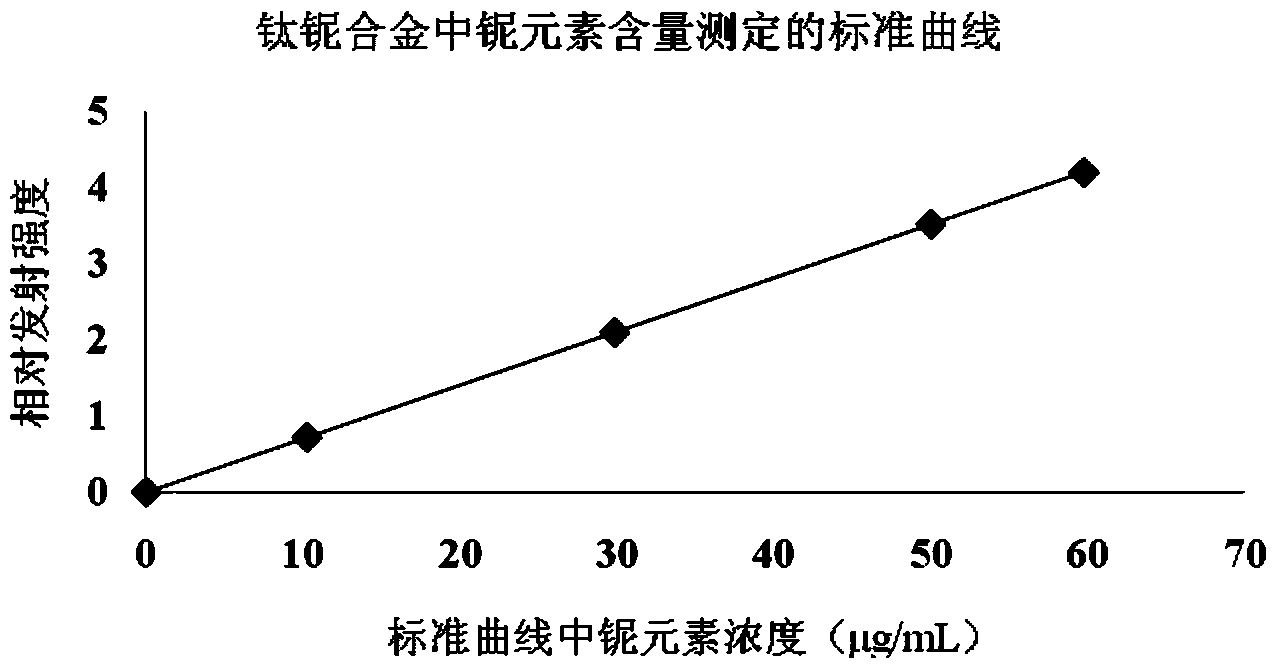

Method for measuring elemental niobium content of titanium-niobium alloy

A titanium-niobium alloy and element content technology, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problem of not being able to find dissolved titanium-niobium alloy samples, and achieves good precision and simple operation. , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

