Composite soluble bridge plug

A bridge plug and vertebral body technology, applied in the field of composite soluble bridge plugs, can solve the problems of unreasonable connection mode, many connecting parts, complex structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

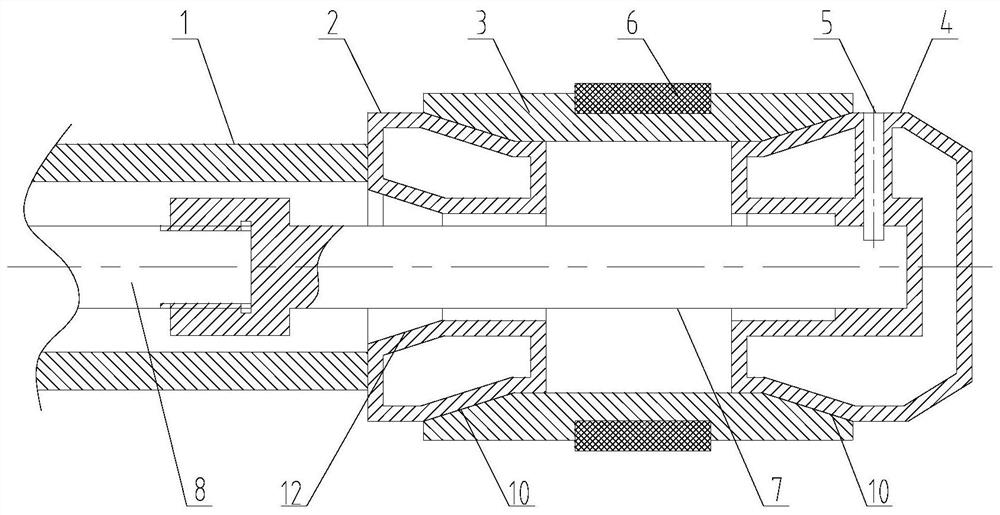

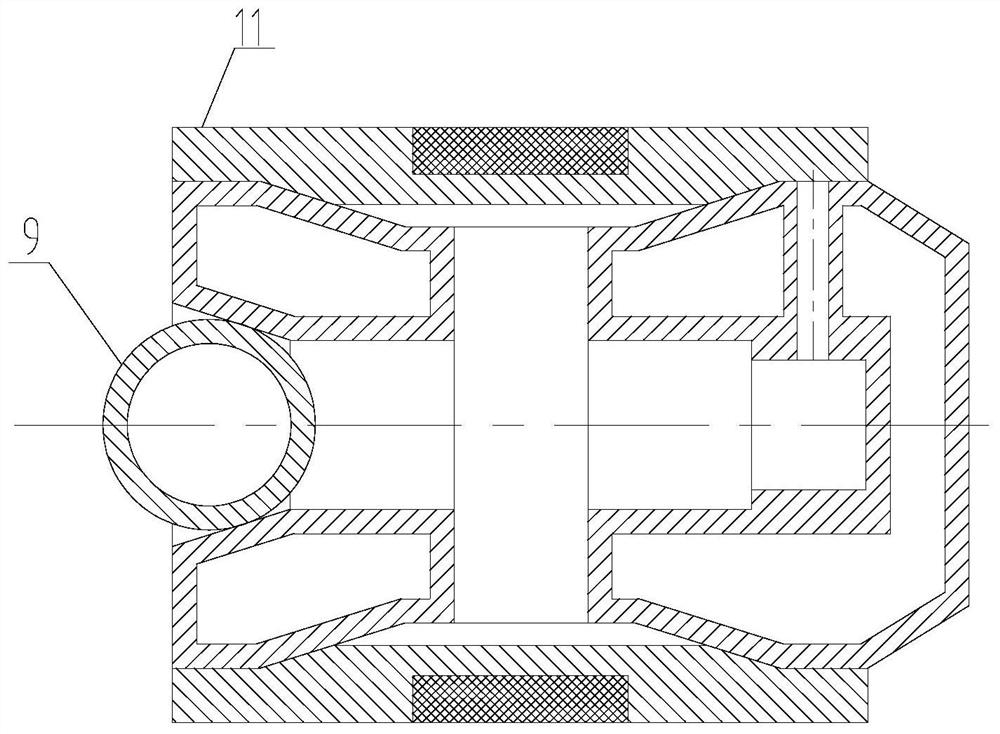

[0020] Depend on figure 1 combine figure 2 As shown, a composite soluble bridge plug includes a setting cylinder 1, an upper vertebral body 2, a sealing cylinder 3, a lower vertebral body 4, a throwing rod 7 and a setting rod 8;

[0021] The lower end of the setting cylinder 1 is attached to the upper surface of the upper vertebral body 2, and the upper end is connected to the peripheral setting tool. In the setting cylinder 1, the lower end of the setting rod 8 is connected to the threaded connection rod 7, and the lower end of the rod 7 is sequentially connected. After passing through the upper vertebral body 2 and the sealing cylinder 3, the throwing rod 7 is connected to the lower vertebral body 4 through the shear pin 5;

[0022] The conical surface of the lower vertebral body 4 cooperates with the lower end of the sealing cylinder 3, and the upper end of the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com