Patents

Literature

81results about How to "Guaranteed sealing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

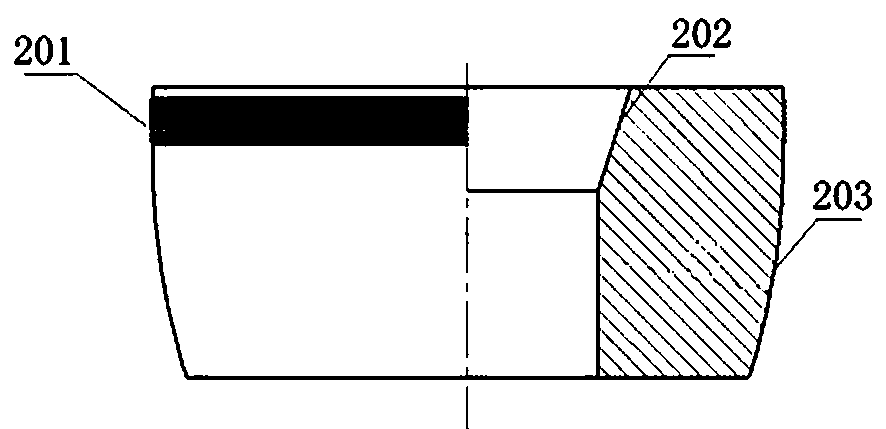

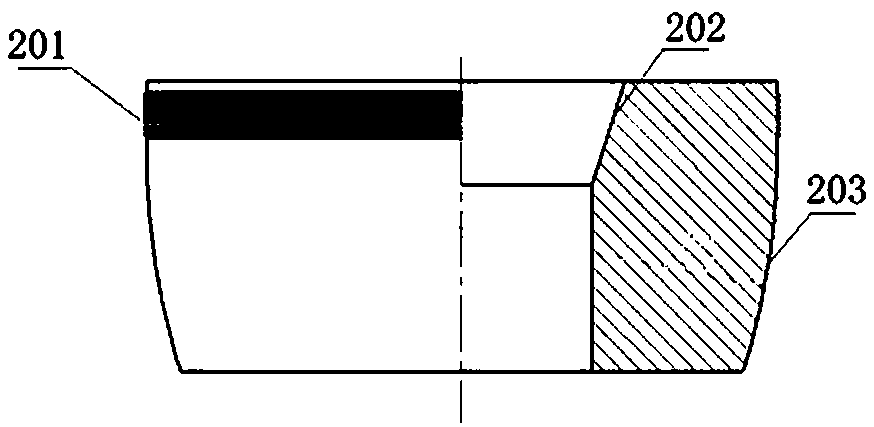

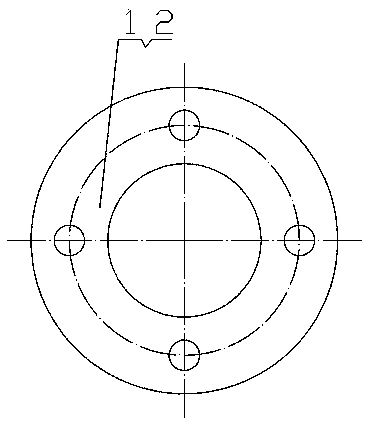

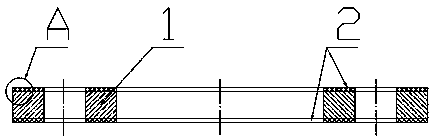

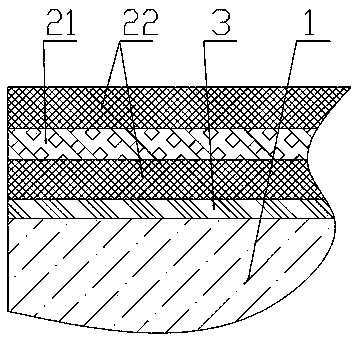

Seal ring

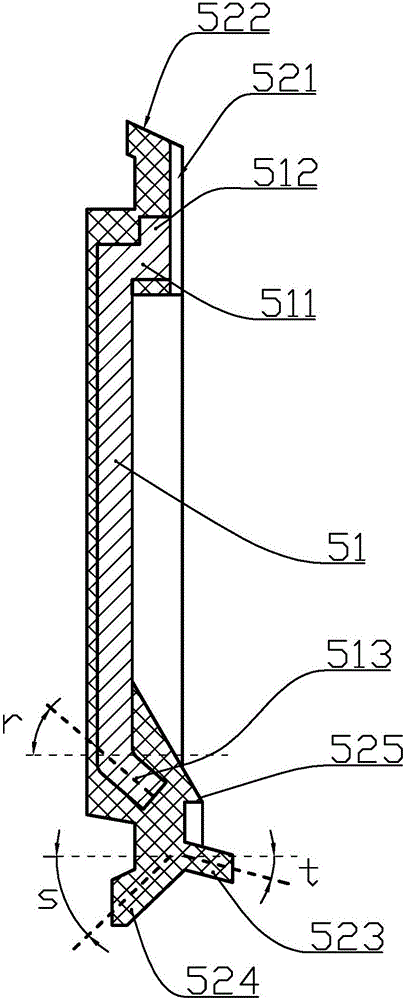

ActiveCN102494133AImprove reliabilityGuaranteed sealing functionEngine sealsFlanged jointsFlangeGas pipeline

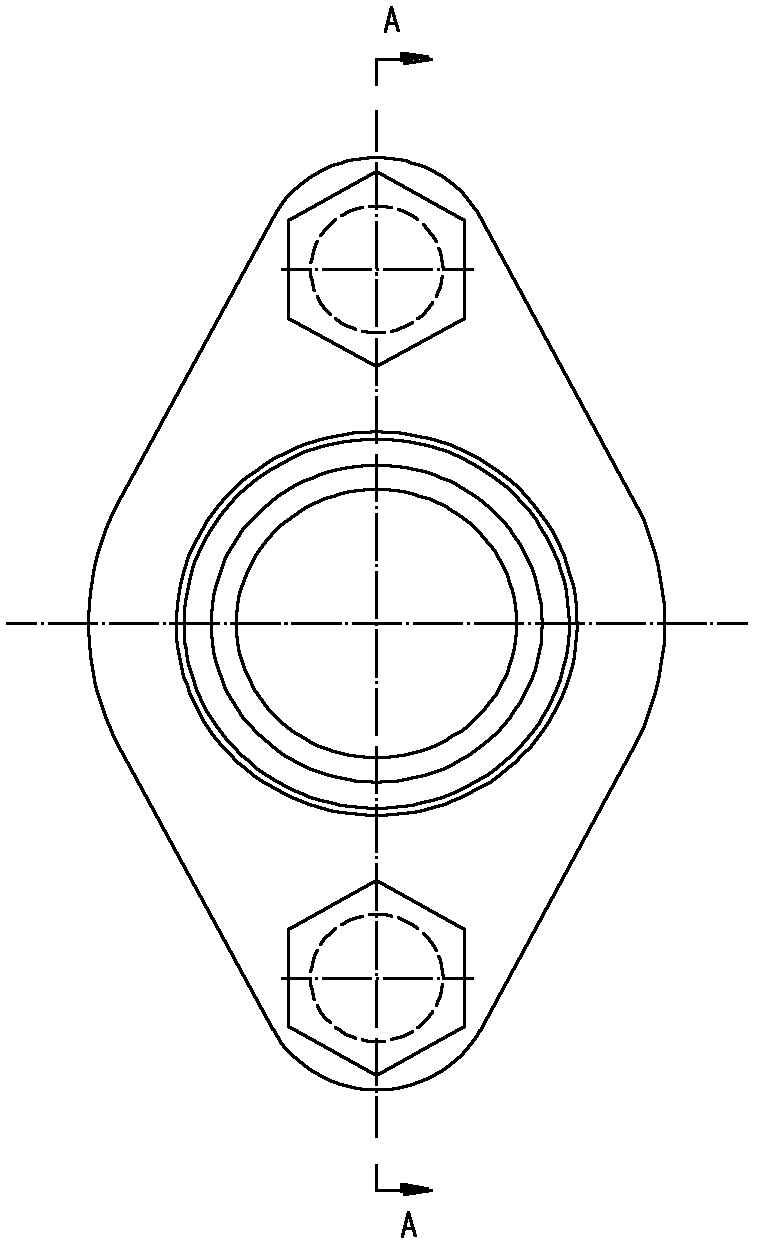

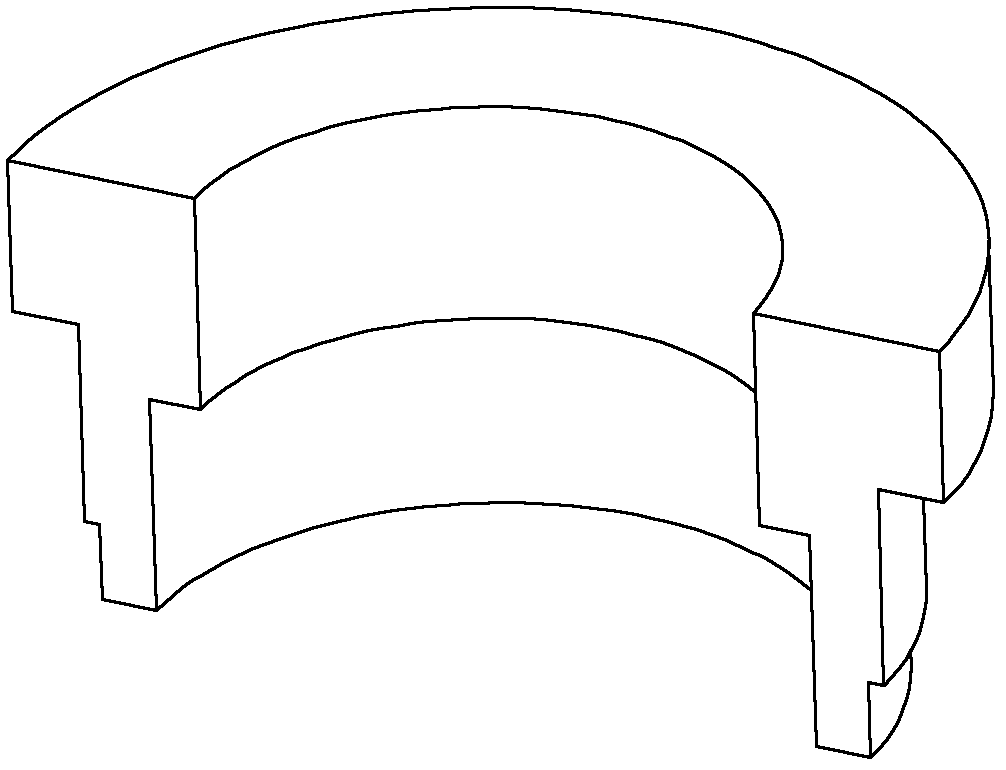

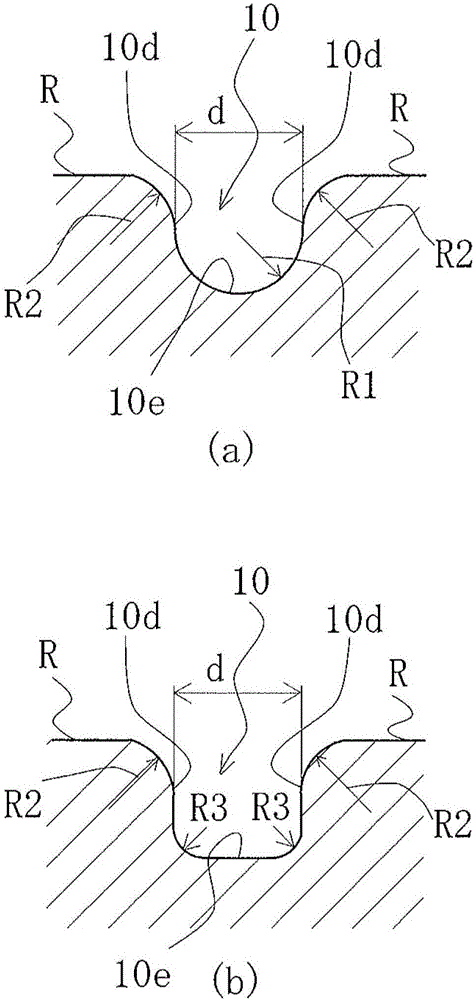

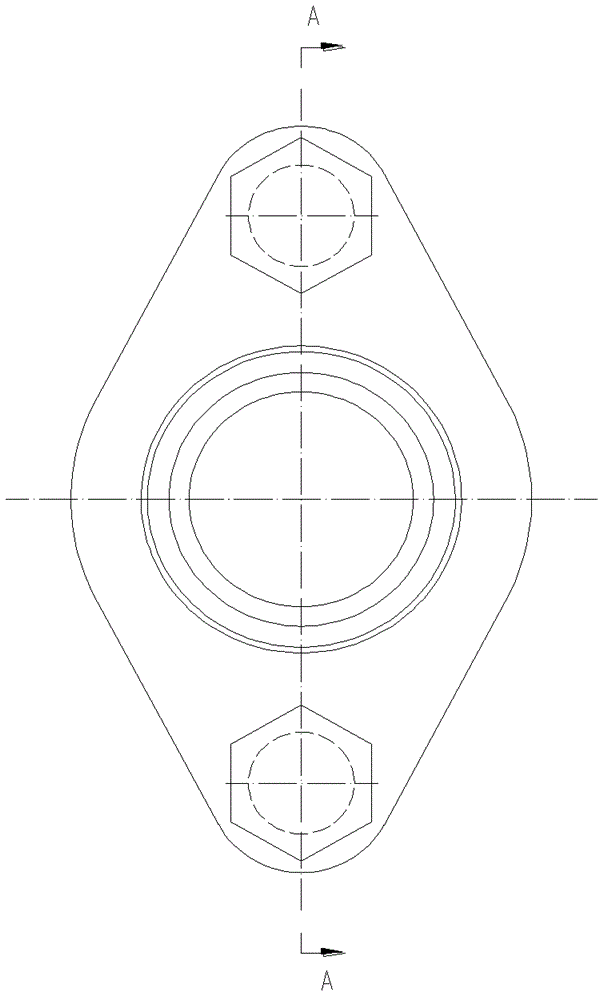

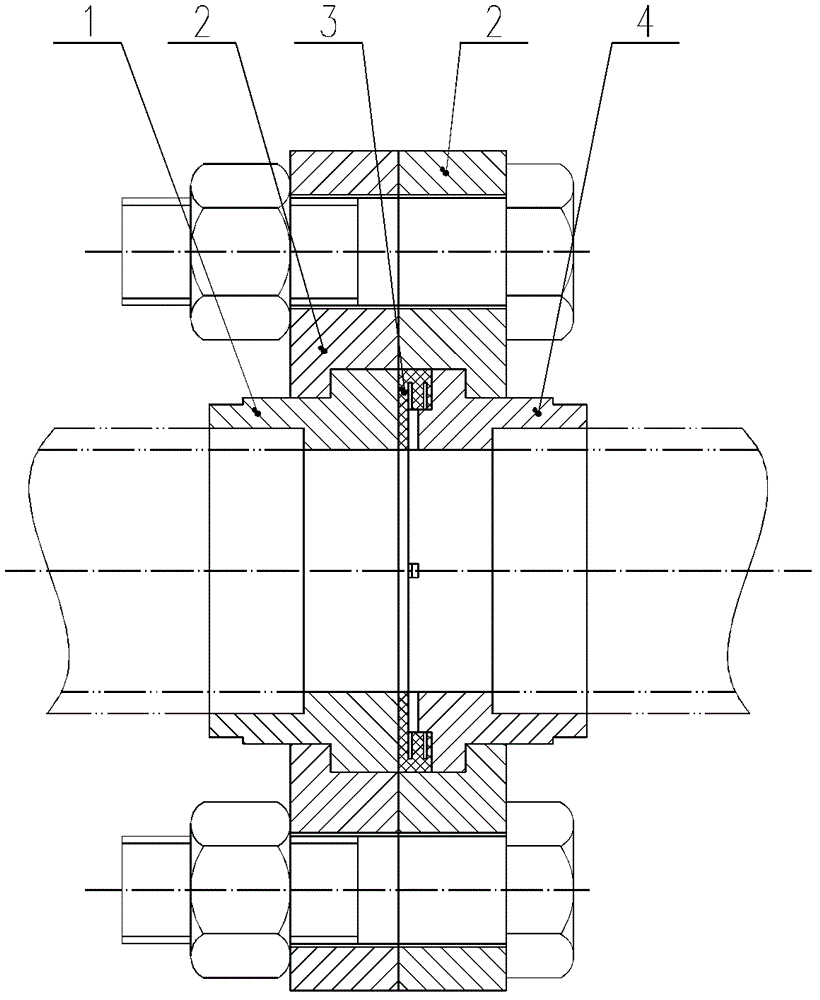

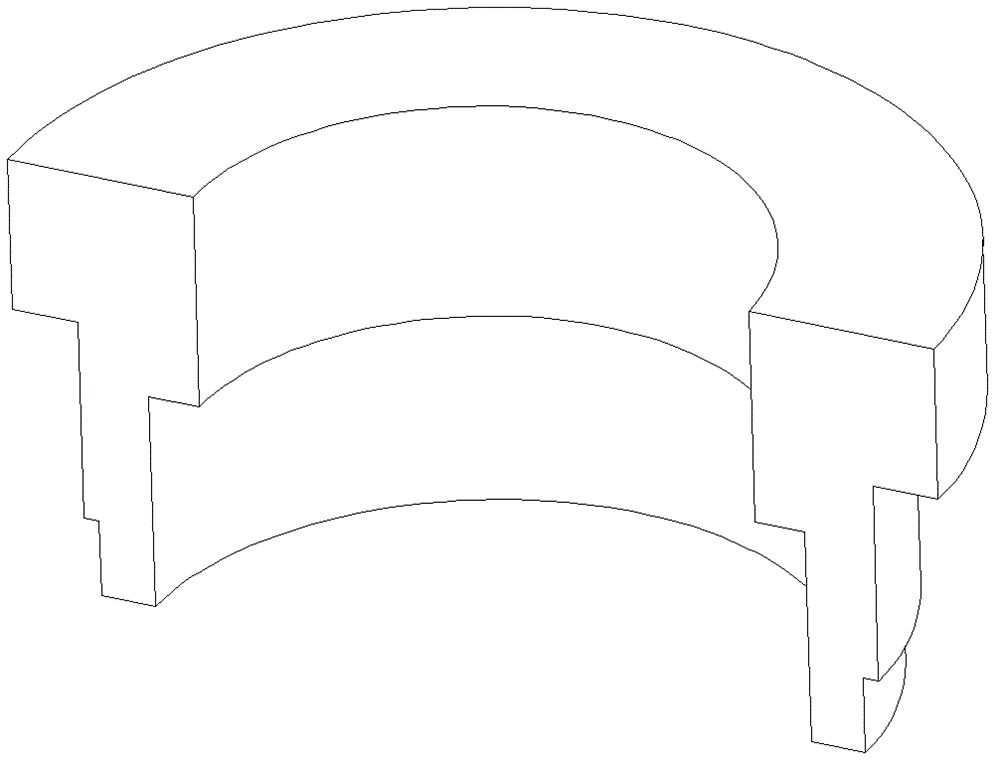

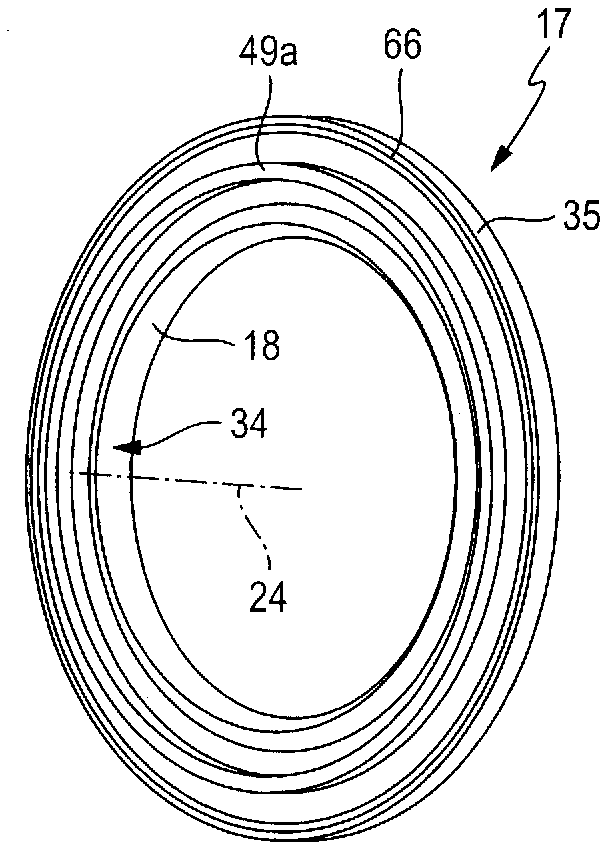

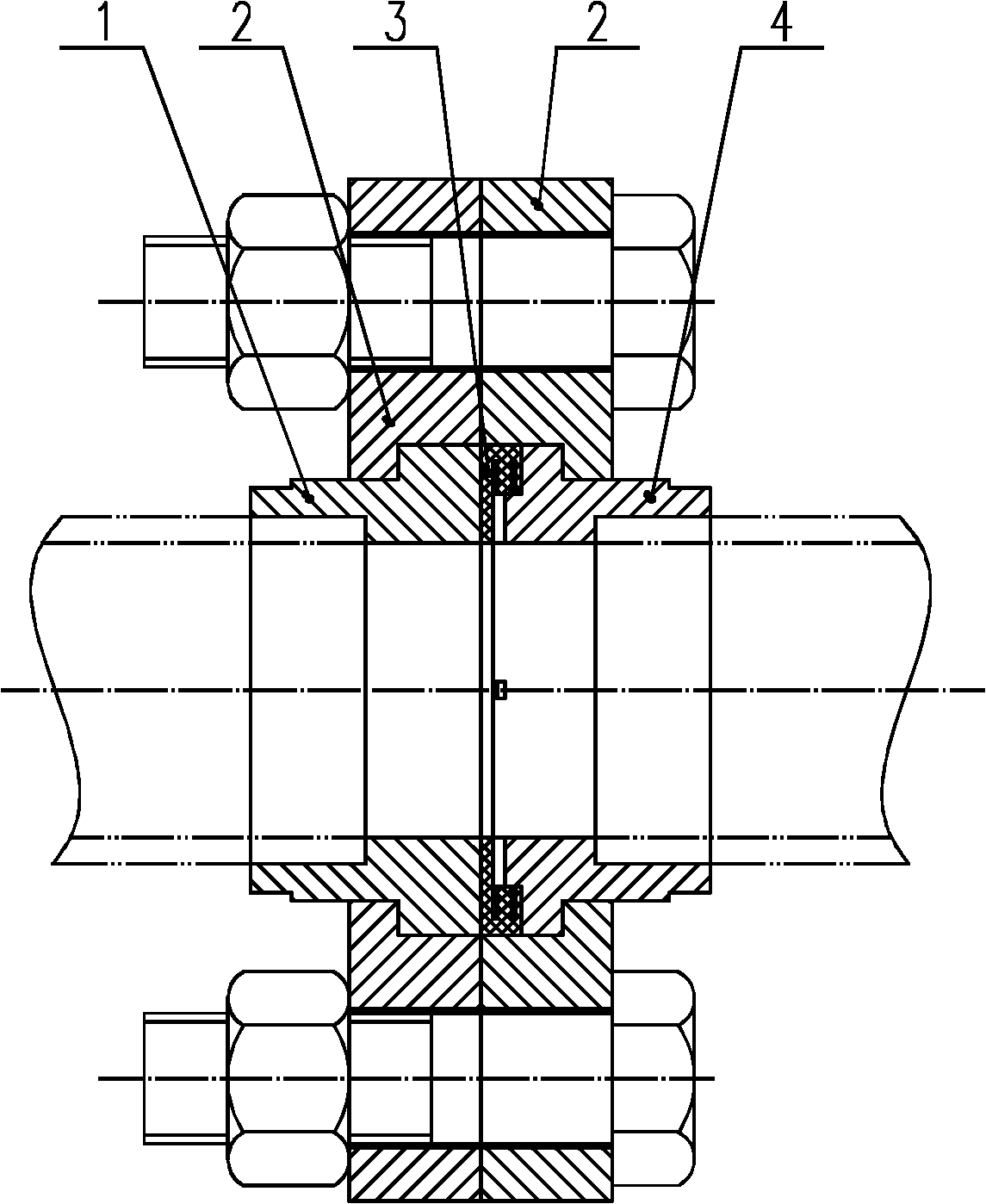

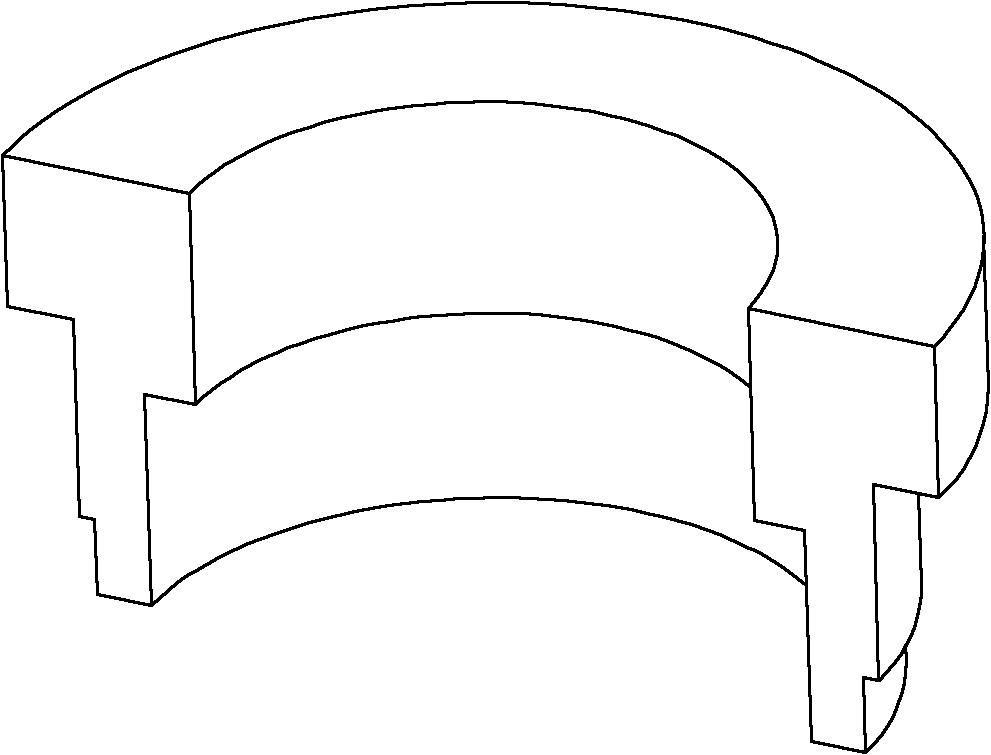

The invention discloses a seal ring, which comprises a ring body. A gap extending along the circumference direction is arranged on the inner side of the ring body, two circumferential sides of the gap form a large outer ring face and a small outer ring face respectively, and the radial width of the large outer ring face is larger than that of the small outer ring face. The seal ring has pressure sealing performance and active sealing performance. When abnormal situations occur in sealing connection and designed sealing conditions are not met to enable normal pressure sealing to be invalid, the seal ring can compensate, generate secondary sealing and enable a sealing structure to have large 'redundancy', thereby improving reliability. Even if other structural parts cannot exert design functions, a sealing function of an originally-designed rectangular ring body can be kept. The rectangular seal ring replaces an existing flange completely, and is reasonable in structure, convenient to use and low in cost, can be used for a novel seal flange and the existing flange, and can be used for sealing connection of a pressure gas pipeline except a flange connector.

