Vehicle steering blade pump stator and preparation method thereof

A pump stator and vane technology, which is applied in the field of automobile steering vane pump stator and its preparation, can solve the problems of slow production efficiency, high cost, and low material utilization rate, so as to improve material utilization rate, increase production efficiency, and ensure mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

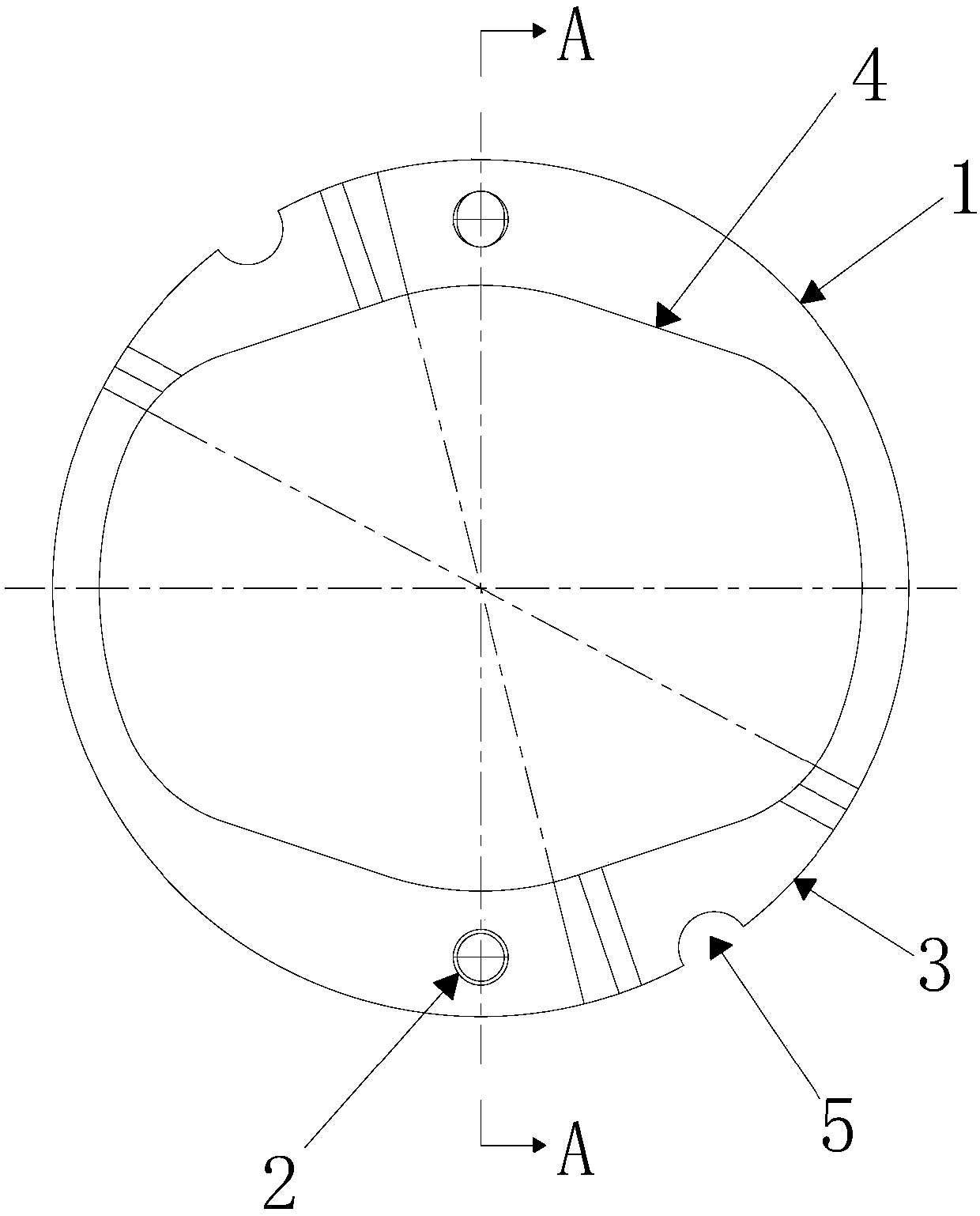

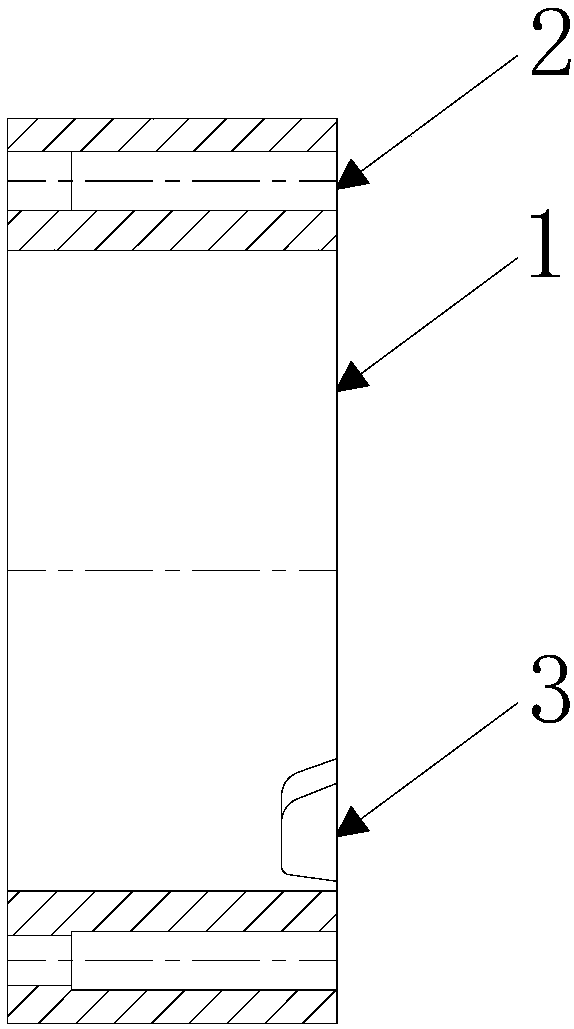

[0026] Such as figure 1 with figure 2 As shown, an automobile steering vane pump stator includes a circular stator base 1 with an inner hole, and two mounting holes 2 and two grooves 3 arranged on the axial upper end surface of the stator base 1. The stator The side of the inner hole of the matrix 1 is an arc-shaped convex surface 4; the surface hardness of the stator matrix 1 is ≥ HRC45, the parallelism of the end surface of the stator matrix 1 is equal to 0.005mm, and the perpendicularity between the inner cylinder surface and the end surface of the stator matrix 1 is equal to 0.01mm. The roughness of the inner hole of the base body 1 is Ra0.1-Ra0.4; two positioning pin holes 5 are arranged on both sides of the stator base body 1, and the two positioning pin holes 5 are arranged symmetrically.

[0027] In this embodiment, the mounting holes 2 are used to install and fix the stator base 1; cooperating with the positioning pin holes 5 can further limit the positioning of the...

Embodiment 2

[0029] A method for preparing a stator of an automobile steering vane pump, comprising the following steps:

[0030] (1) Mixing: design raw material composition and mixing, and mix the following raw materials uniformly by mass percentage: C: 0.8%, Cu: 1.0%, Ni: 1.0%, Mo: 1.5%, and the remainder is Fe.

