Acrylamide particle hydrogel fire extinguishing agent

A technology of acrylamide and hydrogel, which is applied in the direction of fire prevention equipment, etc., can solve the problems of unfavorable fire extinguishing application, high preparation cost, low dissolution rate, etc., and achieve the effect of preventing fire from spreading and expanding, reducing fire loss, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

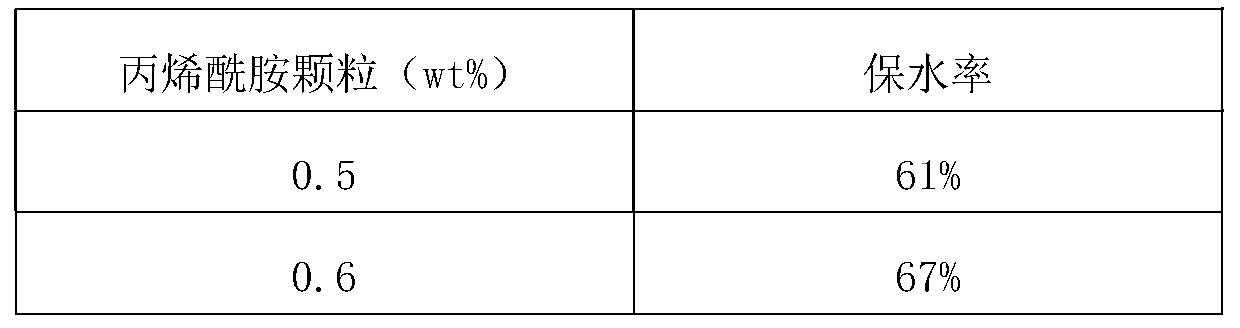

Embodiment 1

[0041] An acrylamide granular hydrogel fire extinguishing agent, prepared from the following raw material components: A. Acrylamide, B. Crosslinking agent: N, N'-methylenebisacrylamide, C. Initiator: over Ammonium sulfate, D. catalyst: tetramethylethylenediamine, E. water;

[0042] Its preparation method comprises the following steps:

[0043] (1) Add component A to deionized water to obtain solution I, the mass fraction of A in solution I is 10wt%;

[0044] (2) B component, C component and D component are added in the above-mentioned solution I respectively, obtain solution II, the mass fraction of B in solution II is 0.002wt%, the mass fraction of C is 0.0015wt%, the mass fraction of D The mass fraction is 0.0002wt%;

[0045](3) Polymerize the above solution II under certain conditions, the reaction temperature is 50-70°C, the time is 1-2 hours, and then dried at 80-100°C to obtain a dry gel;

[0046] (4) disperse the above-mentioned dried gel into particles with a diamet...

Embodiment 2

[0049] An acrylamide granular hydrogel fire extinguishing agent, prepared from the following raw material components: A. Acrylamide, B. Crosslinking agent: N, N'-methylenebismethacrylamide, C. Initiator : Potassium persulfate, D. Catalyst: N, N-dimethyl-1,3-propanediamine, E. water;

[0050] Its preparation method comprises the following steps:

[0051] (1) Add component A to deionized water to obtain solution I, the mass fraction of A in solution I is 20wt%;

[0052] (2) B component, C component and D component are added in the above-mentioned solution I respectively, obtain solution II, the mass fraction of B in the solution II is 0.0002wt%, the mass fraction of C is 0.0002wt%, the mass fraction of D is The mass fraction is 0.0001wt%;

[0053] (3) Polymerize the above solution II under certain conditions, the reaction temperature is 50-70°C, the time is 1-2 hours, and then dried at 80-100°C to obtain a dry gel;

[0054] (4) disperse the above-mentioned dried gel into part...

Embodiment 3

[0057] An acrylamide granular hydrogel fire extinguishing agent, prepared from the following raw material components: A. Acrylamide, B. Crosslinking agent: N, N'-methylenebismethacrylamide, C. Initiator : Sodium Persulfate, D. Catalyst: Tetramethylethylenediamine, E. Water;

[0058] Its preparation method comprises the following steps:

[0059] (1) Add component A to tap water to obtain solution I, and the mass fraction of A in solution I is 15wt%;

[0060] (2) B component, C component and D component are added in the above-mentioned solution I respectively, obtain solution II, the mass fraction of B in solution II is 0.0011wt%, the mass fraction of C is 0.0009wt%, the mass fraction of D The mass fraction is 0.00015wt%;

[0061] (3) Polymerize the above solution II under certain conditions, the reaction temperature is 50-70°C, the time is 1-2 hours, and then dried at 80-100°C to obtain a dry gel;

[0062] (4) disperse the above-mentioned dried gel into particles with a diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com