Flange joint

A flange joint and flange technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems affecting railway transportation safety, leakage and leakage of sealing rings and joint bodies, and achieve automatic Compensate for sealing effect, improve reliability, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above subject of the present invention is limited to the following embodiments.

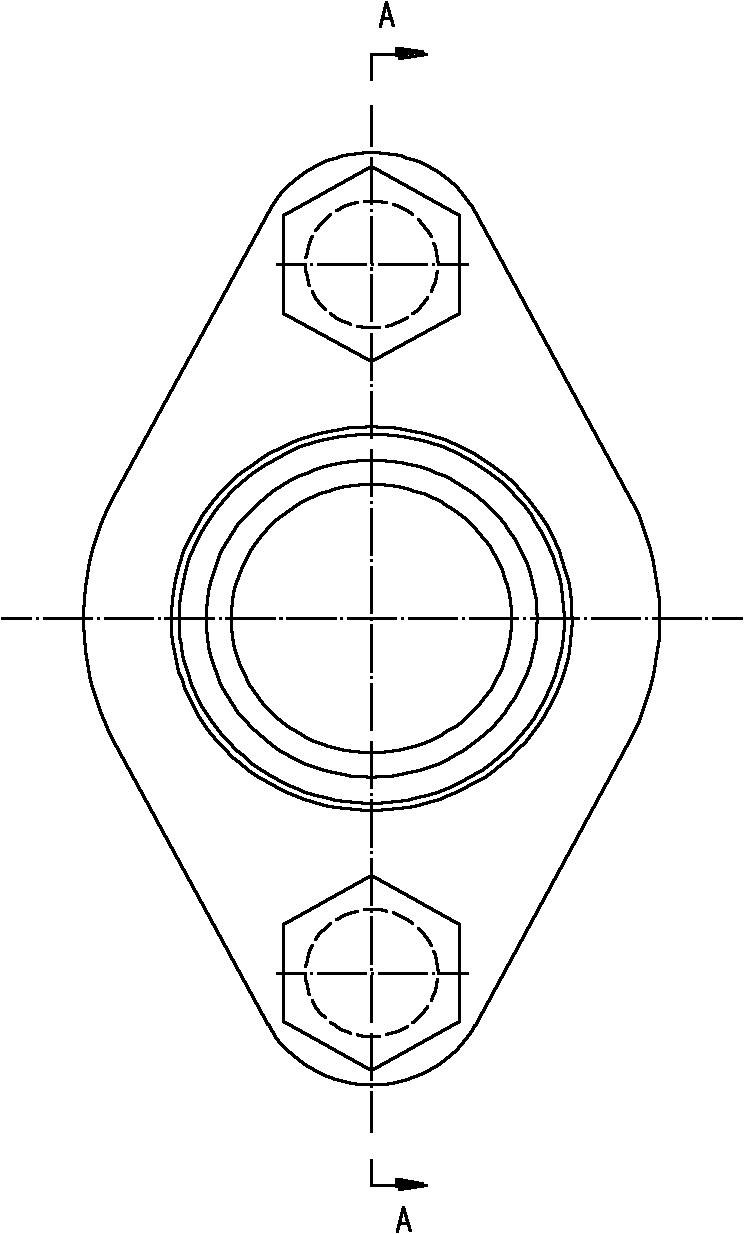

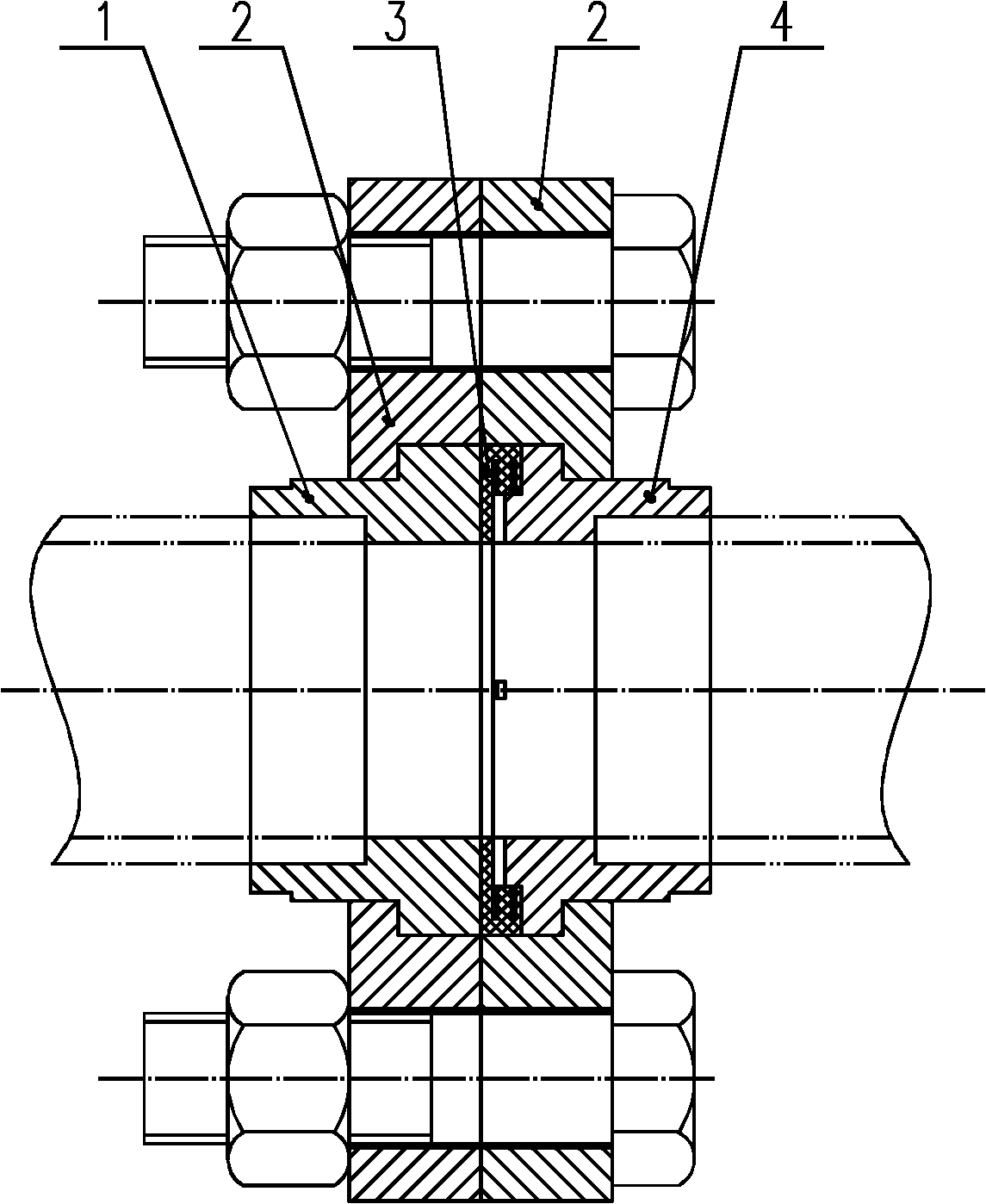

[0035] Such as figure 1 , figure 2 As shown, the flange joint includes two joint bodies: joint body I1 and joint body II4 respectively, two flange bodies 2, sealing ring (rubber sealing ring 3) and bolts and nuts for fixing the two flange bodies 2 .