Owner:CRRC SHANDONG CO LTD

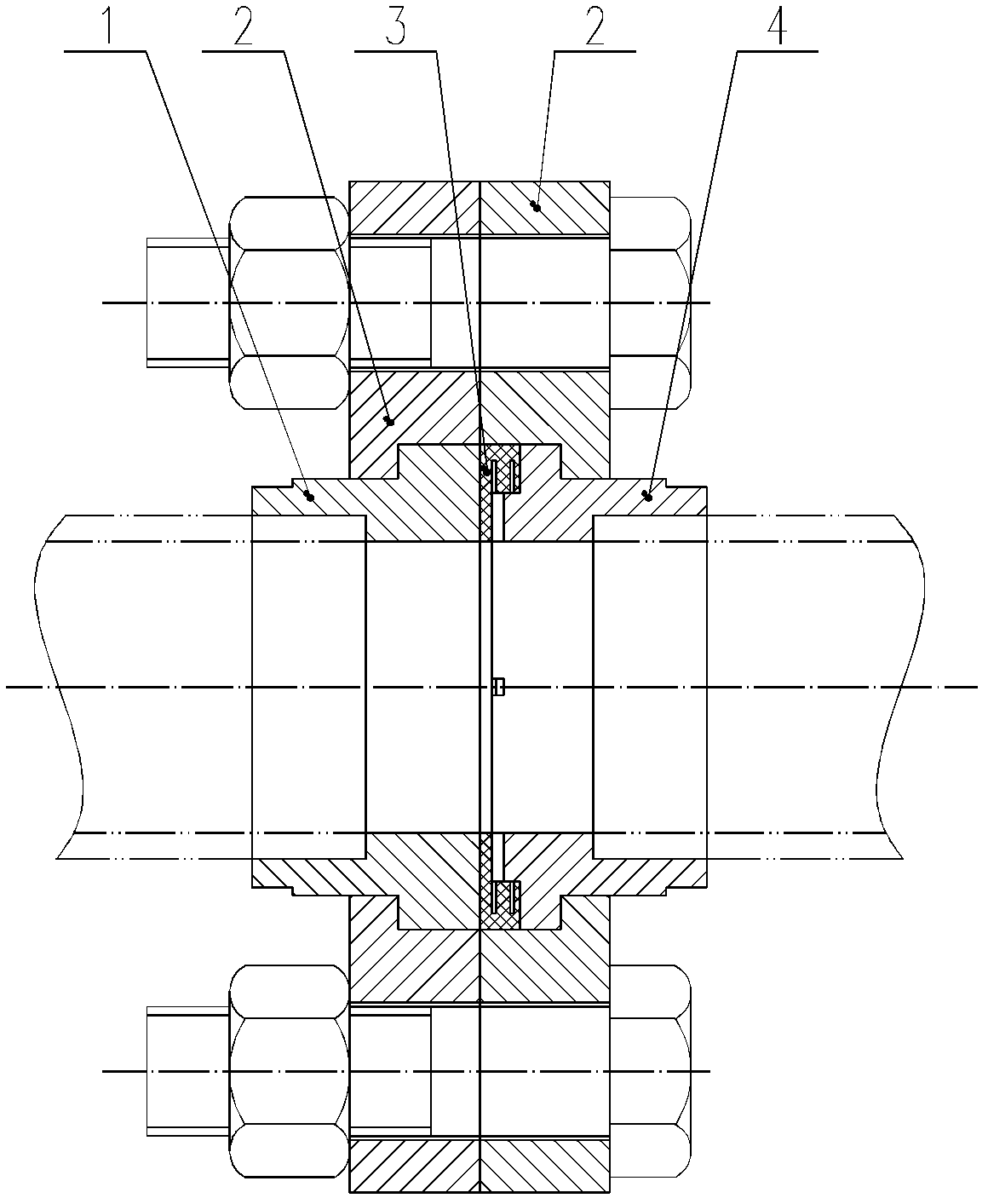

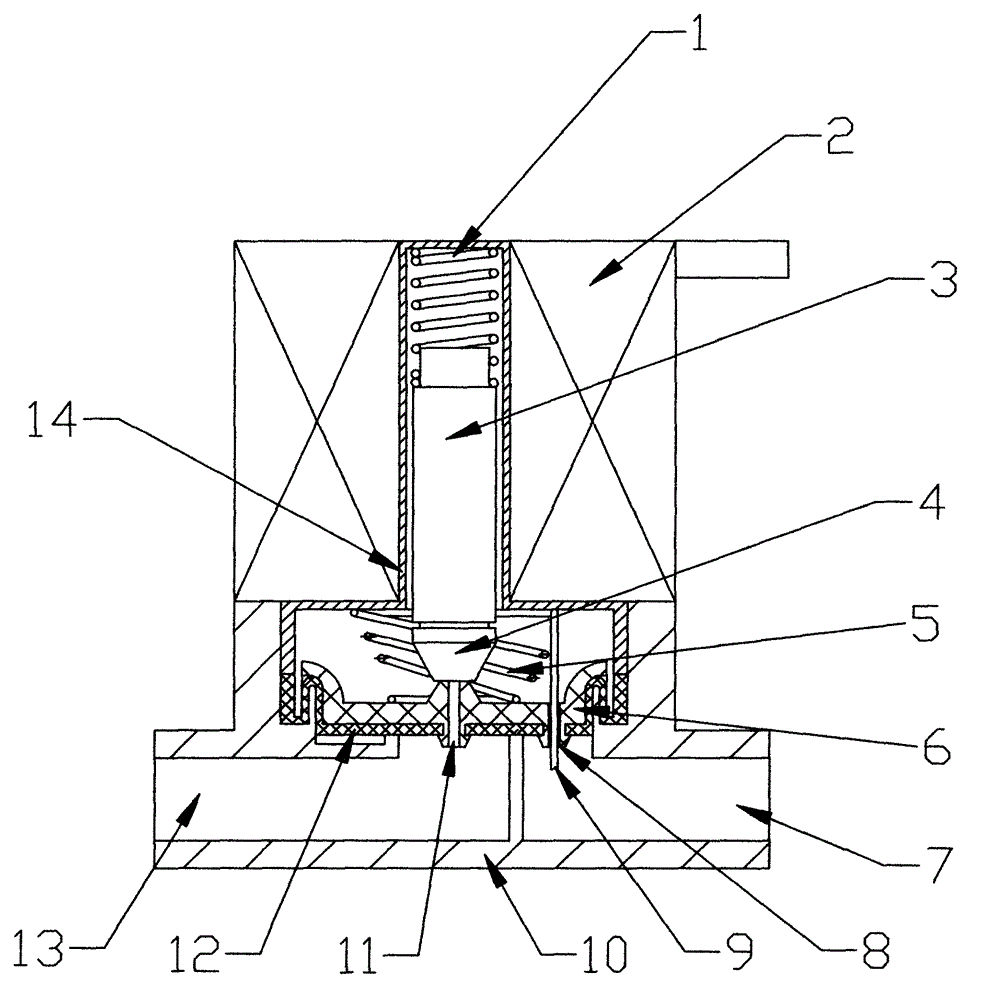

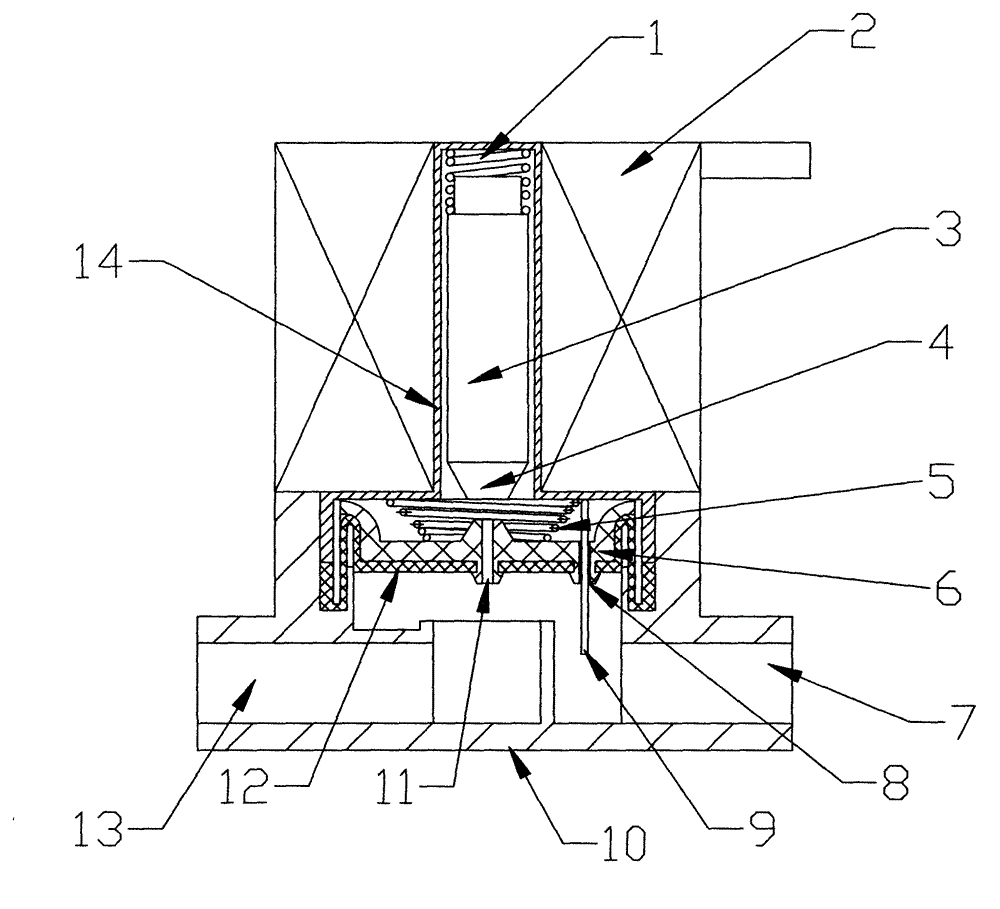

Magnetic valve with compact structure, good tightness and high reliability

InactiveCN102943896ACompact structureImprove sealingDiaphragm valvesOperating means/releasing devices for valvesMagnetic valveEngineering

The invention discloses a magnetic valve with a compact structure, good tightness and a high reliability. The magnetic valve comprises a body, the body comprises a valve seat, a coil arranged on the valve seat and a valve element sleeve arranged in the coil and a valve element arranged in the valve element sleeve, a valve water inlet is arranged on the right side on the lower portion of the valve seat, a valve water outlet is arranged on the left side on the lower portion of the valve seat, a plastic diaphragm and a rubber diaphragm are arranged between the coil and the valve seat and on the lower portion of the valve element sleeve, the plastic diaphragm is arranged on the upper portion of the rubber diaphragm, the plastic diaphragm and the rubber diaphragm are fixed together, a rubber seal head is arranged on the lower portion of the valve element, a valve element reset spring is arranged on the upper portion of the valve element, a pressure control cavity water inlet is arranged on the right portion of the plastic diaphragm, a pressure control cavity water outlet is arranged in the middle of the plastic diaphragm, the pressure control cavity water inlet is opposite to the pressure control cavity water outlet, and a tower-shaped with an unclogging pin is arranged between the plastic diaphragm and the valve element sleeve.

Owner:李志红

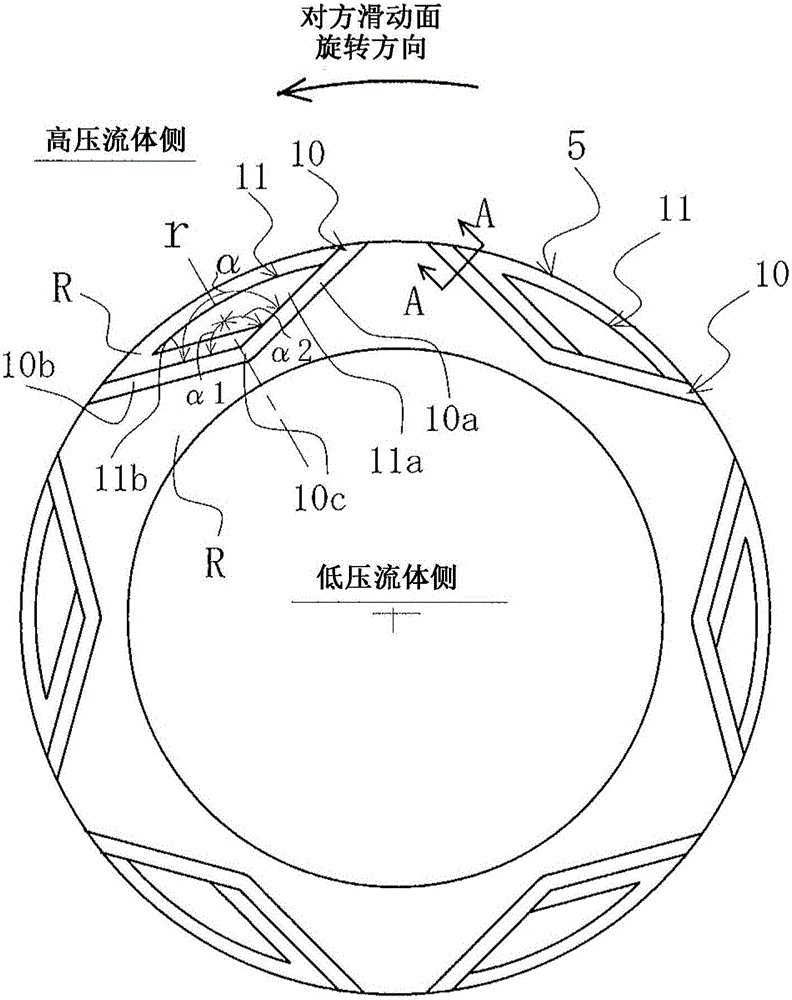

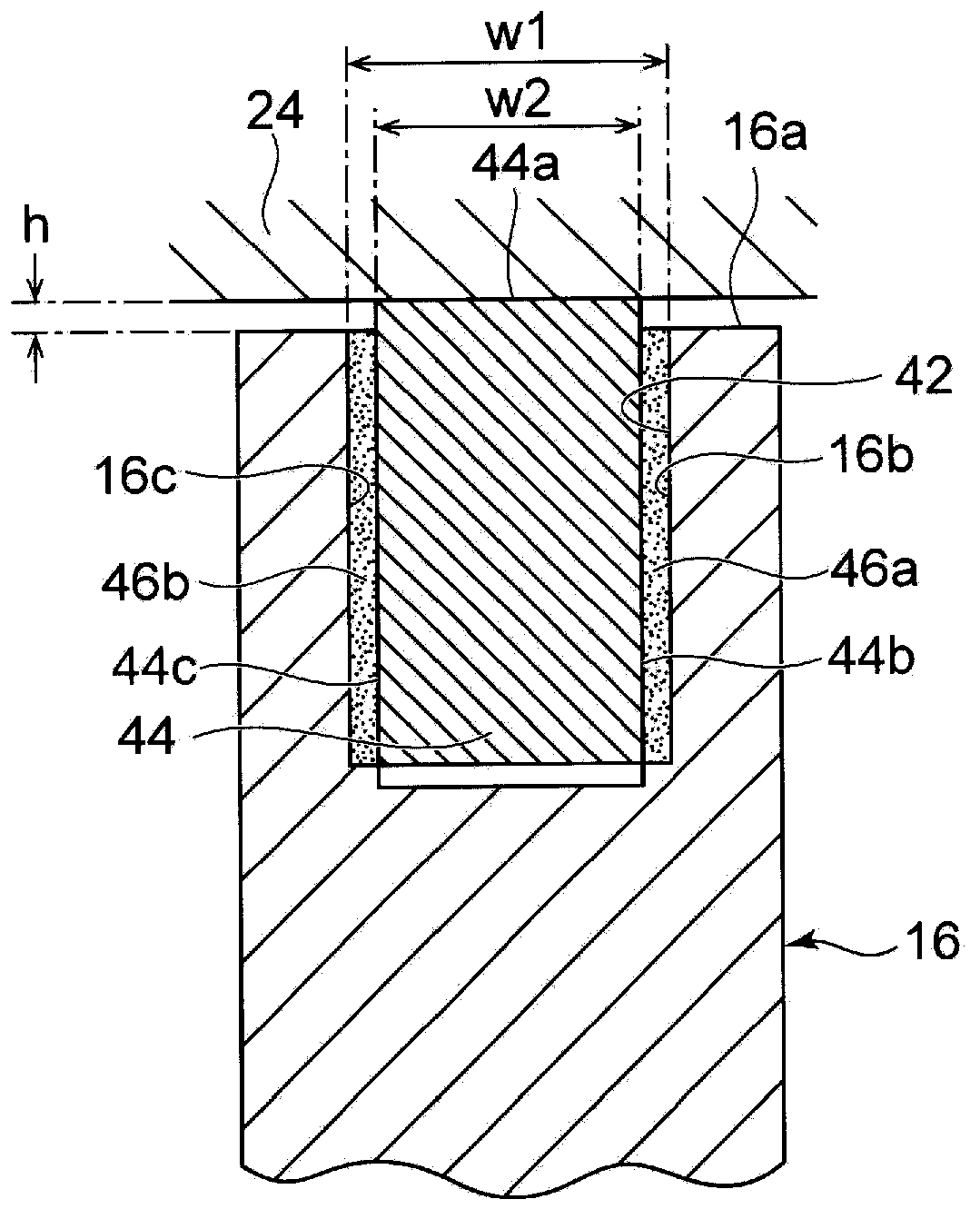

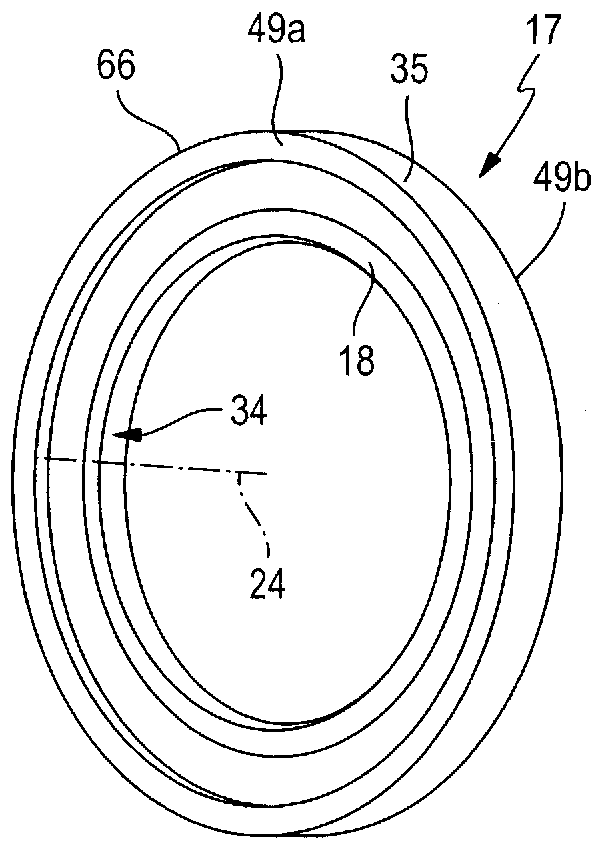

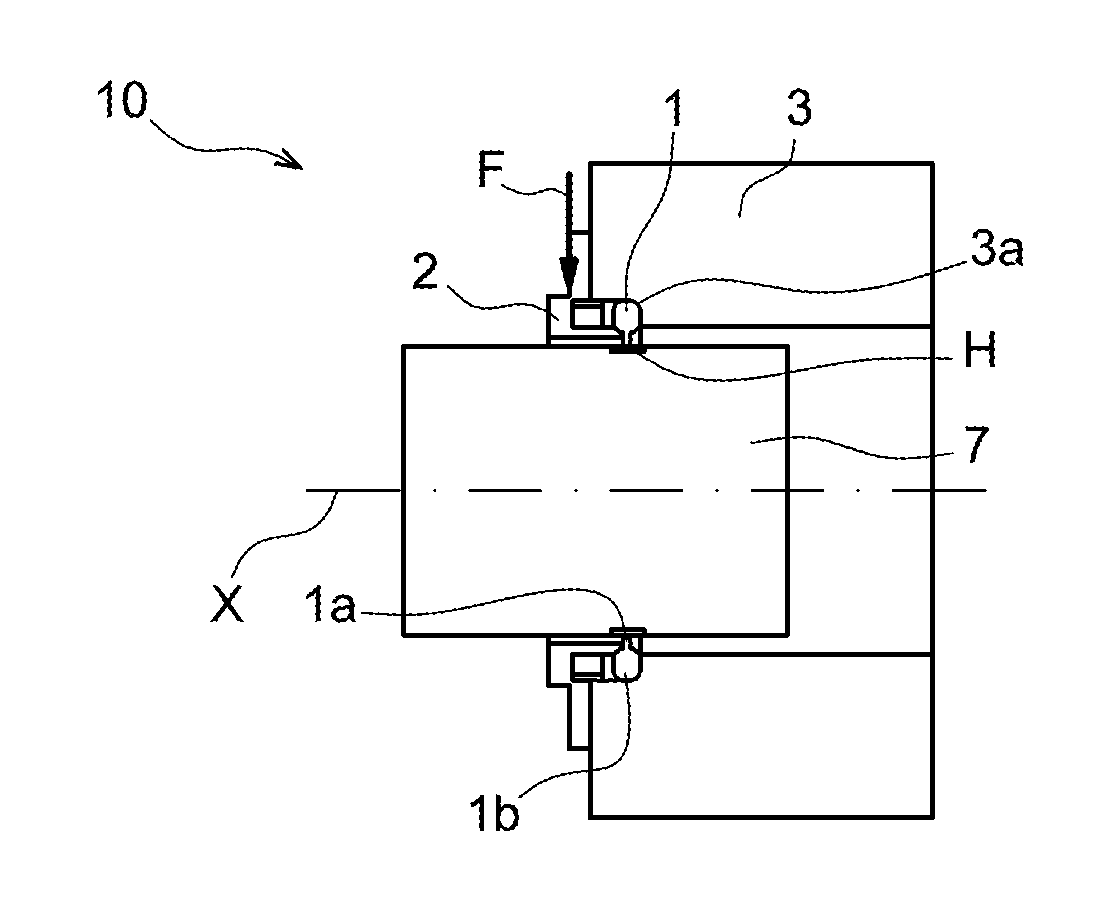

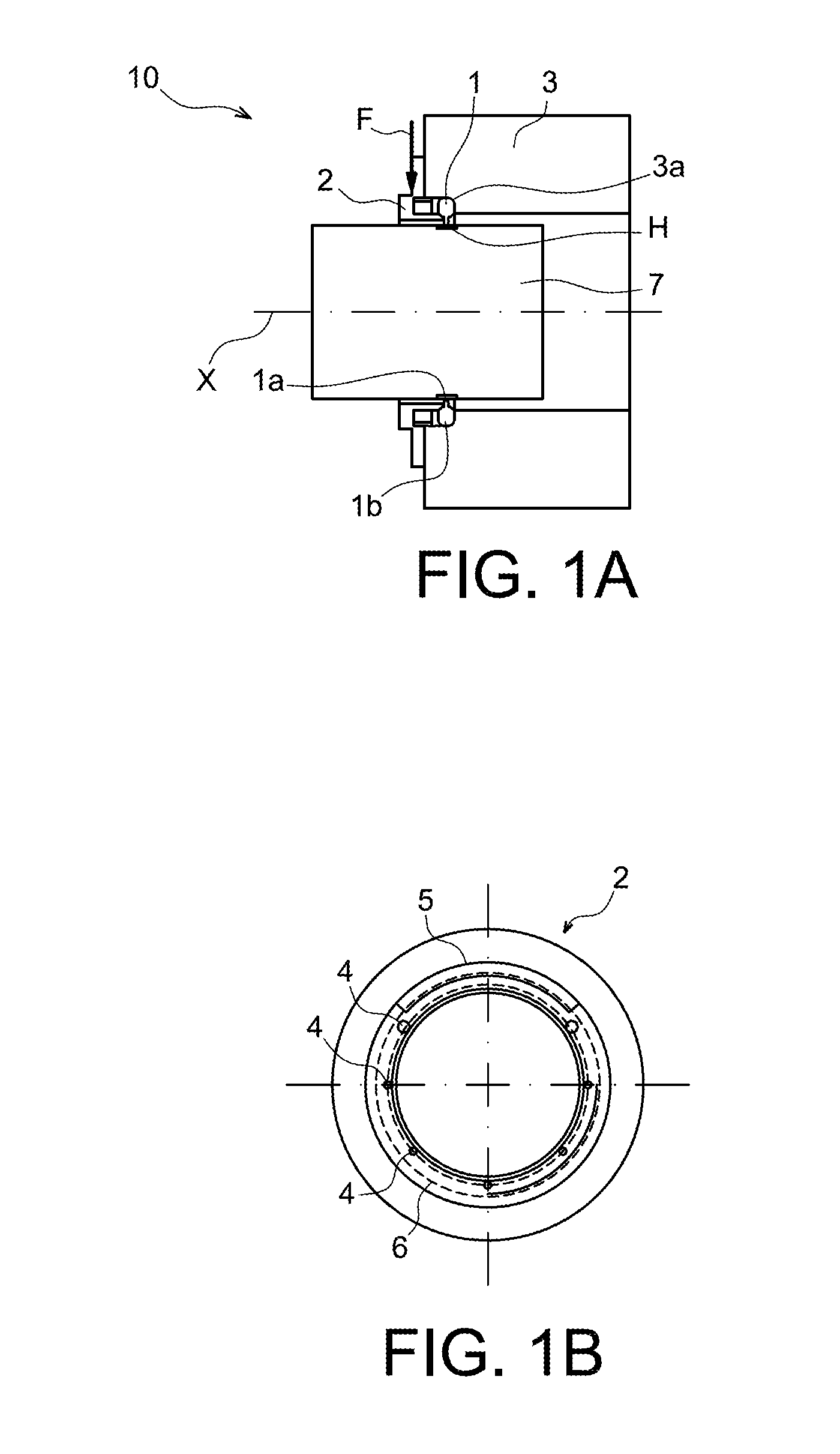

Sliding component

ActiveCN105683632AGood effectGuaranteed sealing functionEngine sealsPump componentsEngineeringHigh pressure

