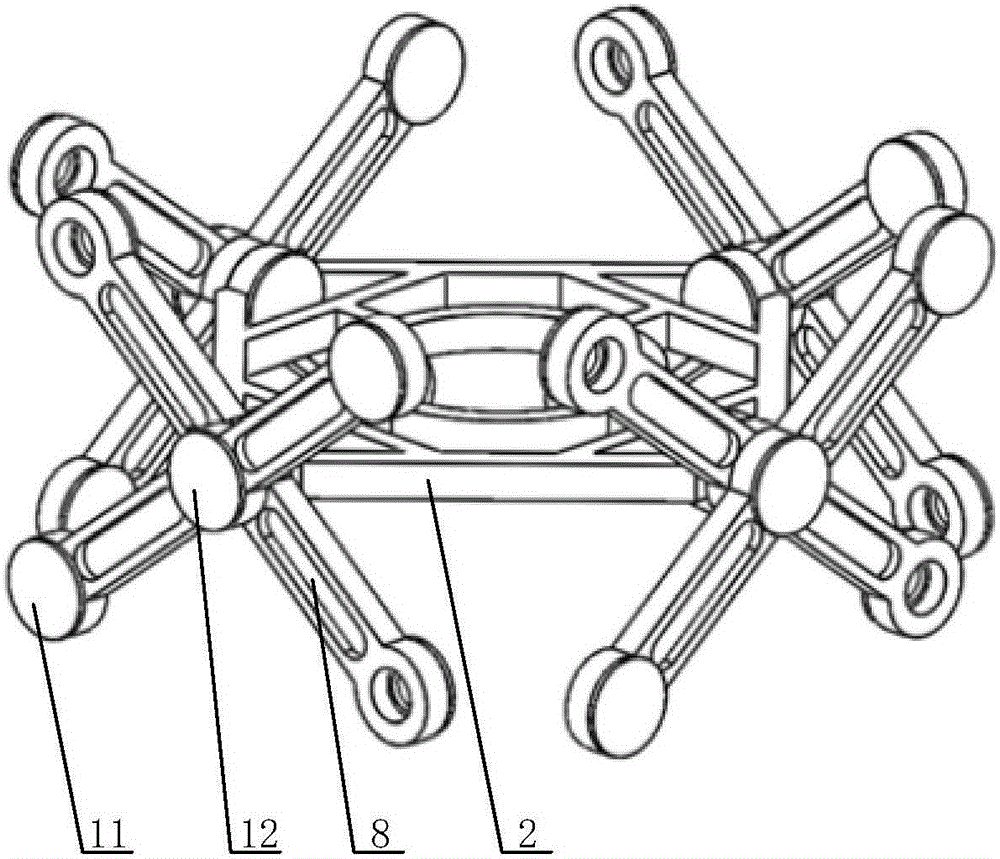

InactiveCN106363661AIncrease lateral stiffnessReduce processing requirementsArmsStatically indeterminateStructural engineering

The invention discloses a high-precision ultra-large-stroke painting robot telescopic arm adopting a statically indeterminate structure. The high-precision ultra-large-stroke painting robot telescopic arm comprises a fixed base, an n-regular-polygonal connecting structure, a tail end workbench structure and a plurality of sets of shear fork serial mechanisms. The shear fork serial mechanisms comprise the n sets of shear fork serial mechanisms which are hinged to the fixed base and the tail end workbench structure. The vertexes of the n-regular-polygonal connecting structure are hinged to the shear fork serial mechanisms. Each set of shear fork serial mechanism comprises a long connecting rod, a short connecting rod, a top revolute pair, end revolute pairs and a middle revolute pair. Compared with the traditional telescopic arm design, the requirement for machining and assembling can be effectively lowered, the lateral rigidity of the telescopic arm is improved, better lateral positioning precision can be achieved during movement, the effect that the position of the center of the tail end workbench structure is unchanged on the plane in the telescoping process of the telescopic arm can be guaranteed, and the motion stability and the vertical positioning precision are guaranteed.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com