Patents

Literature

32results about How to "Avoid sealing difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

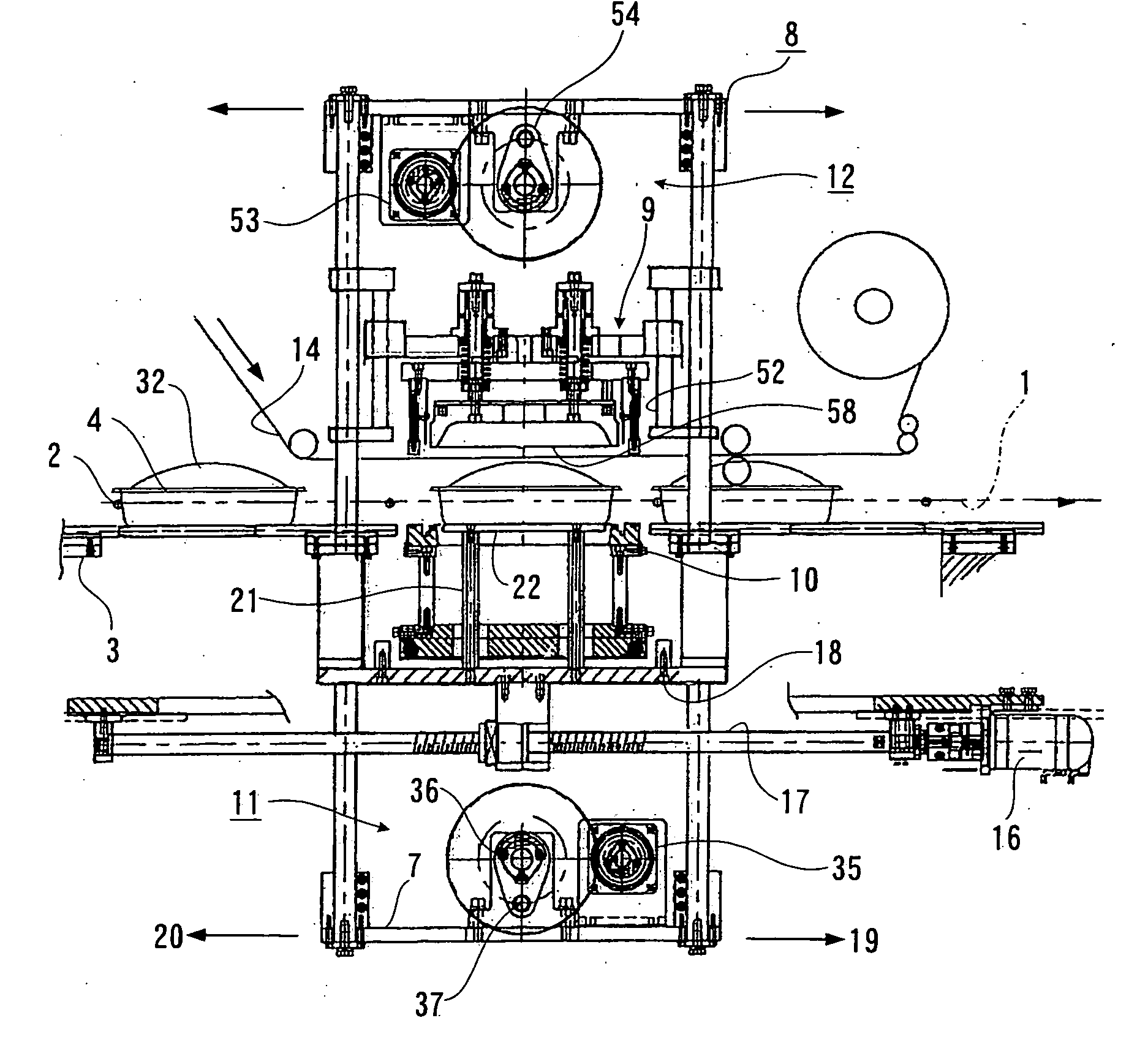

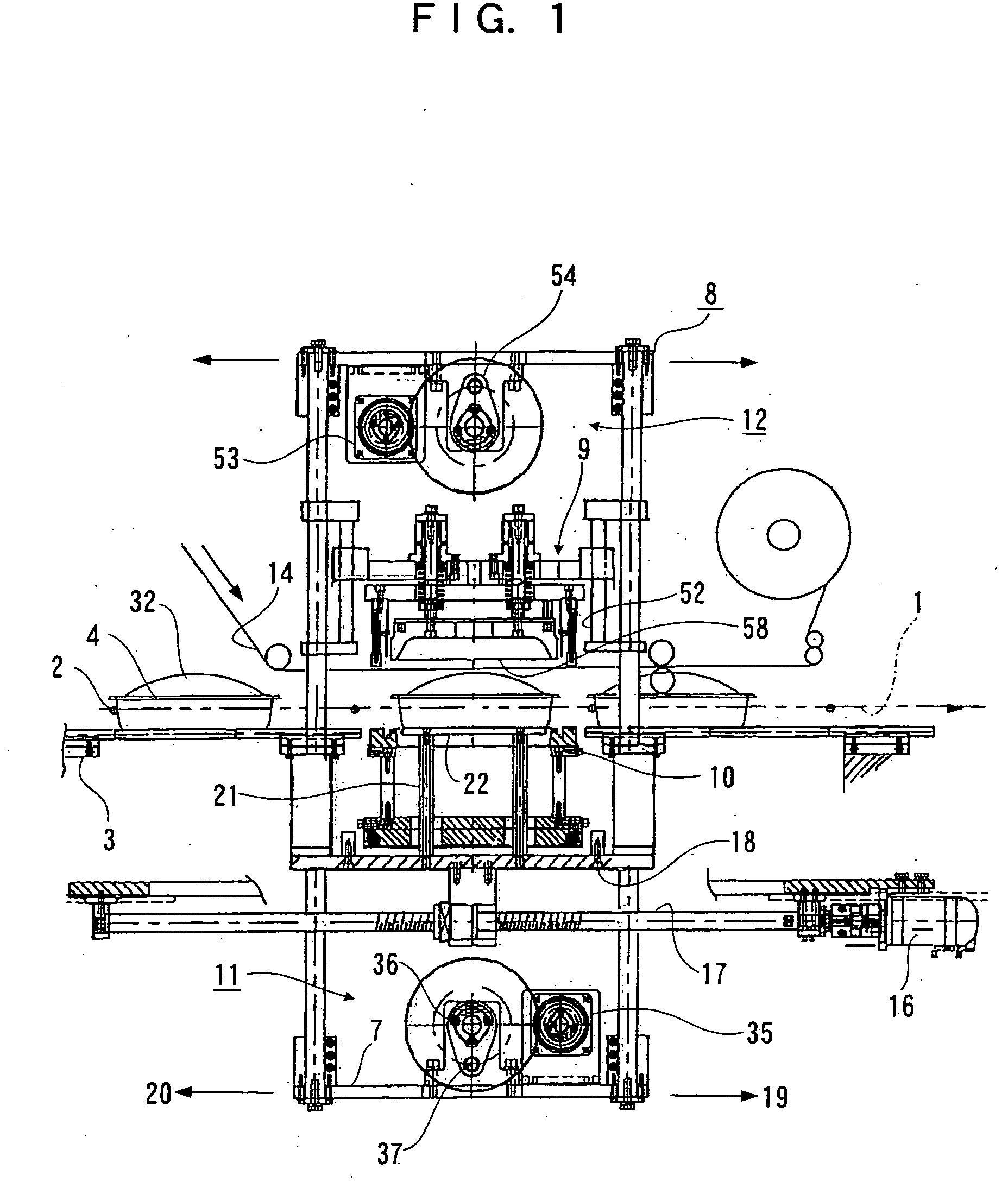

