Patents

Literature

58results about How to "Achieve complete dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively extracting rosmarinus officinalis and preparing fat-soluble instant antioxidant

ActiveCN102604640AAchieve complete dissolutionIncrease production costEssential-oils/perfumesSolid solvent extractionBiotechnologyRosmarinus

The invention relates to the extraction and utilization of rosmarinus officinalis, and discloses a method for comprehensively extracting the rosmarinus officinalis and preparing a fat-soluble instant antioxidant. The method comprises the following steps of: mincing raw materials rosmarinus officinalis tender stems or leaves which are dried in shade, and distilling the minced rosmarinus officinalis tender stems or leaves by using water vapor to obtain rosmarinus officinalis essential oil and distillation residues; and performing percolation extraction on the distillation residues by using ethanol, performing ethanol recovery treatment on extracting solution, obtaining a water-soluble antioxidant from a water phase, dissolving precipitates by using a low-boiling solvent, and decreaming a carnosic acid into cooking oil after decoloring; and performing concentration, and recovering the solvent to obtain a fat-soluble instant antioxidant product with the carnosic acid content of 5 to 20 percent. The method has the advantages of high yield, full raw material utilization, low production cost and the like; and in addition, the application performance of a rosmarinus officinalis antioxidant product is greatly improved, and the rosmarinus officinalis antioxidant can be more conveniently and efficiently used.

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

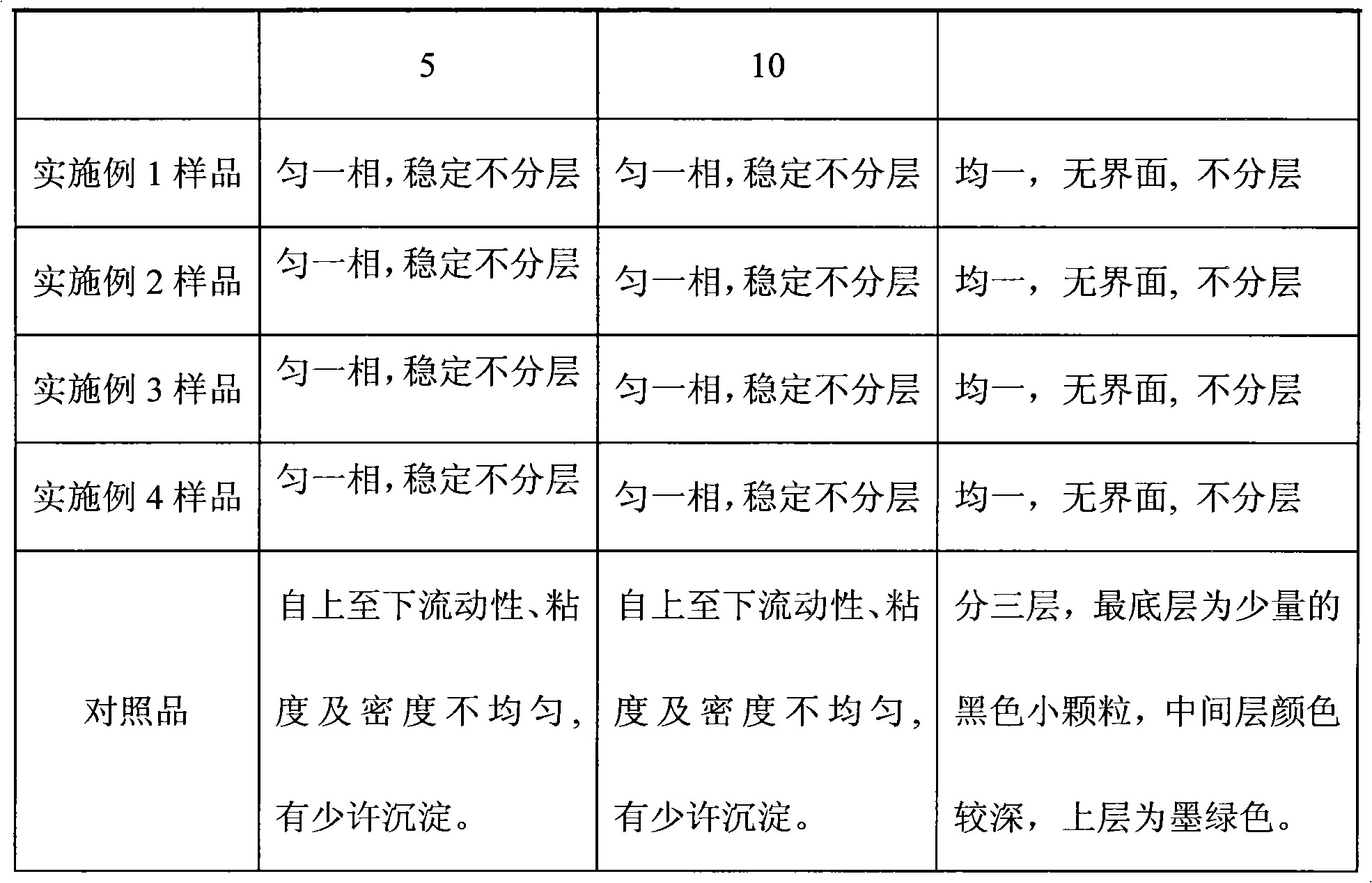

Liquid oil-instant and stable rosemary antioxidant and preparation method thereof

ActiveCN101831302AEasy to useSimple processEssential-oils/perfumesSolid solvent extractionChemistryFlavor

The invention discloses a liquid oil-instant and stable rosemary antioxidant and a preparation method thereof. In the method, the rosemary material is adopted as raw material, edible oil is adopted as a carrier cosolvent to assist the supercritical carbon dioxide to strengthen and selectively extract the oxidation resistance active ingredients in the rosemary material, and then the liquid oil-instant and stable rosemary antioxidant and the rosemary essence oil are prepared by one step. The liquid oil-instant and stable rosemary antioxidant can be instant, stable, safe and highly-efficient, and can be directly used for edible oil, foods, health products, medicines, cosmetics and the like. The prepared rosemary essence oil can be directly used as natural perfumes.

Owner:湖南和广生物科技有限公司

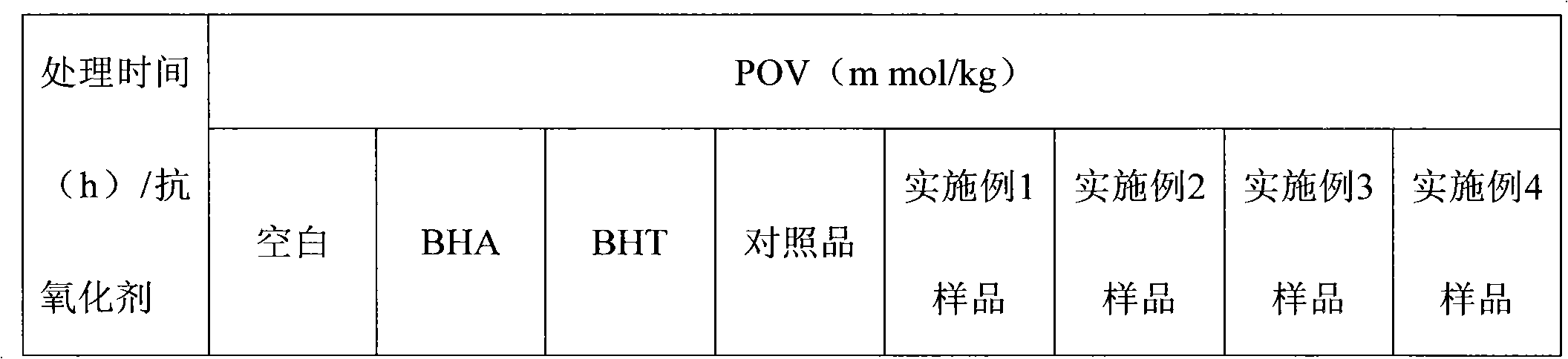

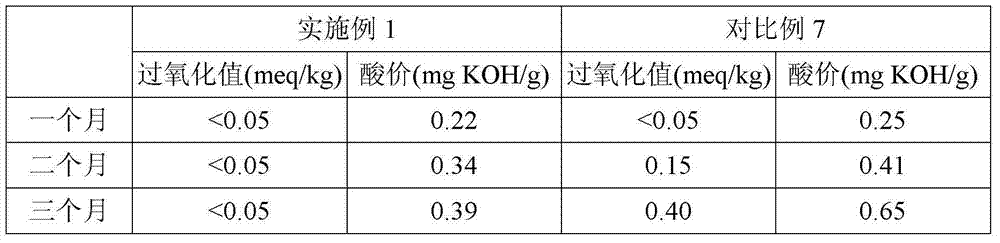

Composition for improving cognitive function of brain, and preparation method and application thereof

ActiveCN103609752AImprove solubilityGuarantee product qualityEdible oils/fatsFood preparationDocosahexenoic AcidsChemistry

The invention provides a composition for improving a cognitive function of a brain, and a preparation method and application thereof. The composition comprises phosphatidylserine, docosahexenoic acid (DHA) and vegetable oil, wherein the mass ratio of the phosphatidylserine to the DHA to the vegetable oil is (50-200):(5-150):(2500-10,000). The invention also provides a preparation method of the composition and a food containing the composition. The phosphatidylserine, the DHA and the vegetable oil are combined together to form a composition, so that the synergistic effects of the phosphatidylserine, the DHA and the vegetable oil act on the human brain, the effective clinic dosage of the phosphatidylserine and fish oil is greatly reduced, reduction of memory ability and reduction of learning ability can be prevented, senile dementia can be prevented, the cognitive ability of the brain is improved. The composition also has an effect of promoting cardiovascular health when the cognitive function of the human brain is improved, and can play a better role by adjusting the content and ratios of omega-6, omega-3 and omega-9 among different vegetable oil.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

