Automobile hydraulic electric power steering reliability test bench and program control test method

A technology of hydraulic power steering and test bench, which is applied in the direction of vehicle steering/bumping performance, etc. It can solve the problems that there is no road surface uneven vibration simulation system, and the performance test of the input terminal cannot be passed, so as to achieve compact space occupation, small occupation space and low requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

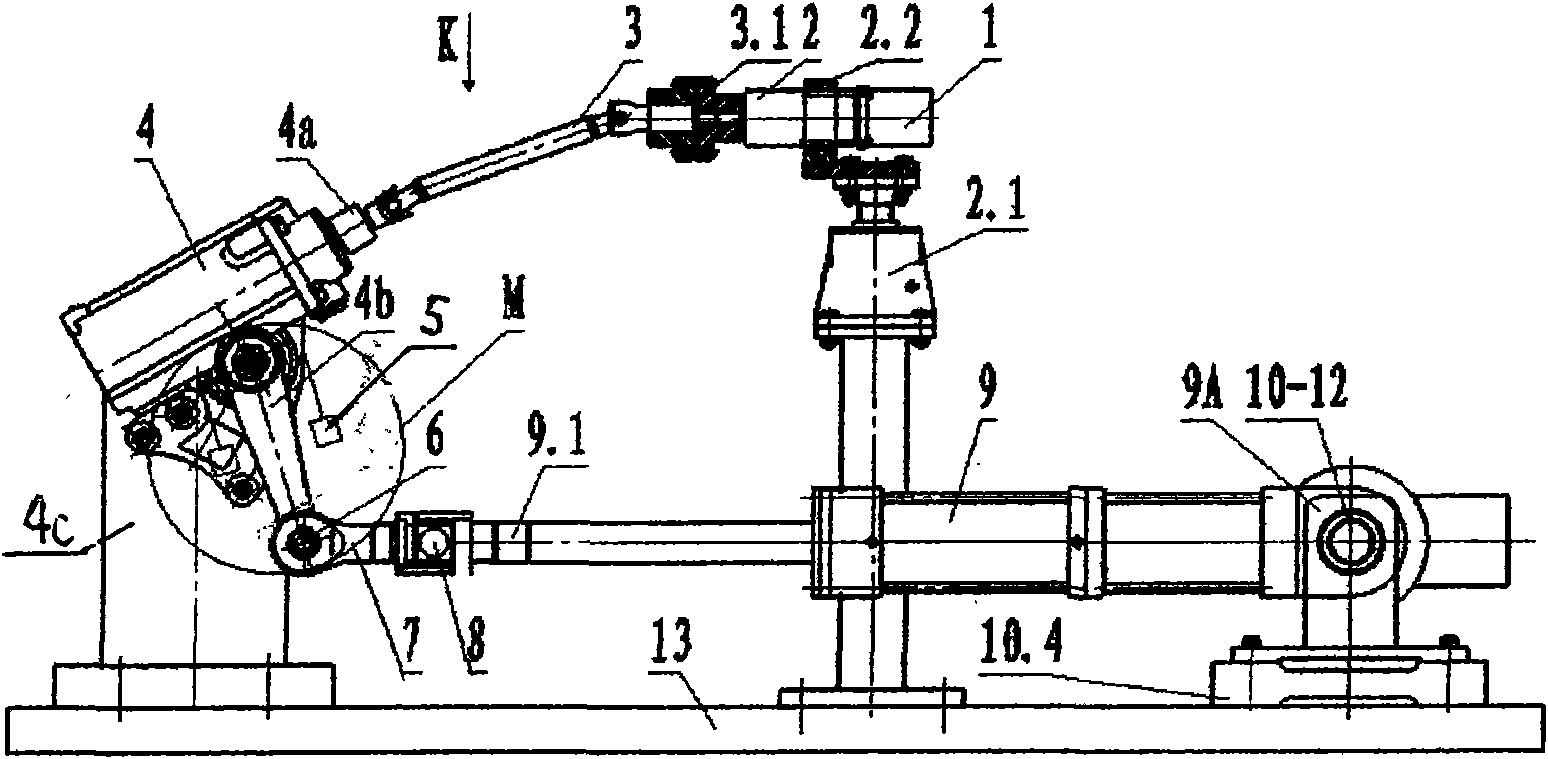

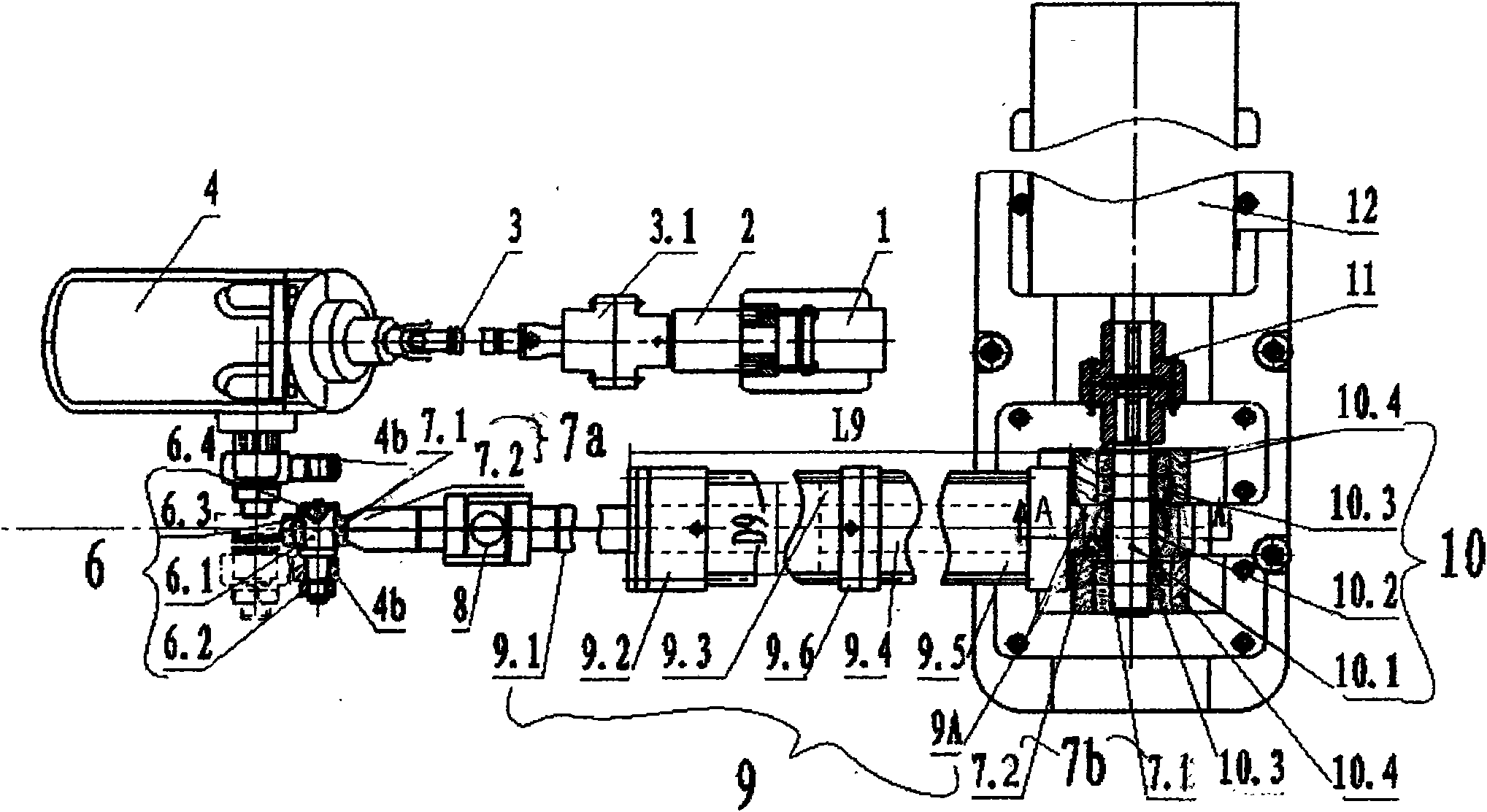

[0031] The reliability test bench of the automobile hydraulic power steering gear of this embodiment is formed as follows:

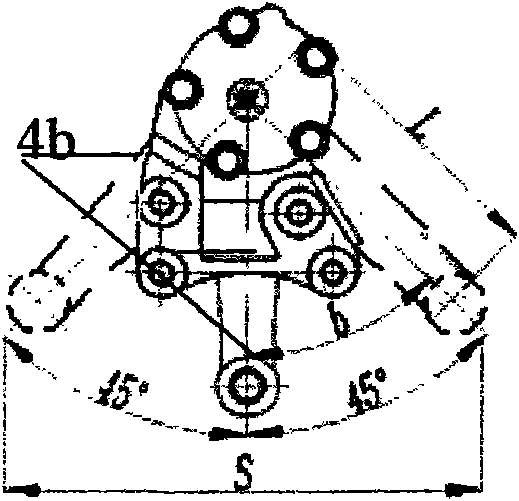

[0032] see figure 1 , figure 2 , The input system is provided with a servo motor 1, a reducer 2 and a universal joint 3 which are connected in sequential transmission; the output end of the universal joint is connected with the input end 4a of the steering gear 4. The steering gear 4 is kept inclined to the horizontal direction, which is similar to the original car installation method, which can meet the variety of test product models. The outer circumference of the reducer is covered with a mounting plate 2.2 fixed to the upper end of the worm gear screw elevator 2.1, and the lower end of the elevator is fixed to the foundation table 13 of the test bench. Therefore, the servo motor and the reducer are installed on the lifting table, and the height can be adjusted arbitrarily. The reducer and the universal joint are connected with a universal-reduction cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com