Owner:EAGLE INDS

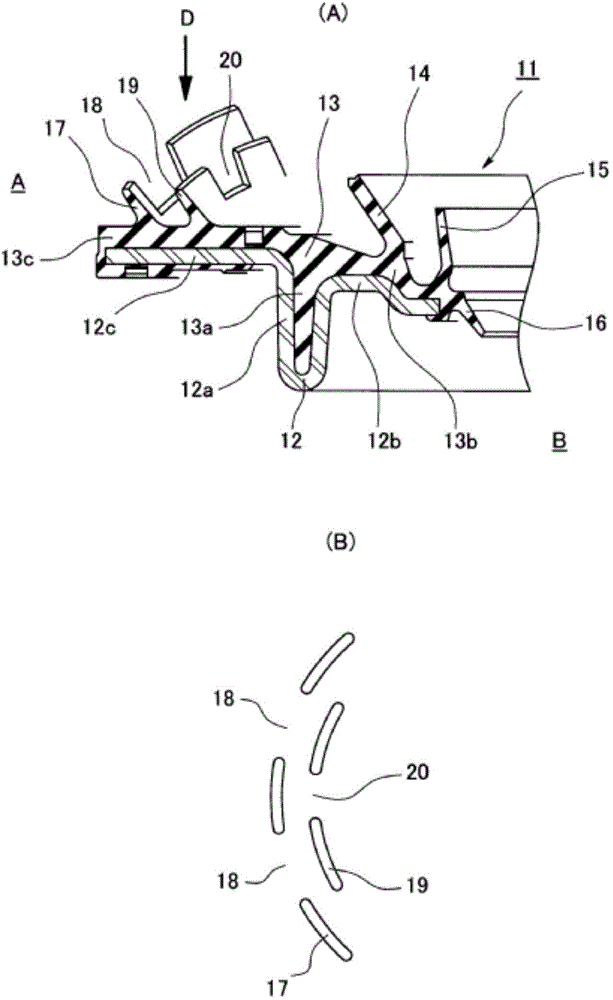

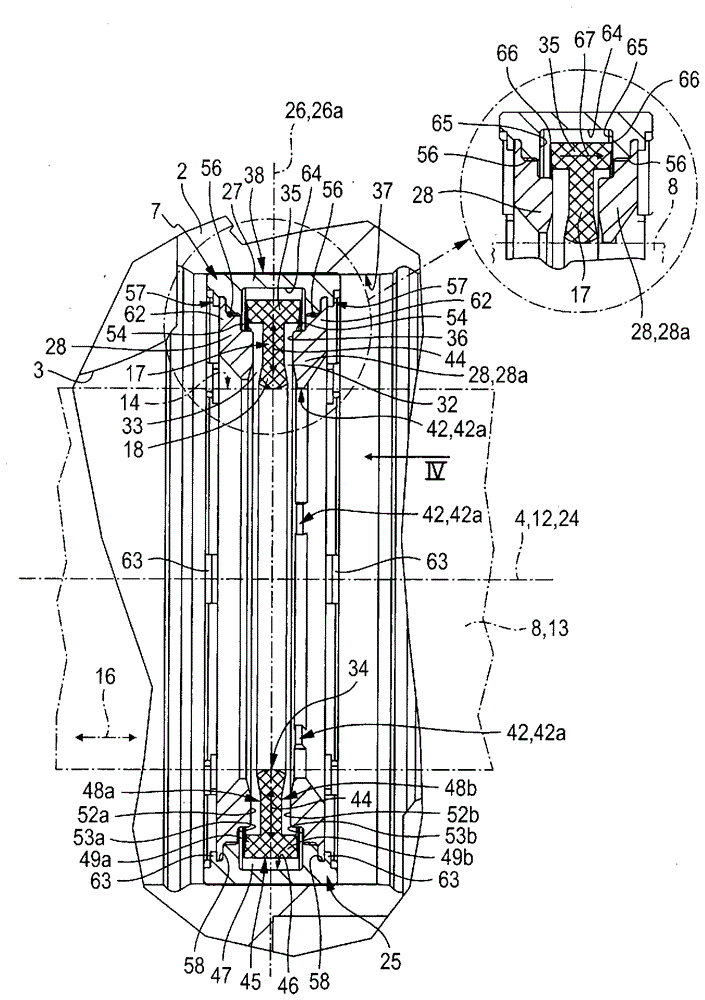

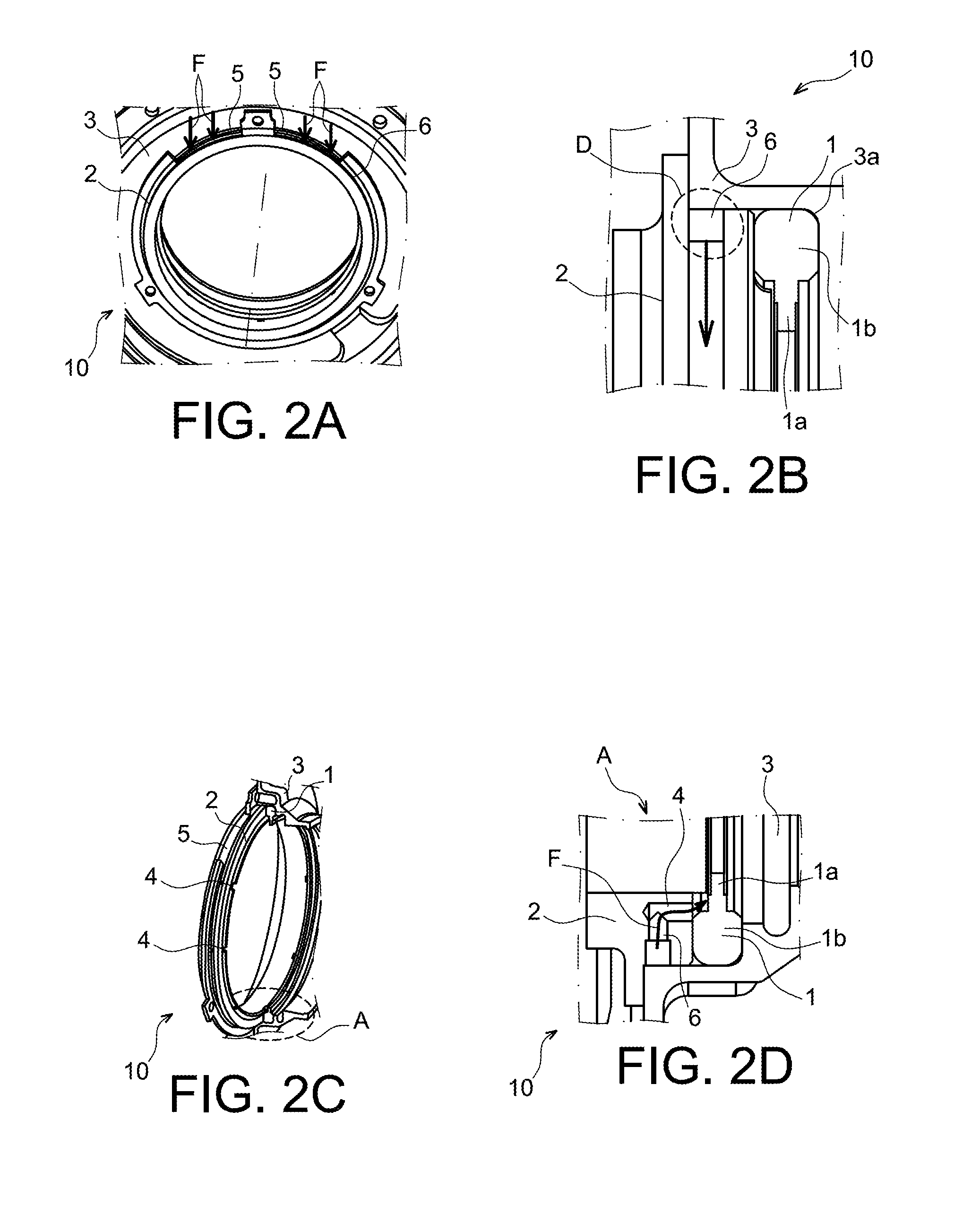

Sealing system for reciprocating piston rod of reciprocating compressor

InactiveCN102644754AGuaranteed sealing functionImprove production safetyEngine sealsPositive displacement pump componentsRing deviceGas compressor

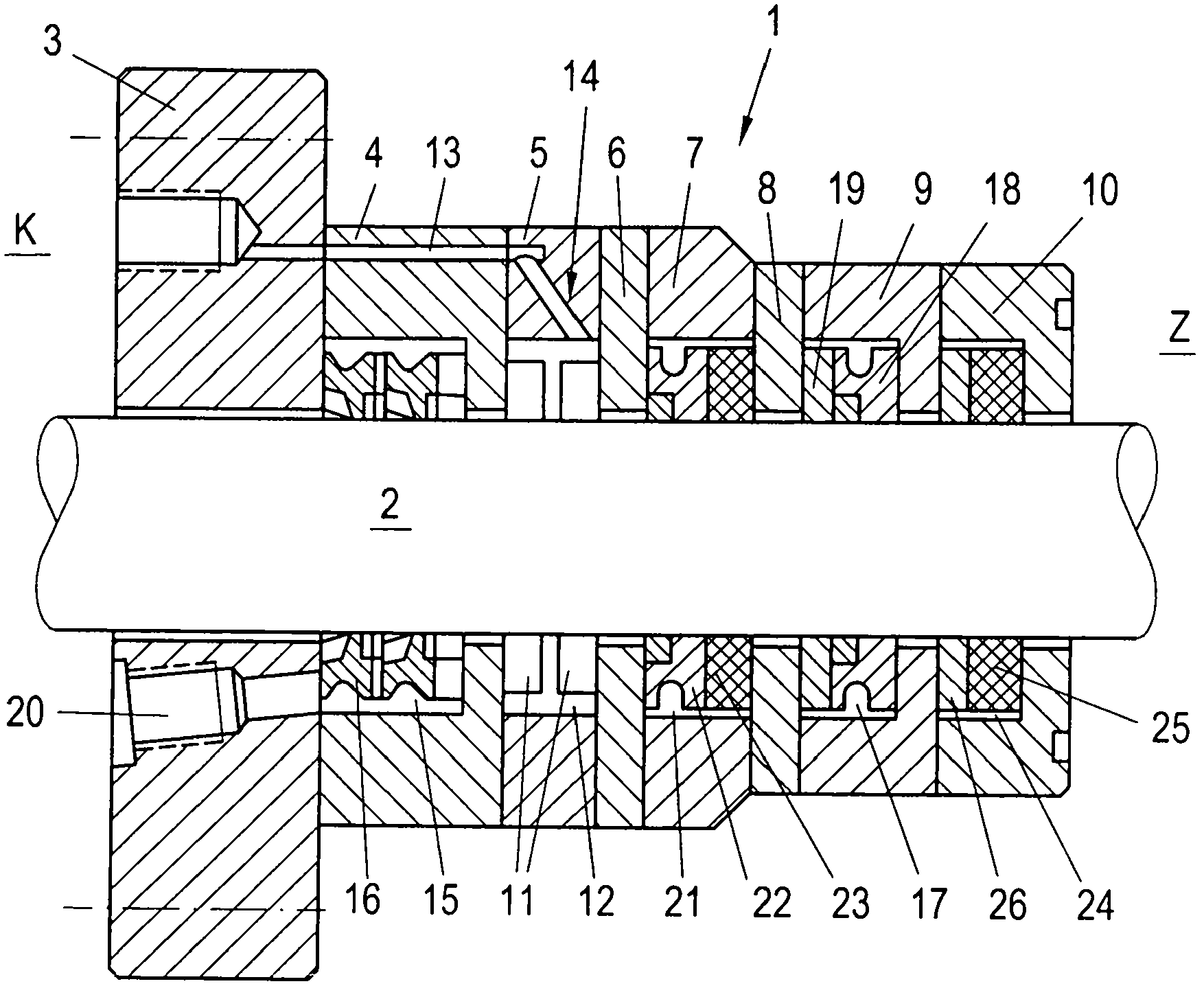

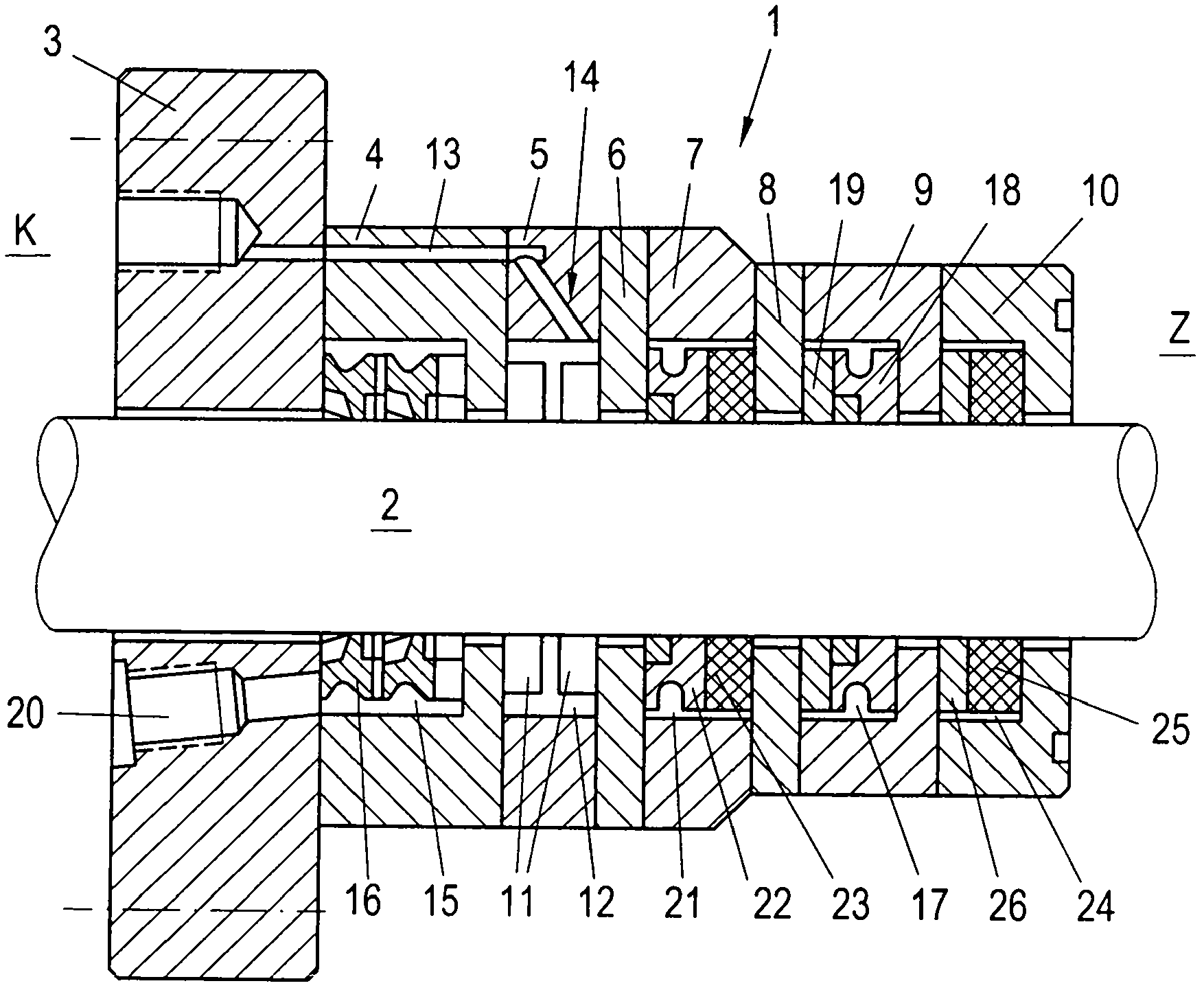

The invention provides a gas-proof sealing system, which can retain the functions in an at least enough way even if one component (e.g. hydraulic supplying or sealing element) is faulty and prevent a compressor from being down. A scraper recess (15) is equipped on the sealing system (1) end located on a crankcase side. A gas-proof scraping ring (16) is equipped inside the scraper recess. A sealing ring recess (17) is equipped on the sealing system (1) end (Z) located on the cylinder side. A sealing ring device (18) is equipped inside the sealing ring recess. A barrier recess (14) is located axially between the scraper recess (15) and the sealing ring recess (17). A discharge pipeline (20) is equipped inside the sealing system (1). The discharge pipeline is communicated with the space between the barrier recess (14) and the scraper recess (15).

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

Composite piston for a motor vehicle transmission

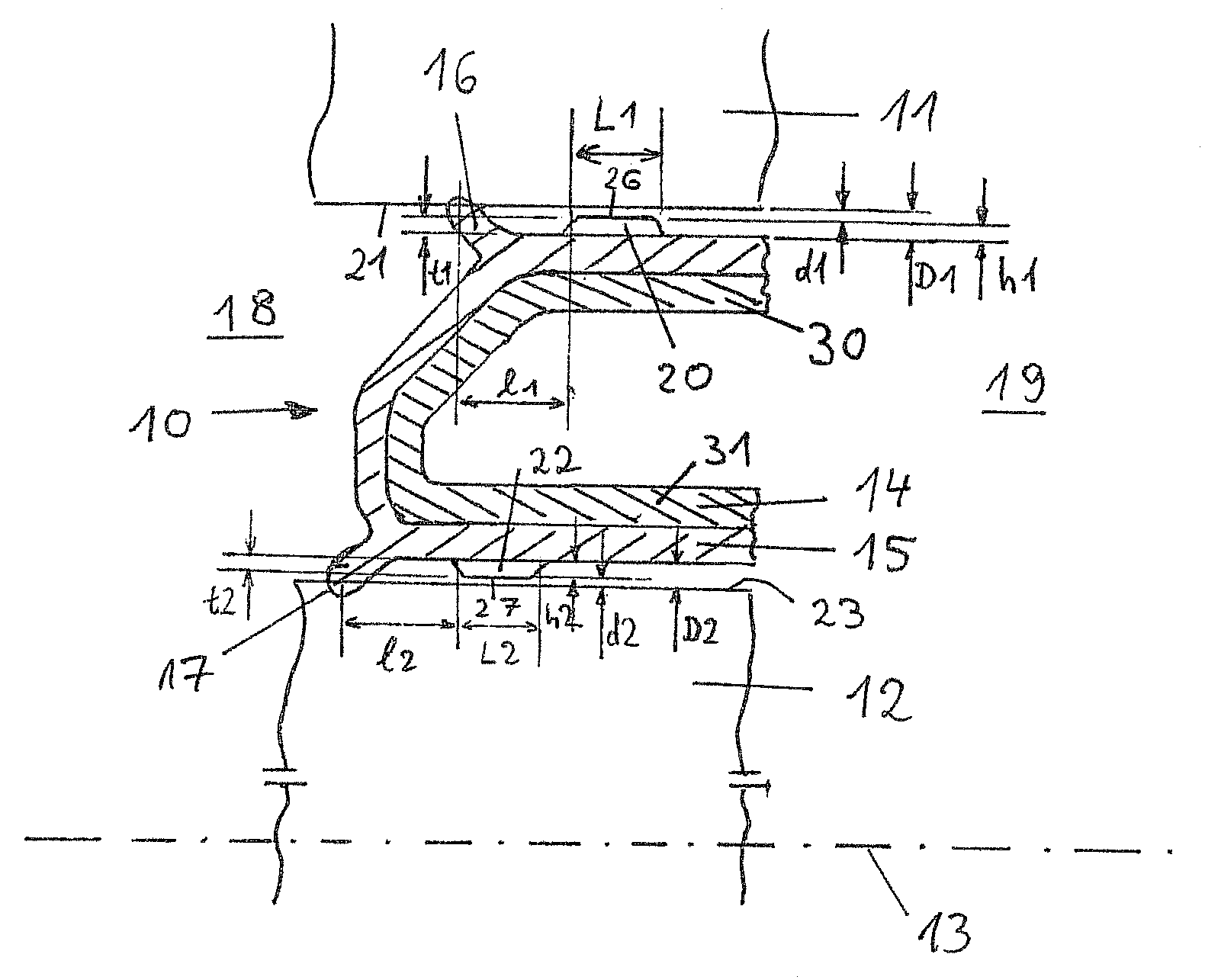

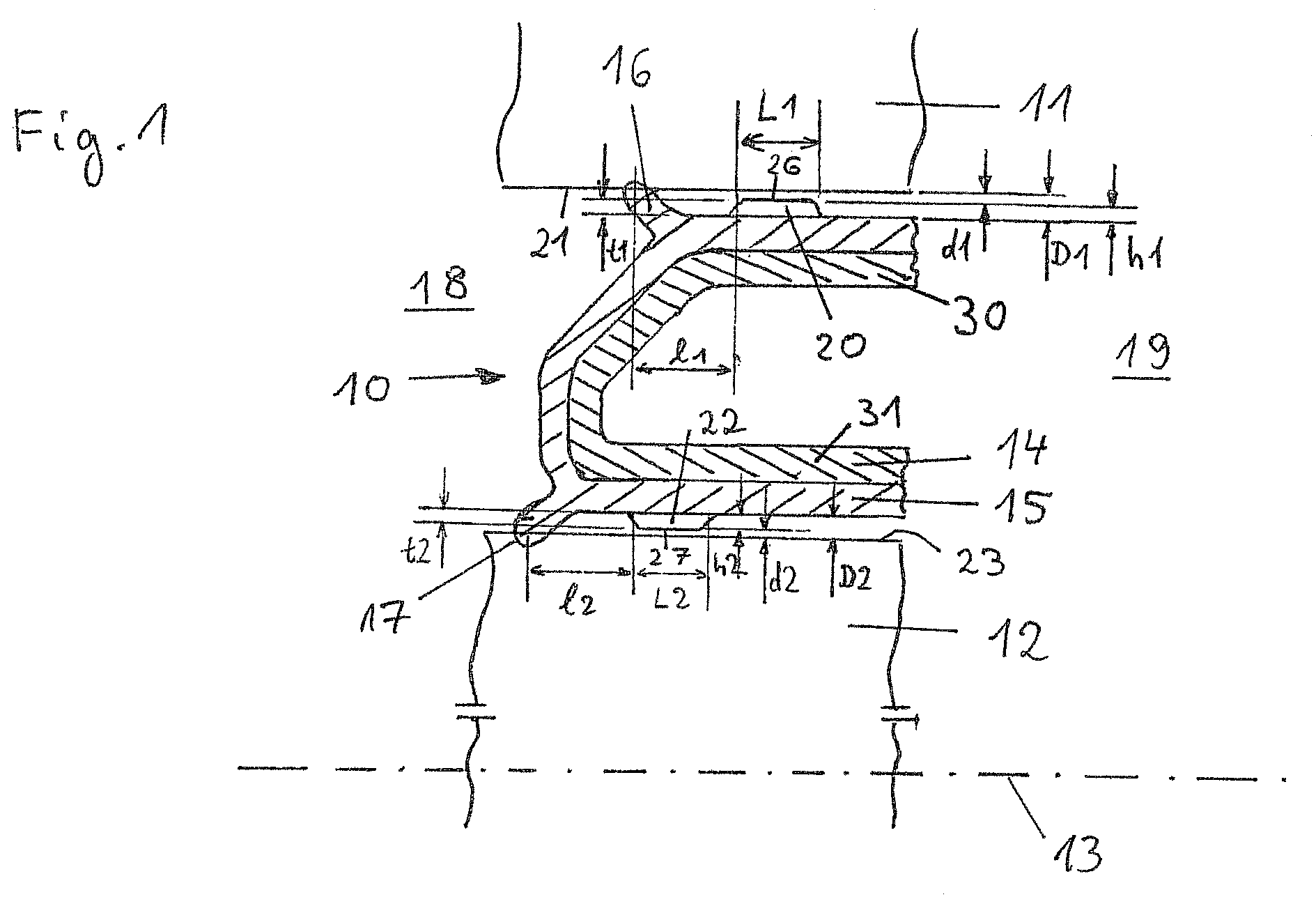

InactiveUS20090282972A1Reduce riskEqually distributedEngine sealsPiston ringsElastomerMechanical engineering

A composite piston (10) for a motor vehicle transmission comprises a support body (14) and at least one rotationally symmetric annular seal comprising an elastomer sealing lip (16, 17) interacting in a sealing manner with a component (11, 12) forming a cylindrical sliding surface (21, 23), wherein the composite piston (10) can be displaced translationally relative to the component (11, 12) forming the cylindrical sliding surface. The annular seal comprises an elastomer annular bead (20, 22) displaced axially relative to the sealing lip (16, 17), wherein the annular bead is arranged to have a distance d1, d2 from the sliding surface (21, 23) in the non-loaded state larger than or equal to zero.

Owner:DICHTUNGSTECHN G BRUSS

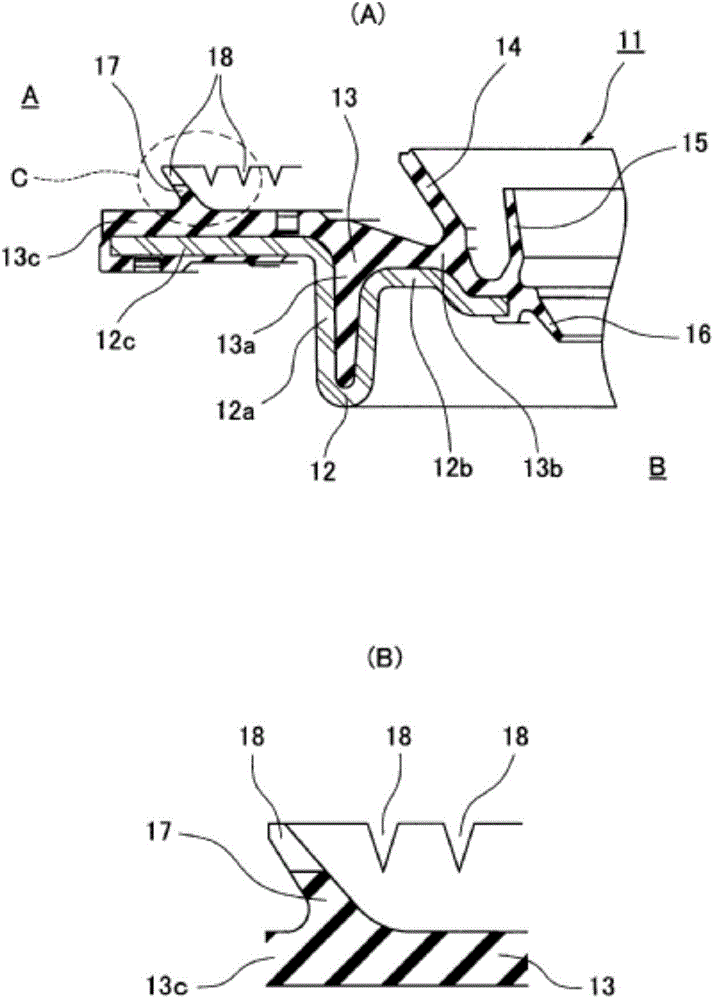

Seal structure using metal gasket

ActiveCN103797286AAvoid corrosionLow costEngine sealsSealing arrangements for enginesSalt waterEngineering

A seal structure is provided using a metal gasket. The structure substantially prevents formation of a gap that would allow salt water to collect between the metal gasket and a casing, thus suppressing corrosion of the casing due to the collection of salt water and allowing long-term maintenance of the seal function. To achieve this purpose, the metal gasket is arranged between a pair of casings. The metal gasket is provided with a bead on the inner circumference of a planar circumference part and a bent part on the outer circumference. When the metal gasket is compressed between the pair of casings, the bead elastically deforms so that the height of the bead is reduced and the outer circumference part elastically deforms accordingly, causing the outer edge of the circumference part to contact one of the casings, thereby preventing the formation of a gap that would allow salt water to collect between the casing and the outer circumference part. The bend-processed part contacts the other casing, thus providing a structure preventing formation of a gap that would allow salt water to collect between the other casing and the outer circumference part.

Owner:NOK CORP

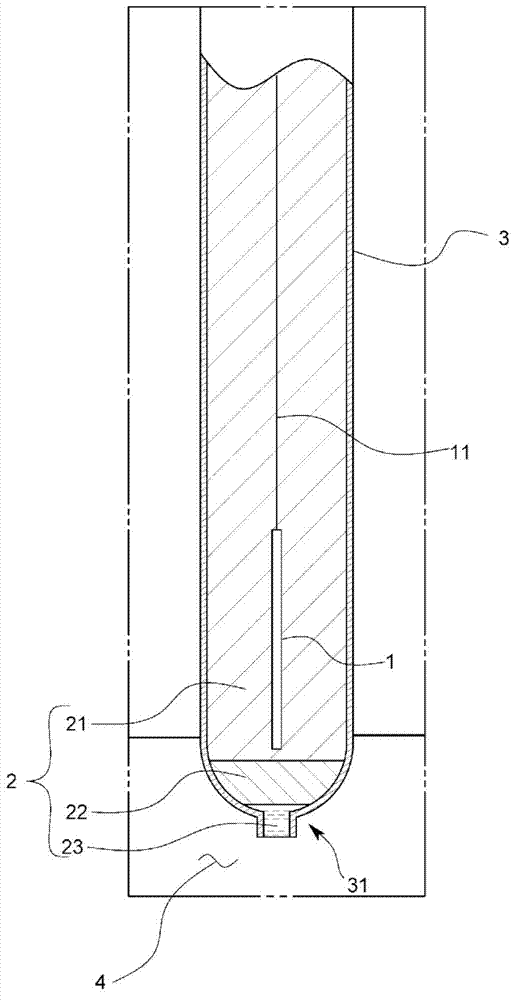

Reference electrode

InactiveCN102971621AContinuous maintenance of sealing functionGuaranteed sealing functionMaterial electrochemical variablesElectricityAqueous electrolyte

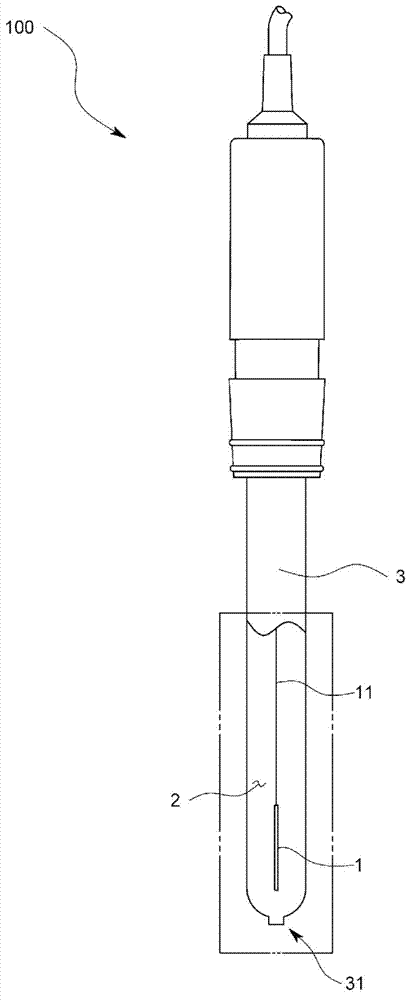

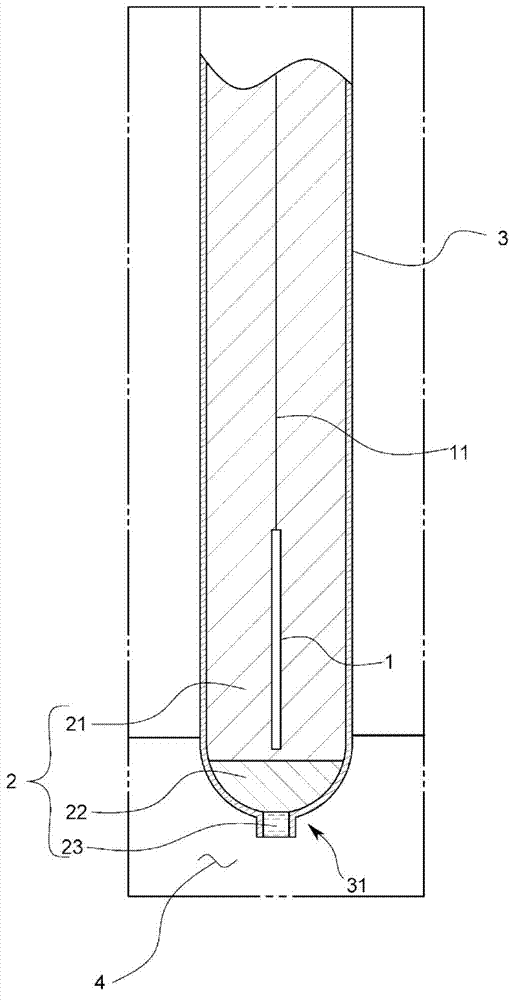

A reference electrode which does not require the use of a gelled hydrophobic ionic liquid that has a hardness or viscosity at or above a prescribed level that is difficult to manufacture, and that is very thick etc., and which is capable of improving product life cycle. The reference electrode (100) is provided with an internal electrode (1), and a container (3) that contains a filler (2) that electrically connects the internal electrode (1) and a sample liquid (4). The filler (2) forms a layer between the internal electrode (1) and an opening (31) provided to the container (3) so that the sample liquid (4) and the filler (2) come into contact. The filler is composed of: a first layer (21) comprising an aqueous electrolyte solution, formed so as to come into contact with the internal electrode; a second layer (22) comprising a hydrophobic ionic liquid, formed so as to come into contact with the first layer; and a third layer (23) comprising a gelled hydrophobic ionic liquid, that comes into contact with the second layer (22) and is formed in the opening (21).