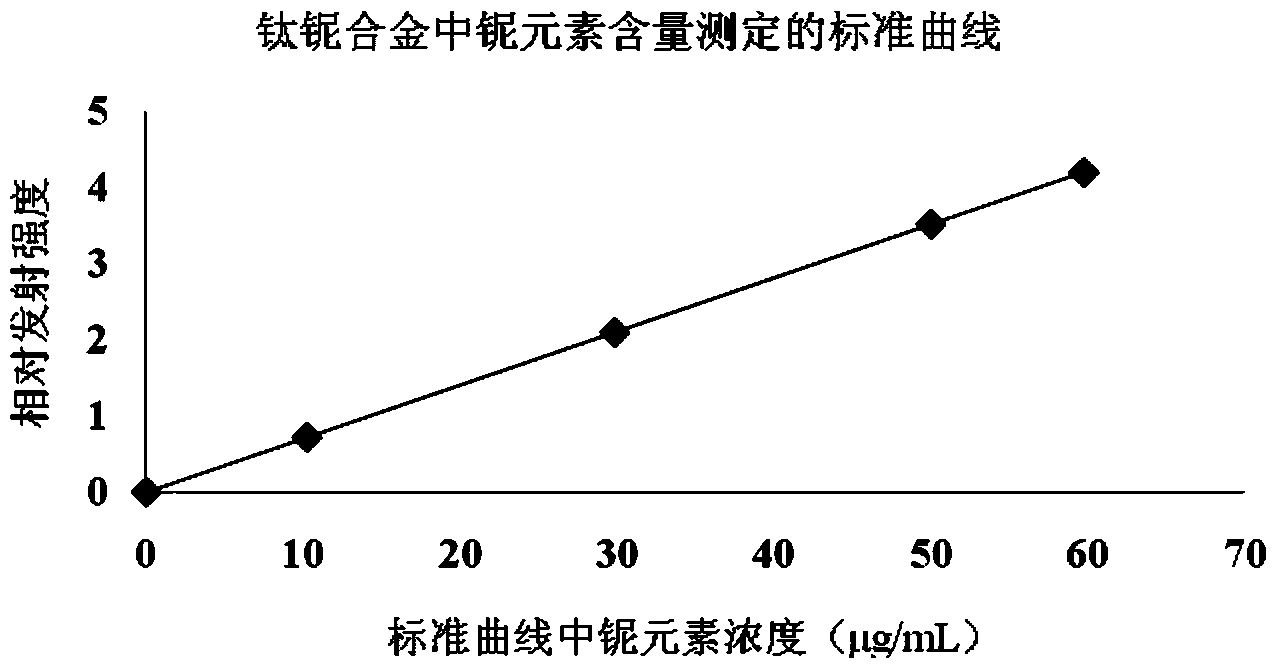

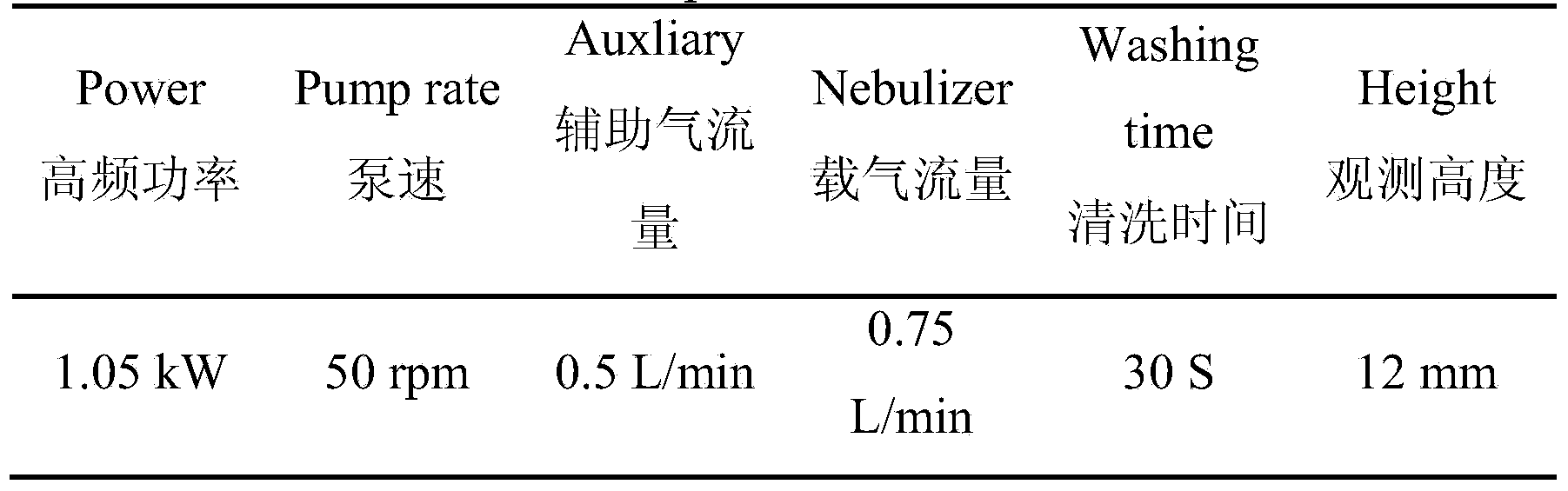

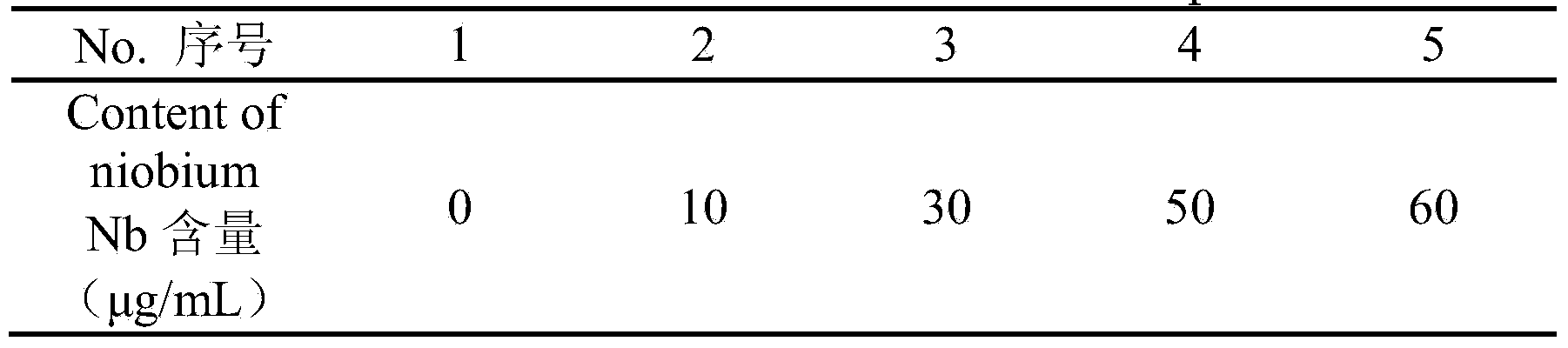

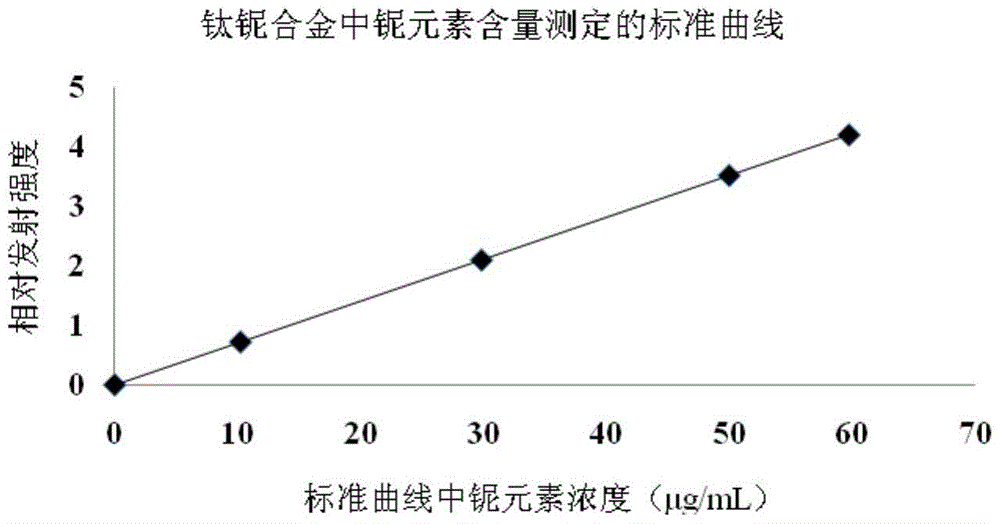

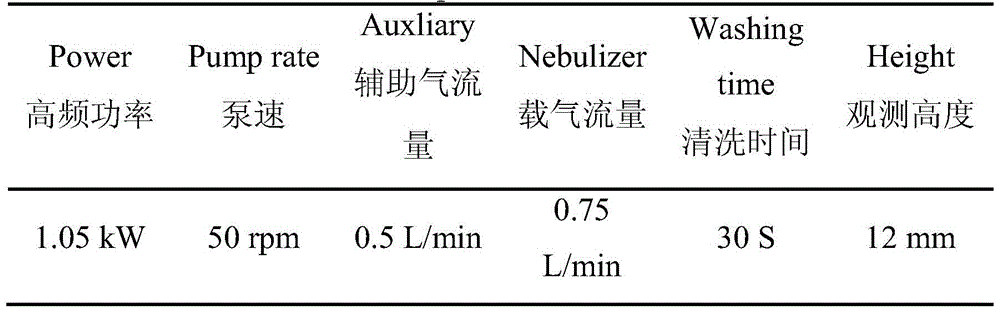

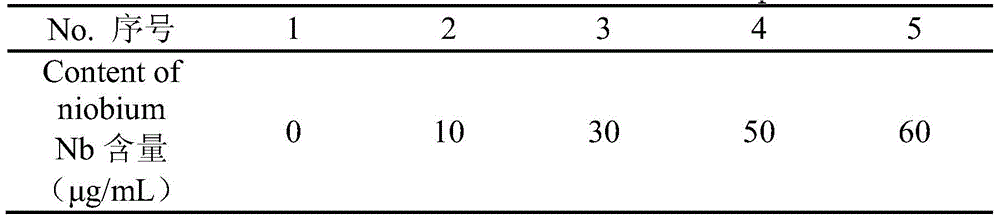

Method for measuring elemental niobium content of titanium-niobium alloy

ActiveCN104020157AAchieve complete dissolutionGuaranteed accuracyPreparing sample for investigationAnalysis by thermal excitationObservational errorRelative standard deviation

The invention provides a method for measuring the elemental niobium content of a titanium-niobium alloy. The method comprises the following steps of dissolving a titanium-niobium alloy specimen by using sulfuric acid and a small amount of hydrofluoric acid, adding an internal standard solution, and after diluting to a certain volume, performing measurement by using an inductively coupled plasma emission spectrometer. Before the measurement, five niobium standard solutions with different concentrations are prepared, titanium substrates of the five niobium standard solutions are matched, the same amount of internal standard solution is added, a standard working curve is drawn, and the elemental niobium content of the titanium-niobium alloy is calculated with reference to the standard working curve. According to the method, the titanium-niobium alloy is completely dissolved, the internal standard solution is added to cancel measurement errors caused by the fluctuation of spectral line intensity due to the fluctuation of working conditions of an instrument, and a substrate matching method is used for reducing the interference of a substrate effect; by the measures, the accuracy of the curve is ensured, and the relative standard deviation is 0.29 percent; the method is high in precision and easy to operate, the elemental niobium content of the titanium-niobium alloy can be accurately measured, and quality guarantee is provided for the use of materials.

Owner:AEROSPACE PRECISION PROD INC LTD

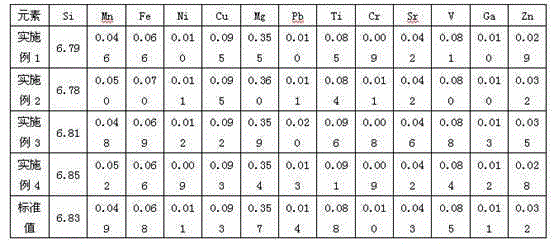

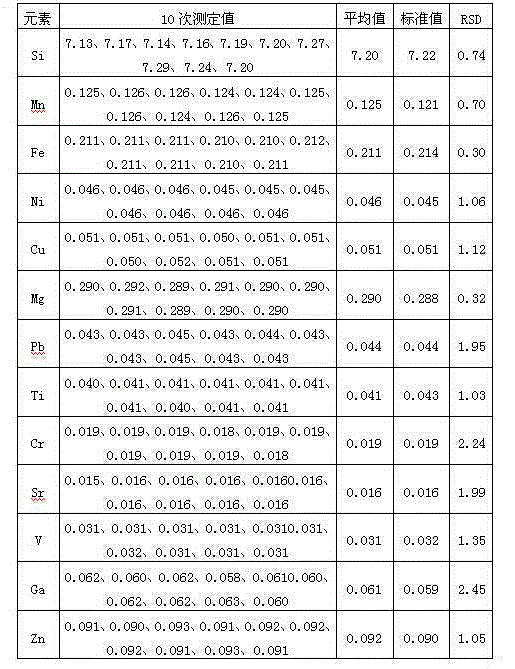

Method for measuring trace element content in aluminium alloy by ICP method

InactiveCN105136777AAchieve complete dissolutionReduce dosagePreparing sample for investigationAnalysis by thermal excitationTrace element5005 aluminium alloy

The invention discloses a method for measuring trace element content in aluminium alloy by an ICP method. A mixture of concentrated hydrochloric acid, concentrated nitric acid and water with a proportion of 1:1:2 is employed for dissolving samples. In the method, an aluminium alloy sample containing higher element silicon content can be entirely dissolved; the contents of a plurality of elements dissolved in the same solution are measured simultaneously and separately in one determination; and the analysis efficiency is high. The matrix is matched and matrix effect is reduced. An aluminium alloy national standard sample is measured and the measurement result meets the requirements; the analysis result is accurate and reliable. The dissolution method is simple and rapid; the method needs little reagent and saves test cost. The correction curve has a wide linear range, can meet test requirements of samples with contents from low to high. In the method, the contents of a plurality of elements are determined simultaneously in one solution; the analysis efficiency is high; and the analysis result is accurate and reliable.

Owner:HEBEI IRON AND STEEL

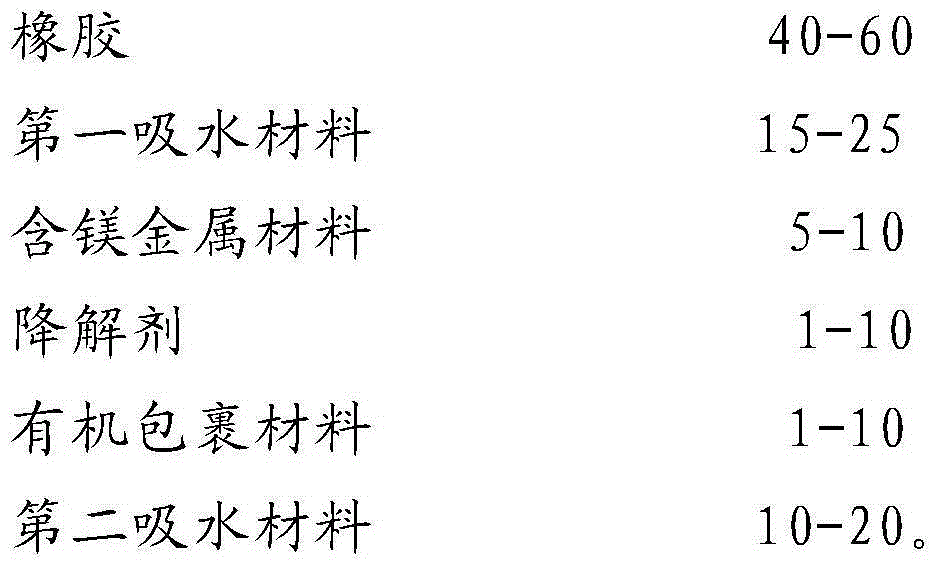

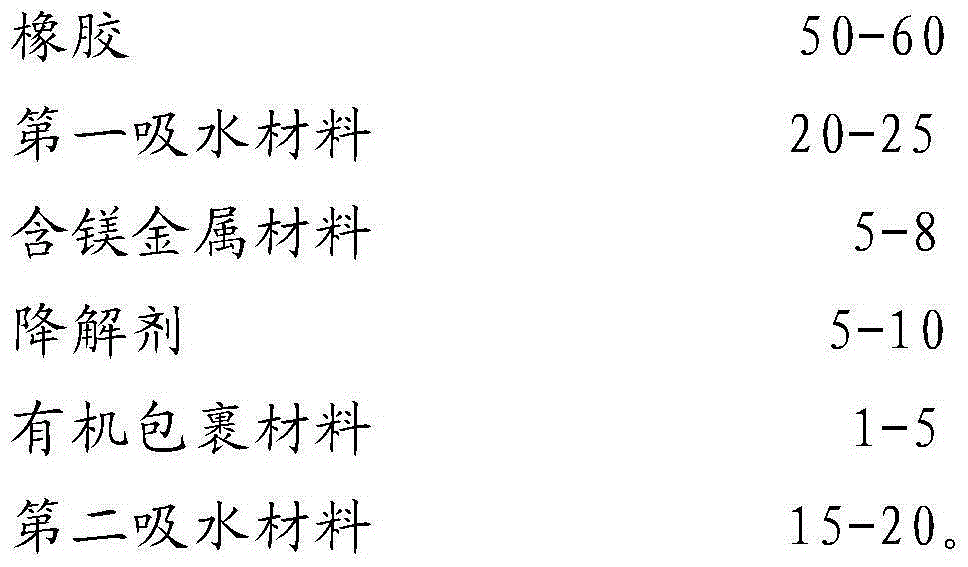

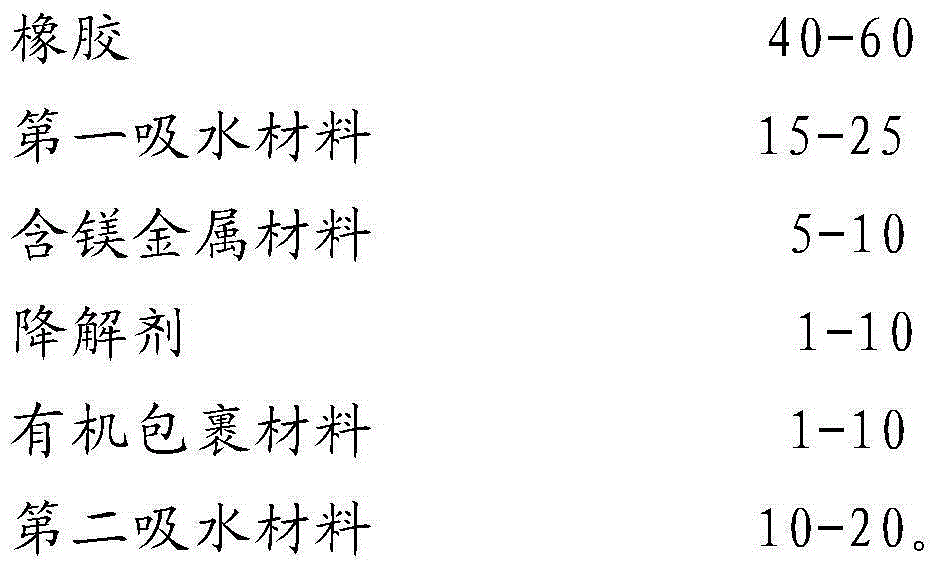

Self-dissolving functional material for making well drilling bridge plug rubber packer and preparation method therefor

The present invention relates to a self-dissolving functional material for making a well drilling bridge plug rubber packer and a preparation method therefor. The self-dissolving polymer functional material is prepared by using the following raw materials in parts by weight: 40-60 parts of rubber, 15-25 parts of a first water-absorbing material, 5-10 parts of a magnesium-containing metal material, 1-10 parts of a degradation agent, 1-10 parts of an organic wrapping material, and 10-20 parts of a second water-absorbing material. The preparation method comprises: completely wrapping the degradation agent by using the organic wrapping materials; and uniformly mixing the other raw materials with a degradation agent covering body that is completely wrapped, to obtain the self-dissolving functional material. The self-dissolving functional material provided by the present invention has higher mechanical strength, so that complete use of the self-dissolving functional material in a short time period can be ensured. According to the present invention, controllability of material self-dissolving time can be realized by adjusting ratios of components in raw materials; and after the material is used, the material can be self-dissolved in an aqueous solution or when heated; the material can be widely applied to exploitation of mineral resources comprising oil, gas and the like; and productivity can be greatly improved because no return operation is needed.