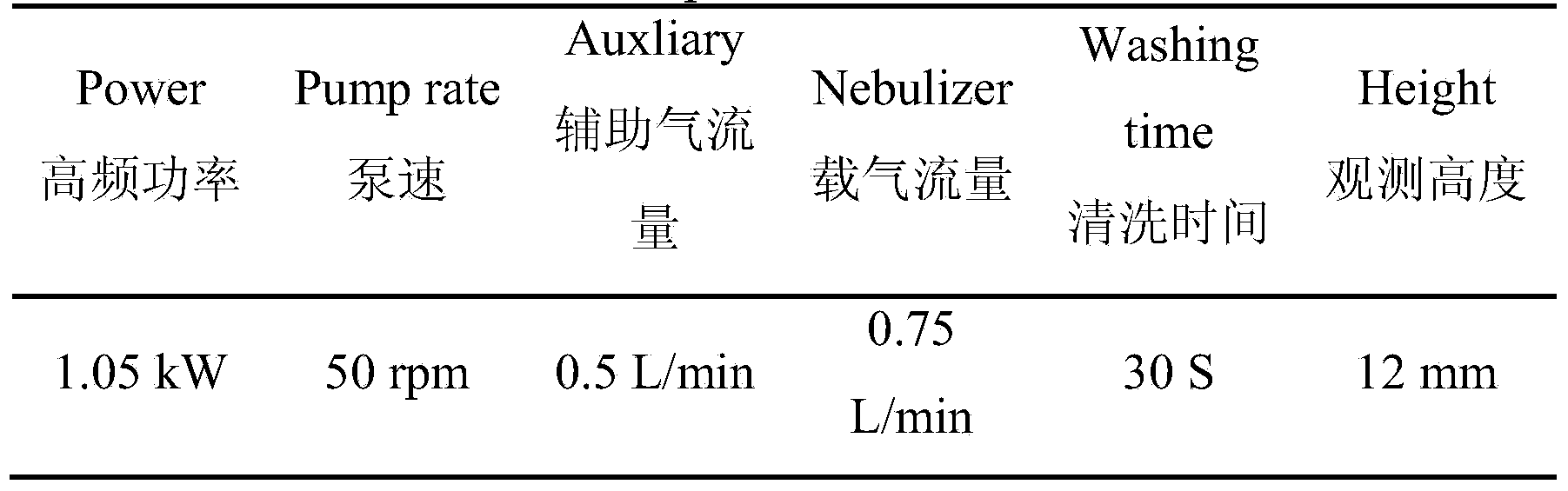

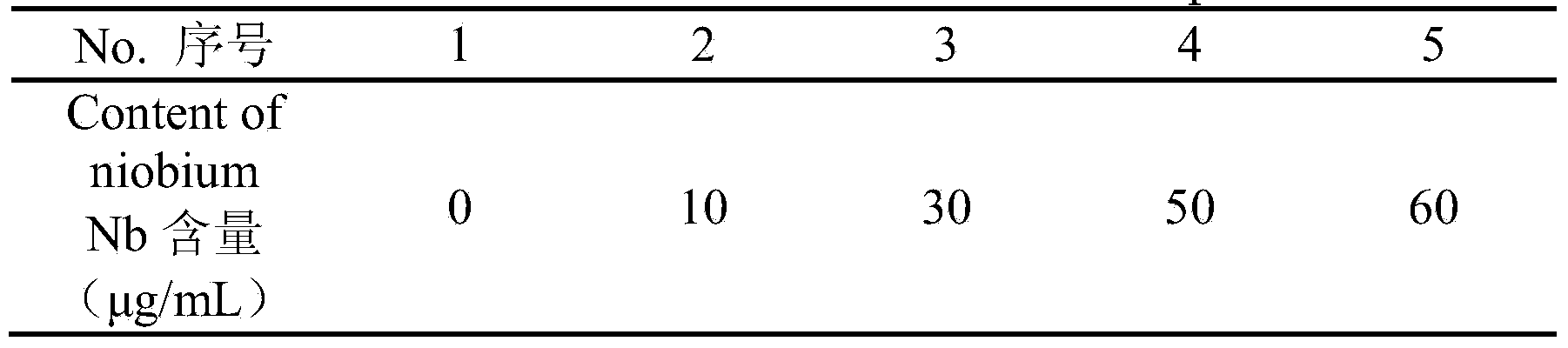

Examples

Embodiment

[0027] S1. Preparation of titanium-niobium alloy solution: Weigh 0.1000g titanium-niobium alloy sample and place it in a 100mL polytetrafluoroethylene beaker, first add 20mL sulfuric acid (1+1), and place the beaker on a temperature-controlled electric heating plate Heating, during the heating process, drop 1mL of hydrofluoric acid into the beaker, stir until the sample is completely dissolved, then add nitric acid until the color of the solution disappears, after cooling, transfer the mixture into a 100mL plastic volumetric flask, and dilute with distilled water Constant volume to scale;

[0028] S2. Preparation of the solution to be tested: Take 10 mL of the titanium-niobium alloy solution in S1 into a 100 mL plastic volumetric flask, add 1 mL of the internal standard solution, and dilute 10 times with distilled water to a volume of 100 mL.

[0029] S3. Preparation of high-purity titanium matrix solution: Weigh 0.0500g of high-purity titanium into a 100mL polytetrafluoroethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com