Self-dissolving functional material for making well drilling bridge plug rubber packer and preparation method therefor

A functional material and self-dissolving technology, which is applied in the field of self-dissolving functional materials and its preparation, can solve the problems of reducing production efficiency, hindering, increasing operating costs, etc., and achieve the effect of improving production efficiency and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

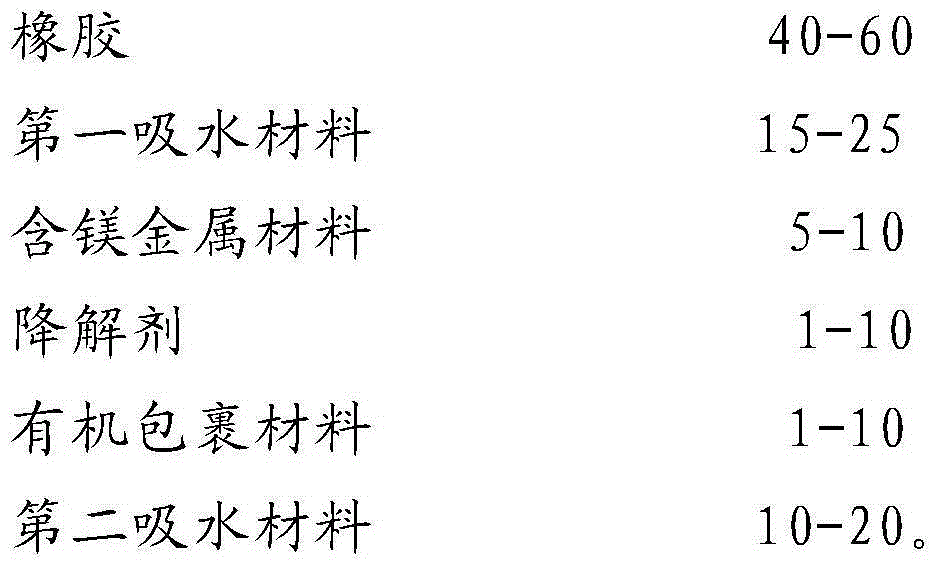

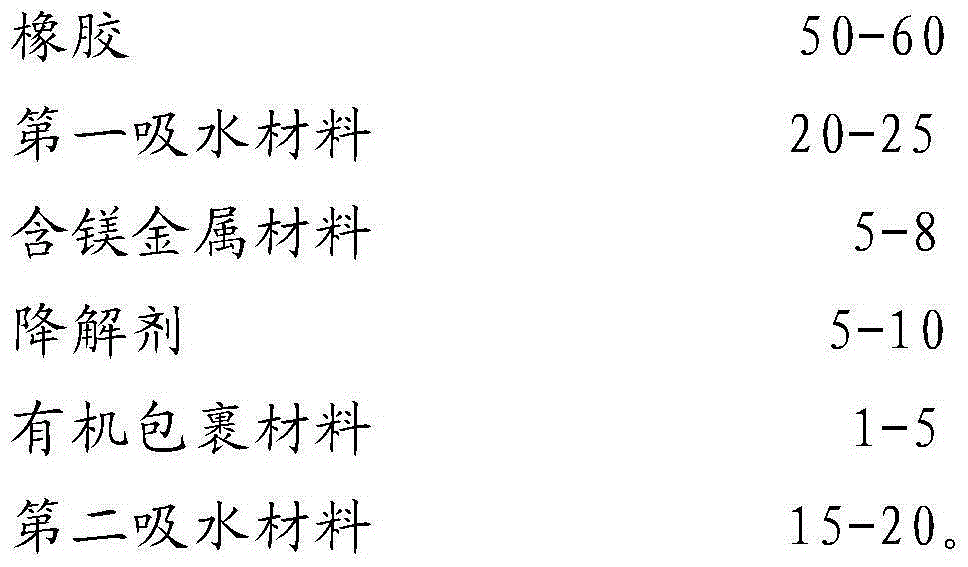

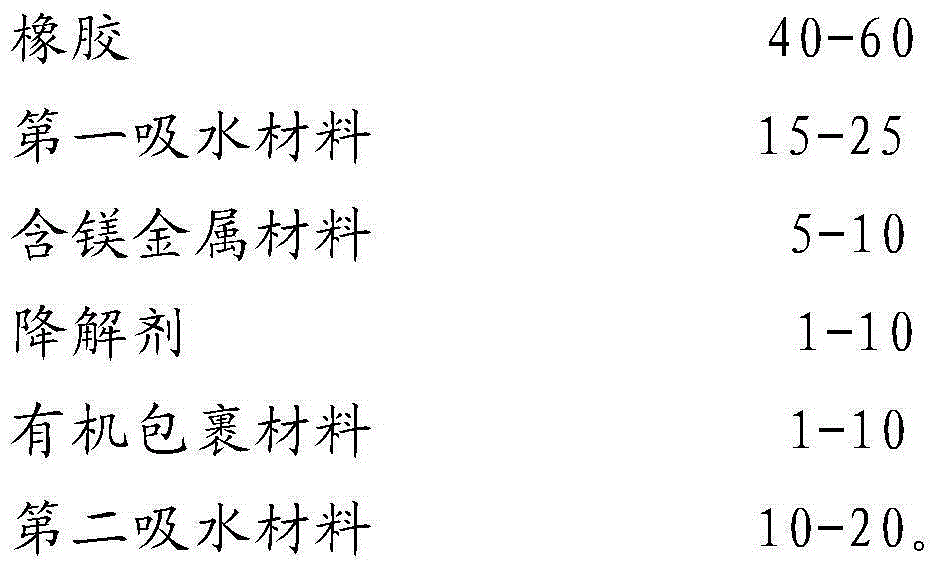

Method used

Image

Examples

Embodiment 1

[0025] Grind 40kg of polyurethane rubber, 1.5kg of sodium hydroxide, 0.5kg of polyvinyl alcohol, and 5kg of magnesium into granules (the particle size is 100-200 mesh), heat the granulated polyvinyl alcohol to melt, and use the melted polyethylene Alcohol carries out repeatedly wrapping to granular sodium hydroxide, until obtaining the sodium hydroxide inclusion body of wrapping completely; With 40kg polyurethane rubber, 15kg diatomaceous earth, 5kg magnesium powder, 10kg cotton fiber (diameter 0.1-0.5mm) and gained The sodium hydroxide inclusions are evenly mixed to obtain the material.

Embodiment 2