Owner:FRACTURING COMPANY OF CNPC GREATWALL DRILLING +1

Cellulose solution prepared with low energy consumption and novel preparation thereof

Owner:DONGHUA UNIV

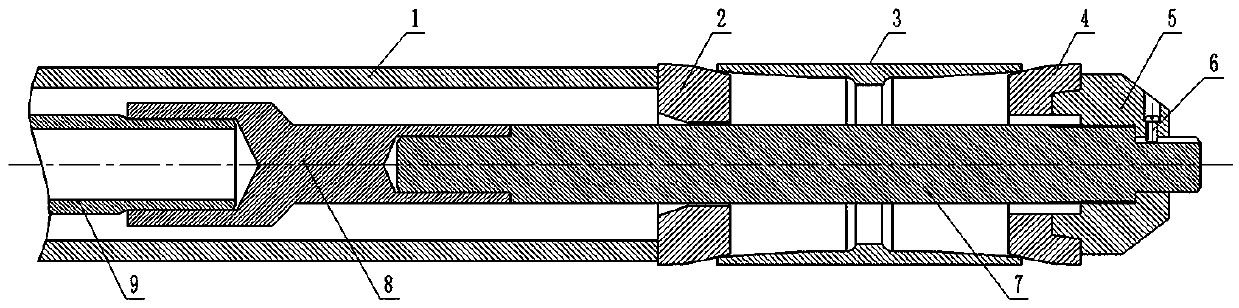

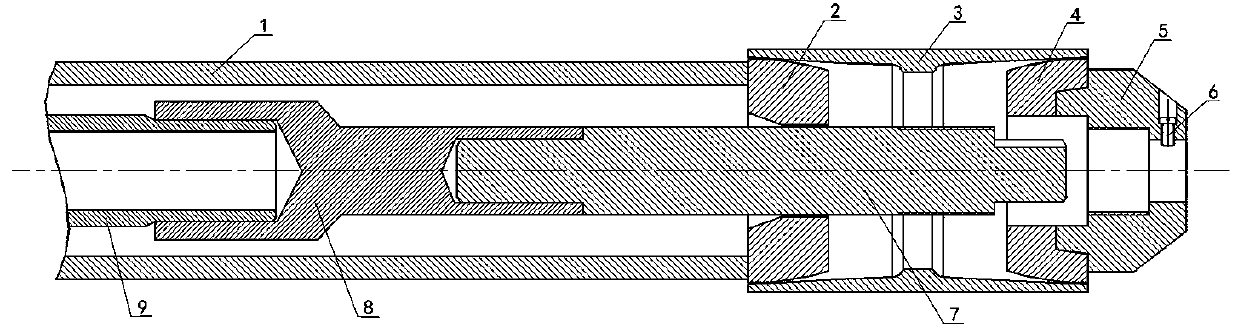

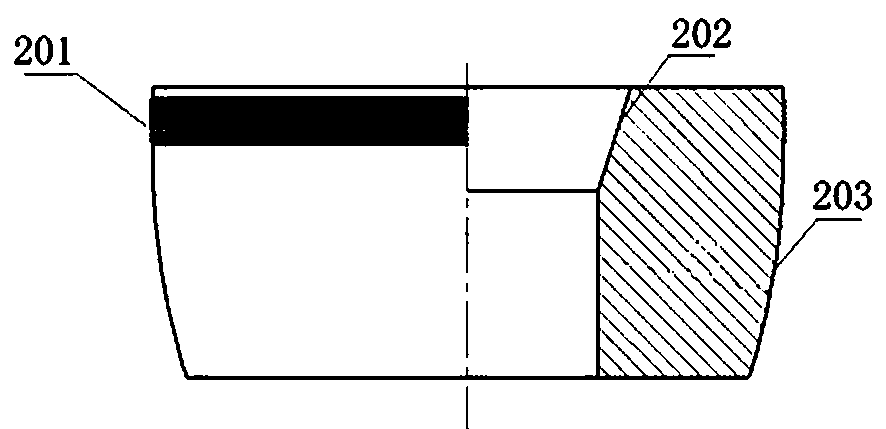

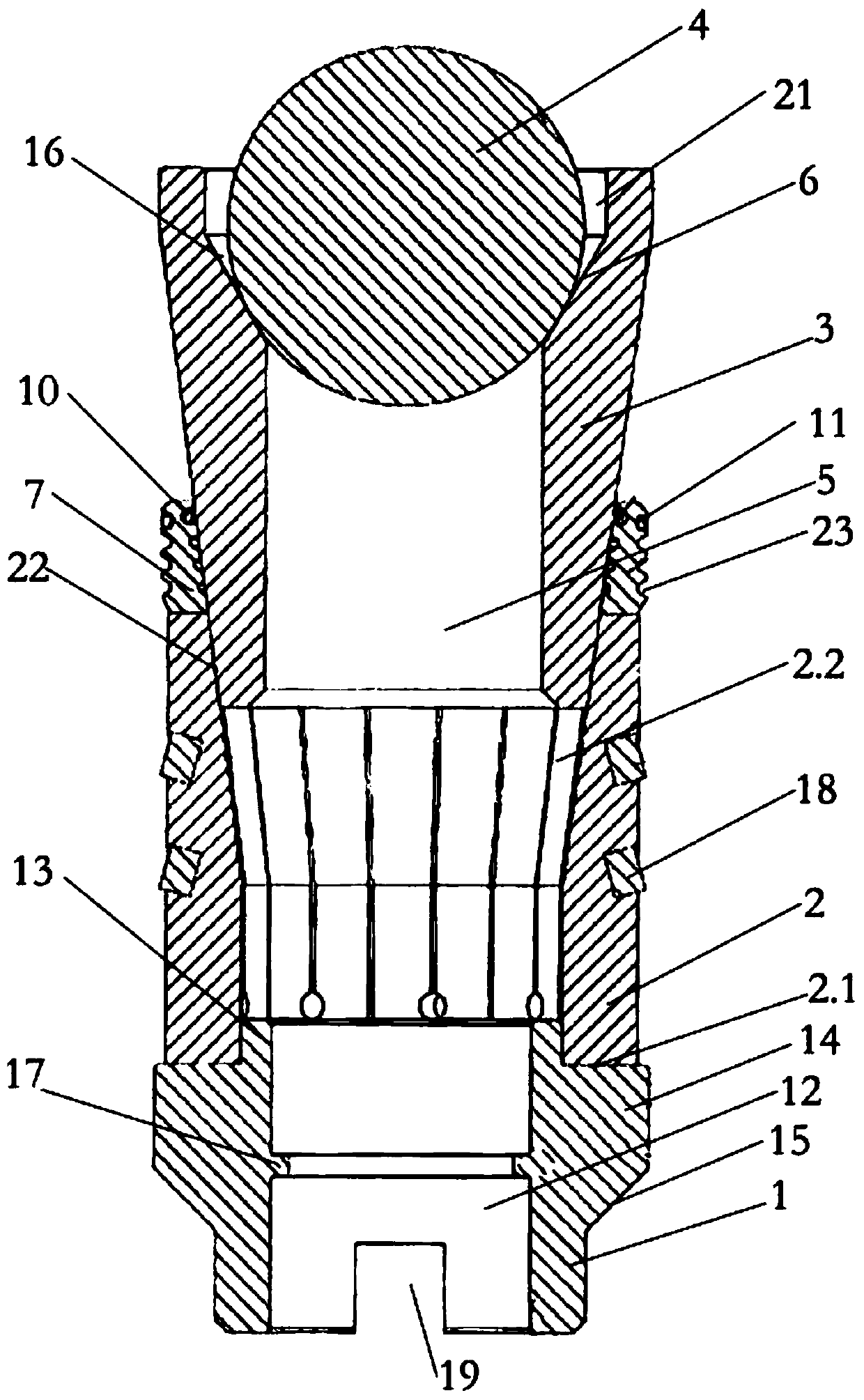

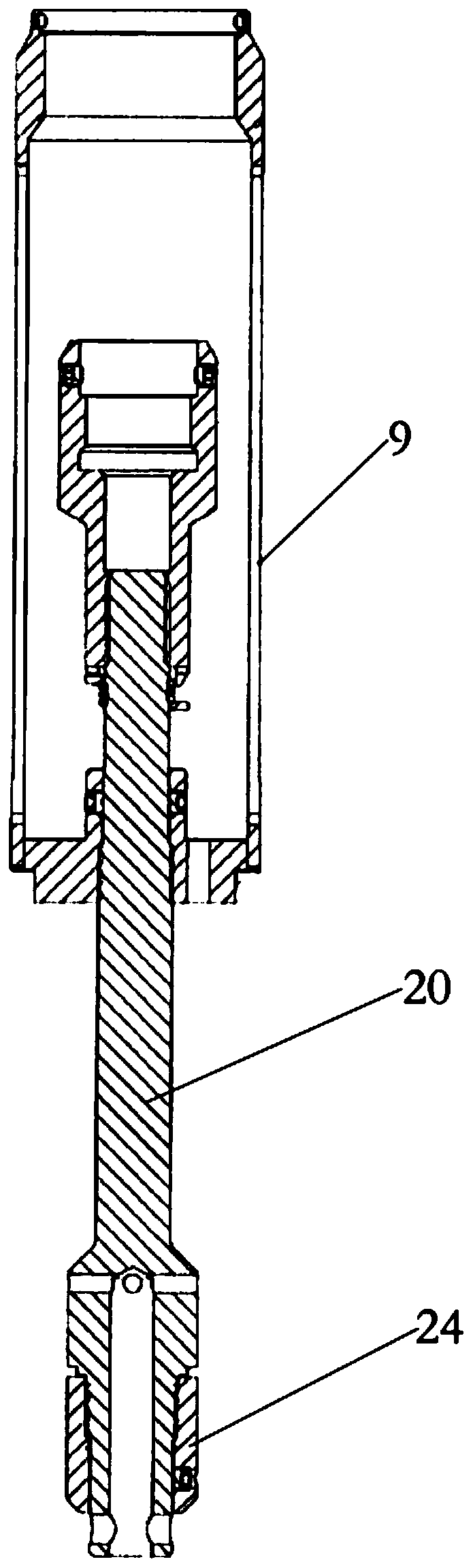

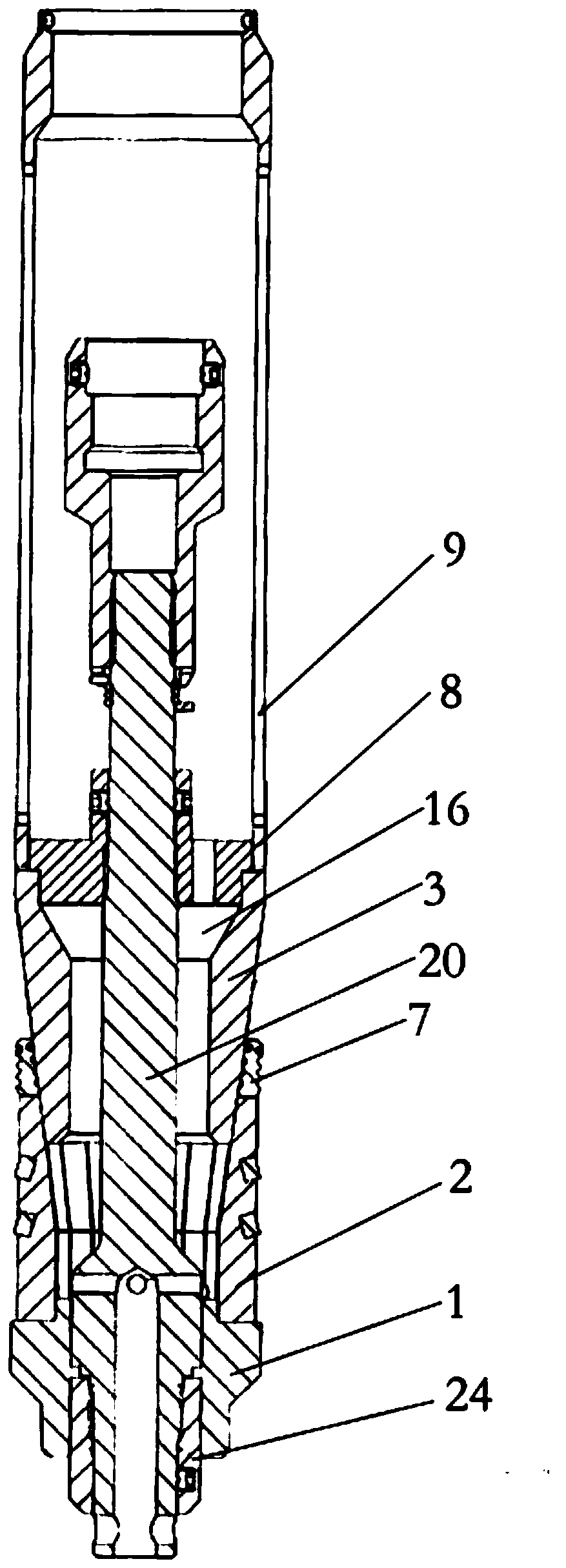

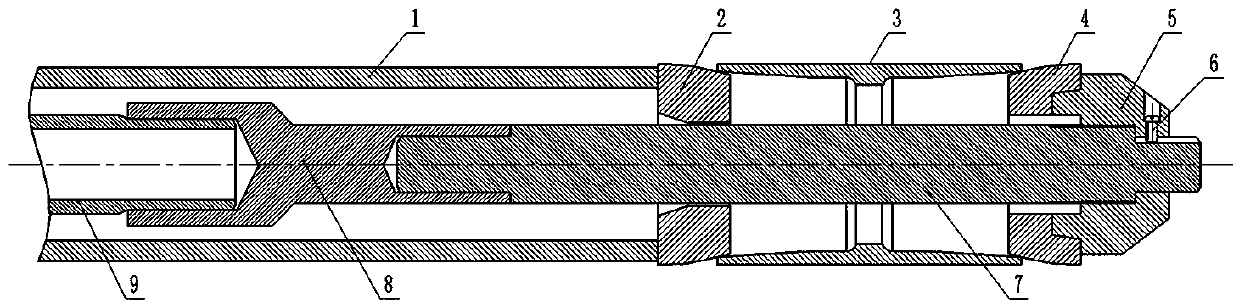

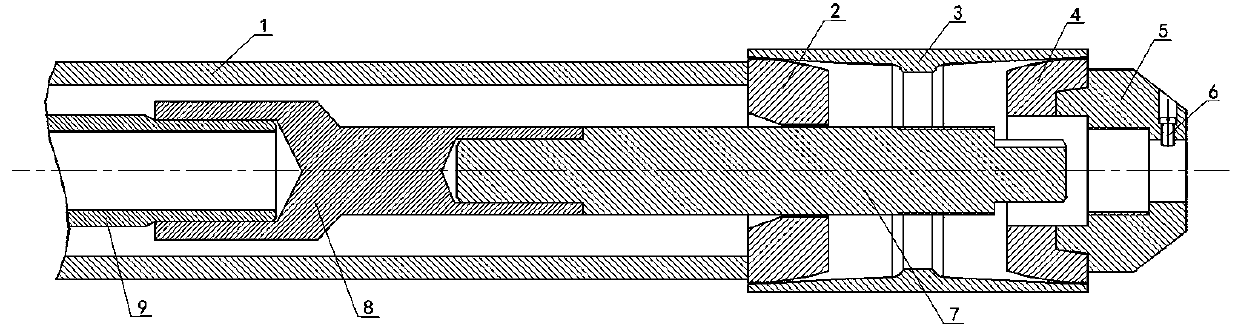

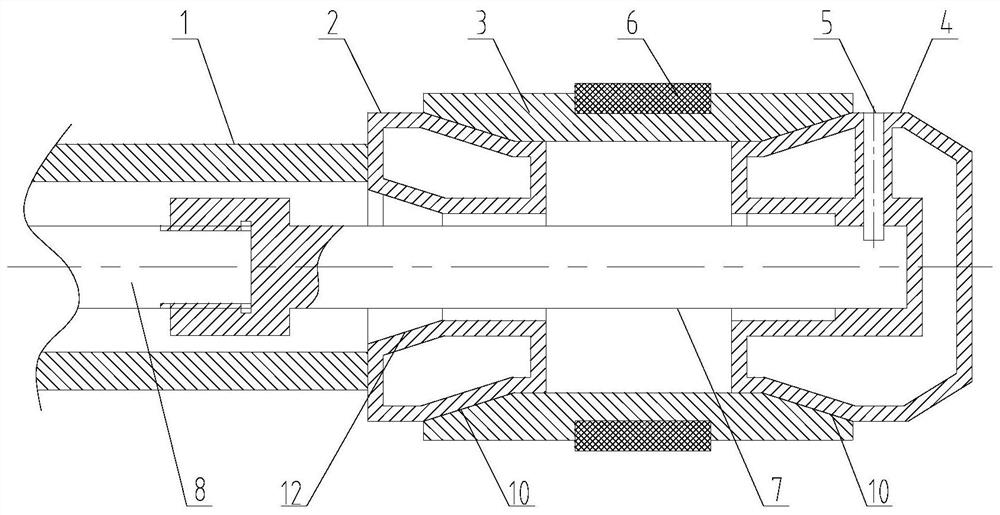

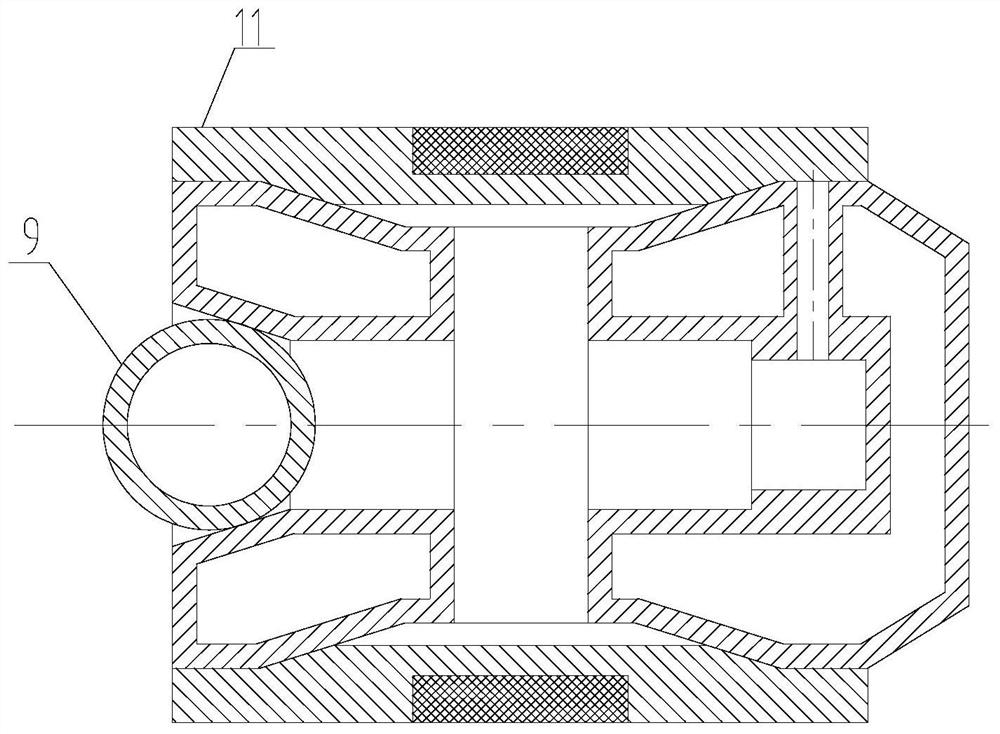

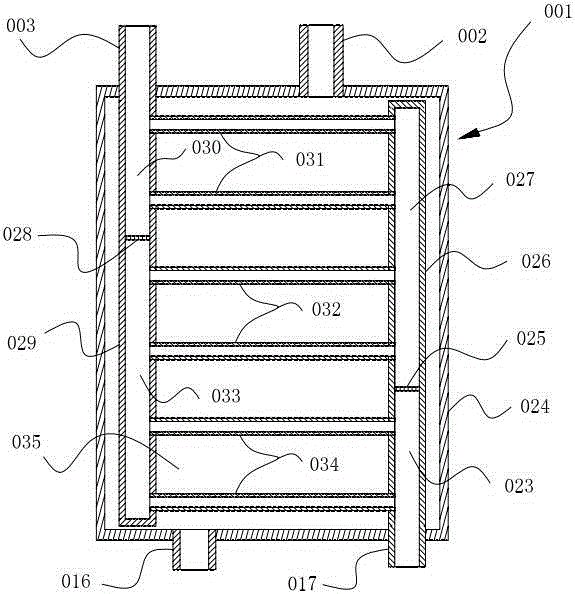

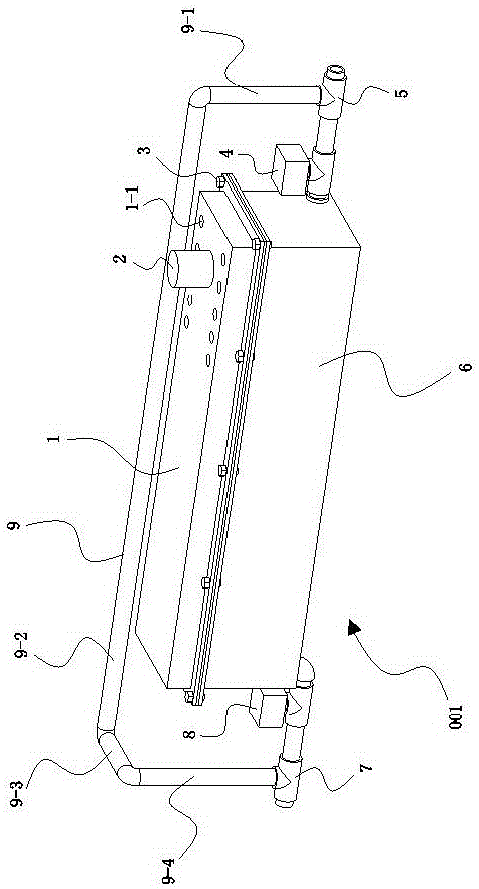

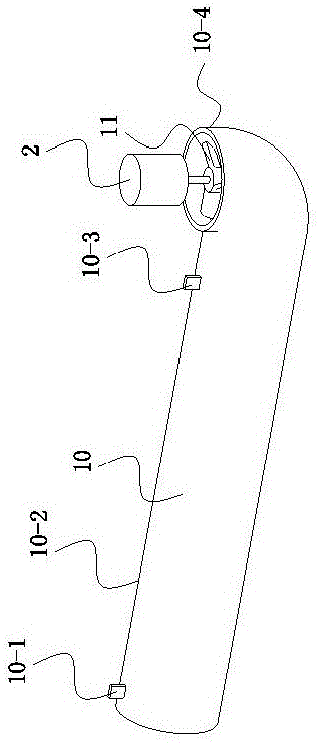

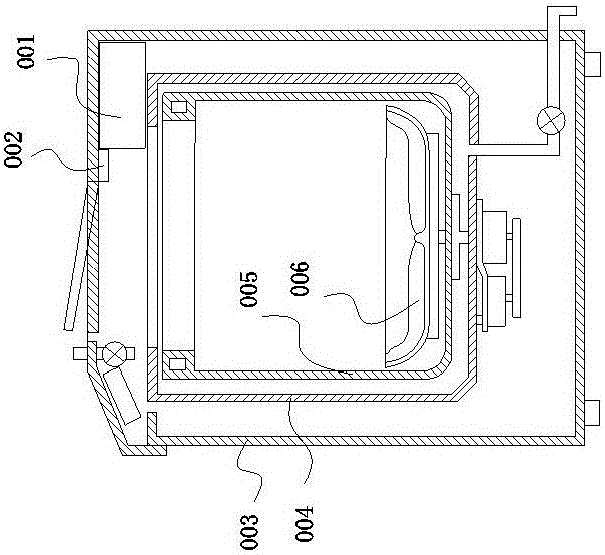

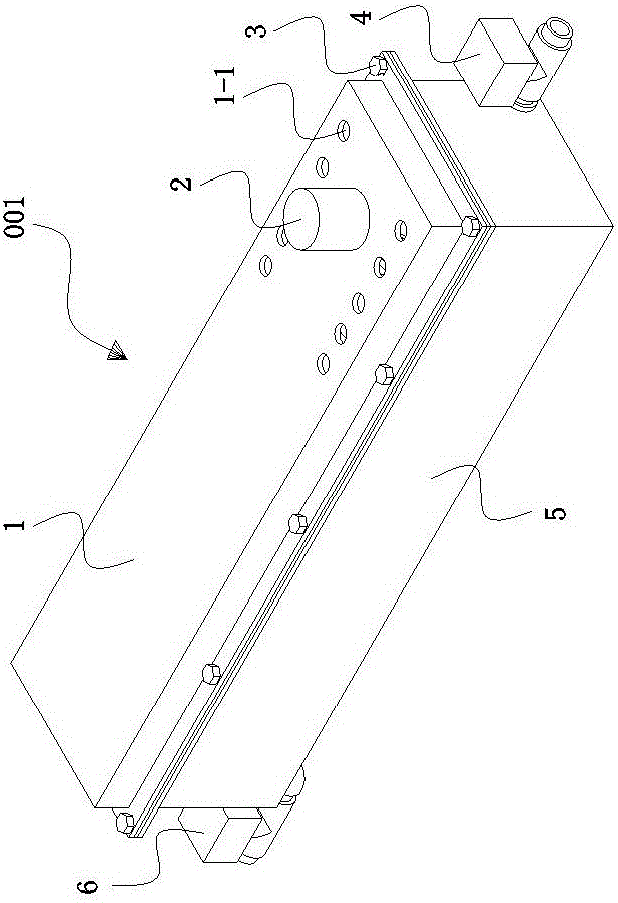

Full-metal soluble bridge plug

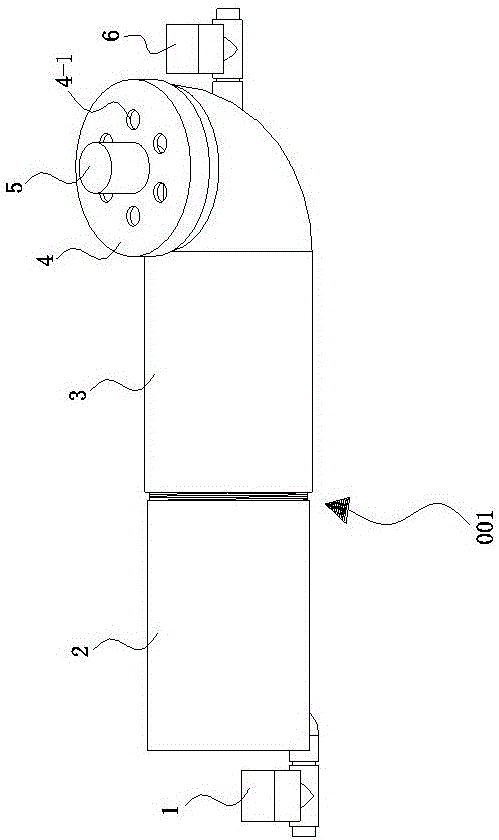

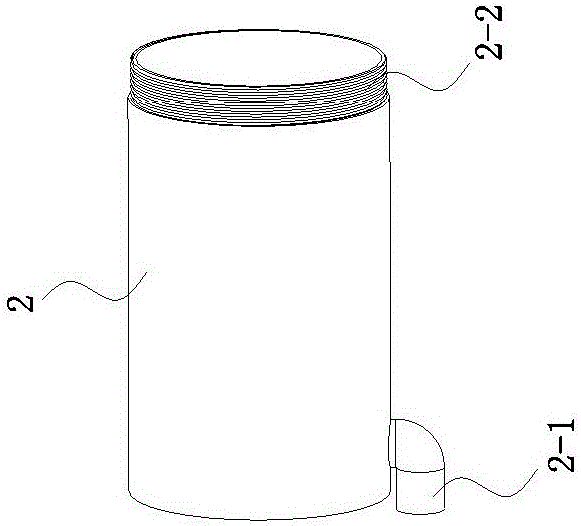

ActiveCN110552659AAccurately grasp the dissolution timeReliable anchoringFluid removalSealing/packingEngineeringDissolution

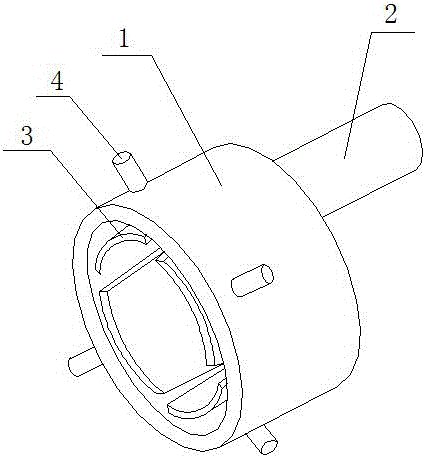

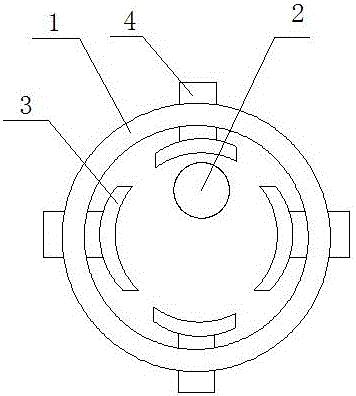

The invention discloses a full-metal soluble bridge plug. The full-metal soluble bridge plug comprises a seat sealing cylinder (1), an upper cone body (2) and a sealing cylinder (3), a lower cone body(4), a lower joint (5), a release rod (7), a conversion joint (8) and a seat sealing rod (9), the lower end of the seat sealing cylinder (1) is attached to the upper end surface of the upper cone body (2), the upper end of the seat sealing cylinder (1) is connected with an externally-arranged seat sealing tool, in the seat sealing barrel (1), the upper end of the conversion joint (8) is connectedwith the lower end of the seat sealing rod (9), the lower end of the conversion joint (8) is connected with the upper end of the releasing rod (7), the lower joint (5) is connected with the releasing rod (7) through threads, the lower joint (5) is connected with the lower cone body (4) through threads, one end of the lower cone body (4) is matched with one end of the sealing cylinder (3) throughthorn teeth, and the other end of the sealing cylinder (3) is matched with the upper cone body (2) through the thorn teeth. The full-metal soluble bridge plug has the characteristics of reliable anchoring, reliable pressure bearing, complete dissolution and the like.

Owner:PETROCHINA CO LTD +1

Metallic seal solvable bridge plug

Owner:FIVE STAR DOWNHOLE SERVICE INC

An all-metal soluble bridge plug

ActiveCN110552659BAccurately grasp the dissolution timeReliable anchoringFluid removalSealing/packingPhysical chemistryMechanical engineering