[0031] (2) Forming: Choose a 160-ton CNC forming press, heat the powder at 100°C, and the female mold at 100°C. The density of the green body is evenly divided, and the overall density is 7.2g / cm 3 , After the green body is demolded, the burrs are automatically brushed.

[0032] (3) Sintering: Put the formed green body into a high-temperature mesh belt furnace for sintering treatment, the sintering temperature is 1120°C, the mesh belt speed is 120mm / min, the sintering atmosphere is an ammonia decomposition protective atmosphere, and the sintering hardness of the product is ≥HRB85.

[0033] (4) Finishing: According to the requirements of stator position and profile, molding and...

Embodiment 3

[0040] A method for preparing a stator of an automobile steering vane pump, comprising the following steps:

[0041] (1) Mixing: Design raw material composition and mixing, and mix the following raw materials uniformly according to mass percentage: C: 0.3%, Cu: 1.5%, Ni: 1.2%, Mo: 1.2%, and the rest is Fe.

[0042] (2) Forming: Choose a 160-ton CNC forming press, heat the powder at 100°C, and the female mold at 100°C. The density of the green body is evenly divided, and the overall density is 7.3g / cm 3 , After the green body is demolded, the burrs are automatically brushed.

[0043] (3) Sintering: put the formed green body into a high-temperature mesh belt furnace for sintering treatment, the sintering temperature is 1130°C, the mesh belt speed is 130mm / min, the sintering atmosphere is an ammonia decomposition protective atmosphere, and the sintering hardness of the product is ≥HRB88.

[0044] (4) Finishing: According to the requirements of stator position and profile, moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Parallelism | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com