H-shaped column minor axis separation type double-T-shaped-piece connecting structure easy to assemble

A connection structure and separate technology, which is applied in the direction of building construction and construction, can solve the problems of no bolt tightening operation construction space, difficulty in meeting assembly requirements, and difficulty in realizing weak shaft connections, etc., achieving superior economy and convenience for construction sites Assembling and reducing the difficulty of design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

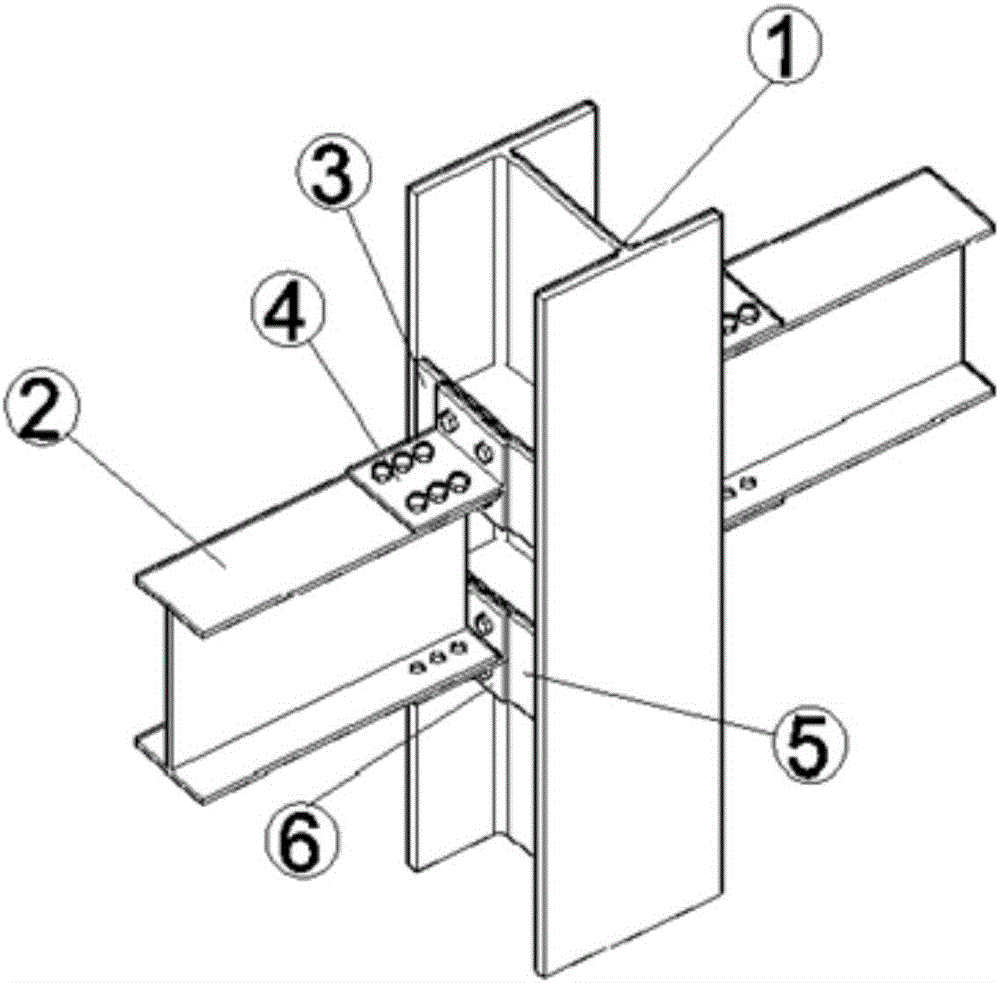

[0021] refer to figure 1 , the easy-to-assemble I-shaped column weak shaft separation double T-shaped connection structure of the present invention includes an I-shaped frame column 1, an I-shaped frame beam 2, a first T-shaped reinforcement 3, a second T-shaped reinforcement 5, the first T-shaped connector 4 and the second T-shaped connector 6, wherein one end of the first T-shaped reinforcement 3 is connected to the web and two flanges of the I-shaped frame column 1, and the first T The other end of the T-shaped reinforcement 3 is connected to one end of the first T-shaped connector 4, the other end of the first T-shaped connector 4 is connected to the upper flange of the I-shaped frame beam 2, and the second T-shaped reinforcement One end of 5 is connected to the web and two flanges of the I-shaped frame column 1, the other end of the second T-shaped reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com