The invention discloses a full-metal soluble bridge plug. The full-metal soluble bridge plug comprises a seat sealing cylinder (1), an upper cone body (2) and a sealing cylinder (3), a lower cone body(4), a lower joint (5), a release rod (7), a conversion joint (8) and a seat sealing rod (9), the lower end of the seat sealing cylinder (1) is attached to the upper end surface of the upper cone body (2), the upper end of the seat sealing cylinder (1) is connected with an externally-arranged seat sealing tool, in the seat sealing barrel (1), the upper end of the conversion joint (8) is connectedwith the lower end of the seat sealing rod (9), the lower end of the conversion joint (8) is connected with the upper end of the releasing rod (7), the lower joint (5) is connected with the releasing rod (7) through threads, the lower joint (5) is connected with the lower cone body (4) through threads, one end of the lower cone body (4) is matched with one end of the sealing cylinder (3) throughthorn teeth, and the other end of the sealing cylinder (3) is matched with the upper cone body (2) through the thorn teeth. The full-metal soluble bridge plug has the characteristics of reliable anchoring, reliable pressure bearing, complete dissolution and the like.

Owner:PETROCHINA CO LTD +1

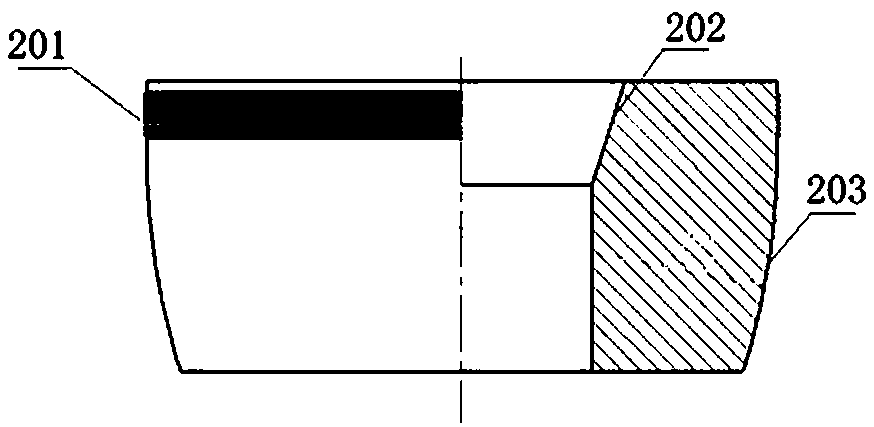

Composite soluble bridge plug

The invention provides a composite soluble bridge plug, and relates to the technical field of oil field downhole tools. The lower end of a setting cylinder is attached to the upper end face of an upper cone, the lower end of a setting rod is in threaded connection with a releasing rod, and the releasing rod is connected with a lower cone through a shear pin; and the upper cone, the lower cone and a fracturing ball are all of hollow structures, and the wall thickness of the hollow outer portions is approximately equal to that of a sealing cylinder. The composite soluble bridge plug has the advantages that the upper cone, the sealing cylinder, the lower cone and the fracturing ball are all made of magnesium-based alloy materials, the wall thicknesses of the hollow structures are the same, the dissolution rate and the dissolution time under the same environment condition are the same, and complete dissolution can be achieved in the later period; and an alloy coating is sprayed to the outer portion of the sealing cylinder, the outer surface of the sealing cylinder and the inner wall of a casing pipe are reliably anchored, sealing is achieved through a sealing ring, the fracturing ball seals the upper pressure, the lower cone of a blind plugging structure seals the pressure of the lower stratum, bidirectional sealing is achieved, and meanwhile fine particles are formed after dissolution and discharged along with flowback fluid.