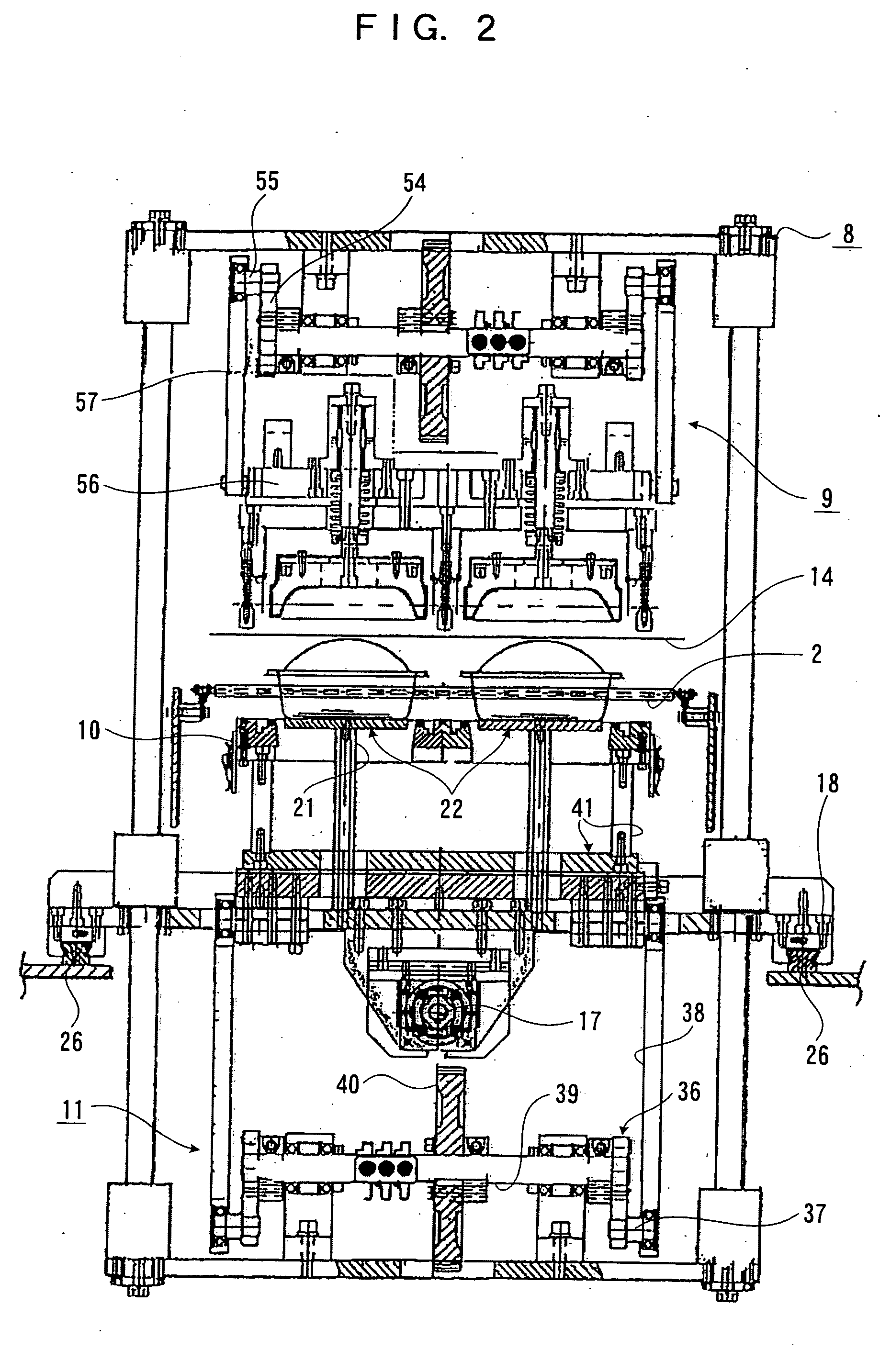

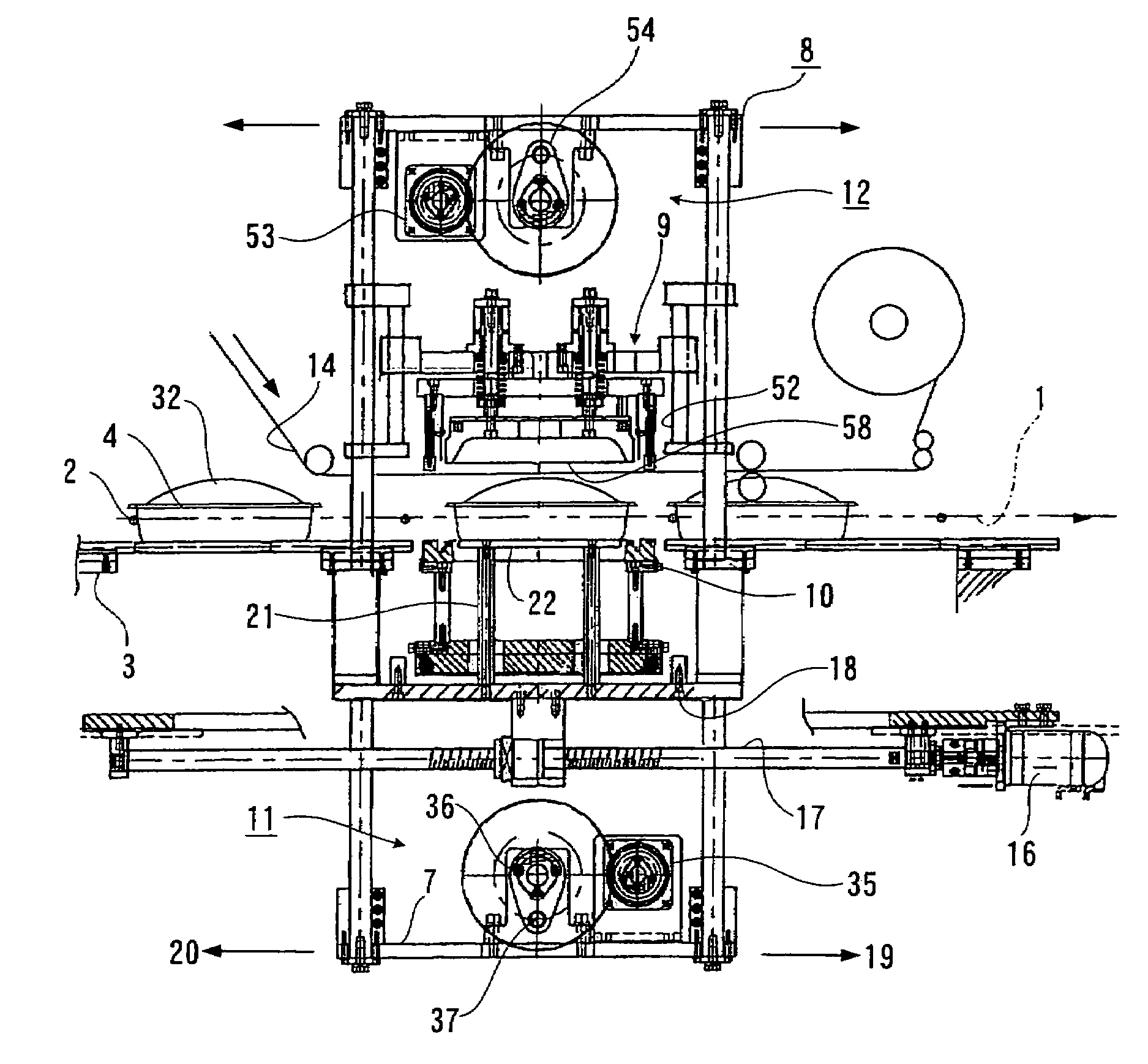

