Laser and MIG electric arc compound welding method for high-strength steel butt joints

A butt joint and composite welding technology, which is applied to laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of high assembly conditions, low efficiency of MIG welding, insufficient welding thickness, etc., and reduce assembly conditions Requirements, good weld performance and low assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) 30CrMnSi material 2mm thick structural plate butt welding

[0031] The specific steps are:

[0032] The first step: the high-strength steel joint to be welded is processed into an I-shaped groove, and the joint form is a butt joint;

[0033] Step 2: Assemble the joint to be welded, and control the assembly gap of the joint to not exceed 0.1δ;

[0034] Step 3: Select a welding wire with a diameter of 1.6mm, and perform pre-welding treatments such as degreasing, pickling, drying, and sandblasting on the weldment and the welding wire. The welding wire can also be bright welding wire without cleaning;

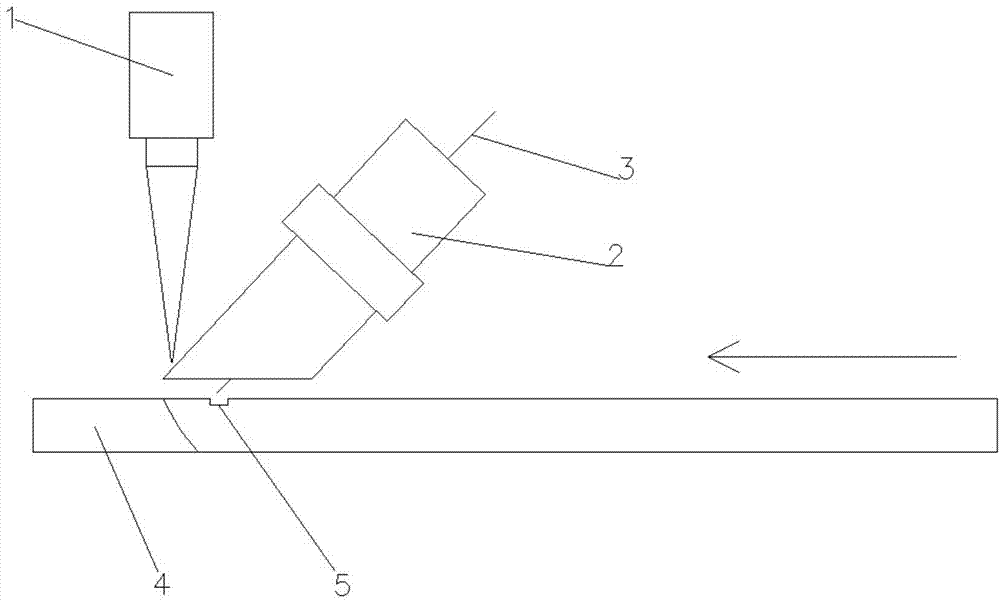

[0035] Step 4: Arrange the laser and MIG heat source: the laser beam is incident vertically 2 mm in front of the MIG, and the welding wire is sent to the upper surface of the workpiece through the MIG gun nozzle at an angle of 30° to the horizontal plane; ensure that the two heat sources form a common molten pool together, The welding wire is sent to the upper surface o...

Embodiment 2

[0040] 2) 30CrMnSi material 5mm thick structural plate butt welding

[0041] The specific steps are:

[0042] The first step: the high-strength steel joint to be welded is processed into an I-shaped groove, and the joint form is a butt joint;

[0043] Step 2: Assemble the joint to be welded, and control the assembly gap of the joint to not exceed 0.1δ;

[0044] Step 3: Select a welding wire with a diameter of 1.6mm, and perform pre-welding treatments such as degreasing, pickling, drying, and sandblasting on the weldment and the welding wire. The welding wire can also be bright welding wire without cleaning;

[0045] Step 4: Arrange the laser and MIG heat source: the laser beam is incident vertically 2 mm in front of the MIG, and the welding wire is sent to the upper surface of the workpiece through the MIG gun nozzle at an angle of 45° to the horizontal plane; ensure that the two heat sources form a common molten pool together, The welding wire is sent to the upper surface o...

Embodiment 3

[0050]3) 30CrMnSi material 7mm thick structural cylindrical butt welding

[0051] The specific steps are:

[0052] The first step: the high-strength steel joint to be welded is processed into an I-shaped groove, and the joint form is a butt joint;

[0053] Step 2: Assemble the joint to be welded, and control the assembly gap of the joint to not exceed 0.1δ;

[0054] Step 3: Select a welding wire with a diameter of 1.6mm, and perform pre-welding treatments such as degreasing, pickling, drying, and sandblasting on the weldment and the welding wire. The welding wire can also be bright welding wire without cleaning;

[0055] Step 4: Arrange the laser and MIG heat source: the laser beam is incident vertically from 3 mm in front of the MIG, and the welding wire is sent to the upper surface of the workpiece through the MIG gun nozzle at an angle of 60° to the horizontal plane; ensure that the two heat sources form a common molten pool together, The welding wire is sent to the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com