Owner:DAQING TIANDEZHONG PETROLEUM SCI & TECH CO LTD

Preparation method of mirabegron and intermediate thereof

PendingCN114539084AReduce dosageLow costOrganic compound preparationOrganic chemistry methodsMirabegronActive ingredient

The invention discloses a preparation method of mirabegron and an intermediate thereof. According to the preparation method, on one hand, the relative dosage of auxiliary materials can be reduced, the cost expenditure of the auxiliary materials can be effectively reduced, and on the other hand, generation and / or residues of dehydroxylation impurities can be reduced, so that the content of the dehydroxylation impurities in the product can be kept in a very low level range; the product quality and safety of the mirabegron intermediate and / or the raw material medicine can be better guaranteed.

Owner:SHANGHAI VIWIT PHARMA CO LTD

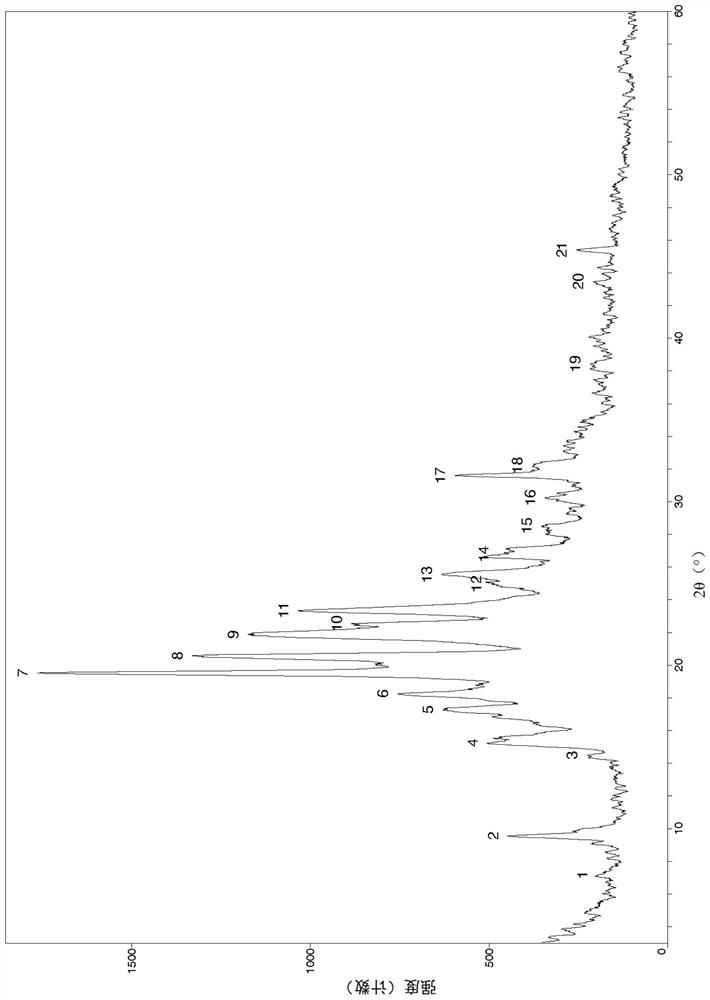

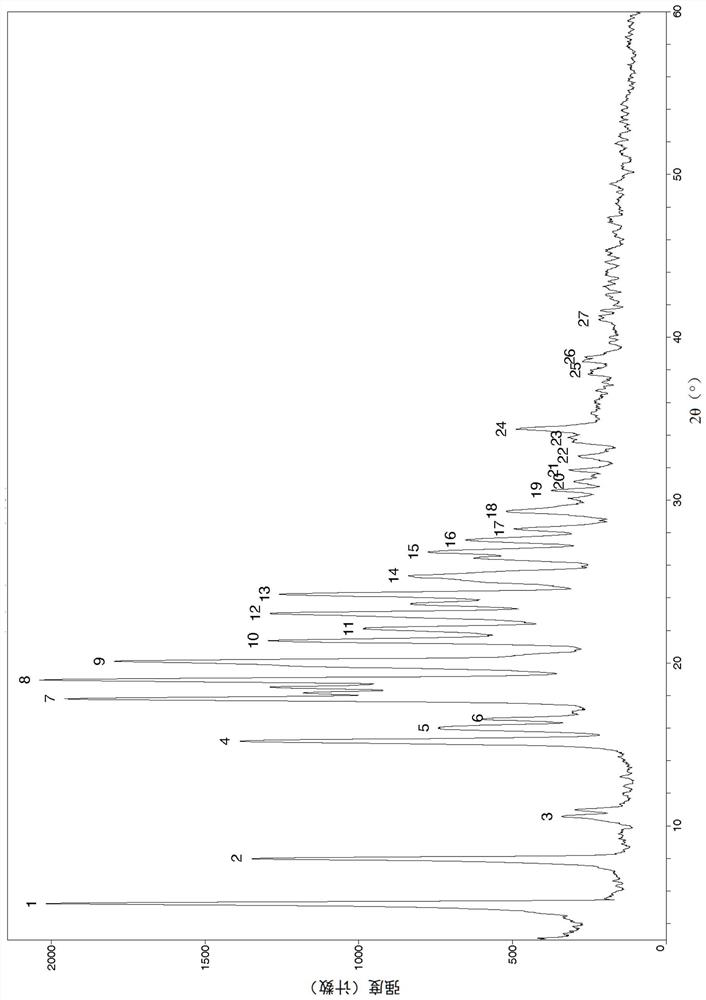

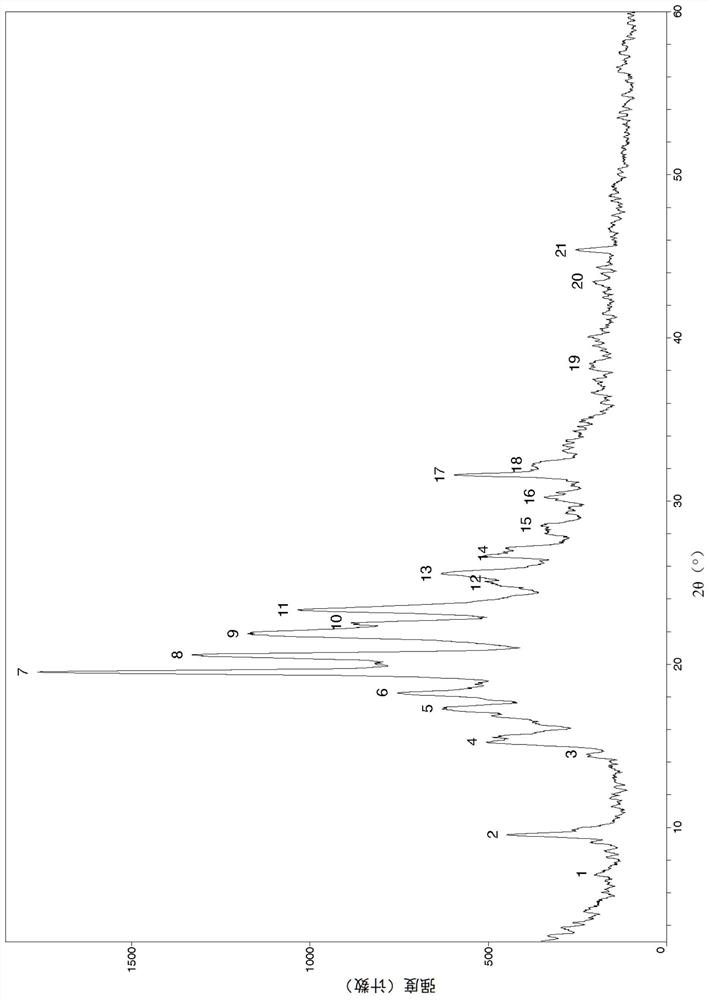

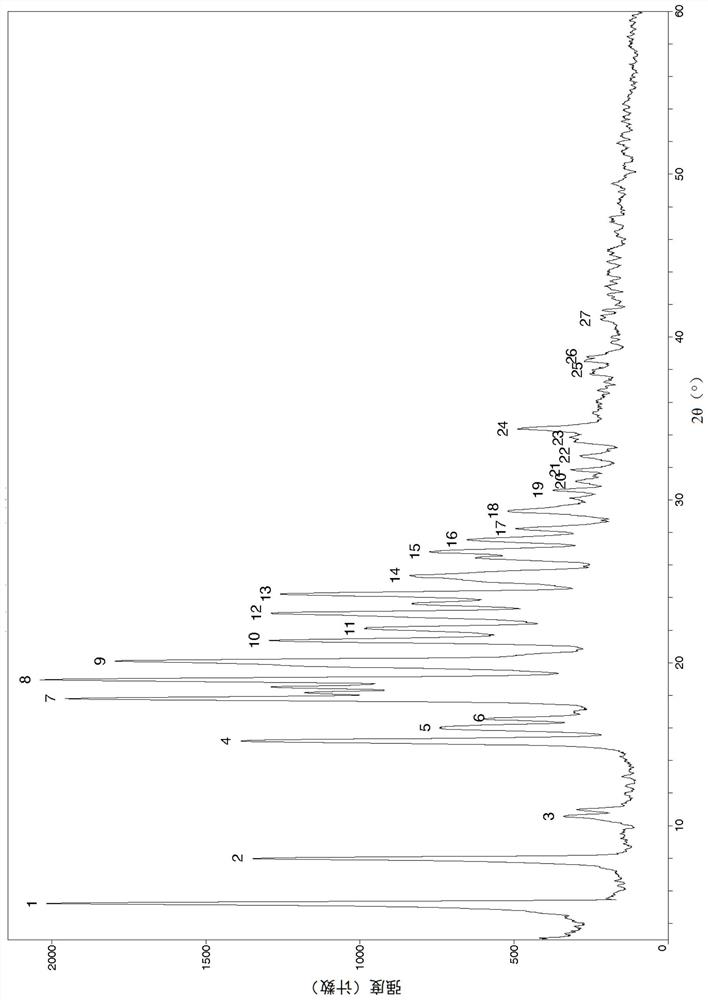

Crystal transformation solvent, application thereof and preparation method of mirabegron alpha crystal form

PendingCN114539182AImprove stabilityAchieve complete dissolutionOrganic chemistry methodsEthylic acidSeed crystal

The invention provides a crystal transformation solvent and application thereof and a preparation method of a mirabegron alpha crystal form. According to the present invention, by using the newly found property of the solvent combination of the isopropyl acetate solvent and the water, the conversion from the mirabegron beta crystal form to the mirabegron alpha crystal form is successfully achieved by using the solvent combination as the mirabegron crystal transformation solvent, such that the mirabegron alpha crystal form can be prepared without the seed crystal, the process conditions are mild, the cost is low, and the method is suitable for industrial production. The method is convenient to operate and control, high in yield and purity, low in energy consumption, low in cost, safe, environment-friendly and suitable for industrial production.