Owner:HORIBA LTD

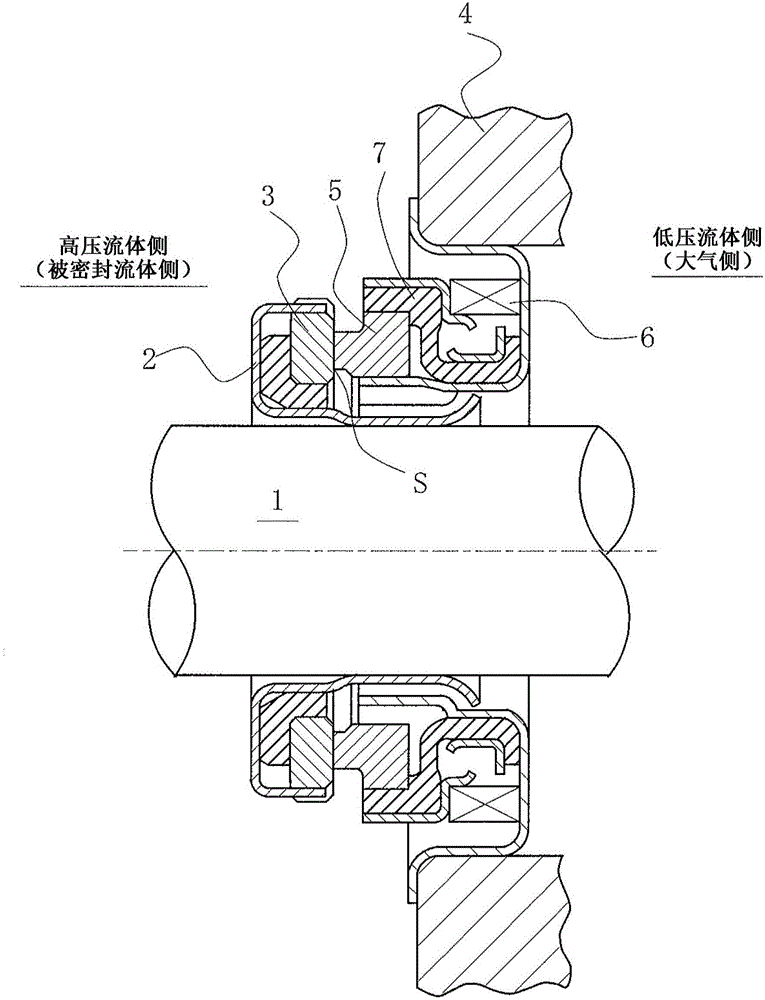

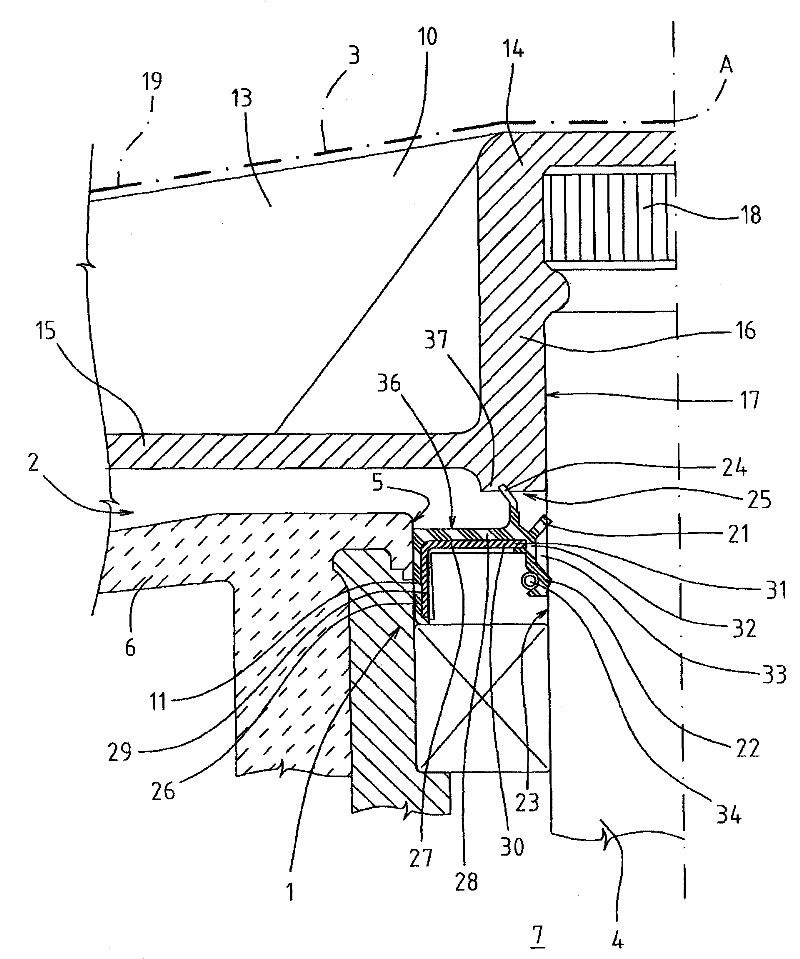

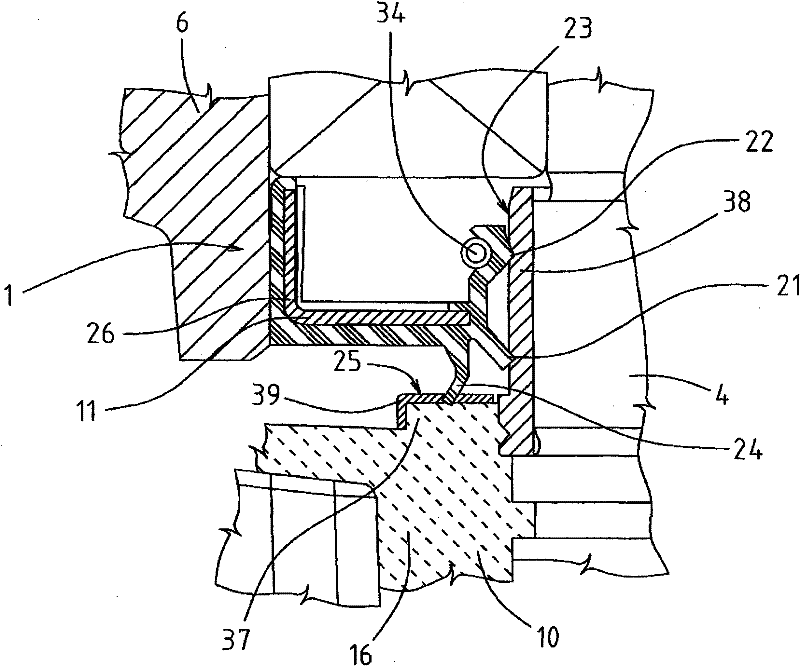

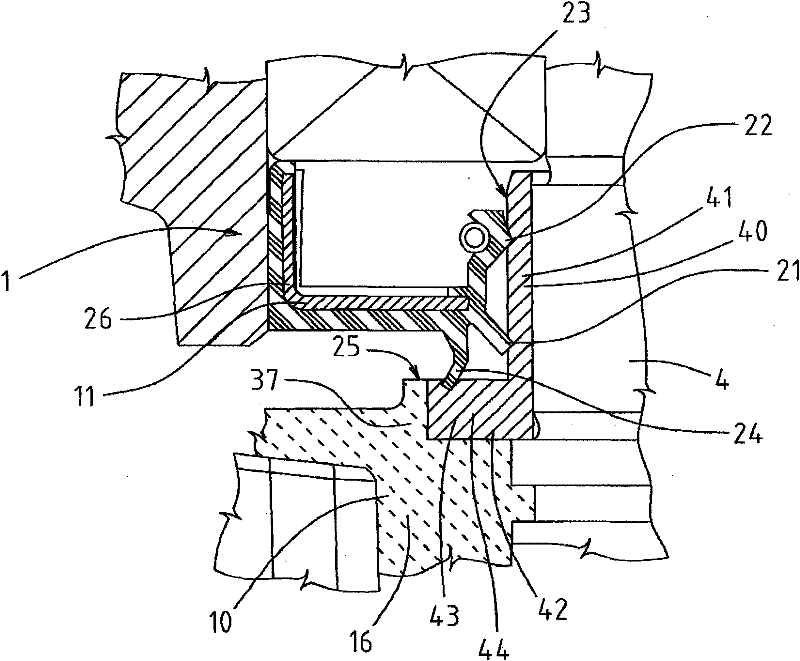

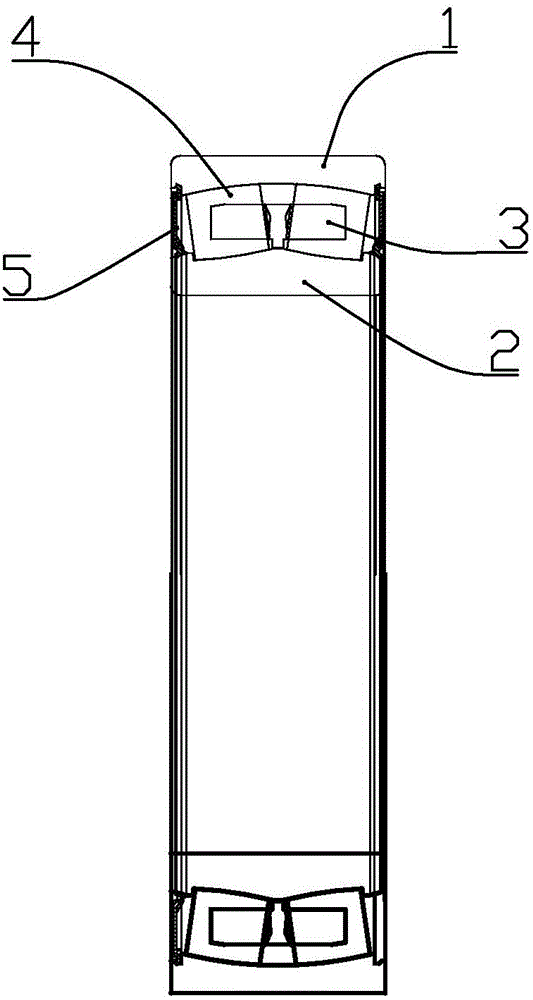

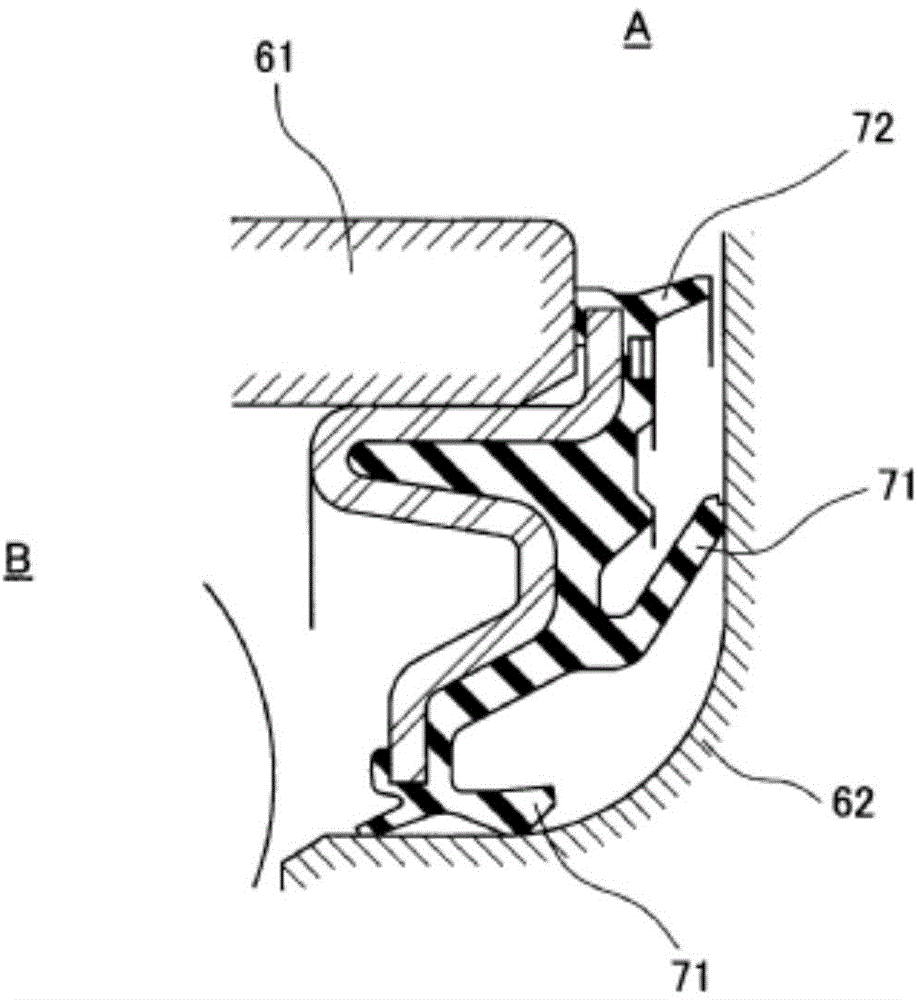

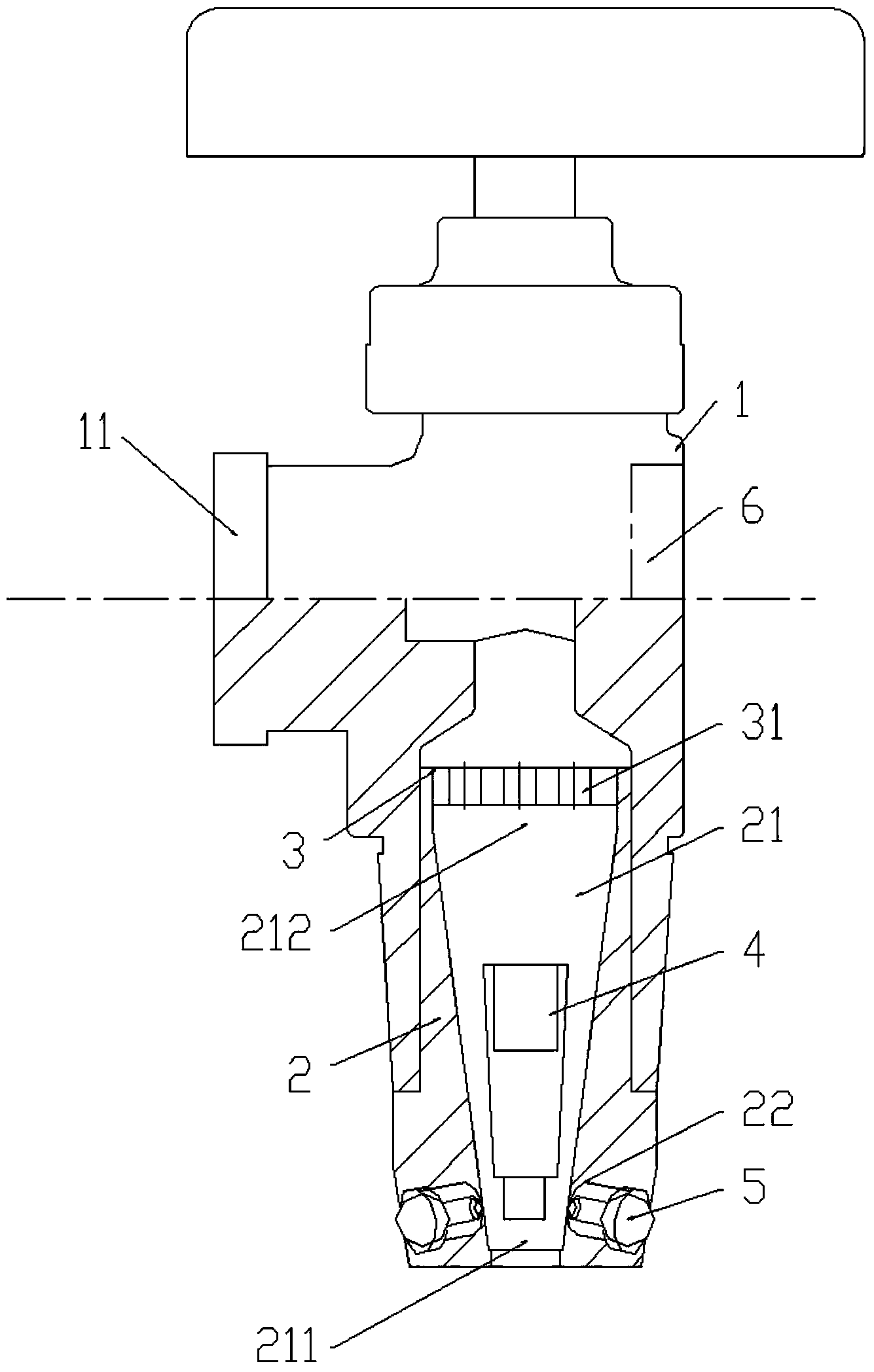

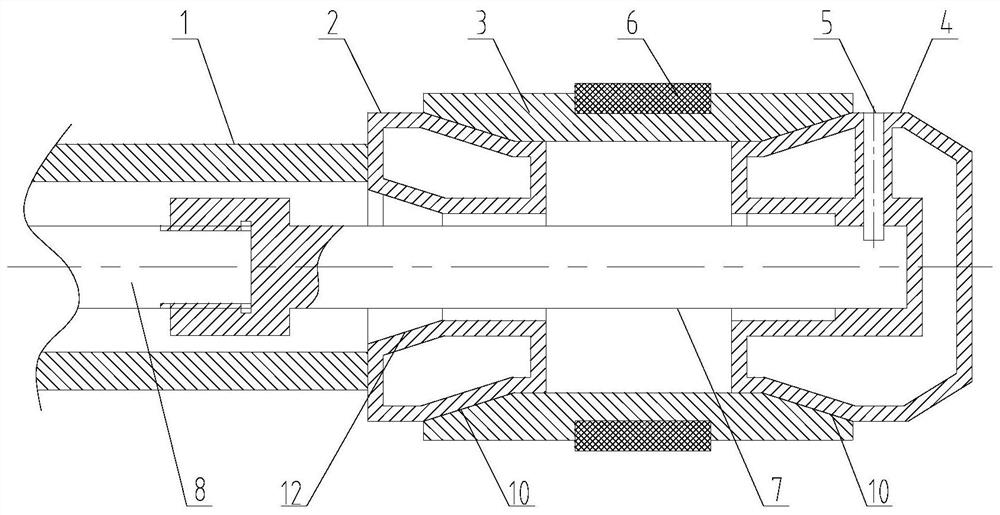

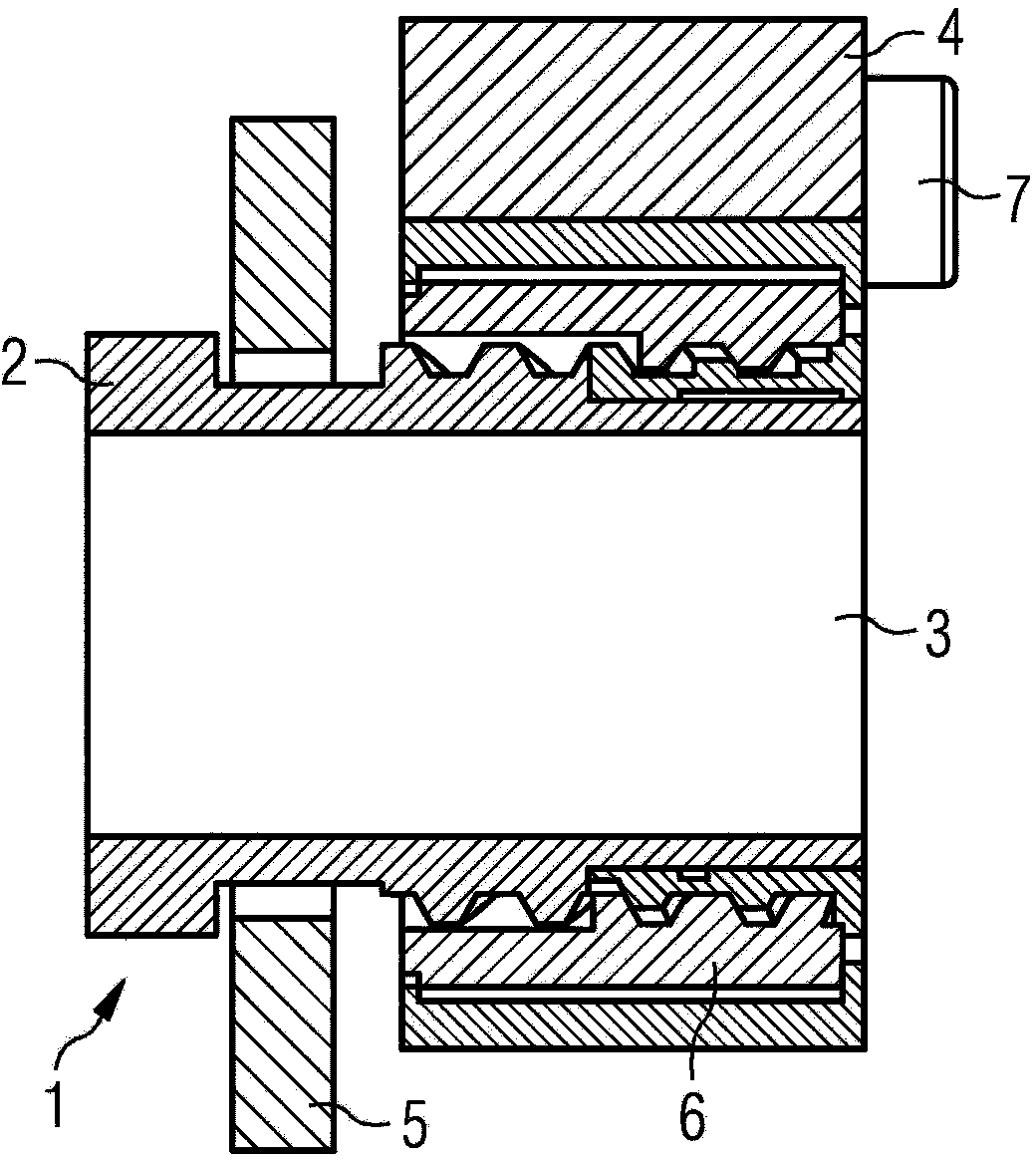

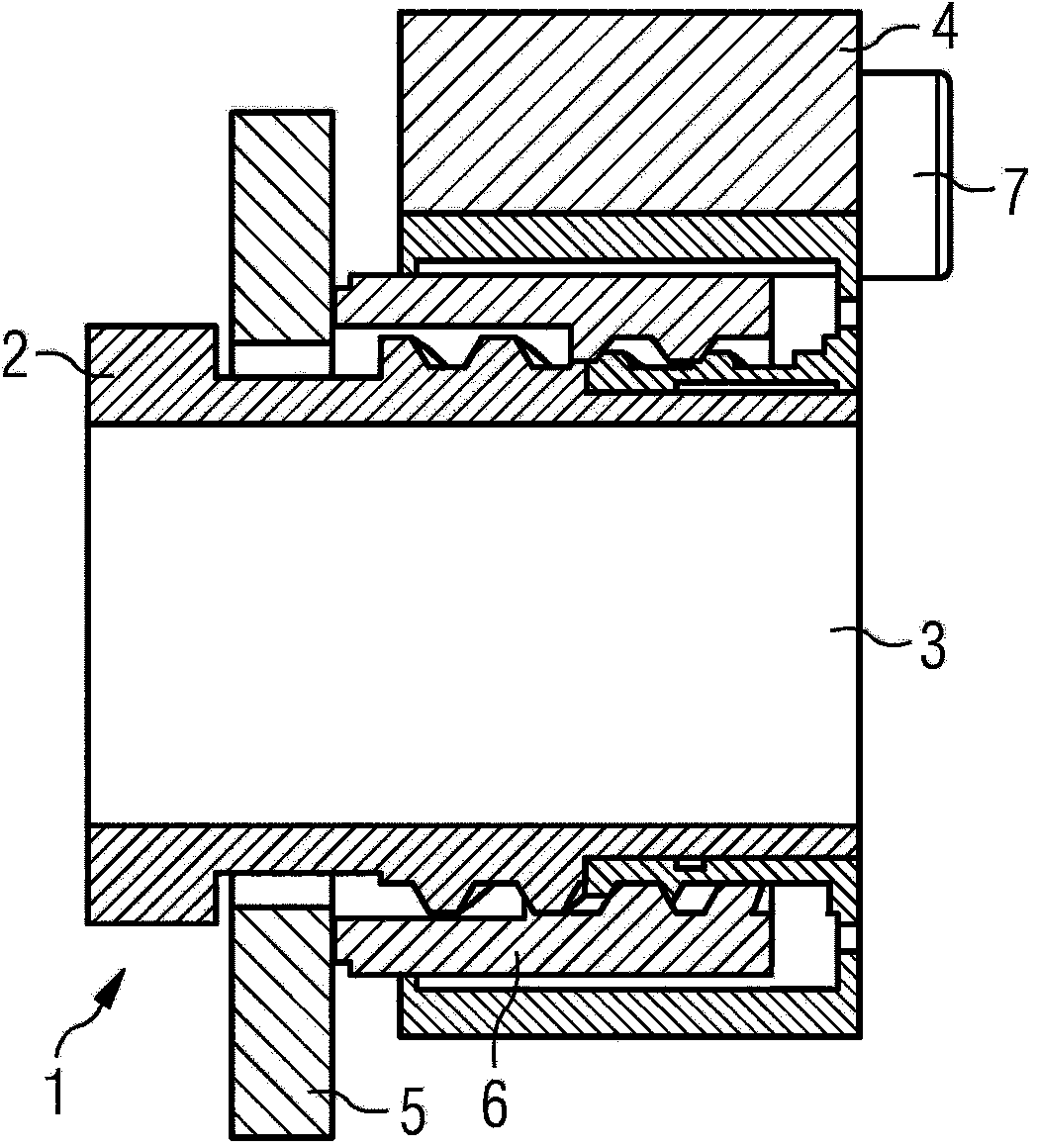

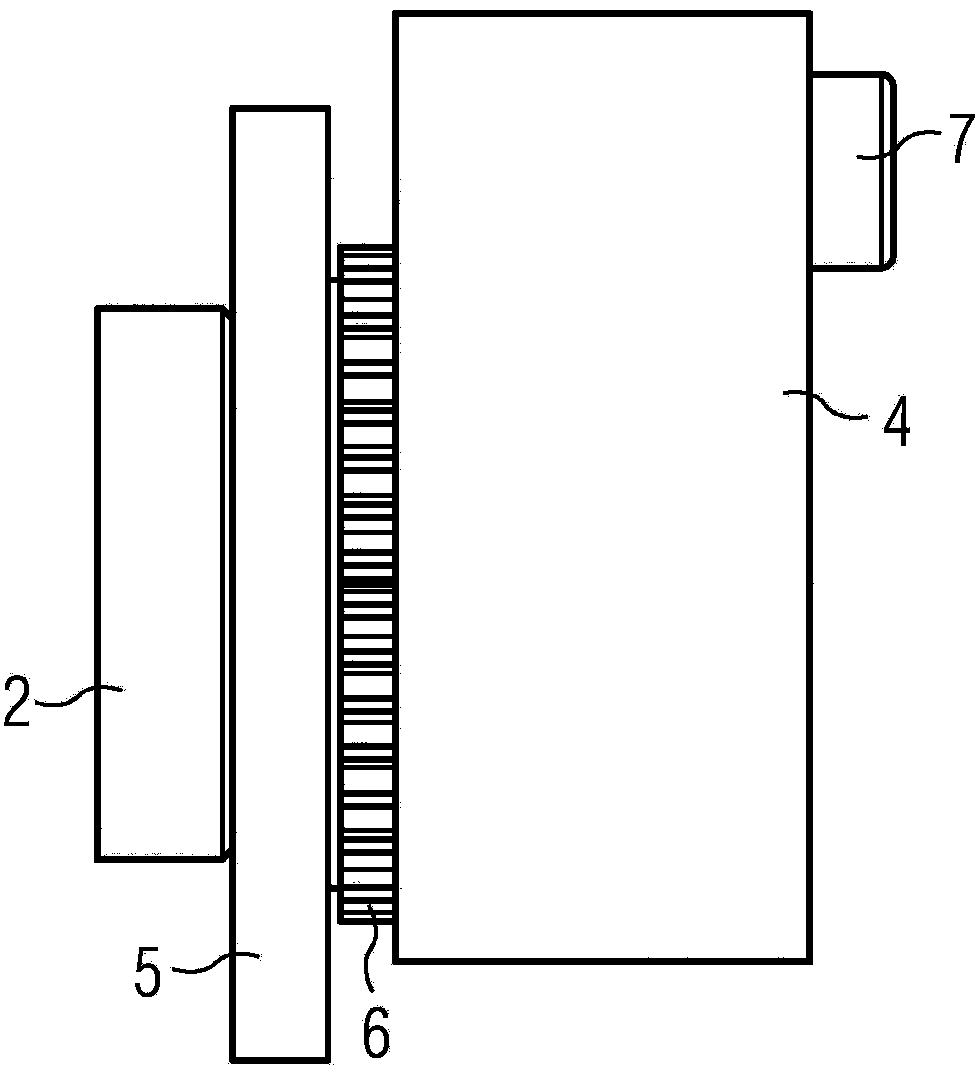

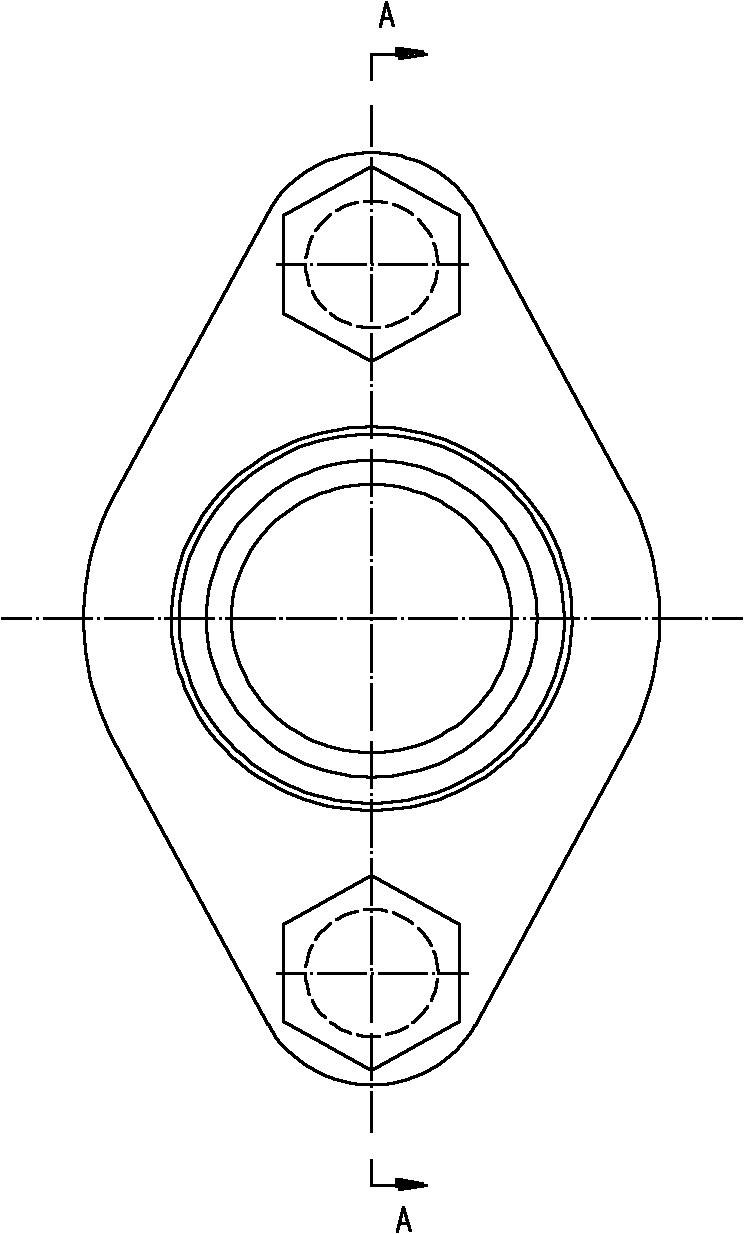

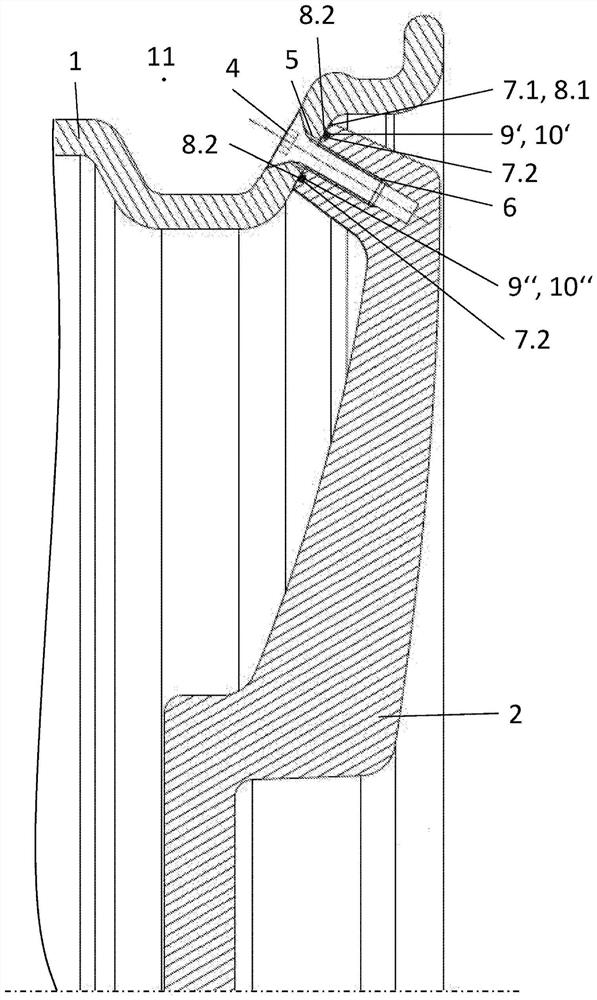

Sealing component for drum of washing machine and washing machine with same

ActiveCN102127852AImprove featuresImprove efficiencyEngine sealsOther washing machinesEngineeringMechanical engineering

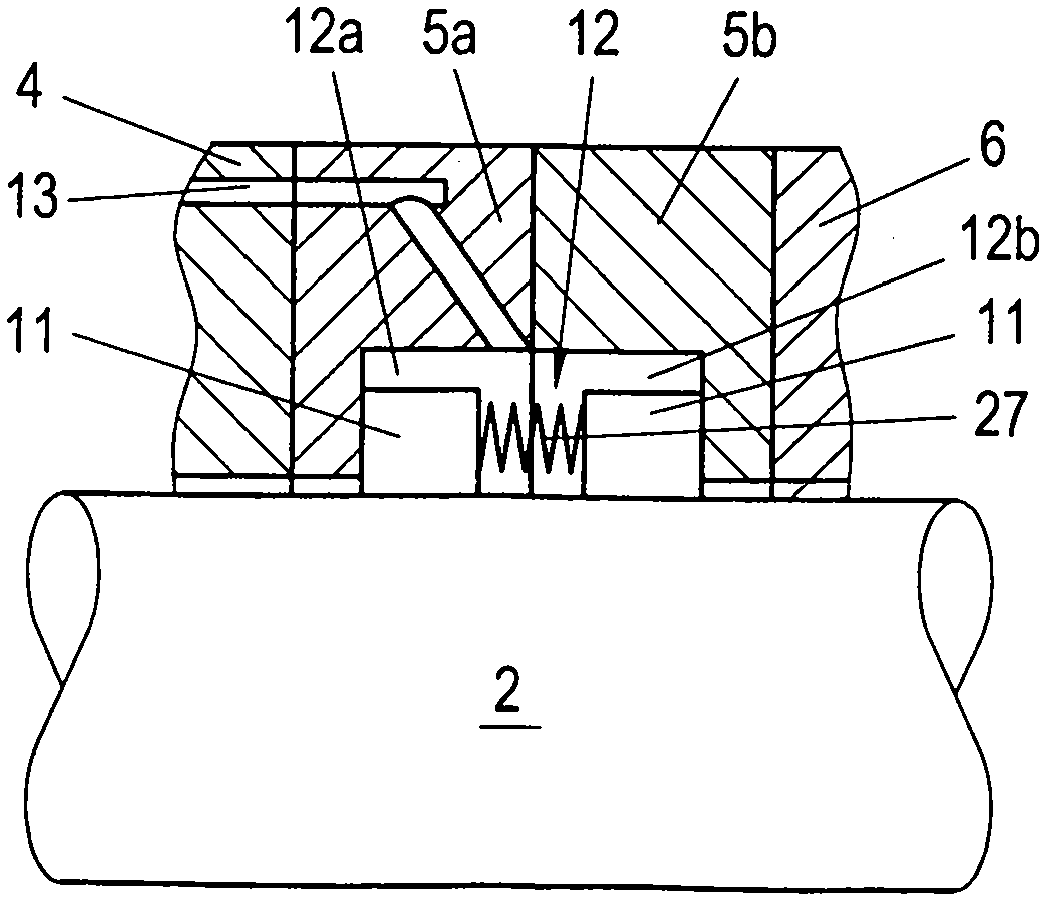

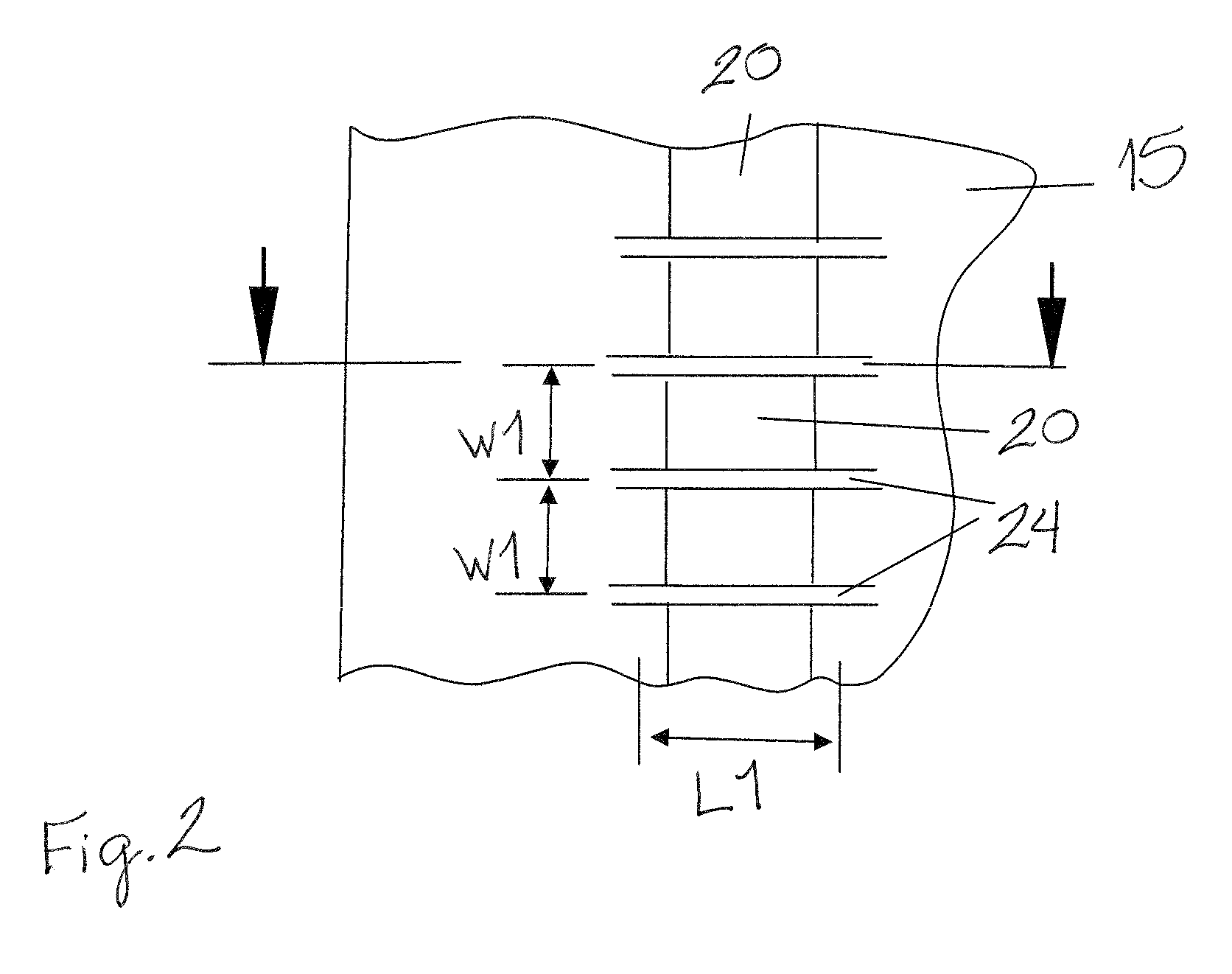

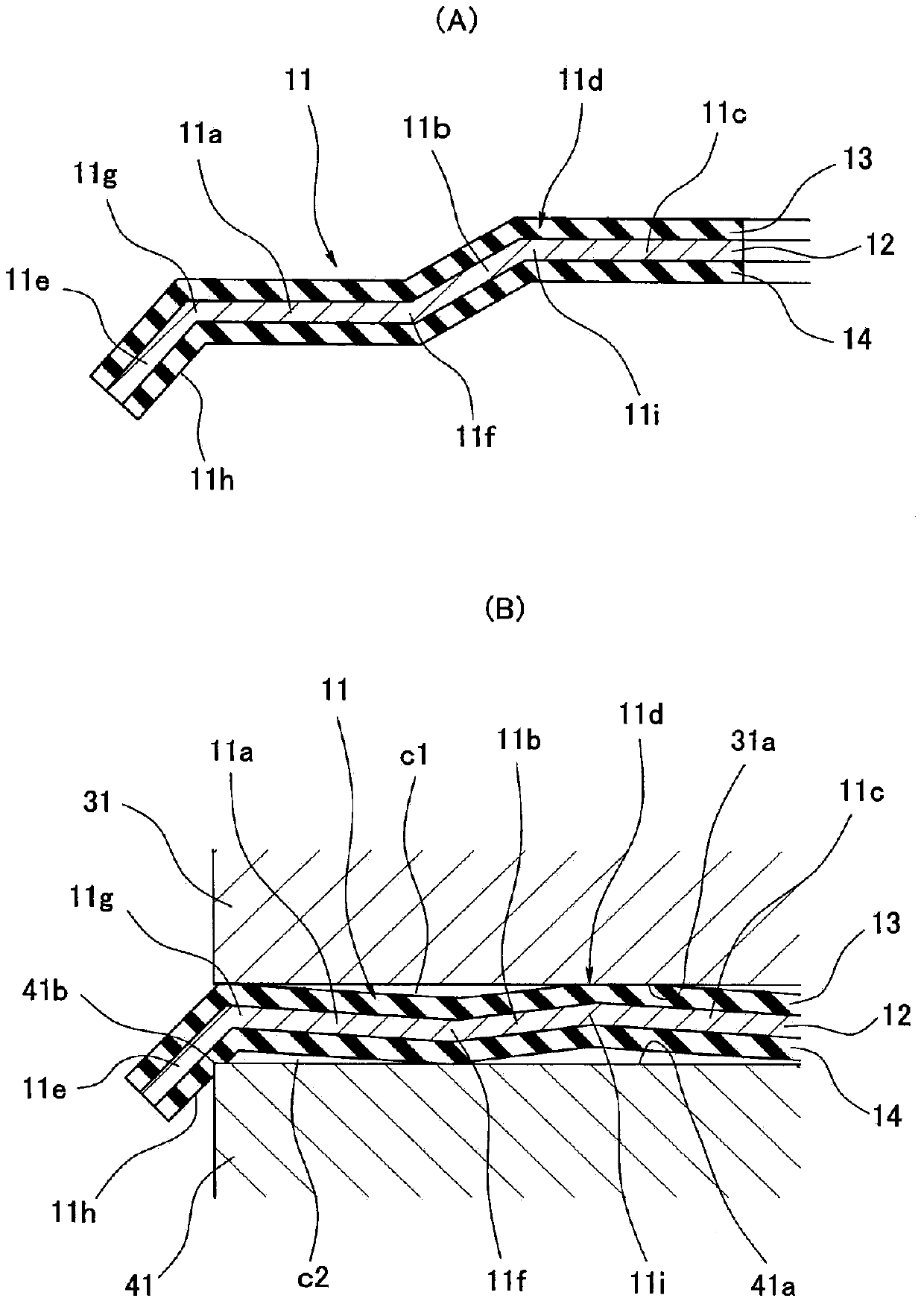

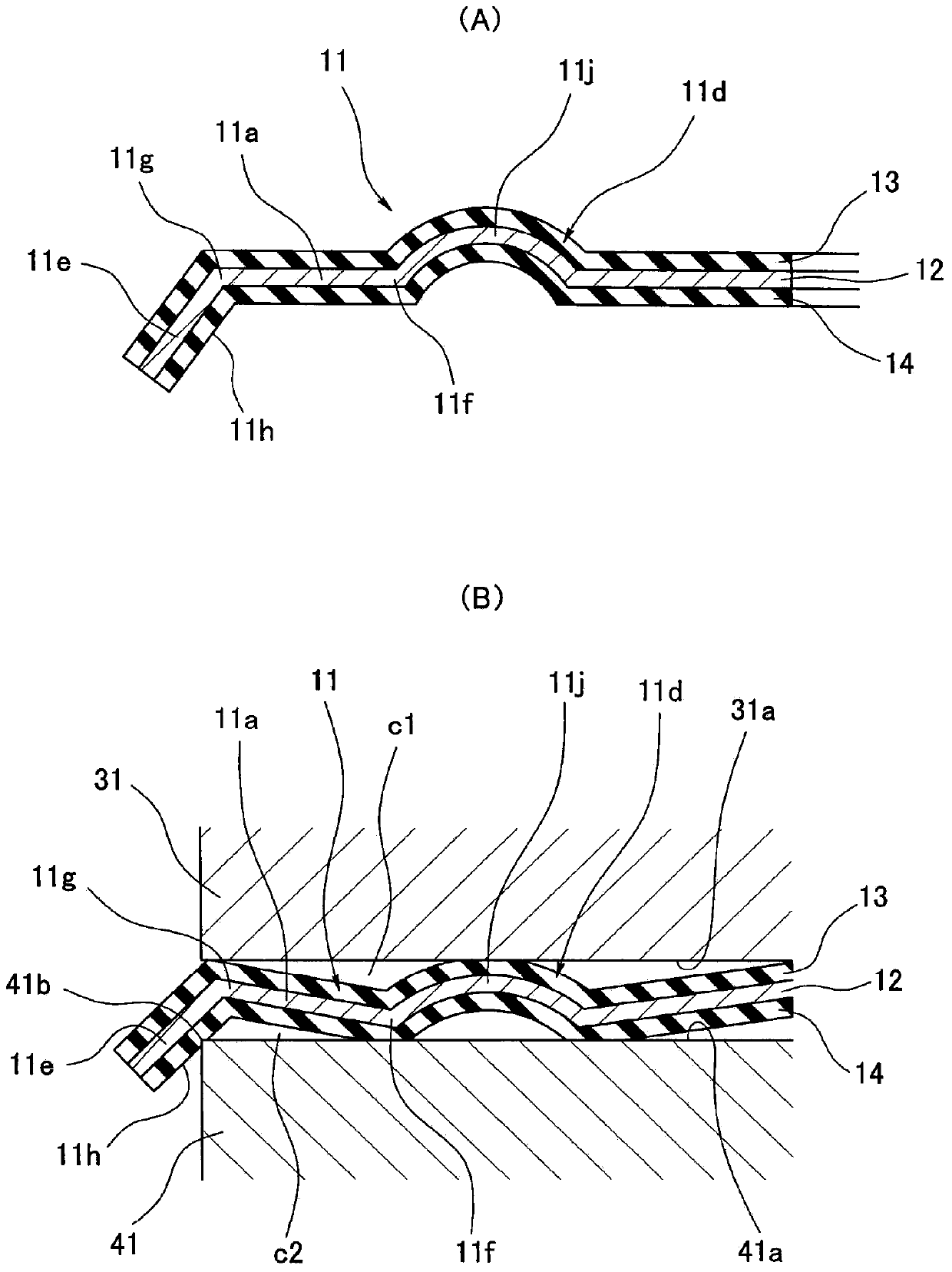

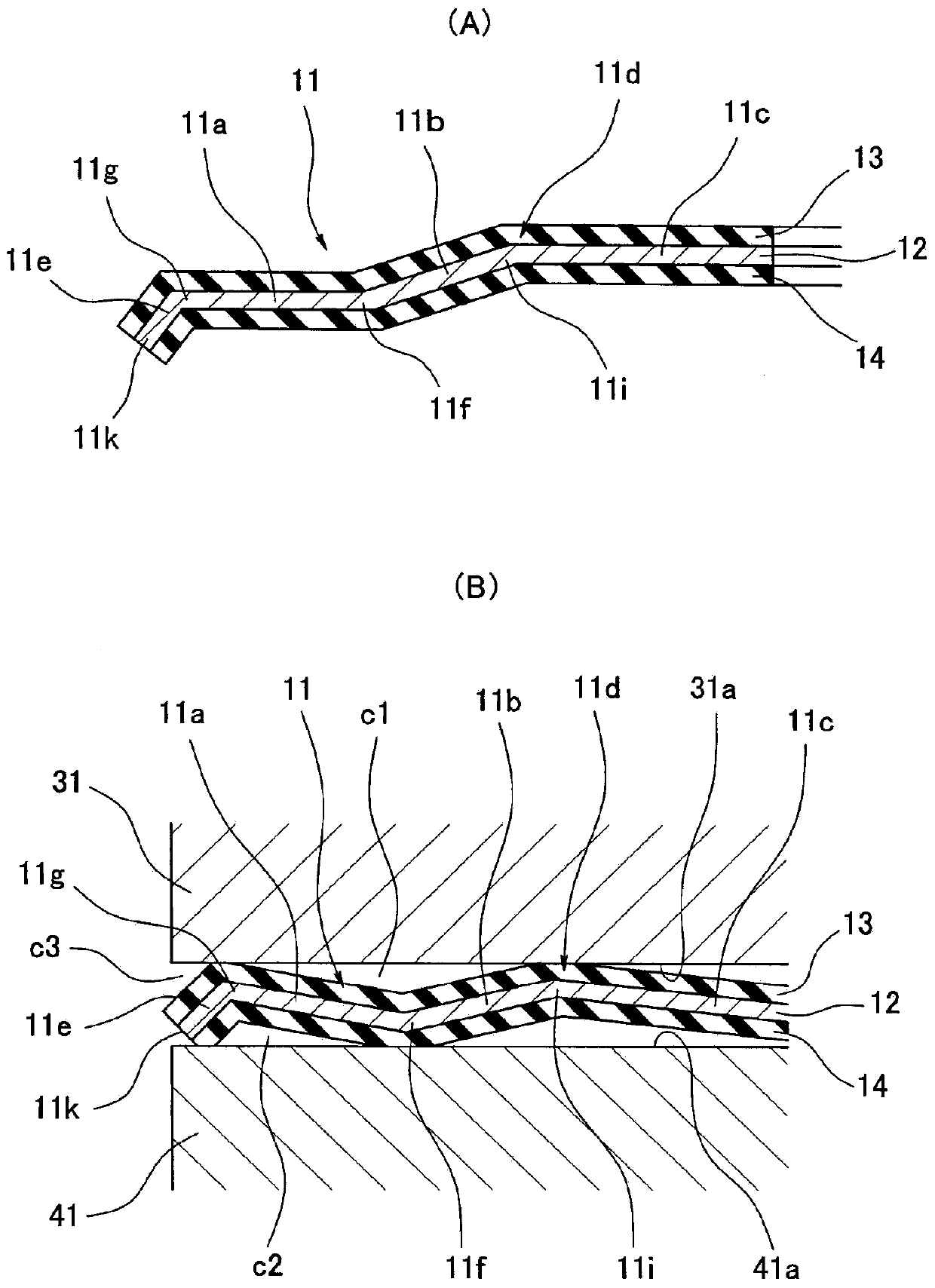

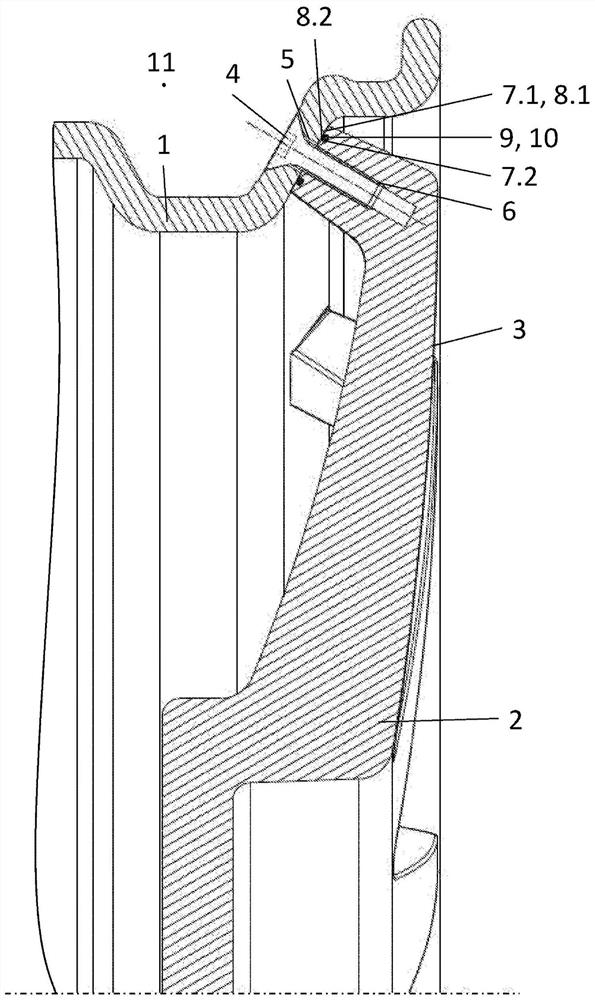

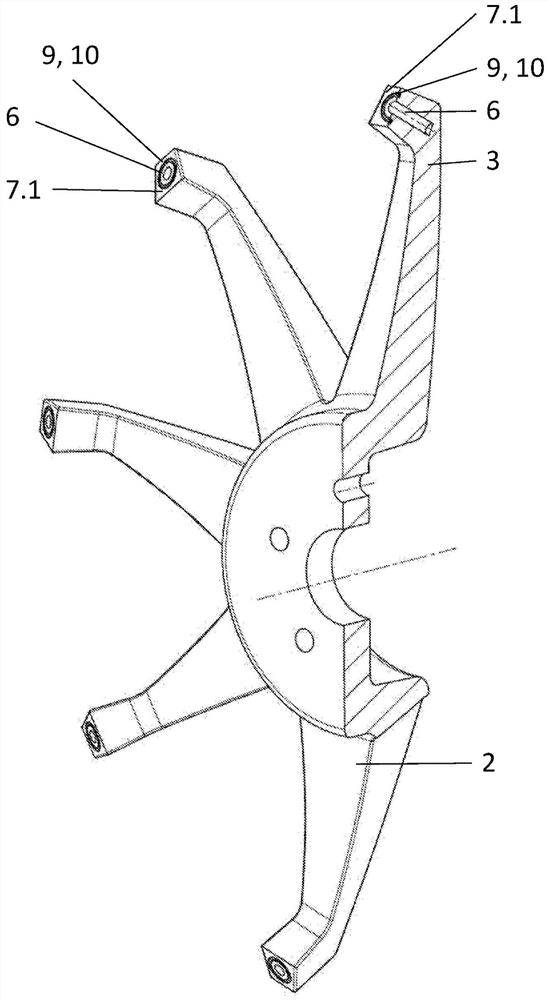

The invention relates to a sealing component (1) for a drum (3) of a washing machine and the washing machine with the same. The sealing component comprises a drum shaft (4), a supporting member (10) for supporting the drum, and a sealing element (11), wherein the drum shaft (4) extends along an axis (A), rotates around the axis and passes through a hole (5) on a wall (6) of the washing machine; the supporting member (10) is fixed to the drum and is integrally connected to the drum shaft so as to rotate the drum; and the sealing element (11) seals the hole (5) in a liquid-tight mode and is provided with a pair of radial sealing lips (21 and 22) and at least one axial sealing lip (24); the pair of radial sealing lips (21 and 22) are arranged side by side along the axis (A) and are in sliding fit with a cylindrical sealing surface (23) which is arranged around the drum shaft (4); the axial sealing lip (24) is matched with a front sealing surface (25); and the front sealing surface (25) is carried by the supporting member (10) and is basically vertical to the axis (A).

