Piston fuel pump for an internal combustion engine

A piston type and fuel pump technology, which is applied to fuel injection pumps, parts of pumping devices for elastic fluids, fuel injection devices, etc., can solve problems such as cylinder honing, reduce oil leakage, improve fatigue strength, Reduces the effect of axial tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

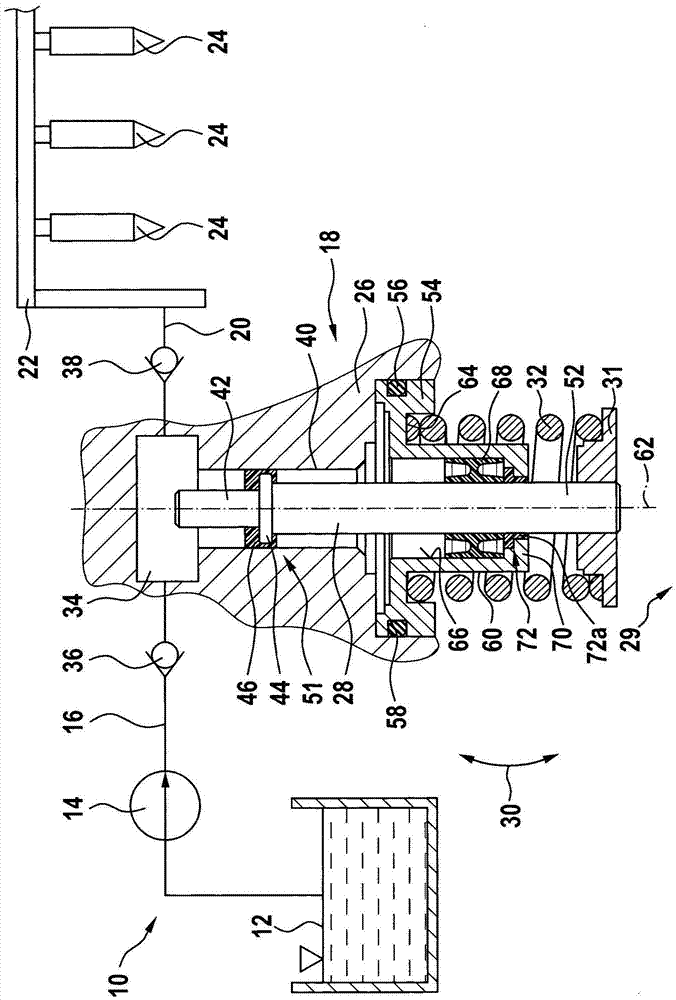

[0032] The fuel system of an internal combustion engine is figure 1 in total bears the reference number 10 . The fuel system comprises a fuel container 12 from which an electric pre-feed pump 14 delivers fuel into a low-pressure line 16 . The low-pressure line leads to a high-pressure pump in the form of a piston fuel pump 18 . A high-pressure line 20 leads from the high-pressure pump to a fuel rail 22 . Adjoining the fuel rail are a plurality of injectors 24 which inject fuel directly into the combustion chambers (not shown) which are each associated with the injectors.