Owner:SHANGHAI VIWIT PHARMA CO LTD

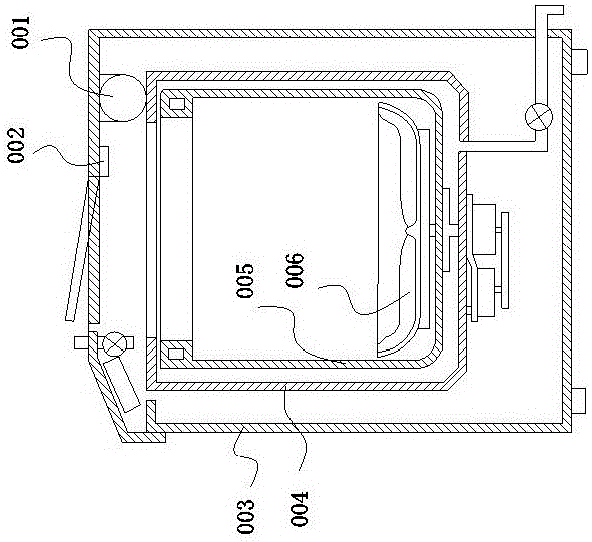

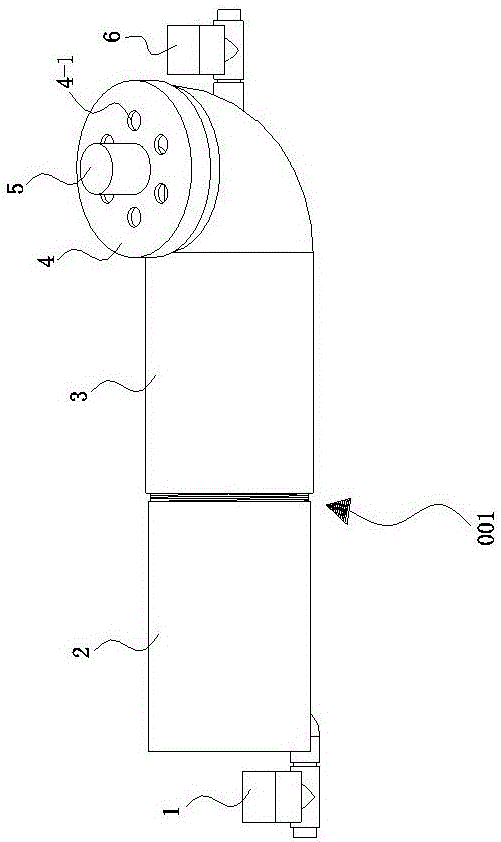

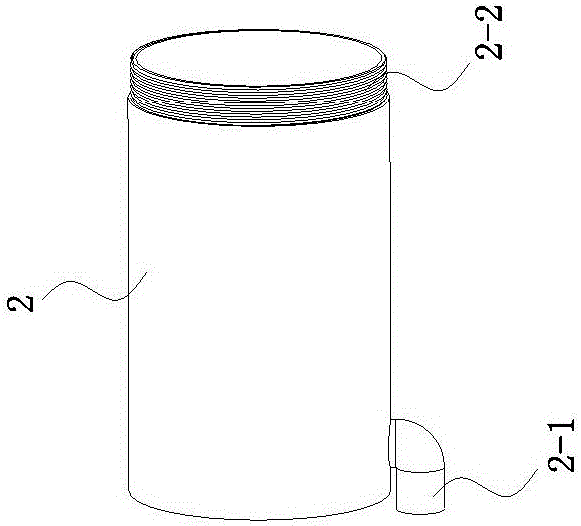

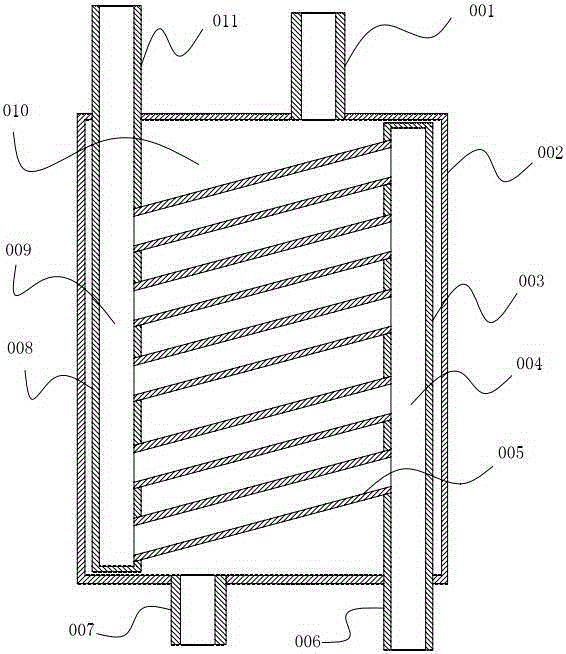

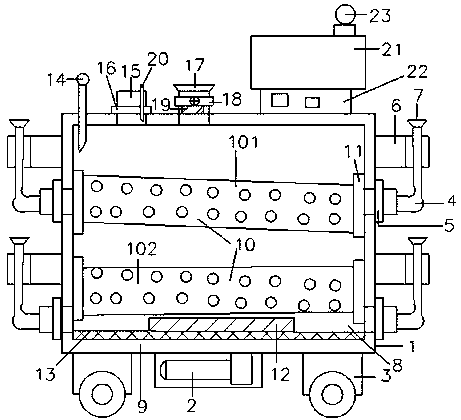

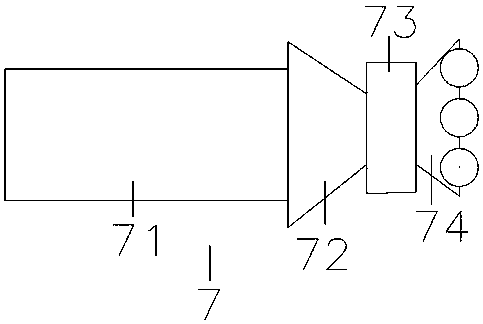

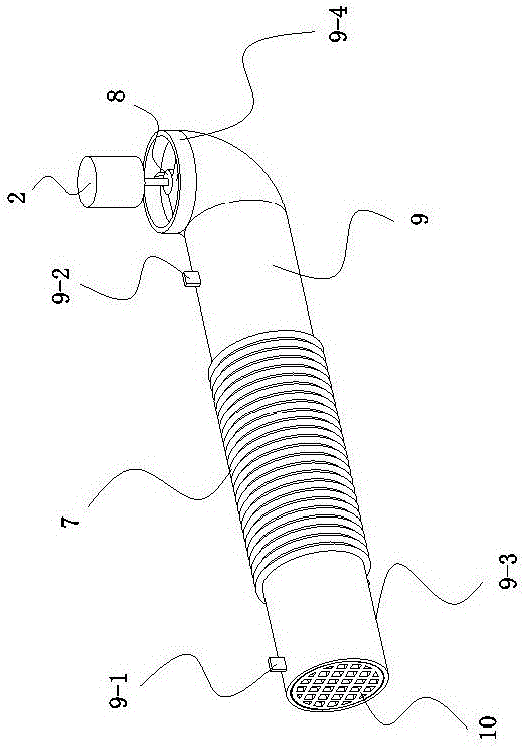

Washing machine with washing powder dissolving device

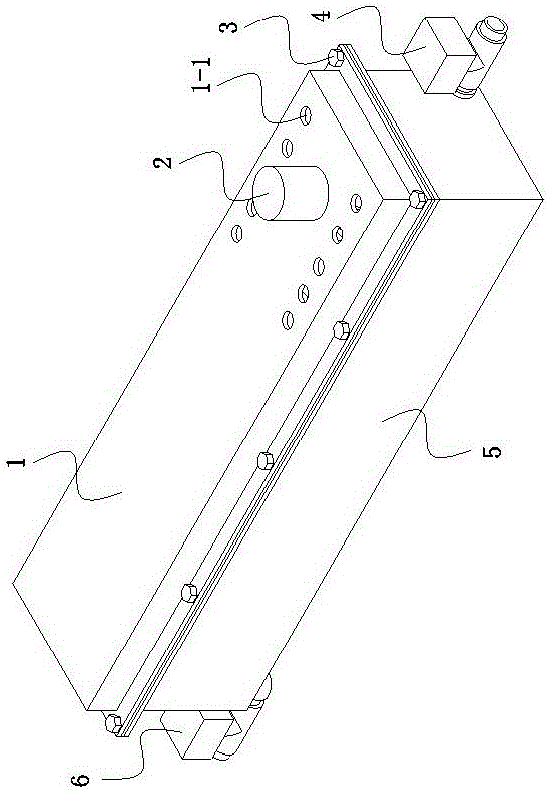

InactiveCN105113180AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperImpellerWater flow

The invention discloses a washing machine with a washing powder dissolving device. The washing machine comprises a machine shell, an outer tub, an inner tub and an impeller. A detergent box and the washing powder dissolving device are arranged at the upper portion of the machine shell. The washing powder dissolving device comprises a water containing pipe, a guide pipe and a stirrer. The guide pipe is divided into a guide pipe vertical section, a guide pipe elbow section and a guide pipe horizontal section. An electric heating wire is wound around the outer side of the guide pipe horizontal section. A resistance plate is arranged on the inner side of the guide pipe horizontal section. The stirrer comprises a motor and a stirring impeller. The motor is installed above the water containing pipe. An output shaft of the motor penetrates into the water containing pipe and is inserted into the guide pipe vertical section. The stirring impeller is fixedly installed at the lower end of the output shaft of the motor. A water inlet and a water outlet are formed in the water containing pipe. A water inlet electromagnetic valve is installed on the outer side of the water inlet. A water outlet electromagnetic valve is installed on the outer side of the water outlet. The water inlet electromagnetic valve is connected with the detergent box through a water pipe. The water outlet electromagnetic valve is connected with a water pipe for guiding washing water flowing through the water outlet electromagnetic valve into the inner tub. A liquid level sensor and a temperature sensor are arranged in the water containing pipe.

Owner:蒋凤英

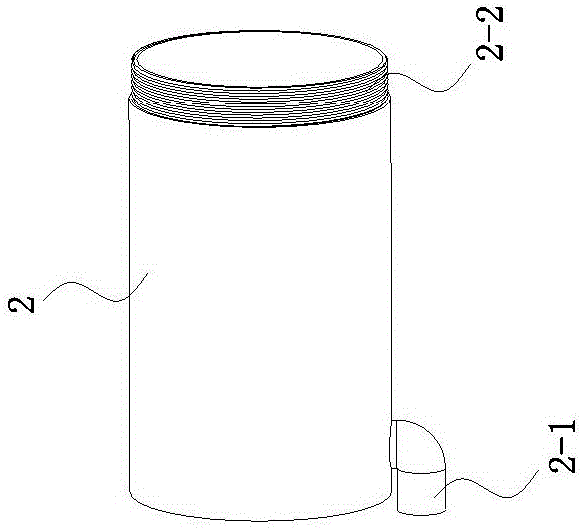

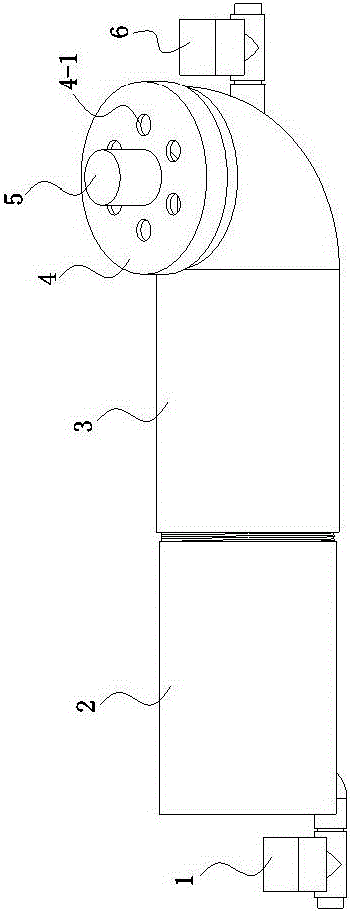

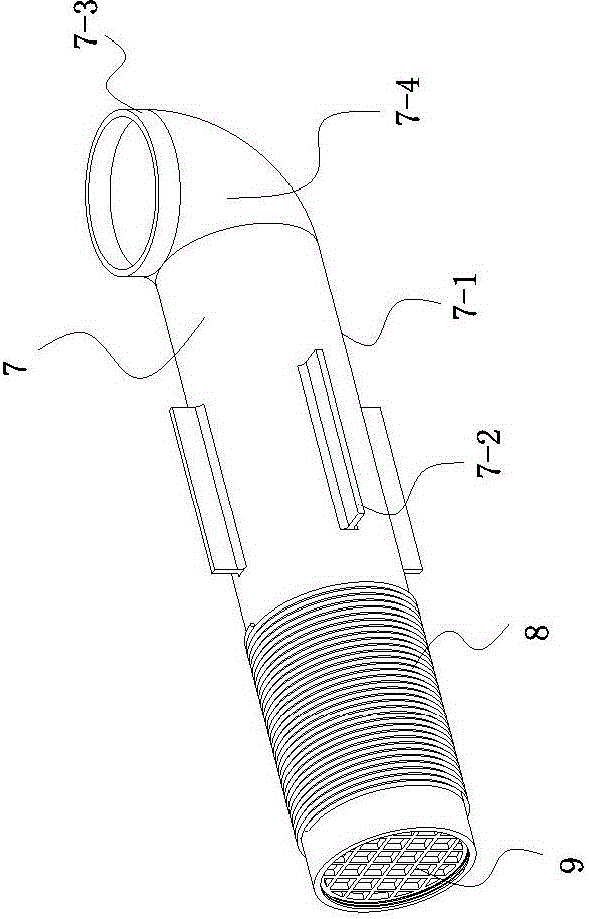

Washing powder dissolving device

InactiveCN105113181AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperImpellerEngineering

The invention discloses a washing powder dissolving device which comprises a water containing pipe, a guide pipe installed in the water containing pipe and a stirrer installed on the water containing pipe. The guide pipe is divided into a guide pipe vertical section, a guide pipe bend section and a guide pipe horizontal section. The lower end of the guide pipe vertical section is integrally connected with the upper end of the guide pipe bend section. The lower end of the guide pipe bend section is integrally connected with the front end of the guide pipe horizontal section. An electric heating wire is wound on the outer side of the guide pipe horizontal section. A resistance plate is disposed on the inner side of the rear end of the guide pipe horizontal section. The stirrer comprises a motor and a stirring impeller. The motor is fixedly installed on the upper portion of the outer side of the water containing pipe. An output shaft of the motor penetrates into the water containing pipe to be inserted into the guide pipe vertical section. The stirring impeller is fixedly installed at the lower end of the output shaft of the motor. The water containing pipe is further provided with a water inlet and a water outlet. A water inlet electromagnetic valve is installed on the outer side of the water inlet. A water outlet electromagnetic valve is installed on the outer side of the water outlet. A liquid level sensor and a temperature sensor are further disposed in the water containing pipe.

Owner:蒋凤英

Sample dissolving method for testing titanium in pig iron and cast iron through diantipyrylmethane colorimetric method

InactiveCN105588743AAchieve complete dissolutionThe test result is accuratePreparing sample for investigationDissolutionTitanium

The invention discloses a sample dissolving method for testing titanium in pig iron and cast iron through a diantipyrylmethane colorimetric method. The method comprises the steps that S1, 0.5000 g of samples are weighed and put in a 250 ml triangular beaker, 25 ml of sulfuric acid and nitric acid mixed acid is added for dissolution, cooling is performed after dissolution and drainage, 15 ml of 1:1 sulfuric acid is added, concentrated nitric acid is added dropwise, cooling is performed after silicate precipitation, 50 ml of water is added for dissolving salt, and the mixture is boiled till big bubbles are produced, taken down for cooling and filtered into a 100 ml volumetric flask for settlement and dissolution; S2, 10 ml of mother liquor is sucked and put in a 50 ml volumetric flask; S3, 10 ml of ascorbic acid is added, and the mixture is placed for 5 minutes; S4, 1.5 ml of 1:1 hydrochloric acid is added; S5, settlement and dissolution are performed for 5 minutes, then colorimetry is carried out, the wave length is 420 mm, and the reference solution is a 5:95 hydrochloric acid solution. By the adoption of the method, the content of titanium in pig iron and cast iron can be determined precisely.

Owner:吴志强 +1

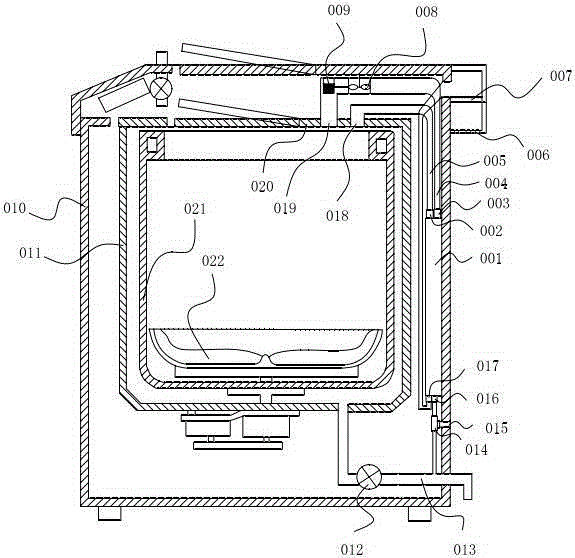

Energy-saving machine provided with box-shaped detergent dissolver

InactiveCN105200727AIncrease volumeAvoid sealing difficultiesOther washing machinesWashing machine with receptaclesImpellerWater pipe

The invention discloses an energy-saving machine provided with a box-shaped detergent dissolver. The energy-saving washing machine is characterized in that a detergent dissolving device is arranged at the upper part of a case, and a heat exchanger is arranged in the case; a wet and hot air inlet, a cold air outlet, a wet and hot air outlet and a cold air inlet are formed in the heat exchanger; the cold air outlet, a fan, an electric heater and a warm air supply port are connected through a pipeline, a wet and hot air exhaust port is connected with the wet and hot air inlet through a pipeline, the wet and hot air outlet is connected with a tee joint through a pipeline, and the tee joint is connected with an exhaust port and a drain pipe through a pipeline respectively; the cold air inlet is connected with a filter and an air suction port through a pipeline. The detergent dissolving device comprises a box, a guiding pipe and a stirrer, wherein a water inlet and a water outlet are formed in the box, and a water inlet solenoid valve and a water outlet solenoid valve are mounted on the outer sides of the water inlet and the water outlet respectively; the water inlet solenoid valve is connected with a detergent box through a water pipe; the guiding pipe is fixed in the box, stirring impellers of the stirrer are inserted into the guiding pipe, and a liquid level sensor is further arranged in the box.

Owner:耒阳市亲民电子商务有限公司

Washing machine provided with washing powder dissolving device

InactiveCN105113185AImprove solubilityIncrease volumeOther washing machinesTextiles and paperImpellerPulp and paper industry

Owner:蒋凤英

Washing machine with detergent dissolution device

InactiveCN105133257AImprove solubilitySimple structureOther washing machinesTextiles and paperImpellerSolenoid valve

The invention discloses a washing machine with a detergent dissolution device. The washing machine comprises a machine casing, an outer barrel, an inner barrel and an impeller. A detergent box and the detergent dissolution device are arranged on the upper portion of the machine casing. The detergent dissolution device comprises a water containing pipe, a guide pipe installed in the water containing pipe and a stirrer installed on the water containing pipe. The stirrer comprises a motor and a stirring impeller, the motor is fixedly installed above the outer side of the water containing pipe, an output shaft of the motor penetrates into the water containing pipe to be inserted in the guide pipe, the stirring impeller is fixedly installed at the lower end of the output shaft of the motor, the water containing pipe is further provided with a water inlet and a water outlet, a water inlet solenoid valve is installed on the outer side of the water inlet, and a water outlet solenoid valve is installed on the outer side of the water outlet. The water inlet solenoid valve is connected with the detergent box through a water pipe, the water outlet solenoid valve is connected with a water pipe for leading washing water flowing through the water outlet solenoid valve into the inner barrel, and a liquid level sensor is further arranged in the water containing pipe.

Owner:蒋凤英

Washing powder dissolving device

InactiveCN105113184AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperEngineeringStructural engineering

The invention discloses a washing powder dissolving device. The washing powder dissolving device comprises a box body, a guiding pipe and a stirrer. A water inlet used for leading washing water into the box body is formed in the right side of the box body, and a water inflow electromagnetic valve is installed on the outer side of the water inlet. A water outlet used for discharging the washing water in the box body is formed in the bottom of the box body, and a water outflow electromagnetic valve is installed on the outer side of the water outlet. The guiding pipe is detachably and fixedly arranged in the box body and composed of a vertical segment, an elbow segment and a horizontal segment, the lower end of the vertical segment and the upper end of the elbow segment are integrally connected, and the lower end of the elbow segment and the front end of the horizontal segment are integrally connected; an electric heating wire is wound on the outer side the horizontal segment, and a resistance plate is arranged on the inner side is arranged at the rear end of the horizontal segment. The stirrer comprises a motor and a stirring impeller, the motor is fixedly installed above the outer side of the box body, and the lower end of a motor output shaft penetrates into the box body through a shaft hole formed in the upper portion of the box body and is inserted into the vertical segment of the guiding pipe. The stirring impeller is fixed to the lower end of the motor output shaft. A liquid level sensor and a temperature sensor are further arranged on the inner side of the box body.