Owner:ROLF

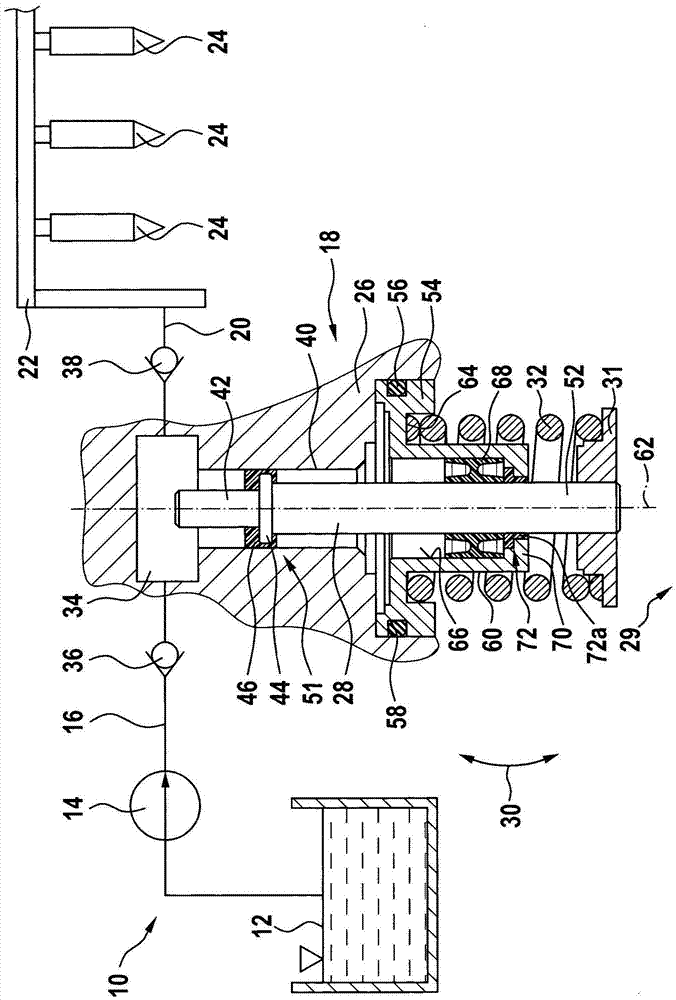

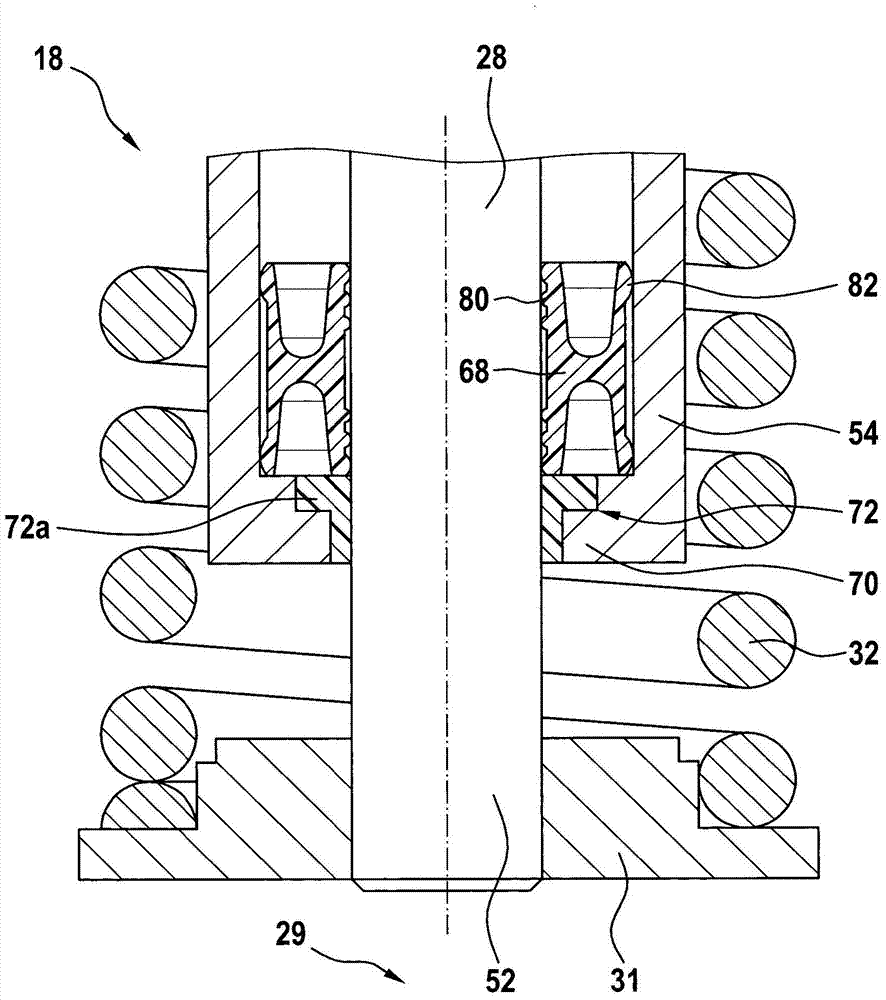

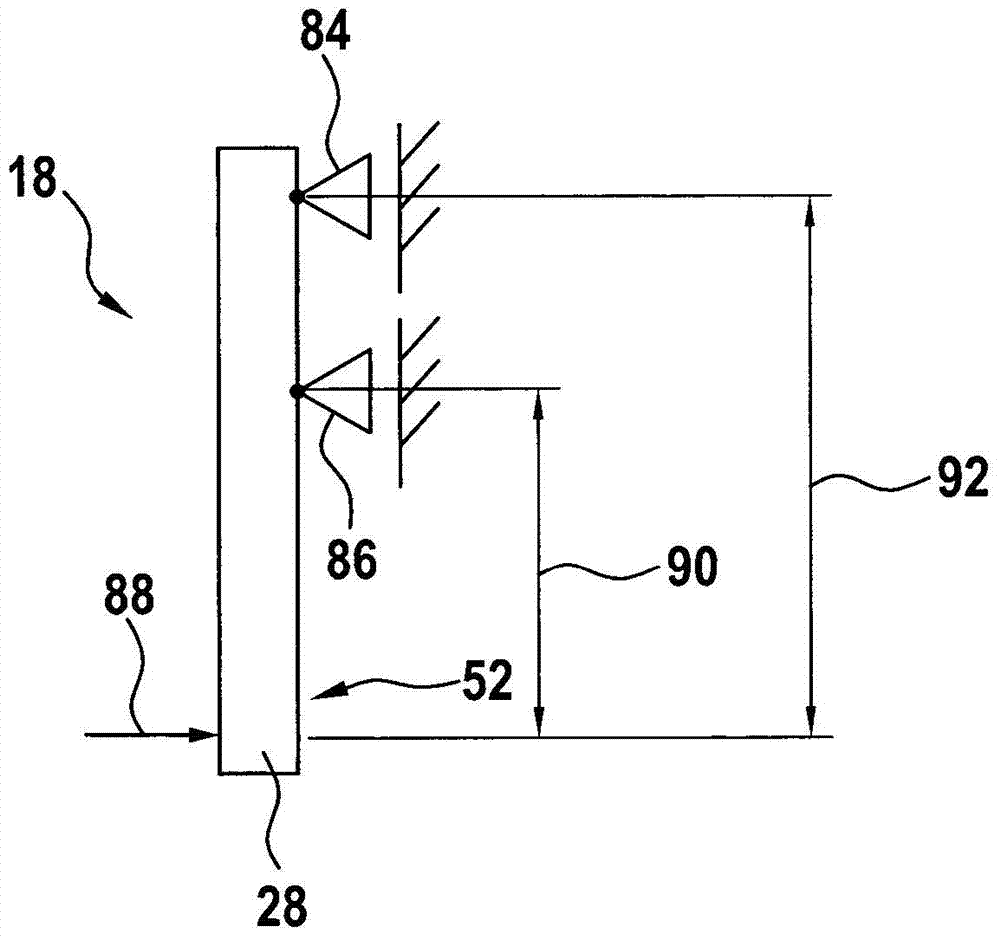

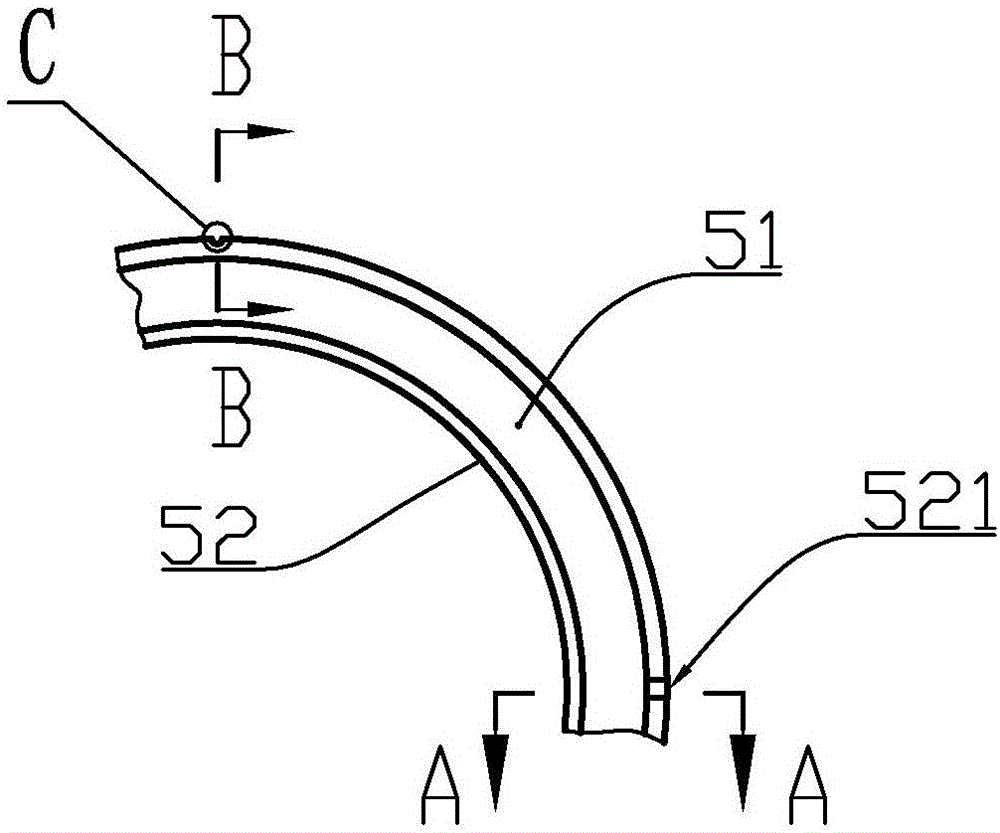

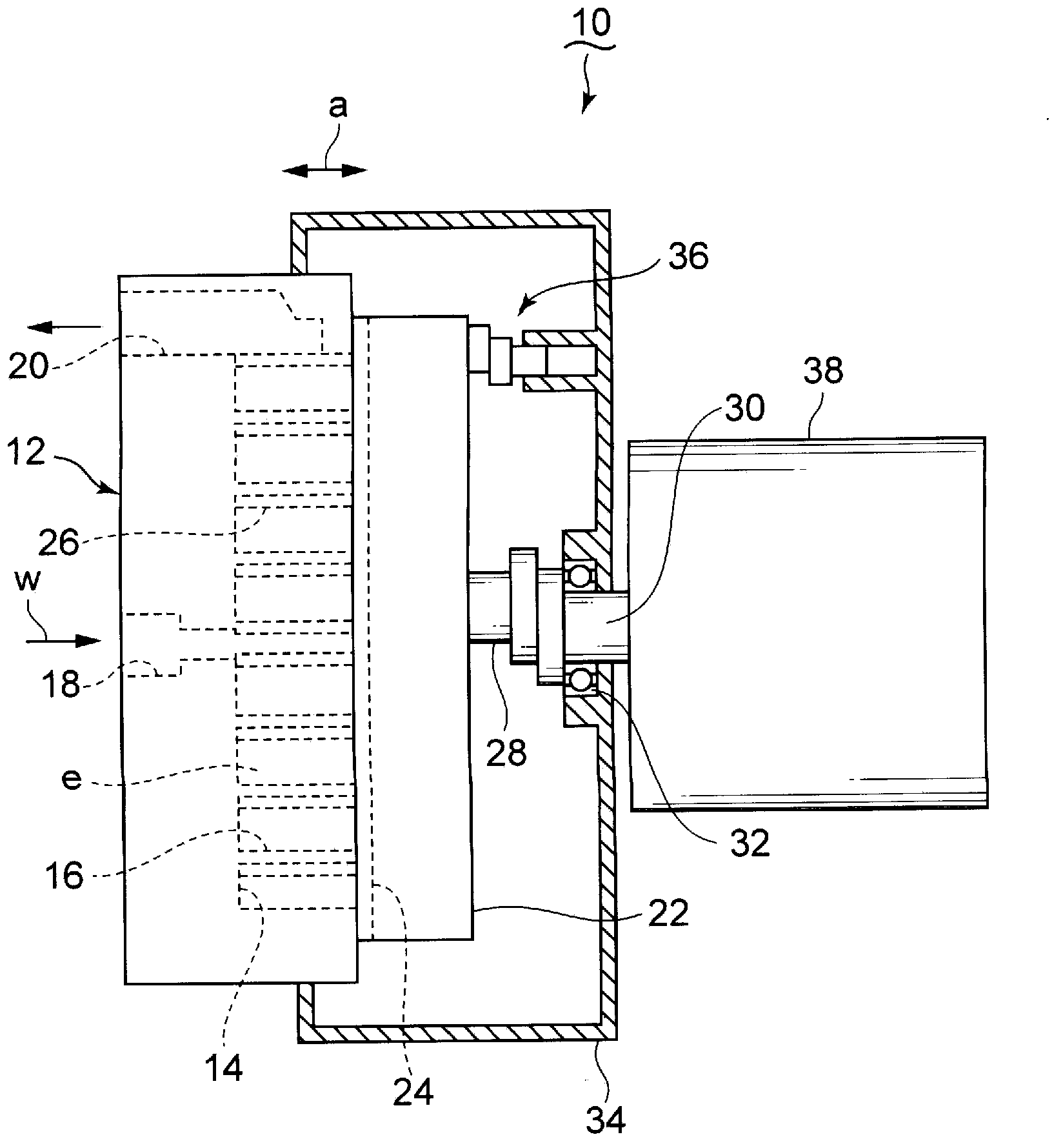

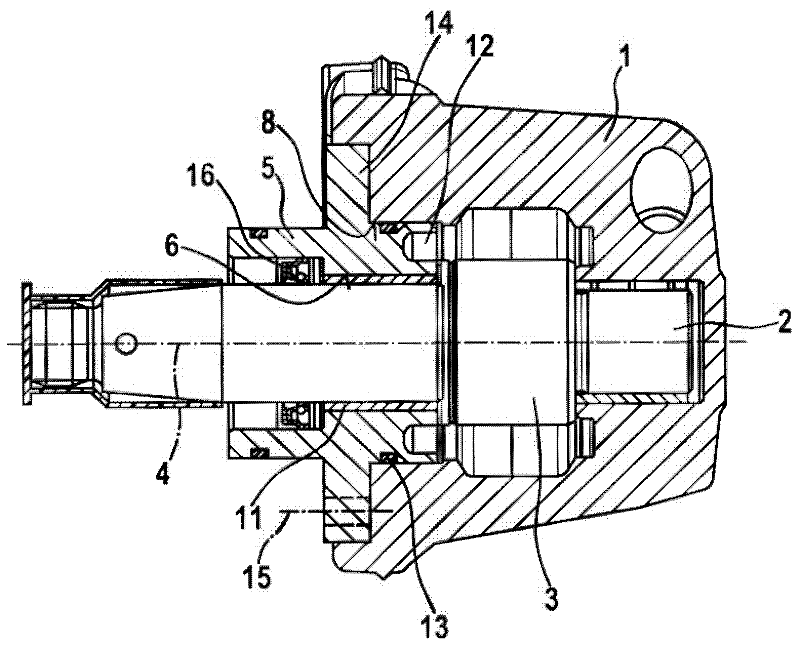

Piston fuel pump for an internal combustion engine

ActiveCN104854341AAvoid wear and tearReduce leakageEngine sealsPositive displacement pump componentsExternal combustion engineEngineering

A piston fuel pump (18) for an internal combustion engine has a pump cylinder (40) and a pump piston (28) received in the pump cylinder (40) so as to be movable. The invention proposes that the pump piston is guided in a radial direction by means of at least a first and at least a second guide section (51, 72), and that the first and the second guide sections are spaced apart from one another in an axial direction, the first guide section being arranged in a pump cylinder of the piston fuel pump and the second guide section being arranged radially outwards in the region of the end section (52) facing the drive (29). The invention further proposes that the piston fuel pump (18) has, at the first guide section (51), a bearing and sealing arrangement (46) for the pump piston (28), which comprises a guide region (48) for the radial guidance of the pump piston (28) in the pump cylinder (40) and a sealing region (50) having a sealing lip.

Owner:ROBERT BOSCH GMBH

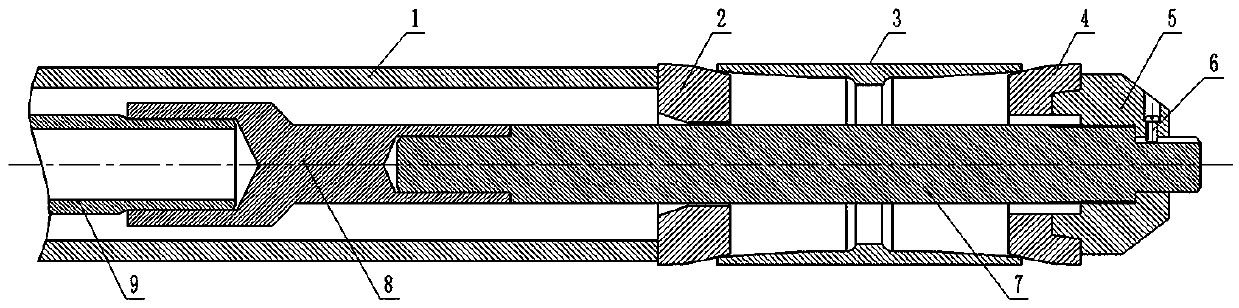

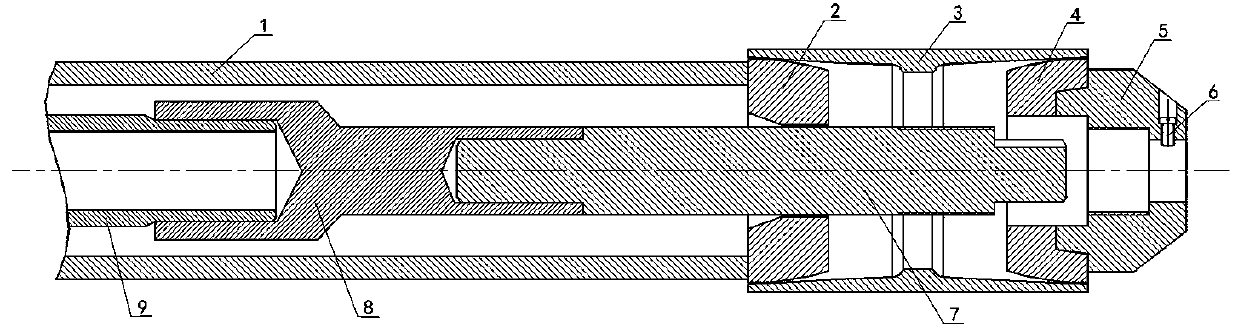

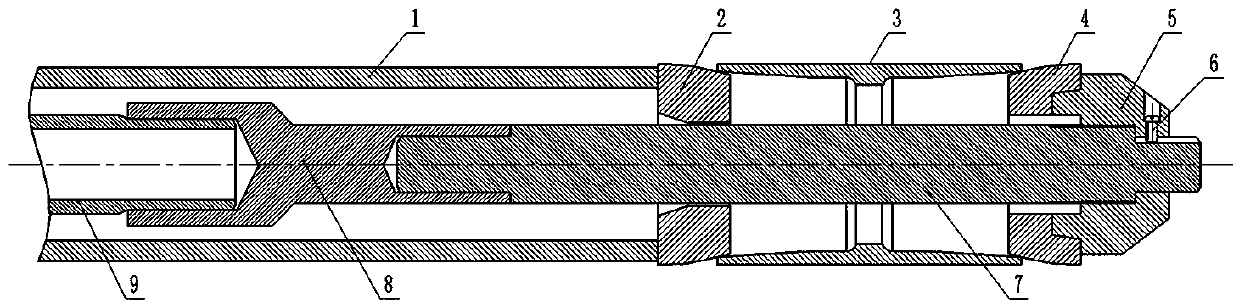

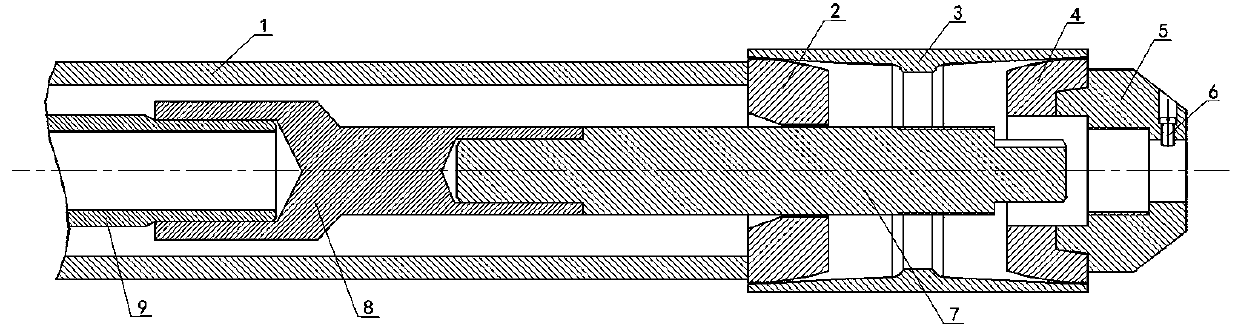

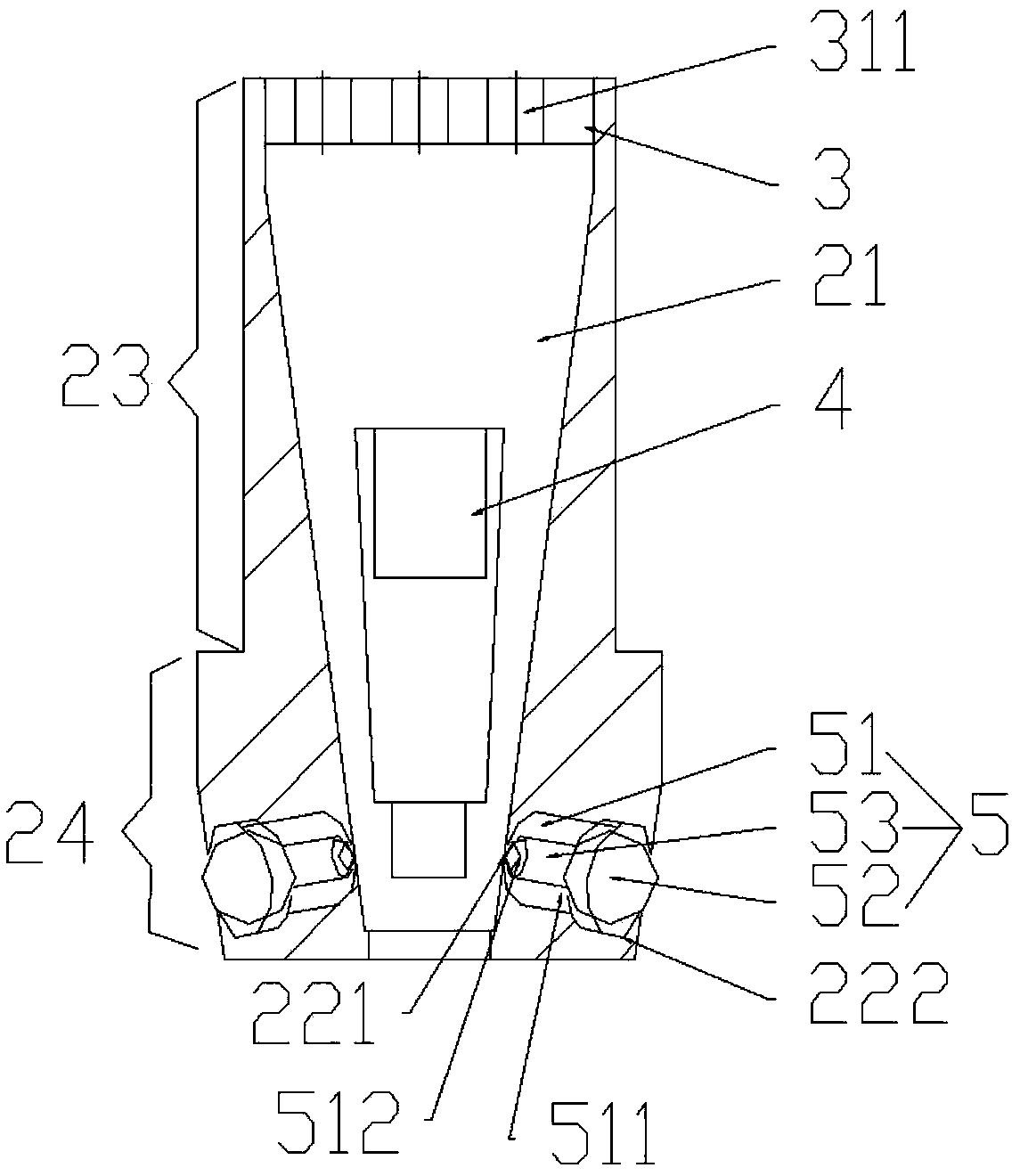

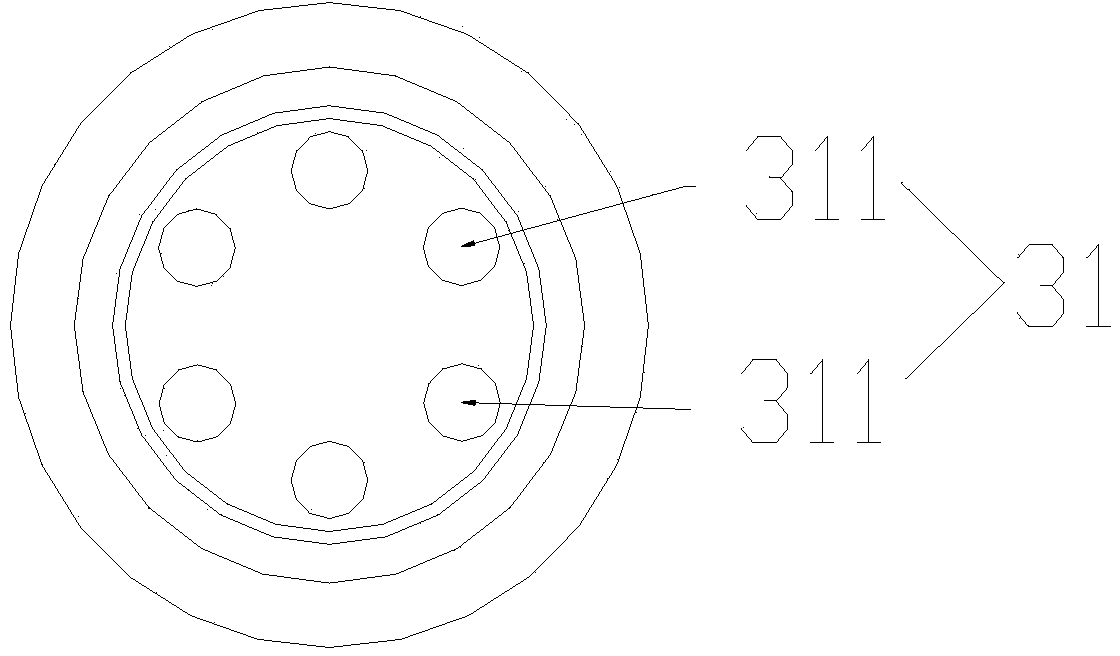

Full-metal soluble bridge plug

ActiveCN110552659AAccurately grasp the dissolution timeReliable anchoringFluid removalSealing/packingEngineeringDissolution

The invention discloses a full-metal soluble bridge plug. The full-metal soluble bridge plug comprises a seat sealing cylinder (1), an upper cone body (2) and a sealing cylinder (3), a lower cone body(4), a lower joint (5), a release rod (7), a conversion joint (8) and a seat sealing rod (9), the lower end of the seat sealing cylinder (1) is attached to the upper end surface of the upper cone body (2), the upper end of the seat sealing cylinder (1) is connected with an externally-arranged seat sealing tool, in the seat sealing barrel (1), the upper end of the conversion joint (8) is connectedwith the lower end of the seat sealing rod (9), the lower end of the conversion joint (8) is connected with the upper end of the releasing rod (7), the lower joint (5) is connected with the releasing rod (7) through threads, the lower joint (5) is connected with the lower cone body (4) through threads, one end of the lower cone body (4) is matched with one end of the sealing cylinder (3) throughthorn teeth, and the other end of the sealing cylinder (3) is matched with the upper cone body (2) through the thorn teeth. The full-metal soluble bridge plug has the characteristics of reliable anchoring, reliable pressure bearing, complete dissolution and the like.