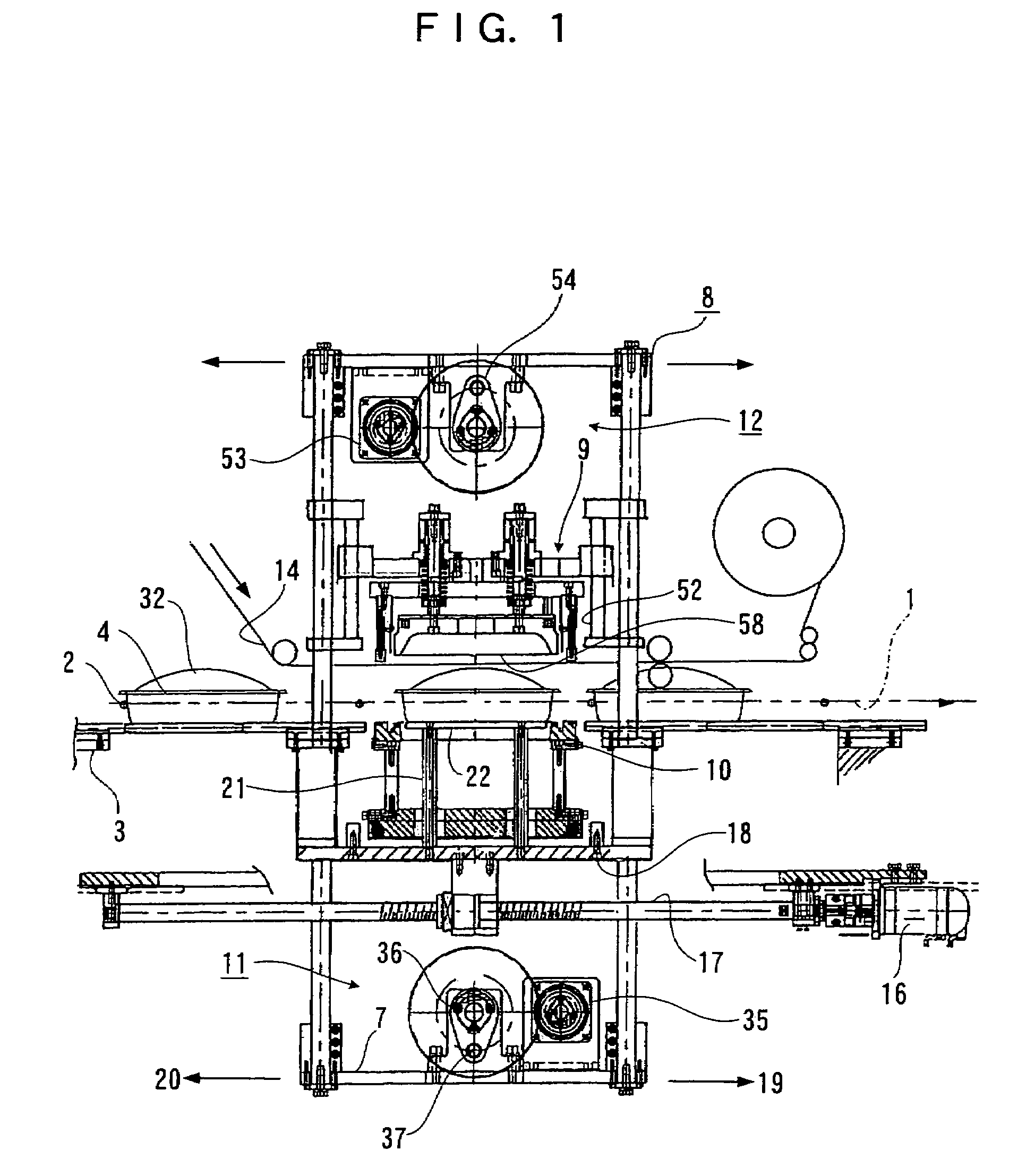

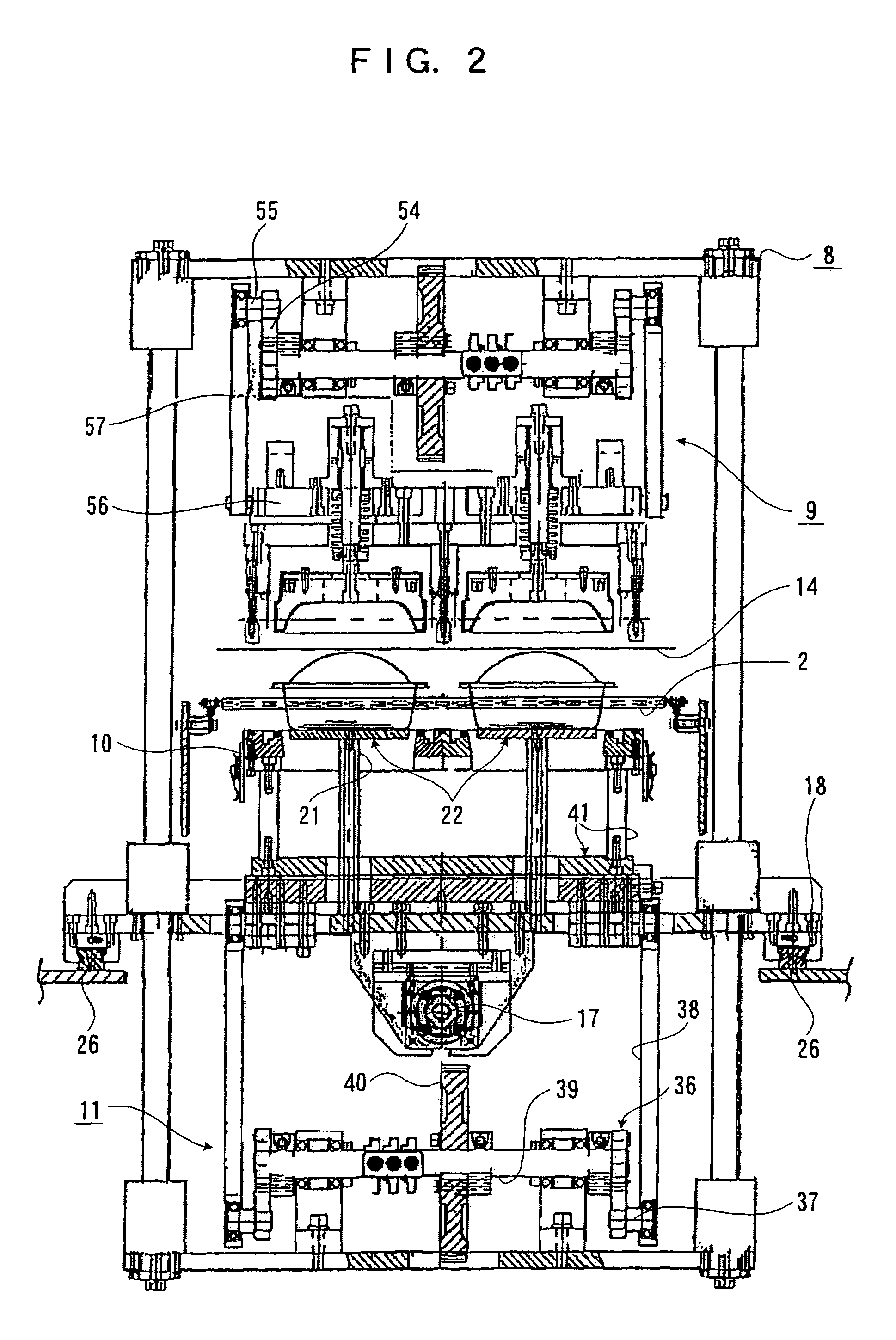

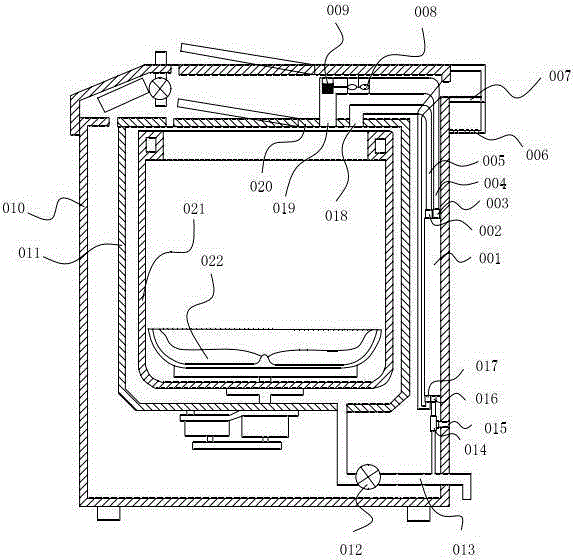

Packaging device for covering and sealing cover film onto tray

InactiveUS20060123739A1Avoid sealing difficultiesWrappers shrinkageWrapper twisting/gatheringFlangeEngineering

