Defect detecting system for steel wire rope

A defect detection and steel wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problems of reducing the sensitivity and accuracy of steel wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

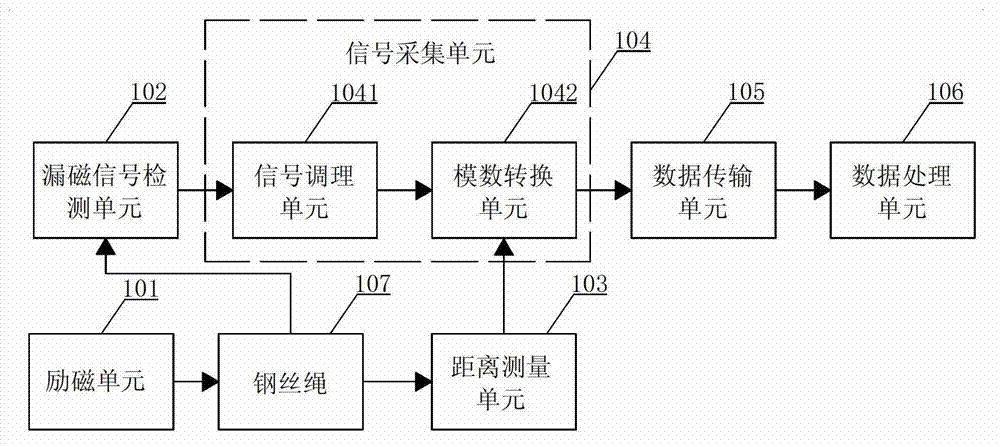

[0035] Please refer to figure 1 as shown, figure 1 The structural diagram of the steel wire rope defect detection system provided by the embodiment of the present invention.

[0036] The wire rope defect detection system in this embodiment includes: an excitation unit 101 , a magnetic flux leakage signal detection unit 102 , a distance measurement unit 103 , a signal acquisition unit 104 , a data transmission unit 105 and a data processing unit 106 . The signal acquisition unit 104 includes a signal conditioning unit 1041 and an analog-to-digital conversion unit 1042 .

[0037] The excitation unit 101 is used to magnetize the detected steel wire rope 107 along its axial direction. Before performing defect detection on the steel wire rope 107 , the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com