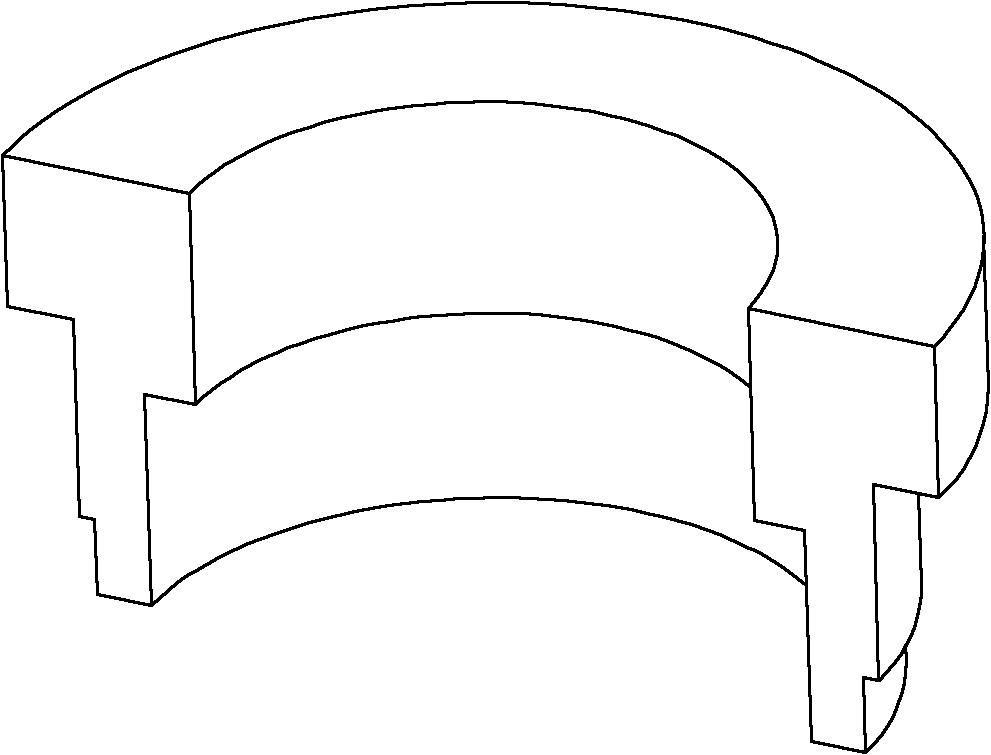

[0036] Such as image 3 As shown, the joint body I 1: there is a circular hole in the middle of the axial direction, and a boss is provided in the outer circumferential direction, and the boss is close to its respective end face, and the opposite end face of the joint body is a smooth plane; the circular hole is axially in the middle The inner side away from the end face is provided with a groove for installing the pipe, so that the section of the circular hole along the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com