Owner:PETROCHINA CO LTD +1

Sealing ring for sealing aligning roller bearing

InactiveCN106090027AGuaranteed tightnessThere will be no stuck problemEngine sealsBearing componentsRubber ringEngineering

The invention discloses a sealing ring for sealing an aligning roller bearing. The sealing ring comprises a rubber ring and a steel plate ring embedded in the rubber ring; a first bending portion perpendicular to the end face of the steel plate ring is molded on the periphery of the steel plate ring, a second bending portion parallel to the end face of the steel plate ring is molded at the outer end of the first bending portion, a third bending portion bent in the inner side direction of the sealing ring is molded on the inner periphery of the steel plate ring, the outer periphery of the rubber ring is a conical face with the narrow interior and the wide exterior, a gap is molded in the outer periphery of the rubber ring in the axial direction, and a ventilation hole is formed in the position, different from the position of the gap, of the circumference of the inner wall of the rubber ring; the gap and the ventilation hole can ensure that the phenomenon that due to the large interior and exterior pressure difference of the bearing, starting torque of the bearing is large, or the bearing is clamped is avoided, and due to the fact that the gap and the ventilation hole are staggered in position, sealing performance of the bearing can be ensured; an outer seal lip and an inner seal lip form a similarly-herringbone structure, and the sealing function of the bearing can be ensured while the aligning roller bearing carries out aligning.

Owner:DEQING TIANMA BEARING CO LTD

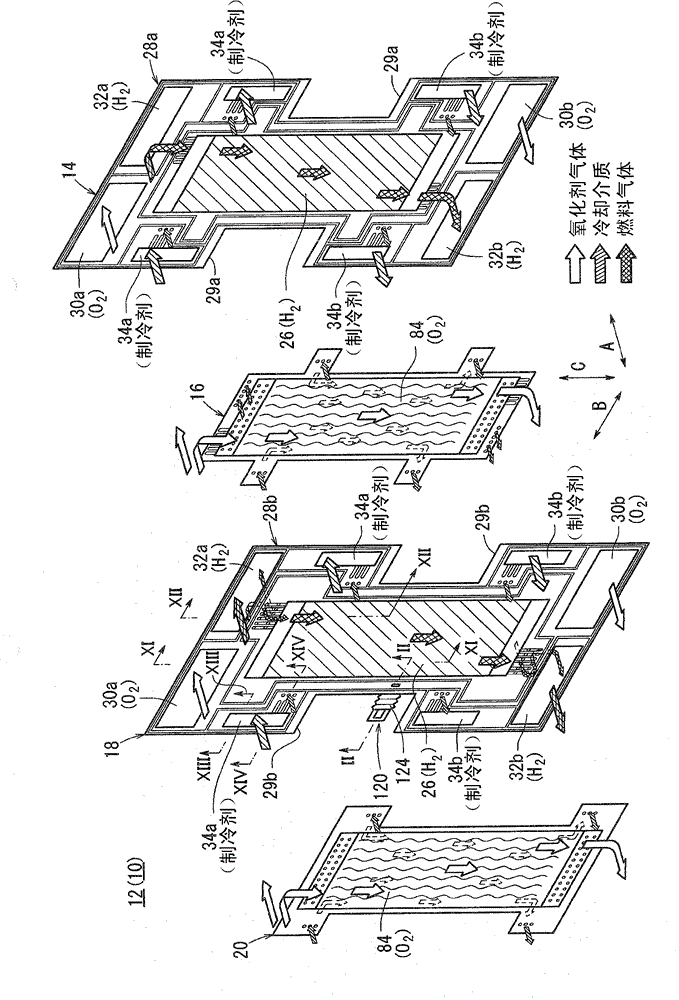

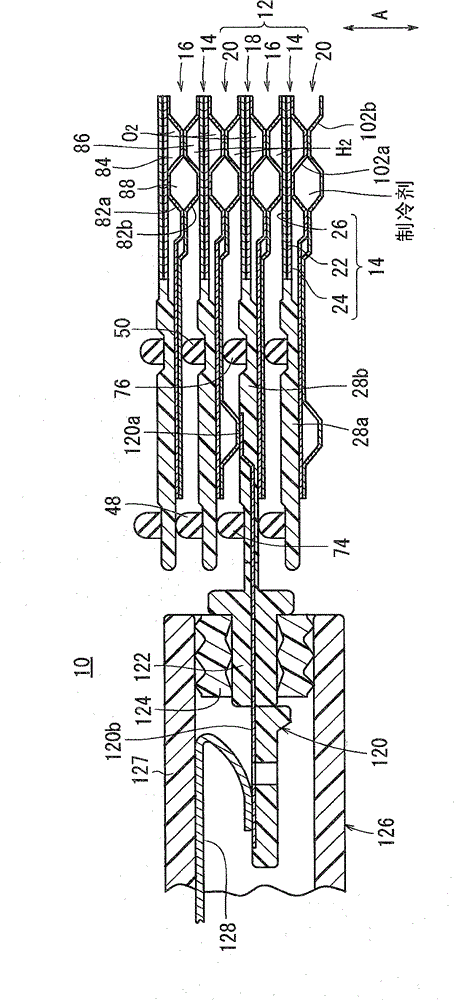

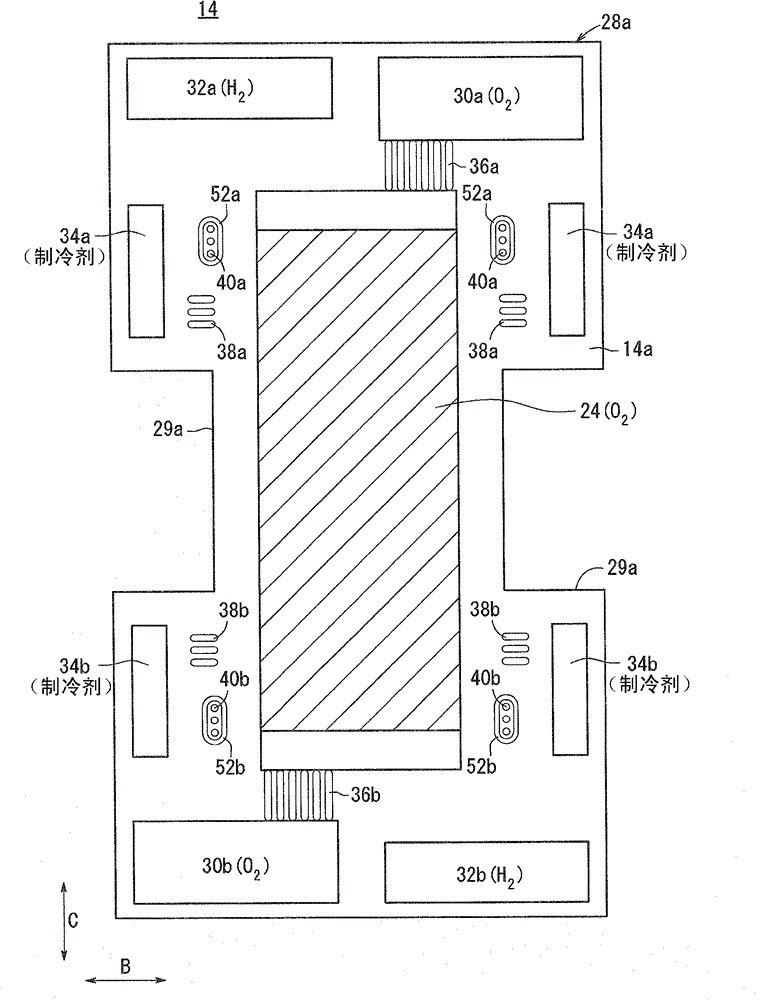

Fuel cell

The invention provides a fuel cell which can prevent the interference of a cell voltage monitor terminal and seal members in a simple structure and can better determine the voltage of cell. The fuel cell (10) includes a first membrane electrode assembly (MEA) (14), a first metal separator (16), a second membrane electrode assembly (MEA) (18), and a second metal separator (20). A frame portion (28a) is arranged on the periphery of the second membrane electrode assembly (MEA) 18, the frame portion (28b) is provided with an inner seal member (76), an outer seal member (74), and a cell voltage monitor terminal embedded at the frame portion (28b). The outer periphery of the second metal separator (20) is configured between the inner seal member (76) and the outer seal member (74), the cell voltage monitor terminal (120) includes an exposed portion (120a) provided between the inner seal member (76) and the outer seal member (74). The exposed portion (120a) is in contact with the metal separator (20) adjacent to the exposed portion.

Owner:HONDA MOTOR CO LTD

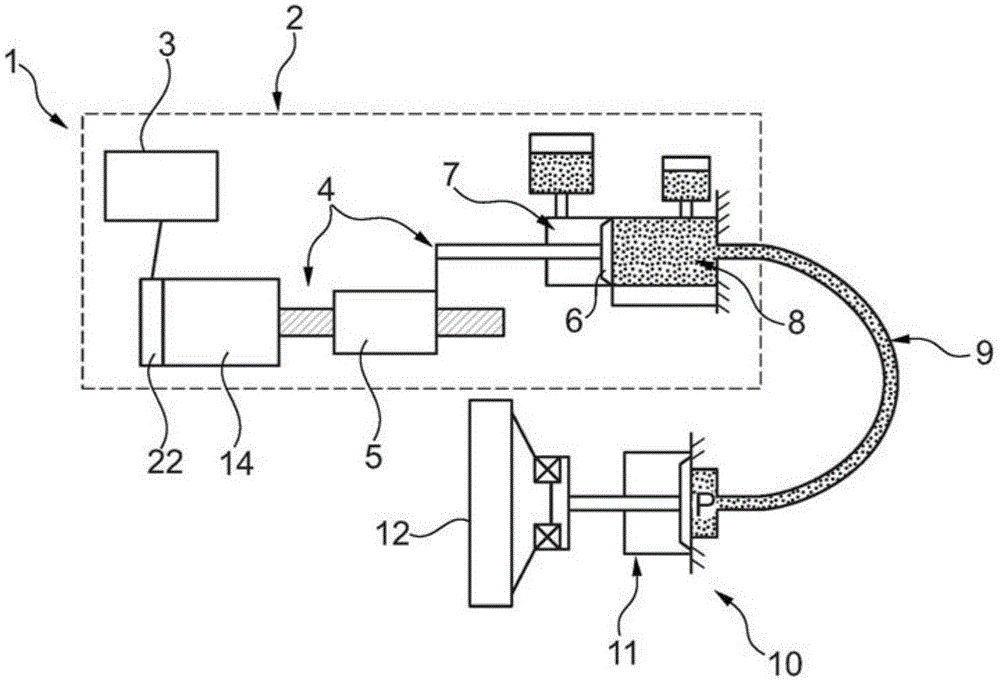

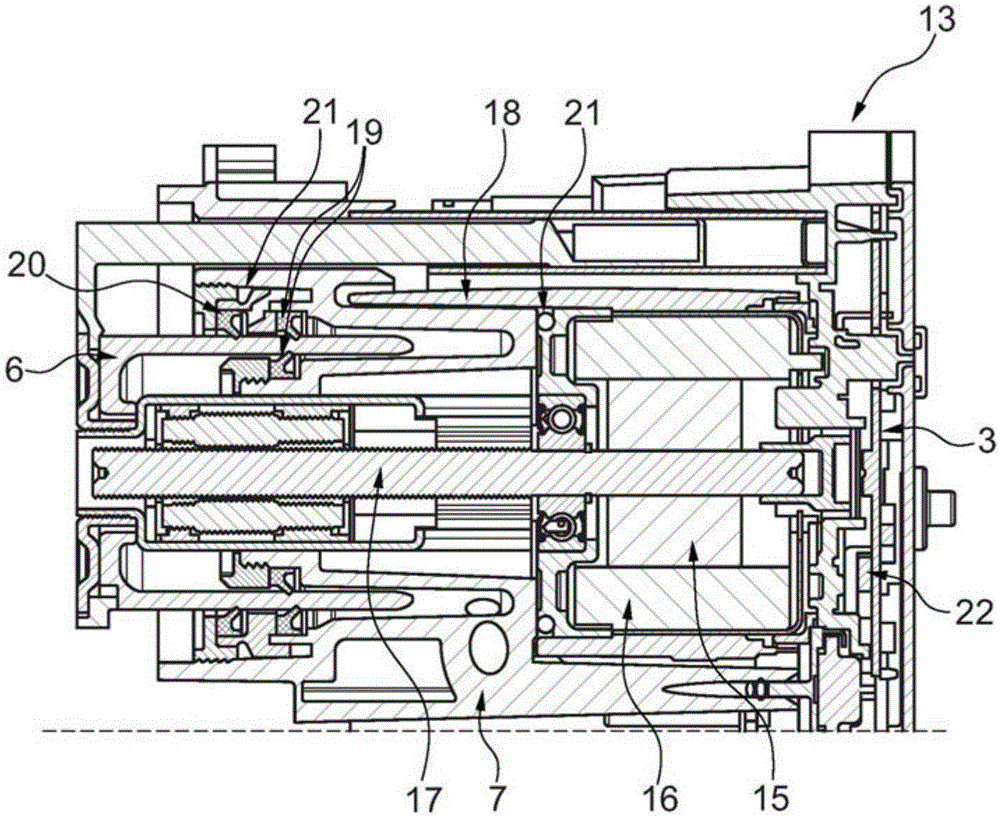

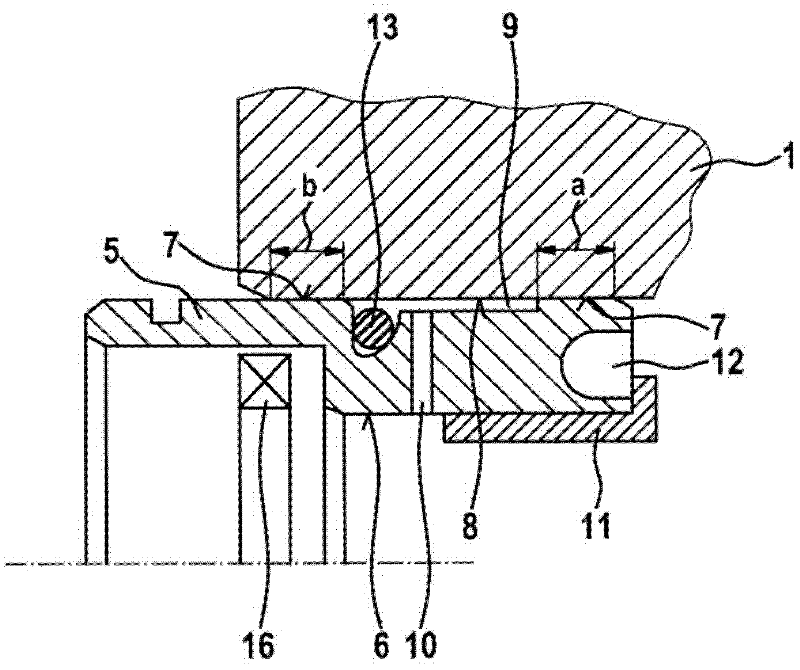

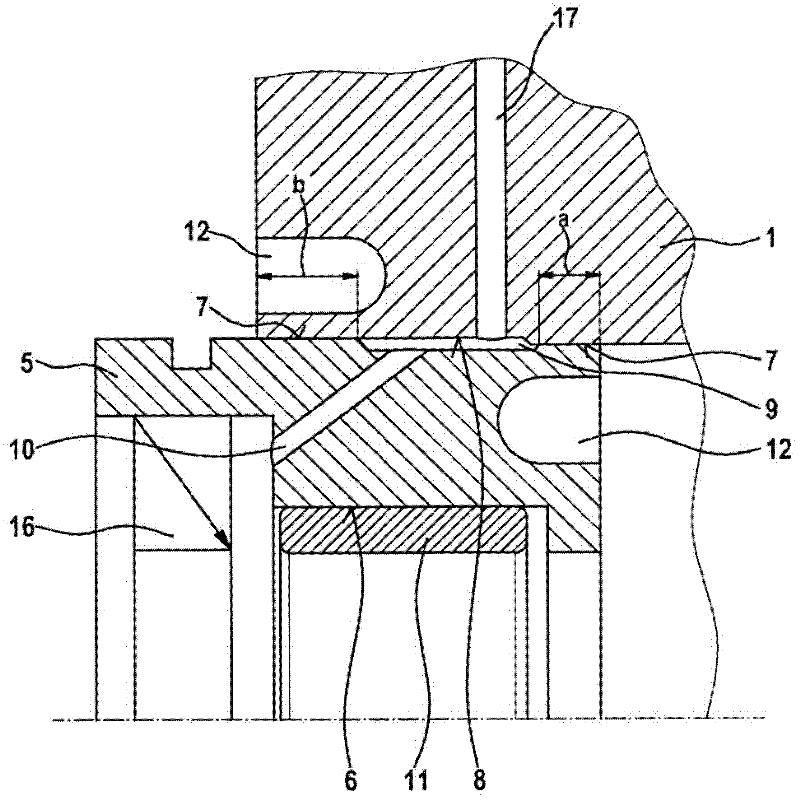

A method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle and a hydrostatic clutch actuator

ActiveCN105370750AIncrease temperatureEnough temperatureFluid actuated clutchesCouplingsElastic componentHydraulic fluid

The invention relates to a method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle, in particular a hydrostatic clutch actuator, in which the hydrostatic actuator (13) comprises a cylinder (7), in which a piston (6) is mounted axially movable , by an electric motor (14) is moved via a transmission (5), whereby a hydraulic fluid (8) in a hydraulic path of the hydrostatic actuator (13) is moved opposite to the area with viscous elastic components (19, 20, 21) is sealed. is the case of a method in which the operation of the hydrostatic actuator over a wide temperature range, at least one viscous elastic component (19, 20, 21) at low outdoor temperatures, and when the ignition of the vehicle is controlled by a current supply of an electrical circuit (22).

Owner:SCHAEFFLER TECH AG & CO KG

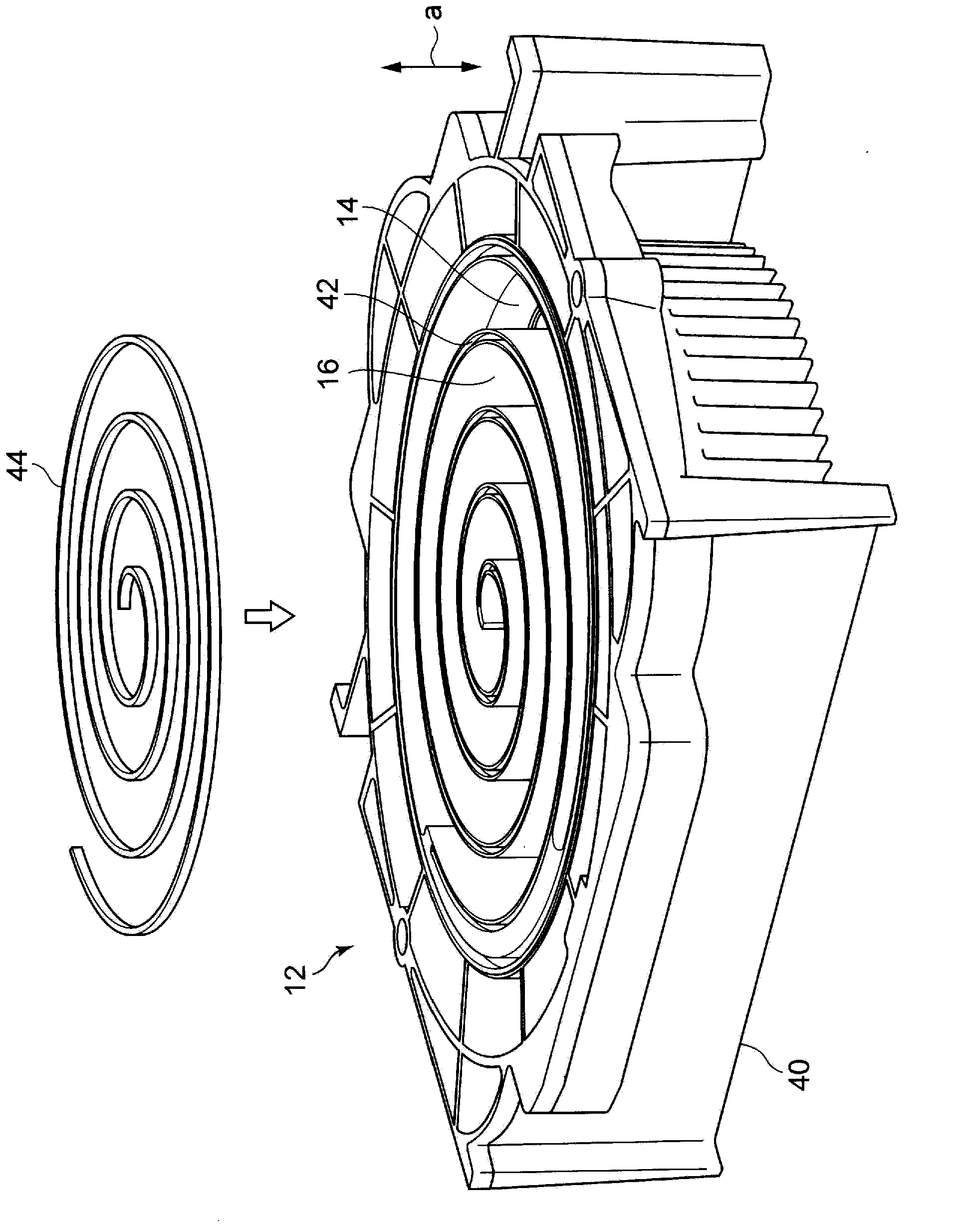

Scroll fluid machine

ActiveCN103388491AInhibit wearAvoid pressingEngine sealsEngine of arcuate-engagement typeMechanical engineering

A seal groove is cut in the distal end face of a wrap of a fixed scroll, with a tip seal being fitted in the seal groove. Swelling members are interposed between both side faces of the tip seal and corresponding opposite side faces of the wrap. Condensed liquid of working medium w and water condensed from steam contained in the working medium w that are present between the tip seal and an end plate provide a sealing effect. When the swelling members swell upon absorbing the condensed liquids, they exert a strong pressing force on the tip seal and the wrap, thereby firmly retaining the tip seal in position. This prevents the tip seal from being pressed against the end plate, so that wear of the tip seal is reduced.

Owner:ANEST IWATA CORP

High-pressure fuel pump

ActiveCN102483017AReduce weightSimple compositionPositive displacement pump componentsFuel injecting pumpsDrive shaftEngineering

The invention relates to a high-pressure fuel pump of an internal combustion engine, comprising a pump housing, in which a drive shaft (2) having a cam or eccentric drive (3) is received and rotatably mounted about a longitudinal drive shaft axis (4) for actuating at least one pump element arranged in the pump housing (1). The pump housing (1) comprises a housing part (5) that has a bearing bore (6) and is connected to the pump housing (1) for receiving and rotatably mounting the drive shaft (2). According to the invention, the housing part (5) is connected to the pump housing (1) by way of a frictional press connection (7), wherein the frictional press connection (7) is formed by the housing part (5) comprising at least one section (a, b) that is radially larger in relation to a recess (8) of the pump housing (1) into which the housing part (5) is inserted.

Owner:ROBERT BOSCH GMBH

Sealing device

ActiveCN104937318AGuaranteed protection functionAvoid deformationEngine sealsRolling contact bearingsForeign matterEngineering

Provided is a sealing device which comprises a sliding lip and a labyrinth lip, the sealing device being configured in such a manner that, even if the labyrinth lip is exposed to foreign matter outside a machine and swells, the deformation of the labyrinth lip is prevented and therefore the sliding lip-protecting function of the labyrinth lip is less likely to be lost. A sealing device is provided with: a sliding lip which performs sealing so that foreign matter outside a machine does not enter the inside of the machine; and a labyrinth lip which makes it less likely that foreign matter outside the machine reaches the sliding lip. The sealing device is characterized in that the front end of the labyrinth lip is provided with a cutout which absorbs the swelling of the labyrinth lip occurring when the labyrinth lip is exposed to foreign matter. Alternatively, the sealing device is characterized in that a second labyrinth lip is provided on the side of the labyrinth lip with which faces the inside of the machine. Alternatively, the sealing device is characterized in that a similar cutout is provided also in the front end of the second labyrinth lip.

Owner:NOK CORP

An all-metal soluble bridge plug

ActiveCN110552659BAccurately grasp the dissolution timeReliable anchoringFluid removalSealing/packingPhysical chemistryMechanical engineering

The invention discloses a full-metal soluble bridge plug. The full-metal soluble bridge plug comprises a seat sealing cylinder (1), an upper cone body (2) and a sealing cylinder (3), a lower cone body(4), a lower joint (5), a release rod (7), a conversion joint (8) and a seat sealing rod (9), the lower end of the seat sealing cylinder (1) is attached to the upper end surface of the upper cone body (2), the upper end of the seat sealing cylinder (1) is connected with an externally-arranged seat sealing tool, in the seat sealing barrel (1), the upper end of the conversion joint (8) is connectedwith the lower end of the seat sealing rod (9), the lower end of the conversion joint (8) is connected with the upper end of the releasing rod (7), the lower joint (5) is connected with the releasing rod (7) through threads, the lower joint (5) is connected with the lower cone body (4) through threads, one end of the lower cone body (4) is matched with one end of the sealing cylinder (3) throughthorn teeth, and the other end of the sealing cylinder (3) is matched with the upper cone body (2) through the thorn teeth. The full-metal soluble bridge plug has the characteristics of reliable anchoring, reliable pressure bearing, complete dissolution and the like.

Owner:PETROCHINA CO LTD +1

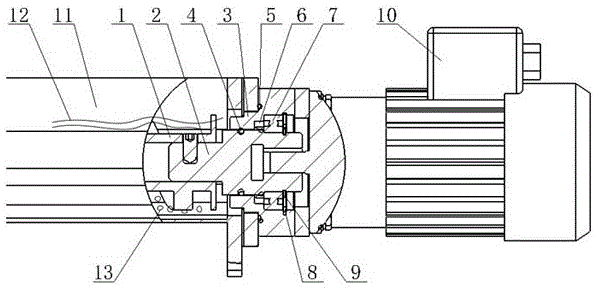

Spiral conveyer sealing device

The invention discloses a spiral conveyer sealing device. The spiral conveyer sealing device is characterized in that a bearing base is fixed in a hole at the right end of a spiral groove body; the left end of the bearing base is a step-shaped structure; a first step surface is contacted with a right end surface of the spiral groove body; a large O-shaped sealing ring is fixed in a groove in the first step surface of the bearing base; a lip-shaped sealing ring and a bearing are mounted in the bearing base; the lip-shaped sealing ring is near a spiral rod end; an elastic retainer ring for hole is mounted in the bearing base; a connecting shaft penetrates through the bearing base and the bearing, one end thereof is connected with a spiral rod, and the other end is connected with a motor, so that the spiral rod and the motor are connected as a whole through the connecting shaft; the connecting shaft is fixed in the bearing base through a contact part at the left end of the bearing base and an elastic retainer ring for shaft at the right end of the bearing base; and a small O-shaped sealing ring is fixed in a groove formed in the contact surface, corresponding to the contact part of the bearing base, of the connecting shaft. The spiral conveyer sealing device has the beneficial effects of solving the problem of outward flowing of cutting liquid in the use process, improving the reliability of the sealing device and prolonging the service life of the sealing device.

