Valve

A valve sleeve and valve core technology, applied in the field of valves, can solve problems such as the troublesome manufacturing process of the single-piece sealed shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Unless otherwise stated, the following explanations apply to all embodiments.

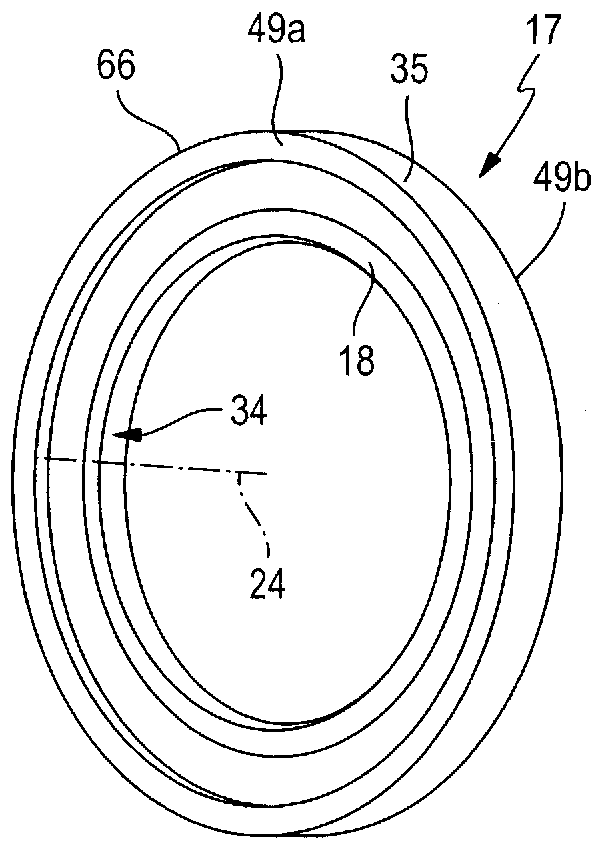

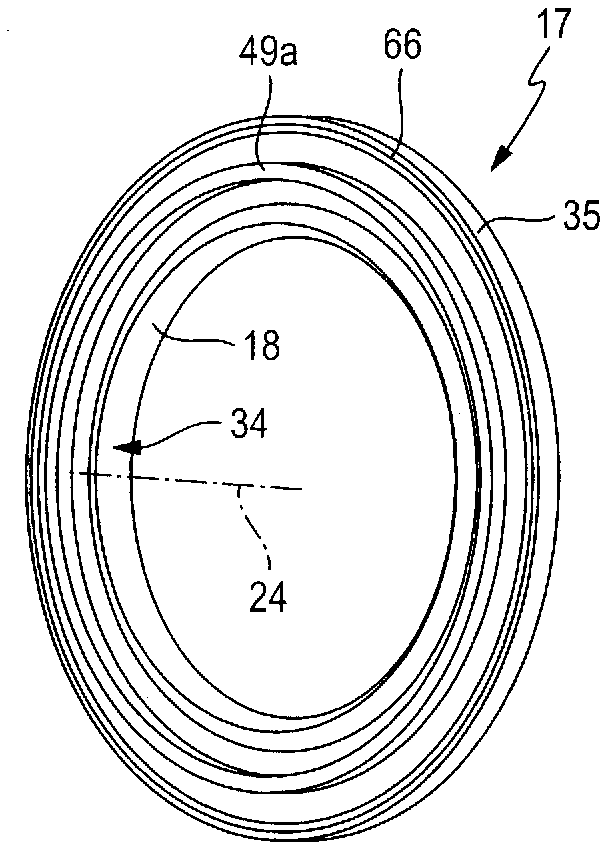

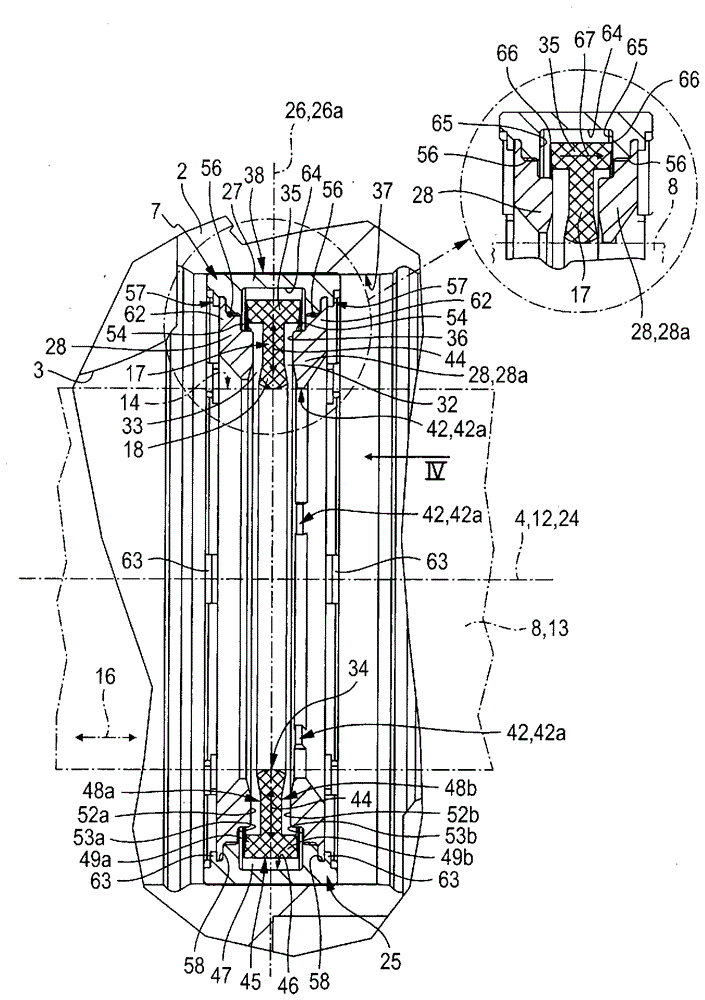

[0034] The valve indicated overall by the reference numeral 1 preferably has the design as a multi-way valve and has a valve housing 2 in which a recess 3 having a linear elongated, preferably cylindrical contour, is formed. The recess 3 has an imaginary central longitudinal axis 4 which is outlined with a dash-dotted line.

[0035] A plurality of valve channels 5 , which pass through the valve housing 2 , open into the recess 3 at locations axially spaced from one another in the periphery. Between the gap section 6 of the gap 3 that communicates with a corresponding one of the valve passages 5, a corresponding sealing ring 7 with a special structure is placed in the gap 3, and further The structure of the sealing ring is discussed. In any case, preferably a plurality of sealing rings 7 having a coaxial arrangement and an axial spacing from one another are arranged in the recess 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com