Surface treatment method for carbon fiber curved plate for decorative tail pipe of automobile exhaust pipe

A technology for decorating tailpipes and automobile exhaust, which is applied in the direction of exhaust devices, pretreatment surfaces, devices for coating liquid on surfaces, etc., and can solve the problem of complex structure of decorative tailpipes, which cannot be adapted to the installation of automobile exhaust pipes of different sizes problems and other problems, to achieve the effect of improving hardness and surface smoothness, providing uniformity of solution, and improving surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

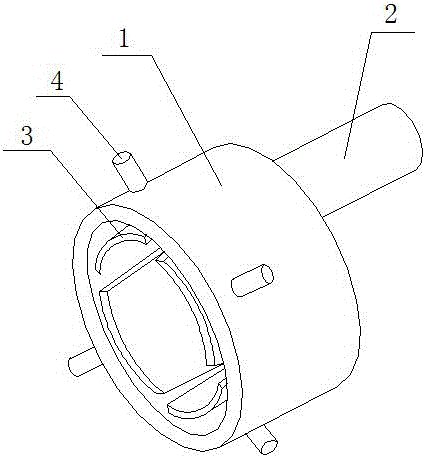

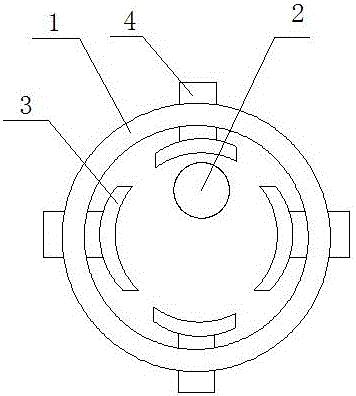

[0023] like Figure 1 to Figure 2 As shown, the present invention provides a decorative tail pipe of an automobile exhaust pipe, comprising a connecting pipe 1 and an exhaust pipe 2 communicating with the connecting pipe 1 .

[0024] Specifically, the diameter of the connecting pipe 1 is larger than the diameter of the air outlet pipe 2, one end of the connecting pipe 1 is open, and the other end is communicated with the air outlet pipe 2; In this embodiment, the number of carbon fiber arc-shaped plates 3 is 4, and the carbon fiber arc-shaped plates 3 are screwed to the connecting pipe 1 through studs 4 .

[0025] When the decorative tail pipe of the automobile exhaust pipe of the present invention is connected to automobile exhaust pipes of different sizes, the length of the stud 4 screwed into the connecting pipe 1 can be adjusted, so that the carbon fiber arc plate 3 can be closely attached to the automobile exhaust pipe. , which is suitable for the installation of automob...

Embodiment 2

[0028] The preparation method of the surface treatment agent of the carbon fiber curved plate for the decorative tail pipe of the automobile exhaust pipe, firstly add 15 parts of hydroxy silicone oil, 25 parts of melamine formaldehyde resin and 10 parts of water into the container, heat to 40 ℃ and stir for 25 minutes; then slowly Add 6 parts of N-tert-butyl-2 benzothiazole sulfenamide, stir while adding, keep stirring at 40 °C for 25 minutes after the addition; then slowly add 15 parts of N,N-dimethylformamide and 10 parts of water , stir while adding, heat to 60 ℃ and stir for 25 minutes after adding; then slowly add 2 parts of protoveratrine, 10 parts of ethanol and 30 parts of water, heat to 80 ℃ and stir for 10 minutes to obtain the surface treatment agent.

Embodiment 3

[0030] The surface treatment method of carbon fiber arc plate for decorative tail pipe of automobile exhaust pipe, the steps are as follows:

[0031] ①. Use acetone to scrub the surface of the carbon fiber arc plate to remove oil stains, then dry the carbon fiber arc plate with a dry cloth, then scrub with ether, and finally dry it in a dust-free environment;

[0032] ②, put the carbon fiber arc plate into the surface treatment agent (prepared in Example 2) preheated to 60 ℃ and soak for 5 minutes;

[0033] 3. After taking out, rinse with 95% ethanol until the pH value is restored to neutrality, and then dry at 50°C for 6 hours;

[0034] ④. Spray a layer of 0.9μm thick polytetrafluoroethylene protective film on the surface of the carbon fiber arc plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com