Magnetic valve with compact structure, good tightness and high reliability

A compact and airtight technology, applied in the field of solenoid valves, can solve the problems of solenoid valve usage occasions and service life limitations, solenoid valve closing performance cannot be guaranteed, product quality is difficult to be completely guaranteed, etc., to reduce production quality control costs , Good closing and sealing performance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

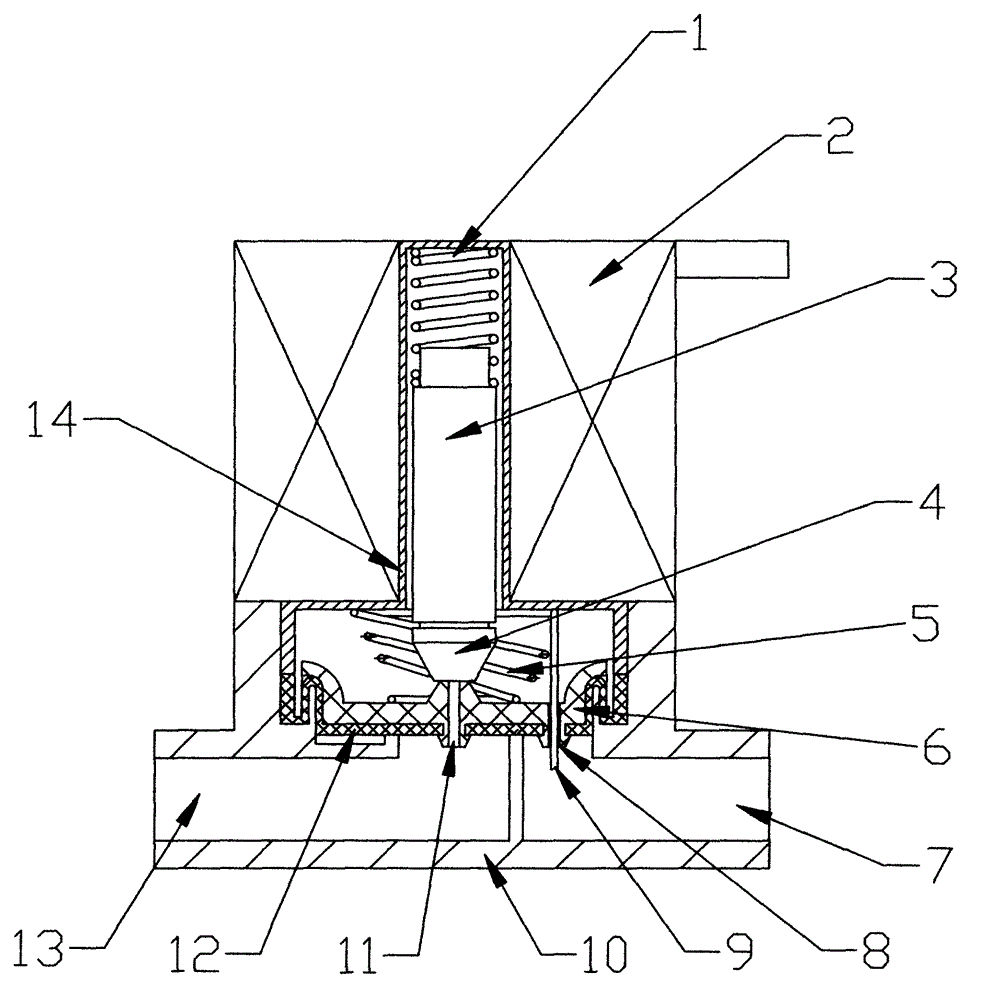

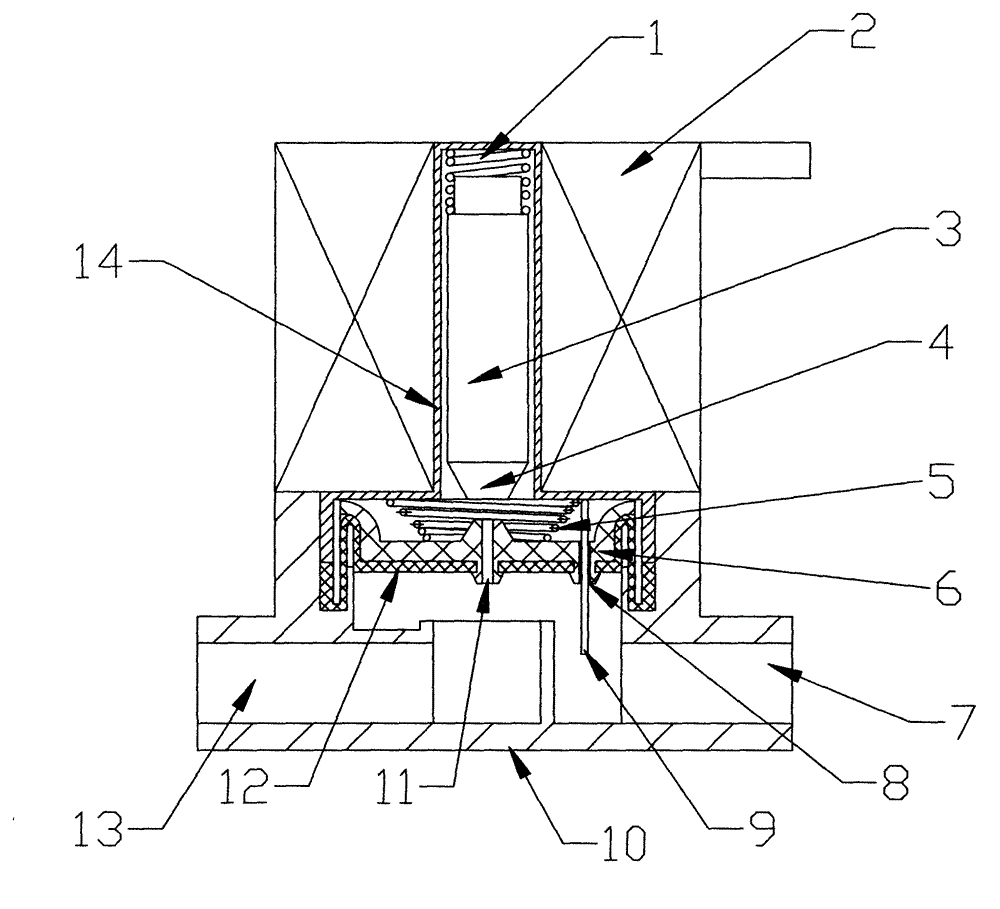

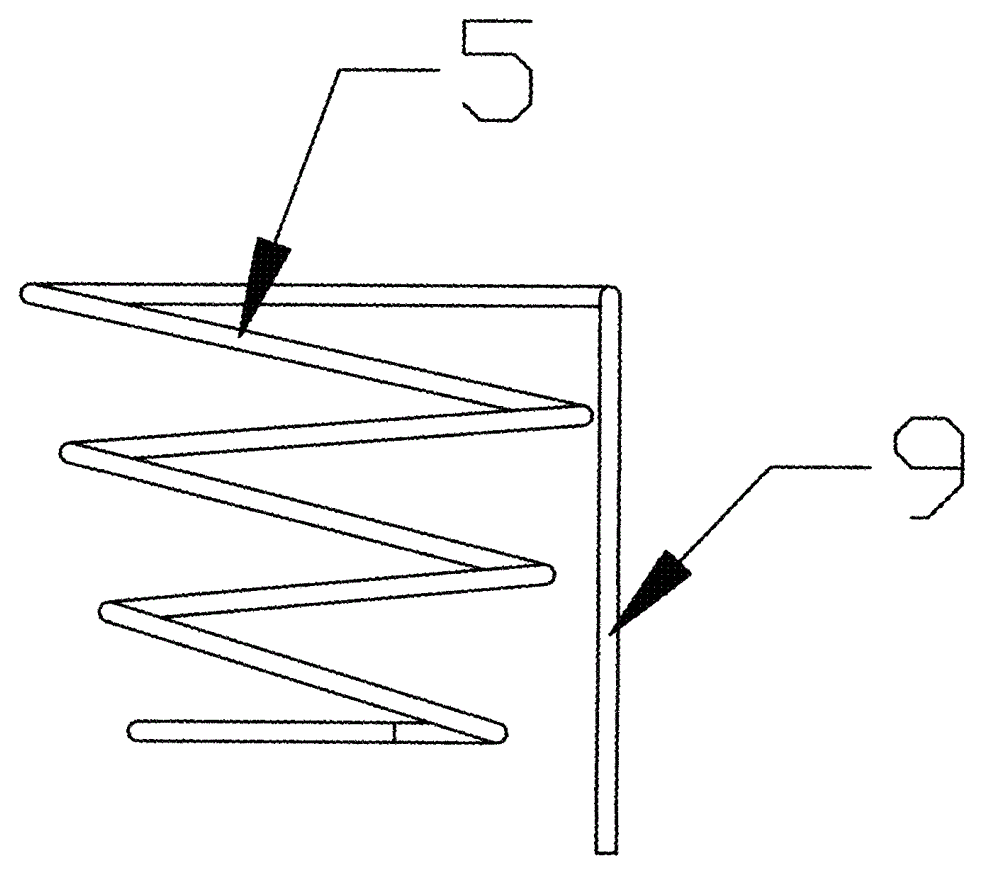

[0014] As shown in the figure, the present invention includes a body, and the body includes a valve seat 10, a coil 2 disposed on the valve seat 10, a valve core sleeve 14 disposed in the coil 2 and a valve core disposed in the valve core sleeve 14 3. The right side of the lower part of the valve seat 10 is the valve water inlet 7, and the left side of the lower part of the valve seat 10 is the valve water outlet 13. There are a plastic diaphragm 6 and a rubber diaphragm 12, the plastic diaphragm 6 is arranged on the top of the rubber diaphragm 12, and the plastic diaphragm 6 and the rubber diaphragm 12 are fixed together, and the lower part of the valve core 3 is provided with The rubber sealing head 4 is provided with a spool return spring 1 on the top of the spool 3, the right part of the plastic diaphragm 6 is provided with a pressure control chamber wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com