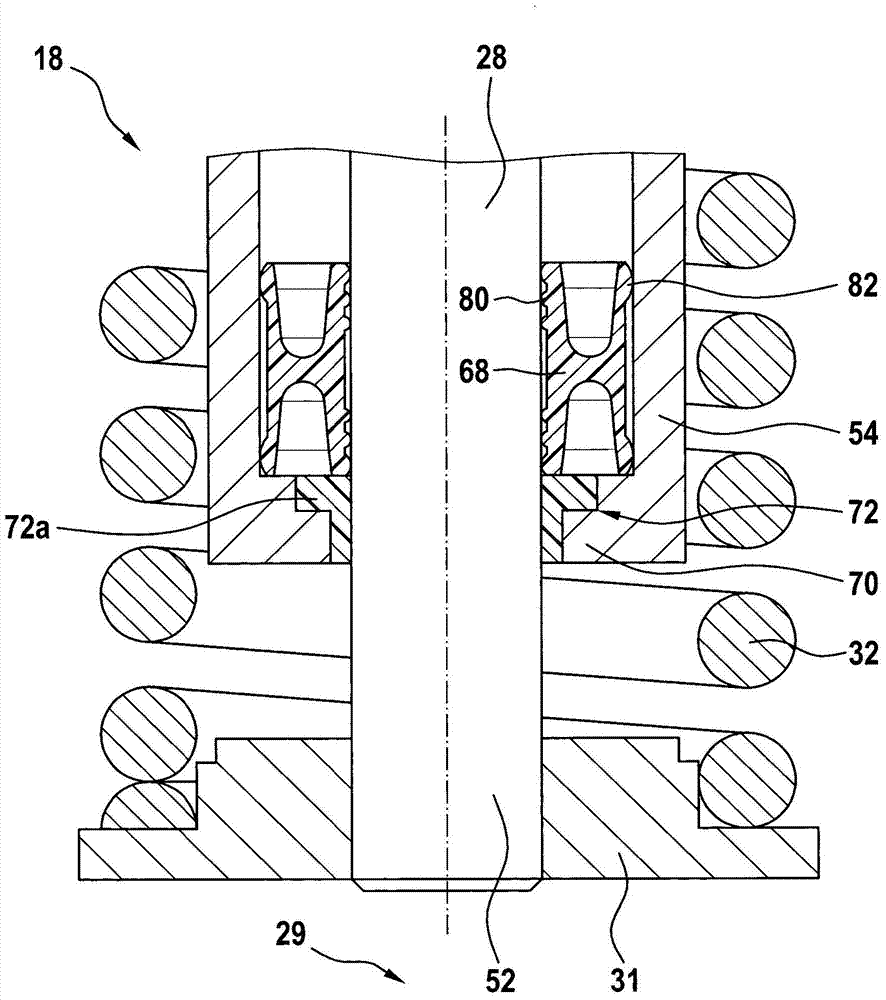

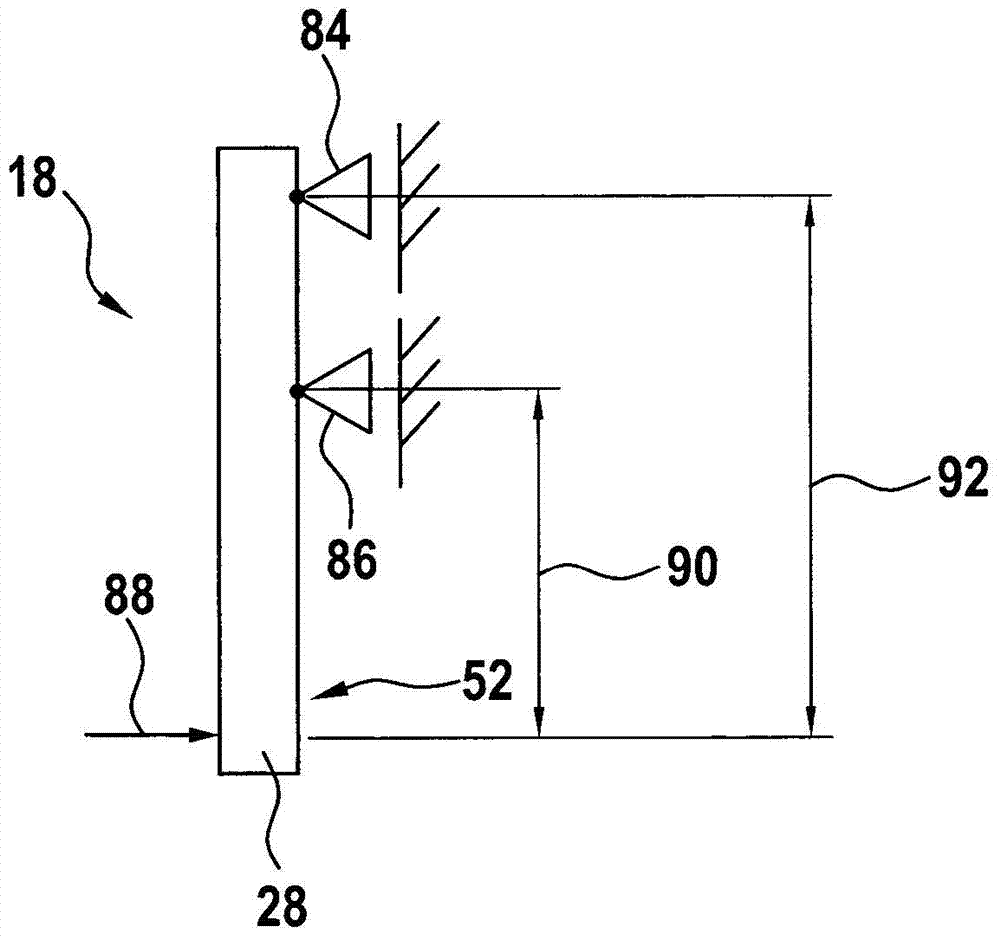

[0033]The piston fuel pump 18 includes a pump housing 26 , shown only partially, in which a pump piston 28 is guided or mounted so that it can move. The pump piston can be set in a reciprocating motion by a drive 29 (roller tappet, cam drive) identified only by its reference number, which is indicated by the double arrow 30 marked on the side. The spring retainer 31 is pressed against the pump piston 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com