Owner:蒋凤英

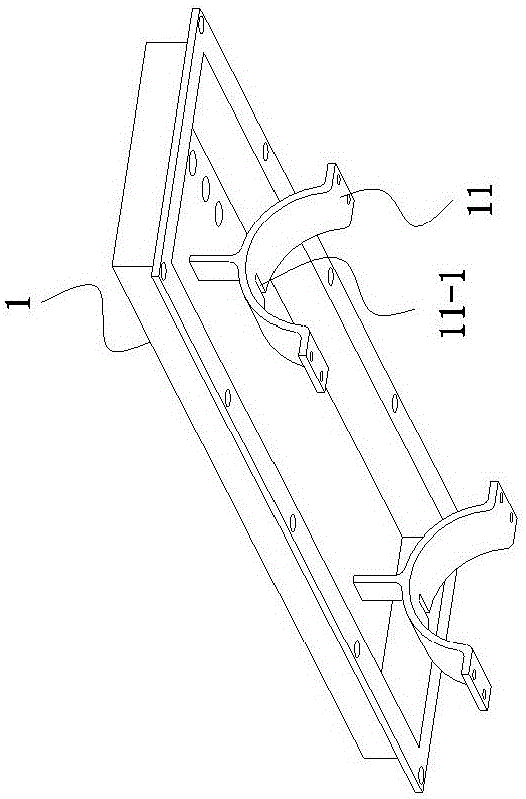

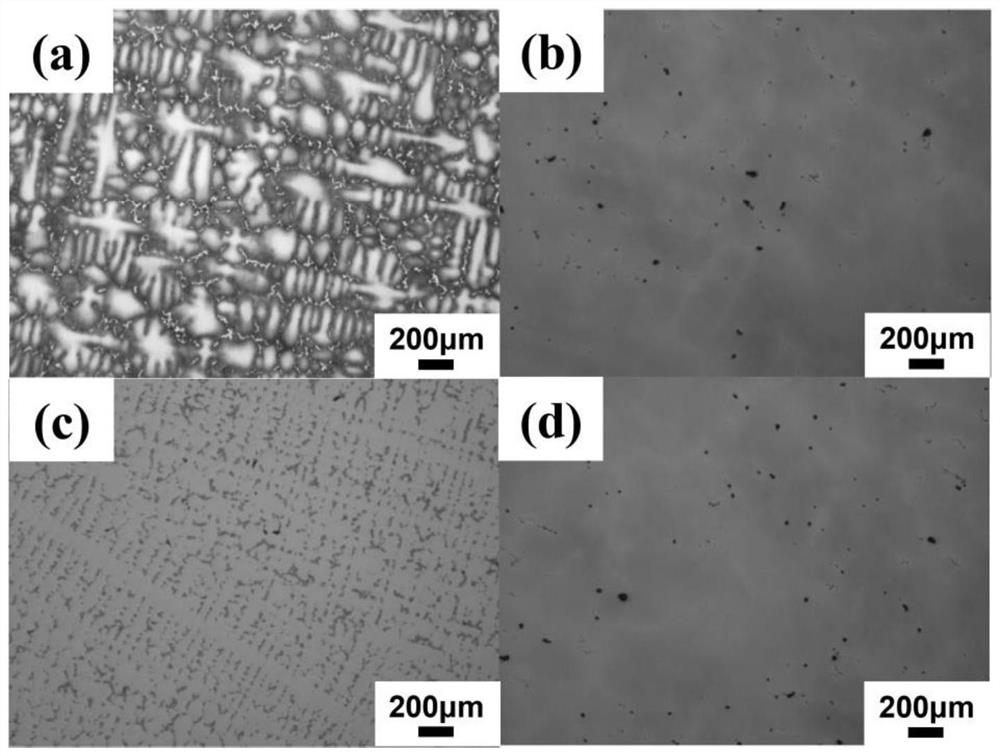

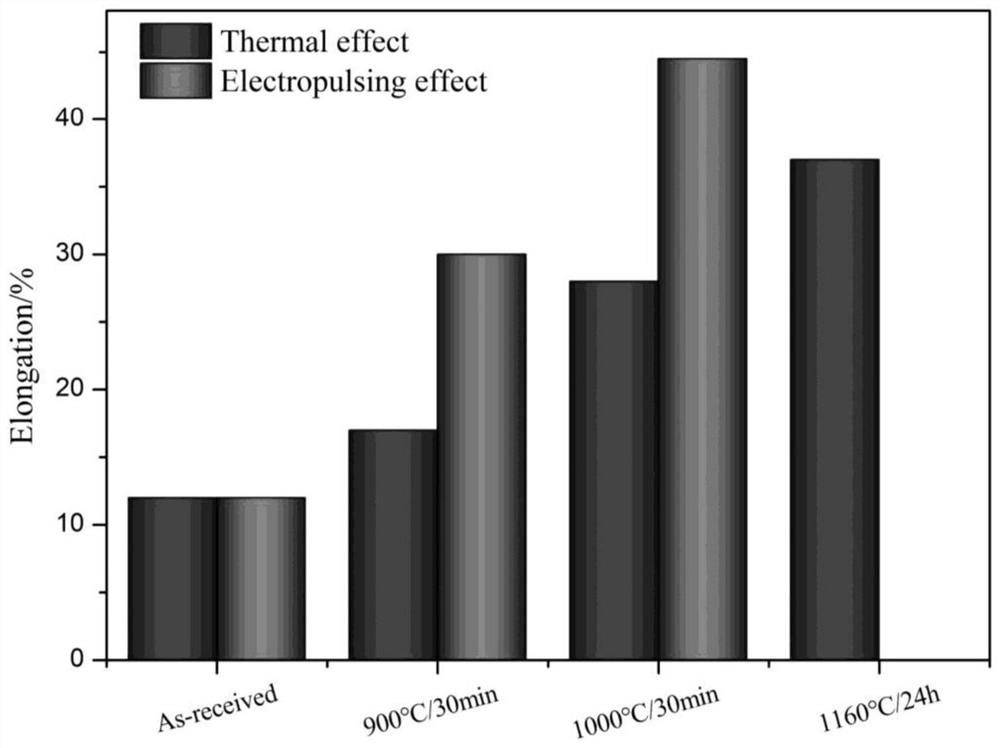

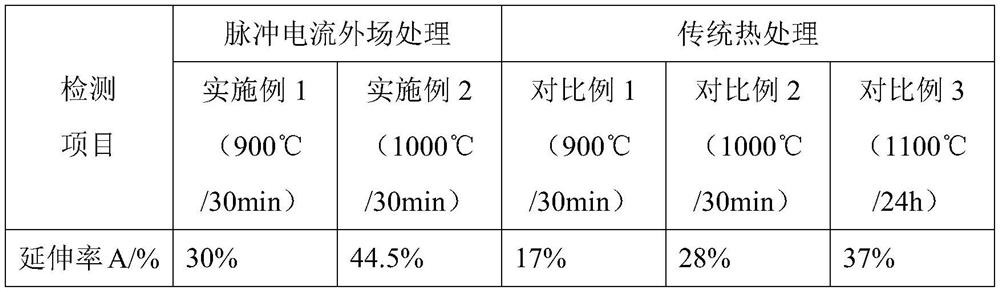

Method for rapidly dissolving Laves phase in deformed high-temperature alloy ingot by pulse current

The invention discloses a method for rapidly dissolving Laves phase in a deformed high-temperature alloy ingot by pulse current. The method comprises the following steps of carrying out pulse currentexternal field treatment on the deformed high-temperature alloy ingot under the following treatment parameters that the pulse frequency is 25000-35000 Hz, the current density is 1A / mm<2> - 100A / mm<2>.The method has the advantages that the Laves phase in the material can be completely dissolved at a relatively low temperature within an extremely short time, the time is short, the temperature is low, the operation is simple, the energy consumption can be greatly reduced, and the requirements of current industrial green development planning are met; and in addition, the plasticity of the alloy can be improved, the alloy is used for deformed high-temperature alloy treatment, subsequent cogging and forging processes are facilitated, and a new method is provided for preparation of a high-temperature alloy turbine disc.

Owner:BEIJING CISRI GAONA TECH +1

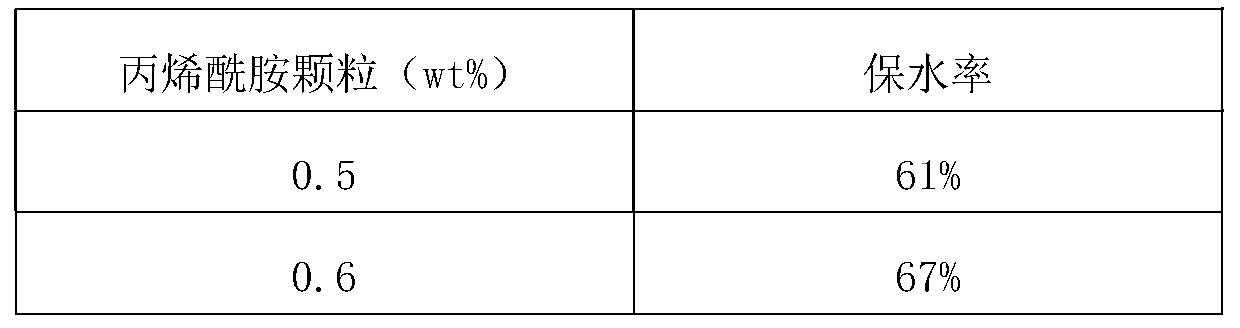

Acrylamide particle hydrogel fire extinguishing agent

The invention discloses an acrylamide particle hydrogel fire extinguishing agent, and belongs to the technical field of fire extinguishing agent production. The hydrogel fire extinguishing agent is prepared from acrylamide, a cross-linking agent, an initiator, a catalyst and water; the cross-linking agent is any one of N,N'-methylenebisacrylamide and N,N'-methylenebismethacrylamide; the initiatoris any one of ammonium persulfate, potassium persulfate and sodium persulfate; and the catalyst is any one of tetramethylethylenediamine and N,N-dimethyl-1,3-propanediamine. The prepared hydrogel fireextinguishing agent has the advantages of good solubility, suitableness for various water qualities, cheap production raw materials, high water-retaining property, high adhesion and high mechanical properties, and can be simply and conveniently operated in practical application.

Owner:JIANGXI SCI & TECH NORMAL UNIV +1

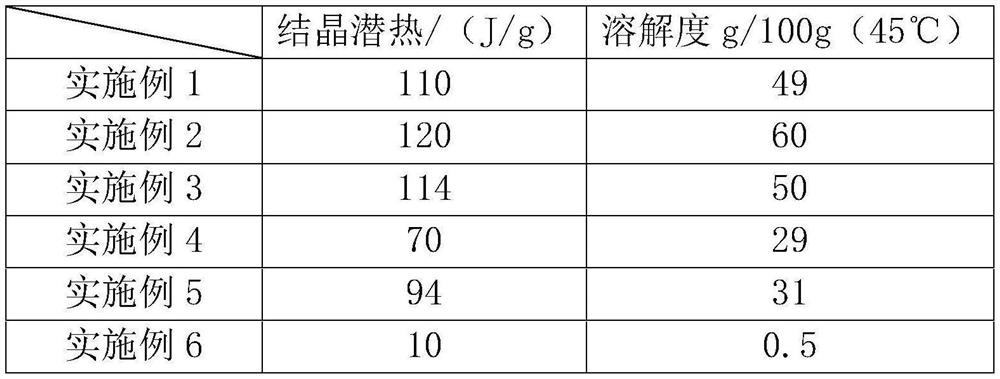

Mirabilite-based phase change material and method for dissolving mirabilite-based phase change material in glycerol system

PendingCN114181667AFully crystallizedReduce subcoolingHeat-exchange elementsGlycerolPhysical chemistry

The invention relates to the field of phase change materials, and particularly discloses a mirabilite-based phase change material and a dissolving method thereof in a glycerol system. The mirabilite-based phase change material is prepared from the following raw materials in parts by weight: 49.5 to 90 parts of mirabilite, 5.5 to 10 parts of sodium carbonate decahydrate, 3 to 7 parts of borax, 7 to 10 parts of sodium hydroxide solid, 20 to 25 parts of glycerol and 80 to 100 parts of water. The dissolving method comprises the following steps: S1, preparing salt; S2, preparing a glycerol solvent; S3, preparing the mirabilite-based phase change material; and S4, standing and forming. The mirabilite-based phase change material disclosed by the invention is more complete in crystallization and better in cycling stability; in addition, the dissolving method provided by the invention has the advantages of simple and accurate process flow operation, and time and labor saving.

Owner:QINGHAI UNIVERSITY

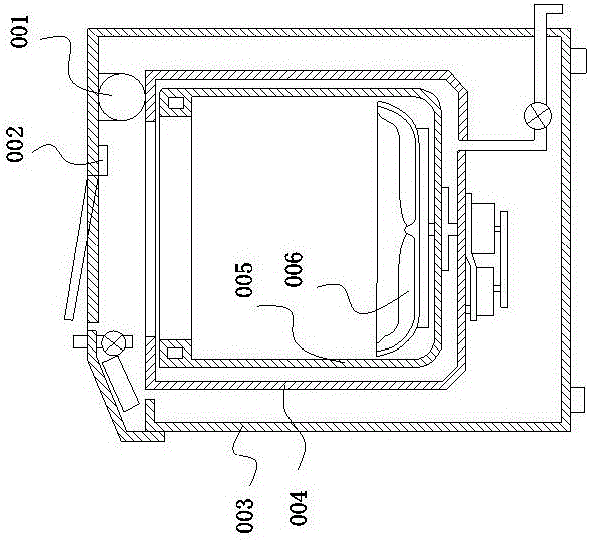

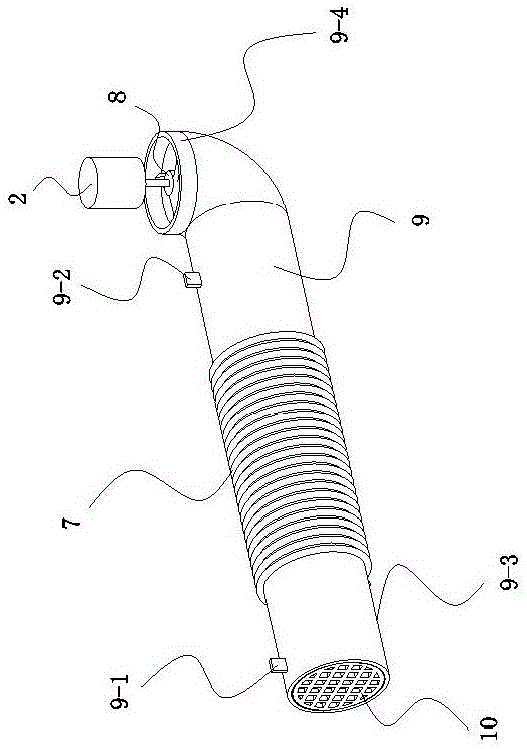

Special fertilizer application device for plants

ActiveCN109348814AImprove securityImprove permeabilityManure treatmentLiquid fertiliser regulation systemsPipe fittingEngineering

The invention relates to a special fertilizer application device for plants. The device comprises a shell body, wherein a motor is arranged at the bottom of the shell body; the motor is connected withuniversal wheels welded and fixed at the bottom of the shell body; four pipe fittings are respectively arranged on both sides of the shell body; cut-off valves are arranged at the bottoms of the fourpipe fittings; the cut-off valves are connected with hanging pieces; the hanging pieces are matched with nozzles arranged at the tops of the pipe fittings; the bottoms of the pipe fittings are connected with an inner cavity of the shell body; a damping layer is arranged between the shell body and the inner cavity; a plurality of vibrating screen plates are arranged in the middle of the inner cavity, and the vibrating screen plates are welded and fixed on the inside of the inner cavity through supporting pieces; a vibration ultrasonic instrument is arranged on a damping plate at the bottom ofthe inner cavity; a liquid level instrument is arranged at the top of the shell body; the liquid level instrument is connected with a liquid inlet pipe; a one-way valve is arranged on the liquid inletpipe; the one-way valve is connected with a flowmeter; the liquid inlet pipe is connected with a feeding hopper; a valve is arranged on the feeding hopper; the valve is connected with a weigher; thefeeding hopper is connected with a controller; the bottom of the controller is connected with an adjusting button; an alarm is arranged at the top of the controller. The device has high working efficiency and precision, good permeability, uniform dispersion, stable shock absorption and convenient use.