[0027] 60kg polyurethane rubber, 2kg potassium hydroxide, 15kg diatomaceous earth, 1kg paraffin, 5kg magnesium aluminum alloy (magnesium 90wt%, aluminum 10wt%) are pulverized into granular (particle size is 100-200 order); Heat to melt, and wrap the granular potassium hydroxide several times with the melted paraffin until the completely wrapped potassium hydroxide inclusions are obtained; 60kg polyurethane rubber, 5kg magnesium aluminum alloy powder, 15kg diatomaceous earth, 10kg nylon fiber (diameter 0.1-0.5mm) and the obtained potassium hydroxide inclusions are evenly mixed to obtain the material.

Embodiment 3

[0029] Grind 30kg of polyurethane rubber, 30kg of butadiene rubber, 4kg of Mg(OH)Cl, 1kg of sodium stearate, 20kg of sodium polyacrylate water-absorbing resin, and 10kg of magnesium into granules (the particle size is 100-200 mesh) into granules ; The granular sodium stearate is heated and melted, and the granular Mg(OH)Cl is repeatedly wrapped with the molten sodium stearate until the complete Mg(OH)Cl inclusions are obtained; the 30kg polyurethane rubber Mix with 30kg of butadiene rubber, 20kg of sodium polyacrylate water-absorbing resin, 10kg of magnesium powder, 15kg of polyester fiber (diameter 0.1-0.5mm) and the obtained Mg(OH)Cl inclusions, stir to make the mixture uniform, and the material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com