Full-metal soluble bridge plug

An all-metal, bridge plug technology, applied in the fields of mining fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult processing, unreasonable connection methods, long operation cycles, etc., to reduce processing difficulties and manufacturing costs. , The connection method is simple and reliable, and the effect of reliable anchoring and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

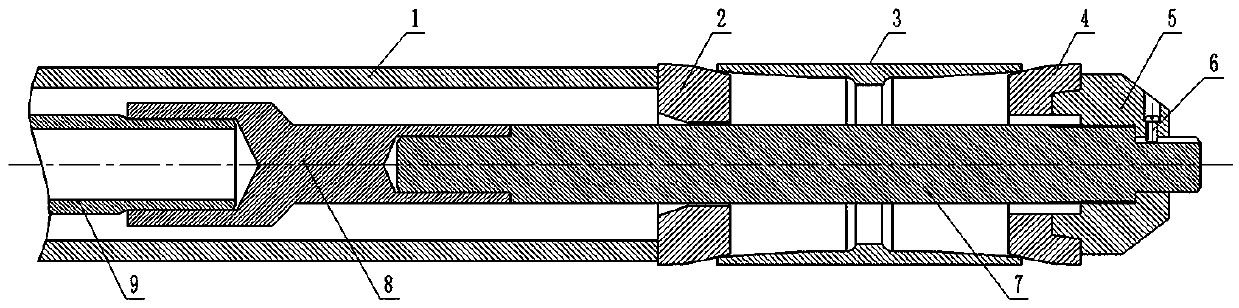

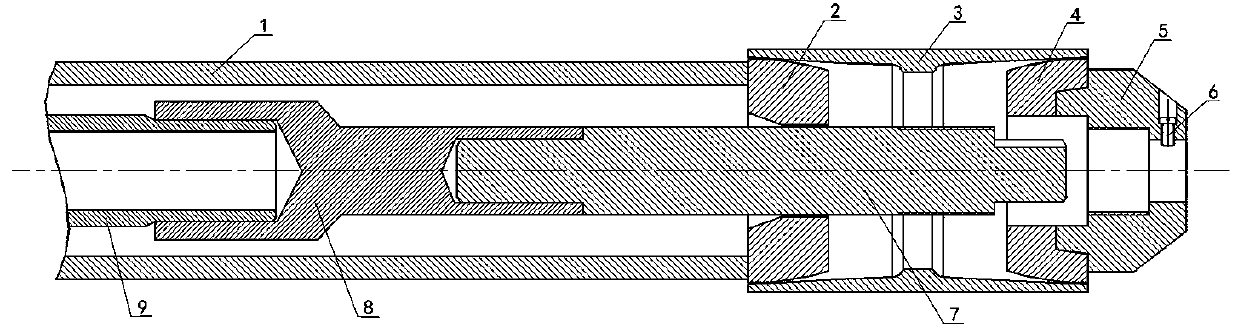

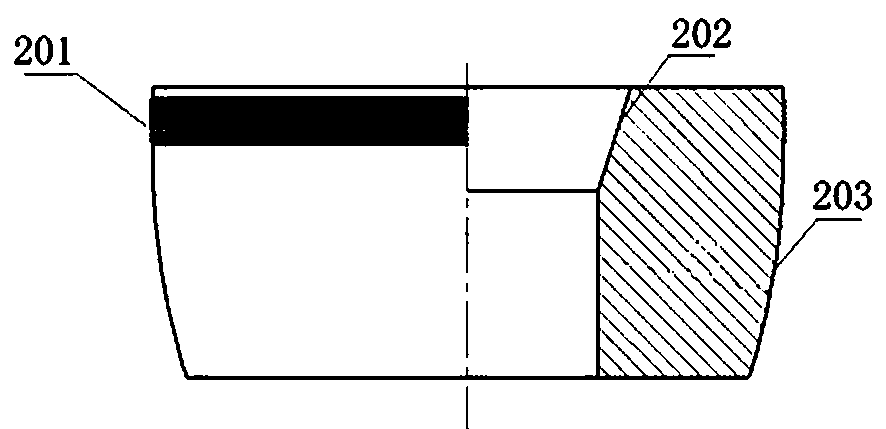

[0024] like Figure 1-7 As shown, an all-metal soluble bridge plug includes a seat seal cylinder 1, an upper vertebral body 2, a seal cylinder 3, a lower vertebral body 4, a lower joint 5, a handle lever 7, a conversion joint 8 and a seat seal rod 9, The inner surface of the upper vertebral body 2 is provided with a ball seat 202, and the ball seat 202 provides a plugging position for the soluble fracturing ball put into the later stage. The inner surface of the lower vertebral body 4 is provided with a joint thread A403, and the lower joint 5 The outer surface is provided with joint threads B503, the inner surface is provided with throwing threads 502, and the lower end of the throwing rod 7 is provided with lower threads 702.

[0025] The lower end of the seat seal cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com