Owner:重庆珍西农业科技集团有限公司

Washing machine provided with washing powder dissolving device

InactiveCN105113183AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses a washing machine provided with a washing powder dissolving device. The washing machine comprises a machine shell, an outer cylinder, an inner cylinder and an impeller. A detergent box and the washing powder dissolving device are arranged above the machine shell. The washing powder dissolving device comprises a box body, a guide pipe and a stirrer. A water inlet and a water outlet are formed in the box body. The outer side of the water inlet is provided with a water inlet electromagnetic valve, the water inlet electromagnetic valve is connected with the detergent box through a water pipe, and the outer side of the water outlet is provided with a water outlet electromagnetic valve. The guide pipe is fixed into the box body and divided into a vertical segment, an elbow segment and a horizontal segment. The lower end of the vertical segment and the upper end of the elbow segment are integrally connected, and the lower end of the elbow segment and the front end of the horizontal segment are integrally connected. Heating wires are wound around the outer side of the horizontal segment, and the inner side of the horizontal segment is provided with a resistance plate. The stirrer comprises a motor and a stirring impeller. The motor is fixed above the box body, and the lower end of an output shaft of the motor is arranged in the box body in a penetrating mode through a shaft hole and inserted into the vertical segment of the guide pipe. The stirring impeller is fixed to the lower end of output shaft of the motor. The inner side of the box body is further provided with a liquid level sensor and a temperature sensor.

Owner:蒋凤英

A method for determining niobium content in titanium-niobium alloy

ActiveCN104020157BAchieve complete dissolutionGuaranteed accuracyPreparing sample for investigationAnalysis by thermal excitationObservational errorRelative standard deviation

Owner:AEROSPACE PRECISION PROD INC LTD

Surface treatment method for carbon fiber curved plate for decorative tail pipe of automobile exhaust pipe

ActiveCN106150645ASimple structureIncreased hardness and surface smoothnessExhaust apparatusPretreated surfacesSurface finishingMicrometer

The invention provides a surface treatment method for a carbon fiber curved plate for a decorative tail pipe of an automobile exhaust pipe. The surface treatment method includes the following steps that firstly, the surface of the carbon fiber curved plate is scrubbed with acetone, oil stains are removed, then the carbon fiber curved plate is wiped and dried with dry cloth, and then the carbon fiber curved plate is scrubbed with ether and finally is air-dried in a dust-free environment; secondly, the carbon fiber curved plate is put into a surface treatment agent which is pre-heated to 60 DEG C and is soaked for 5 minutes; thirdly, the carbon fiber curved plate is washed with ethanol with the concentration being 95% till the pH valve returns to the neutral state after being fished out, and then the carbon fiber curved plate is dried for 6 hours at the temperature of 50 DEG C; and fourthly, the surface of the carbon fiber curved plate is coated with a layer of polytetrafluoroethylene protective film with the thickness being 0.9 micrometer. By the adoption of the surface treatment method, surface treatment of the carbon fiber curved plate can be achieved, both the hardness and the surface smoothness of the carbon fiber curved plate are improved remarkably, and the service life can be prolonged remarkably.

Owner:山东永通汽车配件有限公司

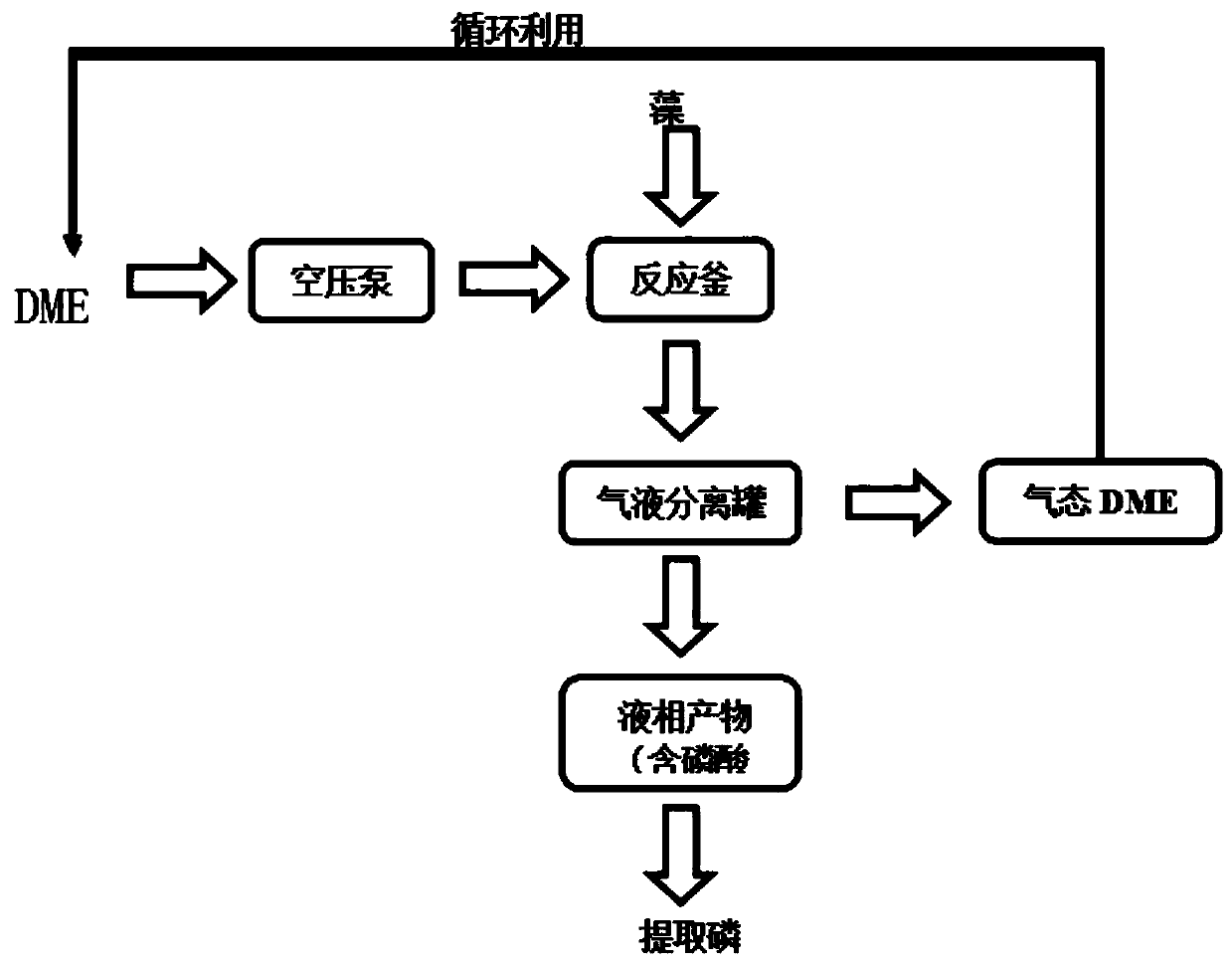

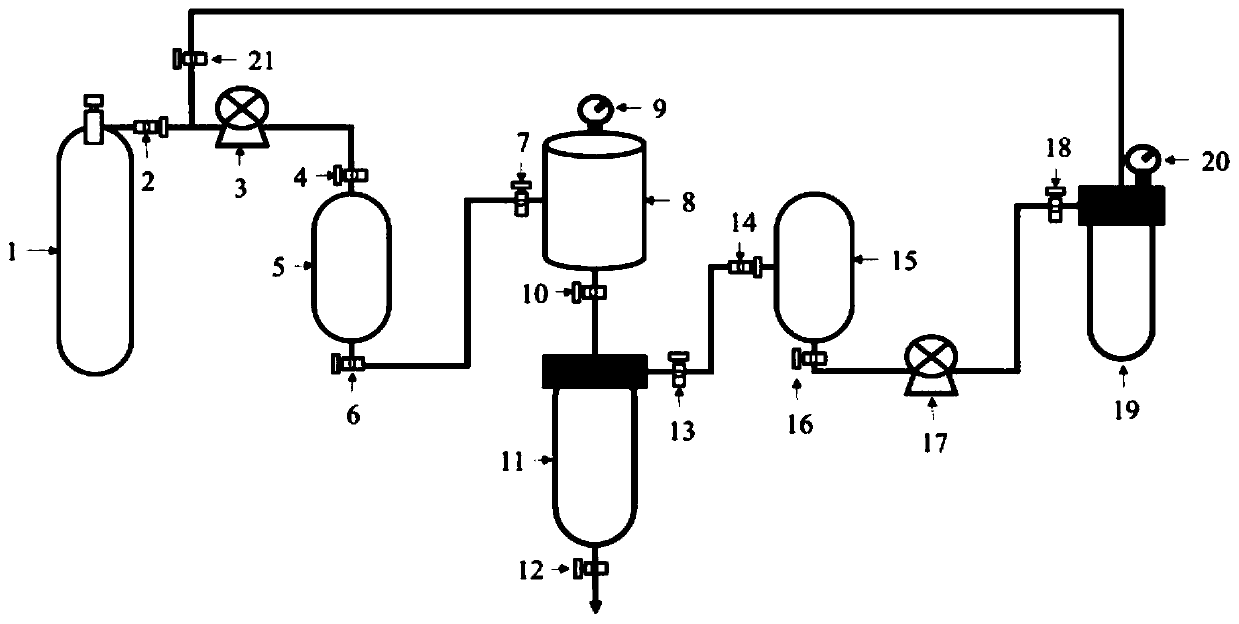

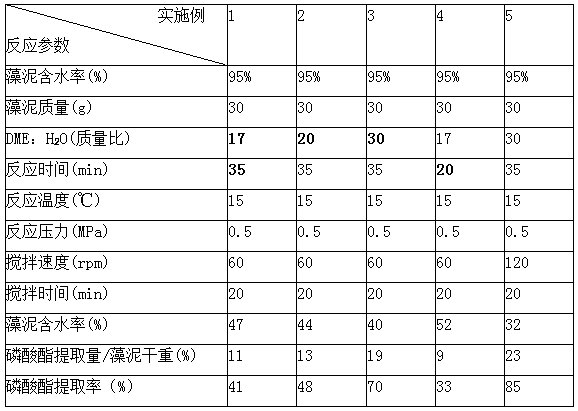

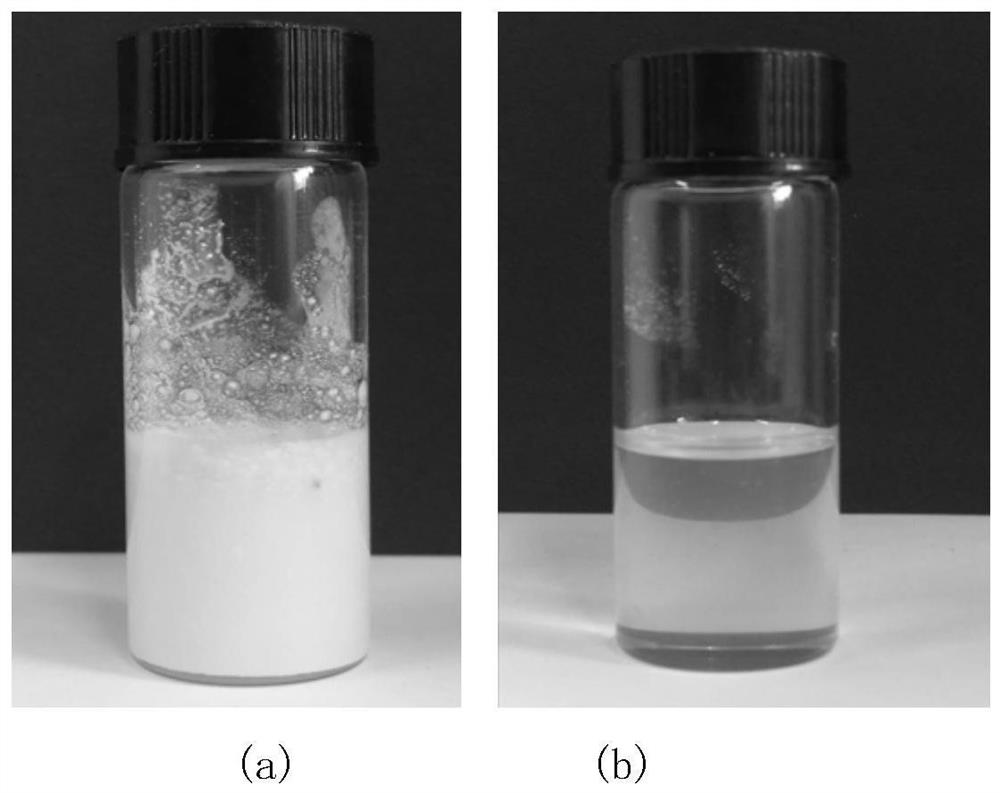

Method for extracting phosphate ester from alga mud by using dimethyl ether

InactiveCN111560035AImprove efficiencyEasy to separateSludge treatmentSolvent extractionPhosphoric Acid EstersFluid phase

The invention relates to a method for extracting phosphate ester from alga mud by using dimethyl ether. The method comprises the following steps: putting alga mud formed after blue algae are fished into a reaction kettle, converting DME into a liquid state by using an air compression pump, and dissolving phosphate ester by adjusting the reaction parameters of the reaction kettle and adjusting thepolarity of DME to be consistent with that of phosphate ester; carrying out solid-liquid separation on the obtained mixture, wherein the obtained solid phase is dehydrated alga mud, the water contentis reduced to 40%, and the subsequent landfill incineration requirement is met; and separating the obtained liquid-phase product, converting the liquid DME into gaseous DME through normal-temperaturepressure reduction, collecting the gaseous DME for reuse, enabling the residual liquid-phase product to be rich in phosphate ester, and further extracting the phosphorus element so as to achieve the purposes of reduction and resource utilization of the alga mud.

Owner:HOHAI UNIV

A kind of dissolving system and dissolving method for dissolving graphite phase carbon nitride

ActiveCN111659271BImprove solubilityDissolve fastTransportation and packagingChemical/physical processesNitrate saltsSulfate

The invention discloses a dissolution system and a dissolution method for dissolving graphitic carbon nitride, comprising: a chemical reagent comprising at least one of the following: halide salts, nitrates or sulfuric acid of lithium, zinc, aluminum, tin At least one of the salts; water as a solvent and graphitic carbon nitride to be dissolved; wherein, the amount of the chemical reagent is 20% to 80% of the total mixture mass, and the solvent accounts for 20% to 80% of the total mixture mass, The total mixture is a mixture of graphitic carbon nitride, chemical reagents and solvents. The invention has the advantages of environmental protection and good solubility.

Owner:MINNAN NORMAL UNIV

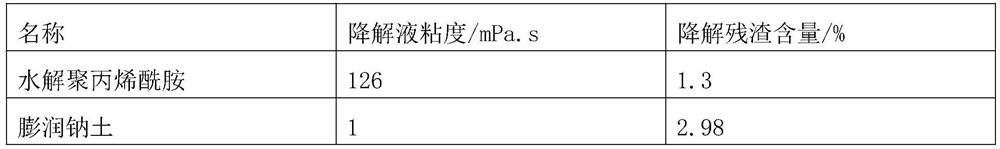

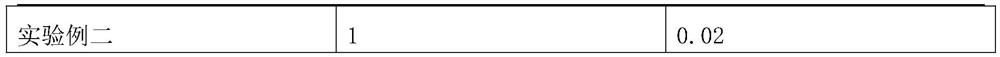

Plugging agent for temporary plugging in oil and gas well repairing

PendingCN113621356AImprove pressure bearing capacityAchieve hydrolysisDrilling compositionMeth-Benzoyl peroxide

The invention belongs to a plugging agent for temporary plugging in oil and gas well repairing. The plugging agent comprising the following raw materials in parts by mass: 20 to 40 parts of a polymeric monomer, 5 to 10 parts of a biopolymer, 0.1 to 1.0 part of a cross-linking agent, 50 to 70 parts of a reinforcing agent, 0.01 to 0.05 part of a gel breaker and 0.001 to 0.003 part of an initiator, wherein the polymeric monomer is selected from a mixture of acrylamide and methacrylamide; the biopolymer is one selected from xanthan gum and guar gum; the cross-linking agent is selected from ethylene glycol dimethacrylate; the reinforcing agent is one or a mixture of more than one selected from potassium chloride, sodium chloride, sodium nitrate and potassium nitrate; the gel breaker is a mixture of benzoyl peroxide and ferrous sulfate, and a molar ratio of benzoyl peroxide to ferrous sulfate is (1-2): 1; and the initiator is 1-((cyano-1-methylethyl)azo)formamide. The plugging agent has the advantages that pressure-bearing strength is good, self-degradation release can be realized, and damage to a stratum is small.

Owner:北京国海能源技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com