Anti-sticking gasket of hydraulic station of lifting machine

A technology of anti-stick gasket and hydraulic station, which is applied in the direction of mechanical equipment, engine components, engine sealing, etc., can solve the problems of increased equipment cost, gasket tearing, equipment maintenance time and cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

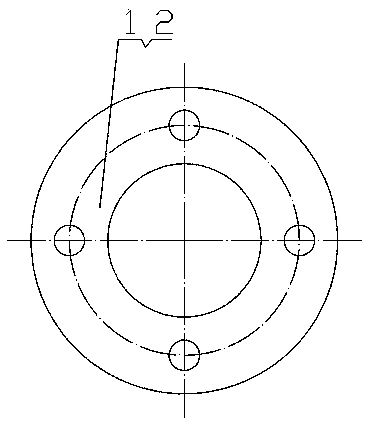

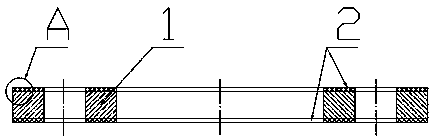

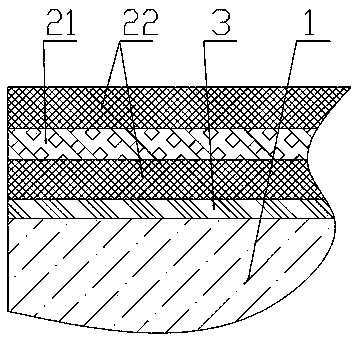

[0016] exist figure 1 , figure 2 and image 3 In the shown anti-stick gasket of the hydraulic station of the hoist, the gasket body 1 is an asbestos rubber gasket, which is in the shape of a circular sheet, and of course it can also be a rectangular ring or any other ring-shaped sheet. . The upper and lower sides of the gasket body 1 are provided with an anti-adhesive layer 2, the anti-adhesive layer 2 is connected to the gasket body 1 through an adhesive layer 3, and the adhesive layer 3 is a silicone adhesive layer formed by using silicon material adhesive; Adhesive layer 2 comprises base cloth 21, and base cloth 21 is glass fiber cloth, is coated with release coating 22 on base cloth 21, and release coating 22 is PTFE resin, and the thickness of release layer 2 is between 0.1 millimeter to 0.4 millimeter. between.

[0017] The above only lists some specific embodiments of the present invention, but the present invention is not limited thereto, and more improvements and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com