Owner:共享机床辅机(大连)有限公司

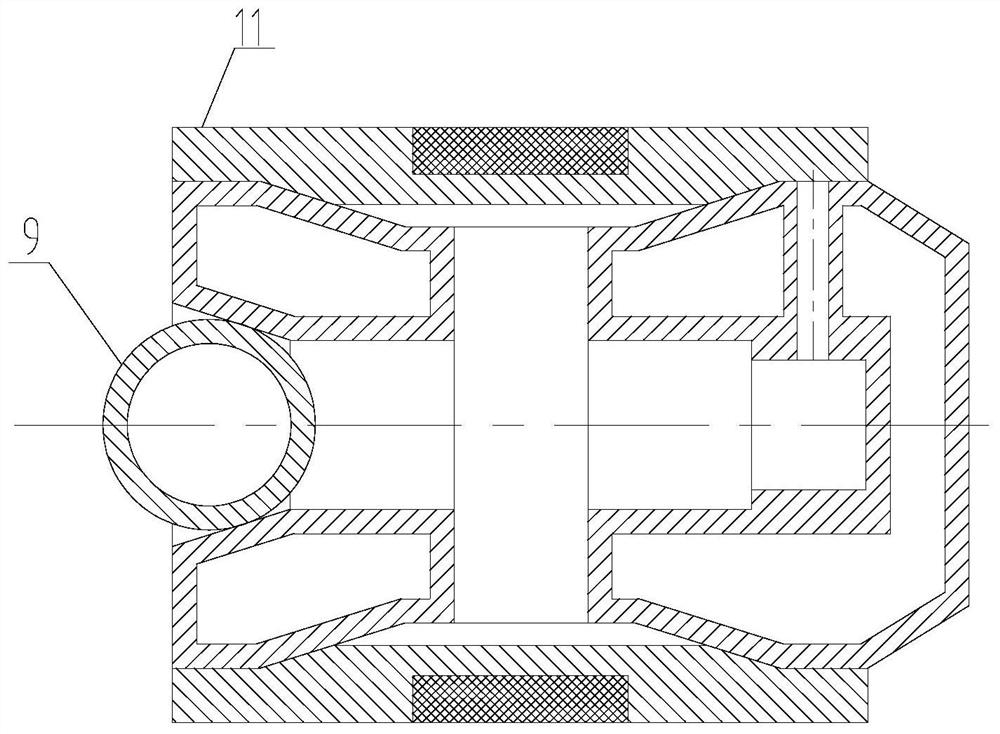

Novel air-inflation-preventing gas valve

InactiveCN103672141AAvoid damage and deformationGuaranteed sealing functionContainer filling methodsContainer discharging methodsEngineeringLiquid gas

The invention discloses a novel air-inflation-preventing gas valve. The novel air-inflation-preventing gas valve comprises a valve body and a valve element, wherein the valve body is provided with an inflation inlet, the valve element is matched with the valve body, and the two ends of the valve element are open; a poking preventing component arranged in the valve element is provided with a first guide hole communicated with the inflation inlet; a second guide hole communicated with the first guide hole is formed in the valve element, and a sealing part making the second guide hole be sealed or through is arranged in the second guide hole. According to the novel air-inflation-preventing gas valve, the poking preventing component is adopted, the first guide hole is formed in the poking preventing component and located above the sealing part, it is prevented that the first guide hole is damaged by the sealing part to deform, the sealing part is separated from the inside the second guide hole, and the sealing function of the sealing part is lost, and the sealing function of the sealing part is guaranteed. Therefore, the phenomenon of air inflation of a liquefied gas steel cylinder can be prevented under the condition that a liquefied gas inflation gun matched with a liquefied gas steel cylinder gate valve is not used.

Owner:汪琪

Composite soluble bridge plug

The invention provides a composite soluble bridge plug, and relates to the technical field of oil field downhole tools. The lower end of a setting cylinder is attached to the upper end face of an upper cone, the lower end of a setting rod is in threaded connection with a releasing rod, and the releasing rod is connected with a lower cone through a shear pin; and the upper cone, the lower cone and a fracturing ball are all of hollow structures, and the wall thickness of the hollow outer portions is approximately equal to that of a sealing cylinder. The composite soluble bridge plug has the advantages that the upper cone, the sealing cylinder, the lower cone and the fracturing ball are all made of magnesium-based alloy materials, the wall thicknesses of the hollow structures are the same, the dissolution rate and the dissolution time under the same environment condition are the same, and complete dissolution can be achieved in the later period; and an alloy coating is sprayed to the outer portion of the sealing cylinder, the outer surface of the sealing cylinder and the inner wall of a casing pipe are reliably anchored, sealing is achieved through a sealing ring, the fracturing ball seals the upper pressure, the lower cone of a blind plugging structure seals the pressure of the lower stratum, bidirectional sealing is achieved, and meanwhile fine particles are formed after dissolution and discharged along with flowback fluid.

Owner:DAQING TIANDEZHONG PETROLEUM SCI & TECH CO LTD

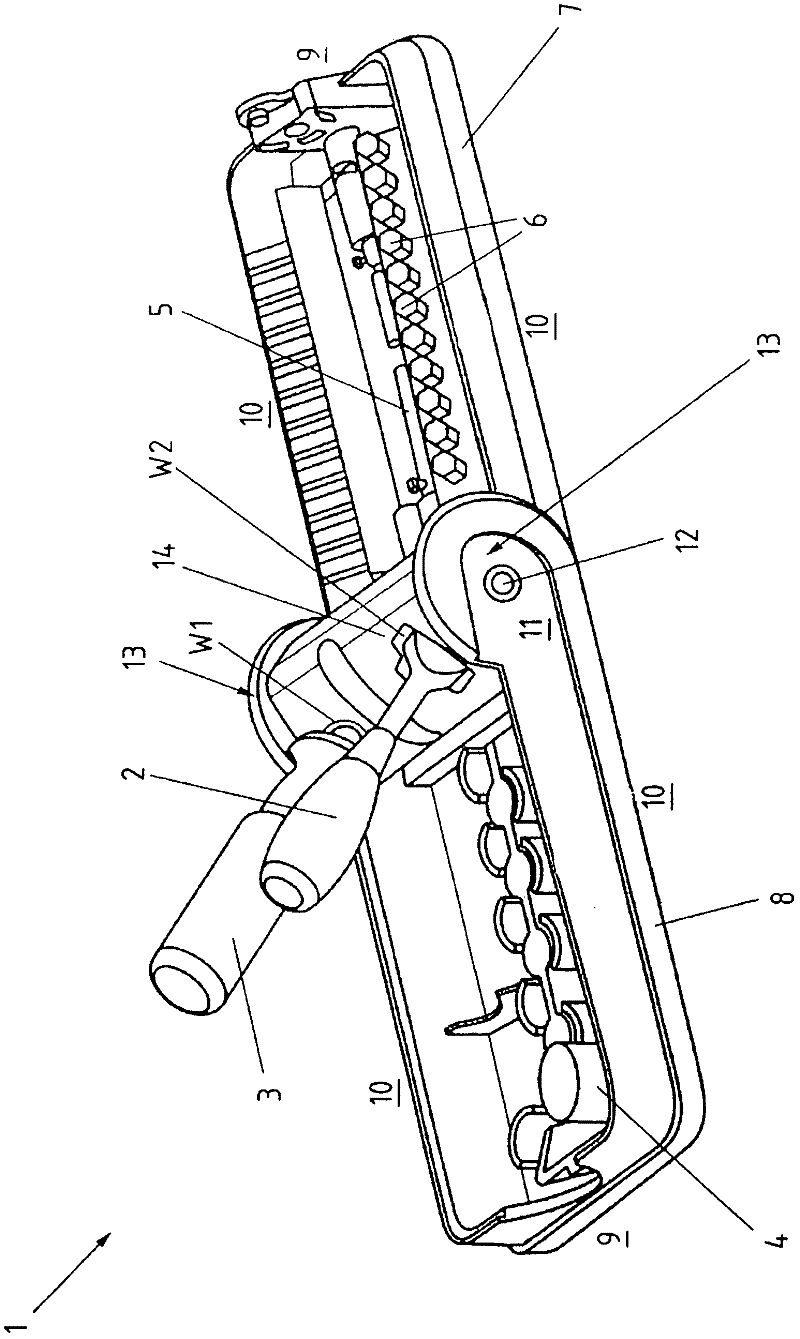

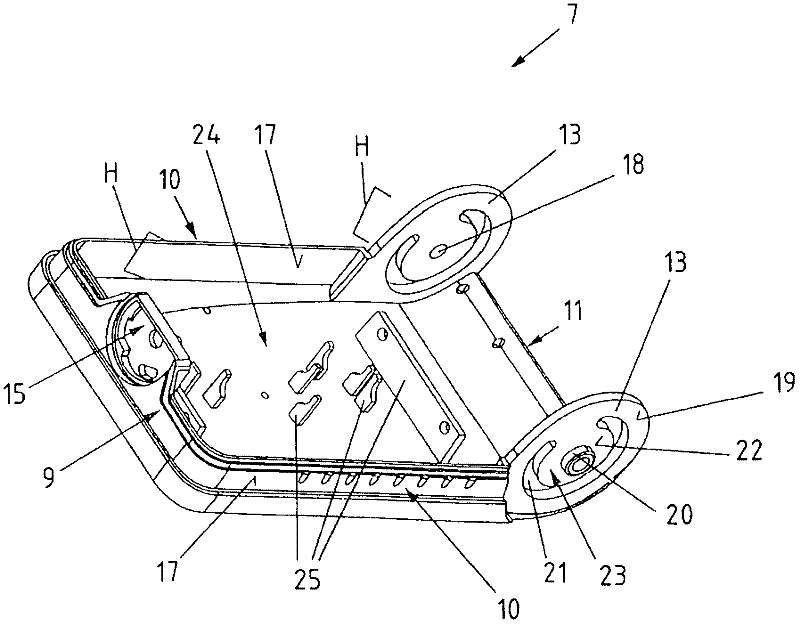

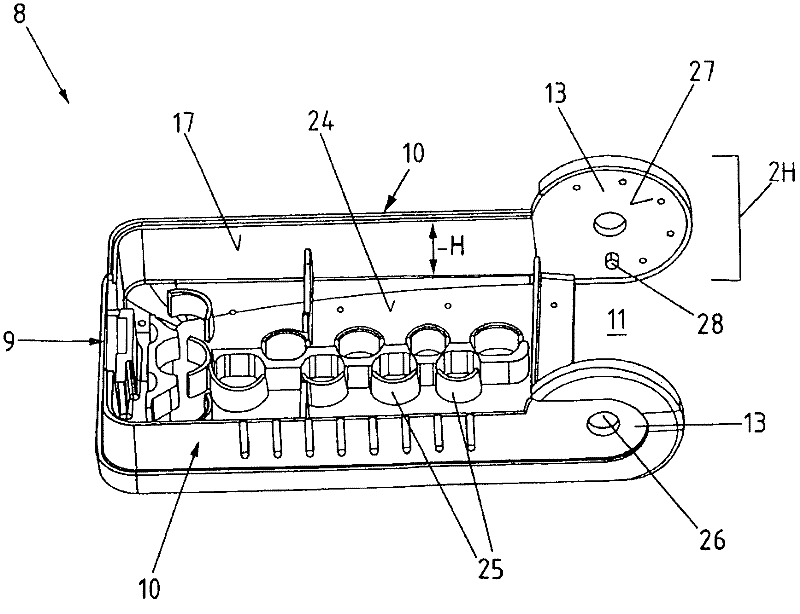

Ratchet box with set-up function

Owner:HAZET WERK HERMANN ZERVER

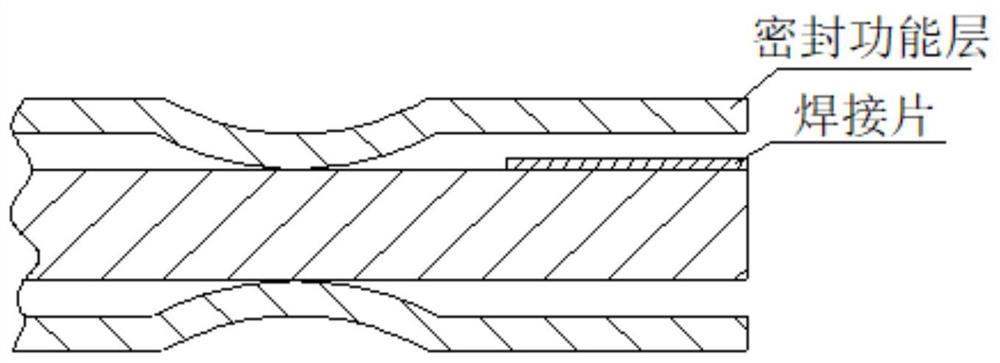

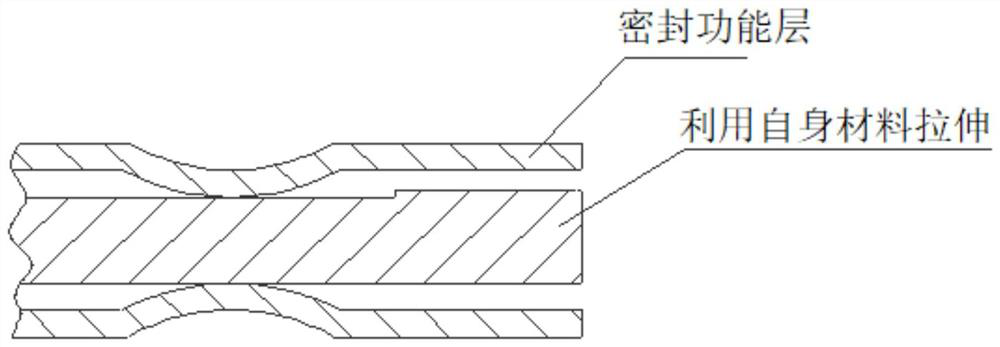

Limiting method for cylinder opening part of cylinder gasket

InactiveCN112128014AImprove efficiencyHigh strengthSealing arrangements for enginesMachines/enginesEngineeringFuel gas

The invention provides a limiting method for a cylinder opening part of a cylinder gasket. The limiting method for the cylinder opening part of the cylinder gasket comprises the following steps: a) arranging an adjusting plate between two sealing function layers, and thinning and stretching the adjusting plate at the cylinder opening part; and hemming the stretched material, filling the hemmed material into the cylinder opening part, and flattening to form a limiting layer, so as to realize that the self material taking of the adjusting plate forms a limiting height difference at the cylinderopening part; wherein the adjusting plate is a soft cold-rolled plate. Compared with the prior art, the limiting method is based on the middle adjusting plate made of the specific material, the thinning and stretching technology is adopted, and a laser welding machine and extra welding materials do not need to be added, so that the cost is remarkably reduced; and moreover, the limiting method is high in efficiency and strength, the limiting layer and a body are integrated, no gap exists between the limiting layer and the body, and an impact of high-pressure fuel gas can be blocked, so that thelimiting function is guaranteed, and finally sealing with excellent stability is achieved.

Owner:长春蓝天密封技术开发有限公司

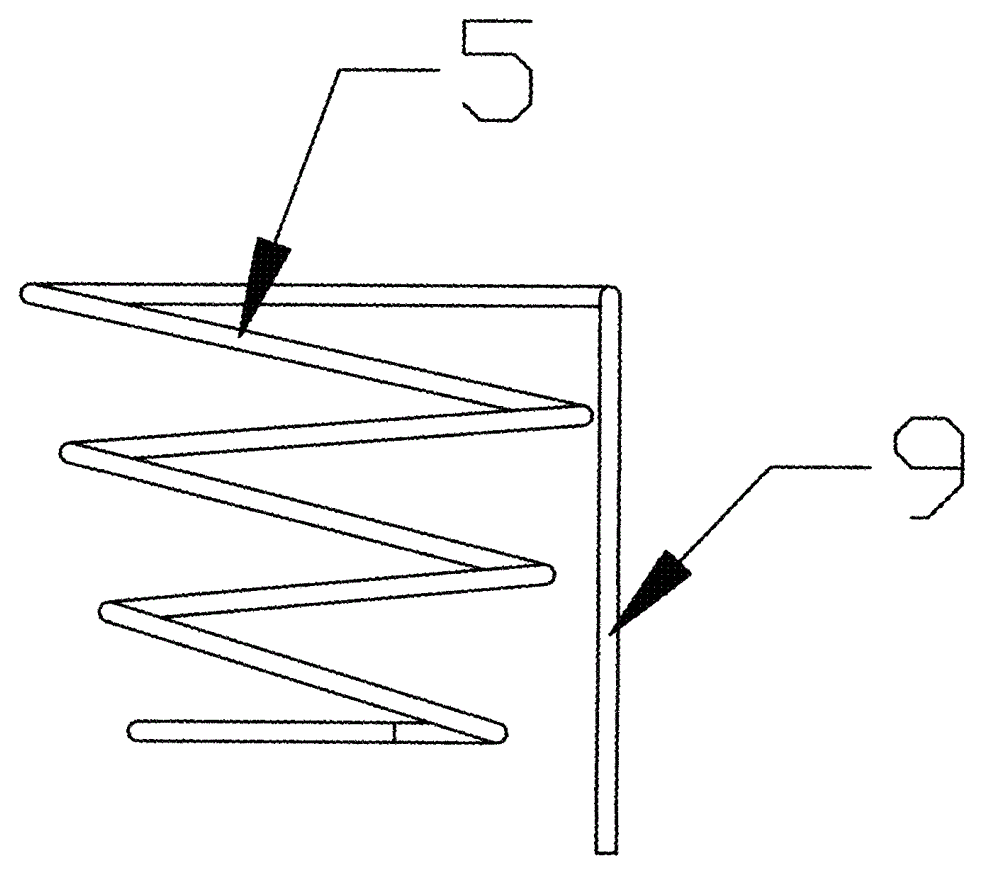

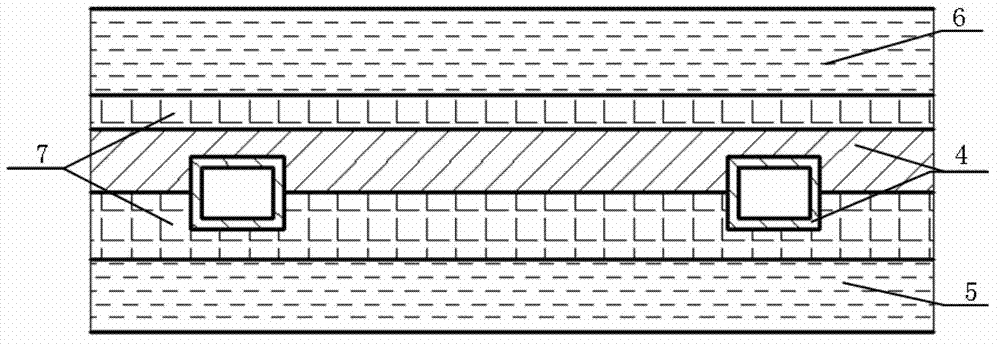

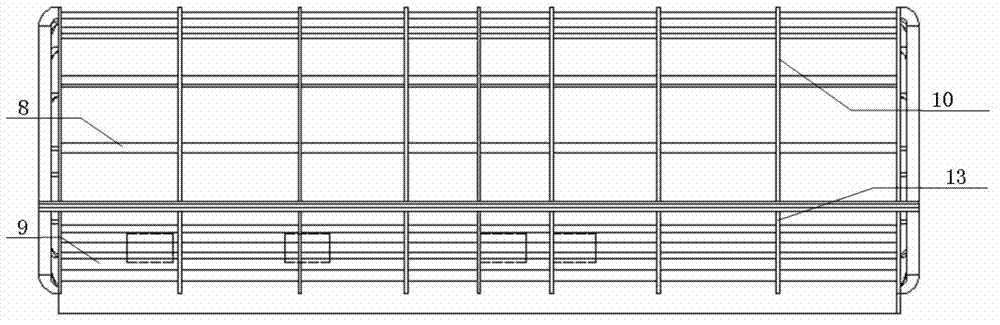

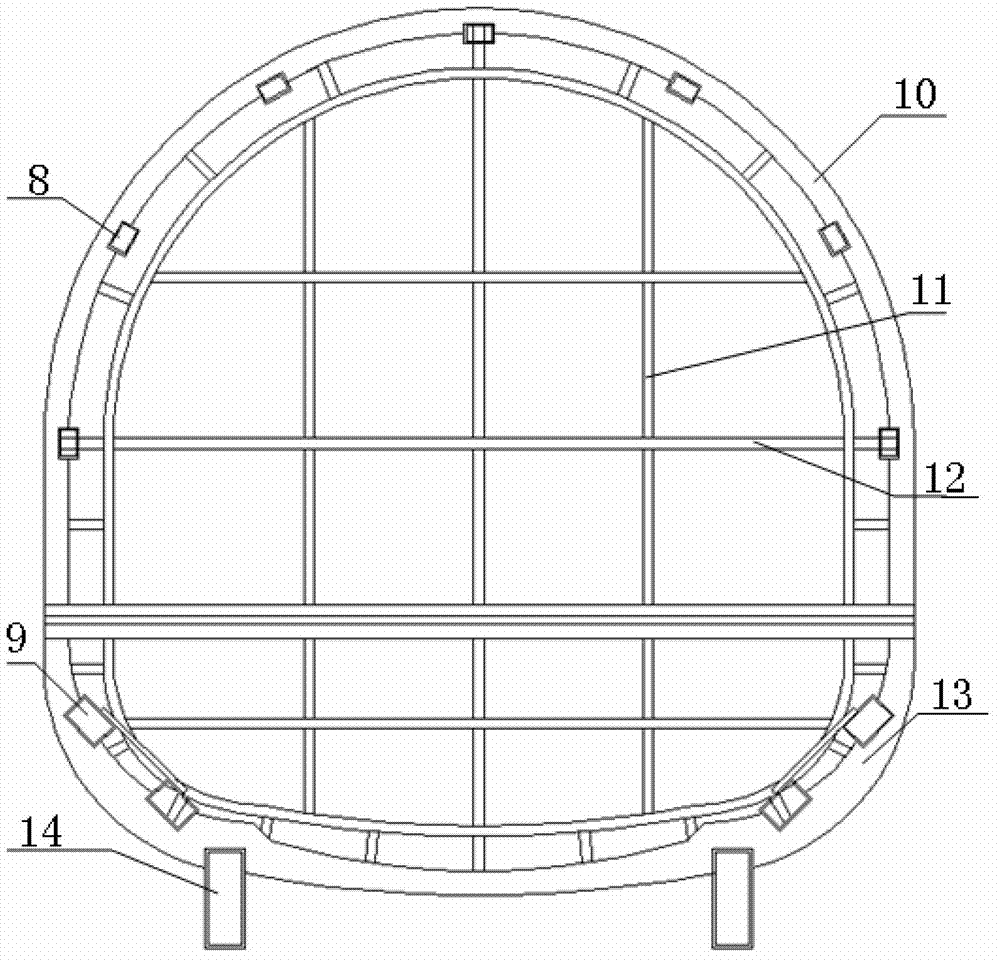

Engine packaging box with sealing function

InactiveCN102951372AHumanized structure designHigh protection levelPackaging vehiclesDomestic cooling apparatusHigh humidityMetal framework

The invention relates to an engine packaging box with a sealing function, which comprises a box body (1), a fixed bracket (2) and a damping device (3), wherein the box body (1) comprises a box bottom (9) and a box cover (8) which are connected by a hasp; the fixed bracket (2) is arranged in the box body (1); the damping device (3) is arranged between the fixed bracket (2) and the box body (1); the box body (1) comprises a metal frame (4), a glass reinforced plastic inner layer (5), a glass reinforced plastic outer layer (6) and a thermal insulating layer (7); the glass reinforced plastic inner layer (5) is arranged inside the metal frame (4); and the thermal insulating layer (7) and the glass reinforced plastic outer layer (6) are arranged on the outer layer of the metal frame (4) from near position to far position. The engine packaging box with the sealing function, which is specially provided by the invention, has a humanized structural design; the protection level can be improved, so that the packaging box can be used for storing and transporting aircraft engines in various harsh environments (such as high temperature, high humidity and high salt mist) without being limited by the environmental conditions.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Seal ring

ActiveCN102494133BImprove reliabilityGuaranteed sealing functionEngine sealsFlanged jointsProduct gasEngineering

Owner:CRRC SHANDONG CO LTD

Valve

InactiveCN105683635AWill not overflowShort timeEngine sealsServomotor componentsMechanical engineering

Owner:FESTO AG & CO KG

Comman and signal device

InactiveCN103682996ASimplifies subsequent assembly stepsThe role of facet extrusionContact mechanismsSubstation/switching arrangement detailsPinionScrew thread

The invention relates to a command and signal device comprising an operation piece (1) and a retaining device (4) for fixing the operation piece (1), and also relates to a method for mounting or dismounting the command and signal device. The operation piece has a cylindrical base body (3). The command and signal device is characterized in that the cylindrical base body (3) of the operation piece (1) is embedded into a gear (6) having screw threads and is connected with a pinion (7) for action, and the final fixation of the operation piece (1) in the retaining device (4) is achieved via the pinion.

Owner:SIEMENS AG

Seal assembly for a turbine engine comprising means for lubricating a brush seal

ActiveUS20160116068A1Good curative effectReducing or even preventing wear on the bristles of such brushesEngine sealsGas turbine plantsBristleEngineering

An assembly forming a seal for a turbine engine, comprising a brush seal formed by a plurality of sealing bristles surrounding a core, a retaining cap comprising a portion at least partially housing the brush seal, and a support cover placed in contact with the brush seal in order to hold it in position against the retaining cap, the brush seal being situated between the retaining cap and the support cover. The support cover comprises a structure for lubricating the bristles of the brush seal, comprising an opening for collecting lubricating oil, a lubricating oil distribution groove connected to the opening, and at least one channel for flow of lubricating oil towards the bristles of the brush seal, connected to the groove.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Anti-sticking gasket of hydraulic station of lifting machine

The invention discloses an anti-sticking gasket of a hydraulic station of a lifting machine. The anti-sticking gasket of the hydraulic station of the lifting machine comprises a gasket body. Anti-sticking layers are arranged on the two side faces of the gasket body. Each anti-sticking layer comprises base cloth. The base cloth is glass fiber cloth and other chemical fiber or plant fiber cloth. Thebase cloth is coated with anti-sticking coating. The anti-sticking coating is PTFE resin or other teflon materials. The anti-sticking layers are connected with the gasket body through adhesive layers. The adhesive layers are silica gel adhesive layers made of silicon material adhesive. By the adoption of the anti-sticking gasket of the hydraulic station of the lifting machine, the seal function of the gasket can be guaranteed, and the anti-sticking gasket can be repeatedly used.

Owner:东台市富康机械有限公司

Flange joint

The invention discloses a flange joint, which comprises two joint bodies, two flange bodies and a seal ring, wherein the end faces of the two joint bodies are opposite; a circular hole is arranged at the middle in the axial direction of each joint body; a boss is arranged in the direction of the outer circumference of the joint body; the bosses are near the respective end faces of the two joint bodies; a ring groove is arranged between the two joint bodies; a seal element is arranged in the ring groove; the end faces of the two flange bodies are opposite; the middles of the two flange bodies are respectively provided with a circular hole; annular locking grooves matched with the bosses are arranged in the circular holes; the bosses of the two joint bodies are locked in the locking grooves of the two flange bodies; the two flange bodies are fixed together through a connecting piece; the joint bodies are provided with a plurality of vent grooves for enabling the circular holes to be communicated with the ring groove; the cross section of the seal ring is in a stepped E shape; the seal ring comprises a ring body, a big outer ring surface and a small outer ring surface; the inner side of the ring body is provided with a gap extending along the circumferential direction; the big outer ring surface and the small outer ring surface are respectively formed at both sides in the circumferential direction of the gap; and the radial width of the big outer ring surface is greater than that of the small outer ring surface. In the flange joint disclosed by the invention, when the seal dual face of the joint deforms or a fastener looses to generate an abnormal seal, under the pressure of seal gas, extending deformation is generated on a seal layer to form a new seal at the position of a sealed gap, and thereby, an effect of automatic seal compensation is achieved.

Owner:CRRC SHANDONG CO LTD

Multi-part vehicle wheel with a seal

PendingCN112020442AStable and undisturbedReduce risk of damageRimsWheel manufactureClassical mechanicsEngineering

Owner:ACTION COMPOSITES HIGHTECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com