A packaging device is provided which prevents trays accommodating packaged items from being broken due to the tension in a film acting from above. The sealing base and the sealer perform a box motion by the combination of the back and forth movement of the general frame, and the upward and downward movement of the sealing base and the sealer, and the film is welded onto the flange of the tray while in movement. In this case, by setting the upper limit of the sealing base to the lower surface of the flange of the tray, it is possible for the deck plate to receive the tension of the film acting on the tray through the packaged item.

Owner:IBARAKI SEIKI

Packaging device for covering and sealing cover film onto tray

A packaging device is provided which prevents trays accommodating packaged items from being broken due to the tension in a film acting from above. The sealing base and the sealer perform a box motion by the combination of the back and forth movement of the general frame, and the upward and downward movement of the sealing base and the sealer, and the film is welded onto the flange of the tray while in movement. In this case, by setting the upper limit of the sealing base to the lower surface of the flange of the tray, it is possible for the deck plate to receive the tension of the film acting on the tray through the packaged item.

Owner:IBARAKI SEIKI

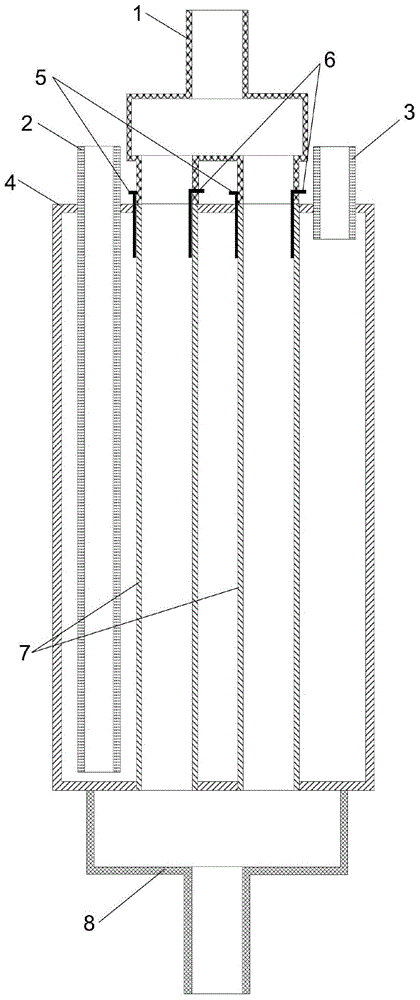

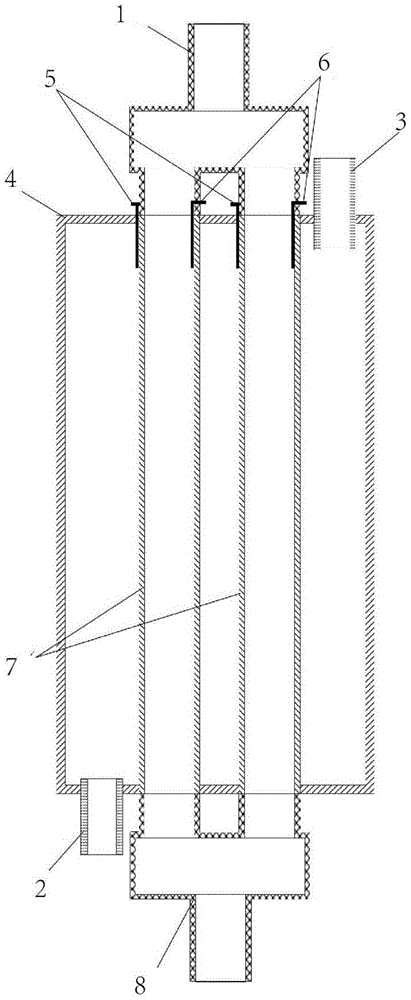

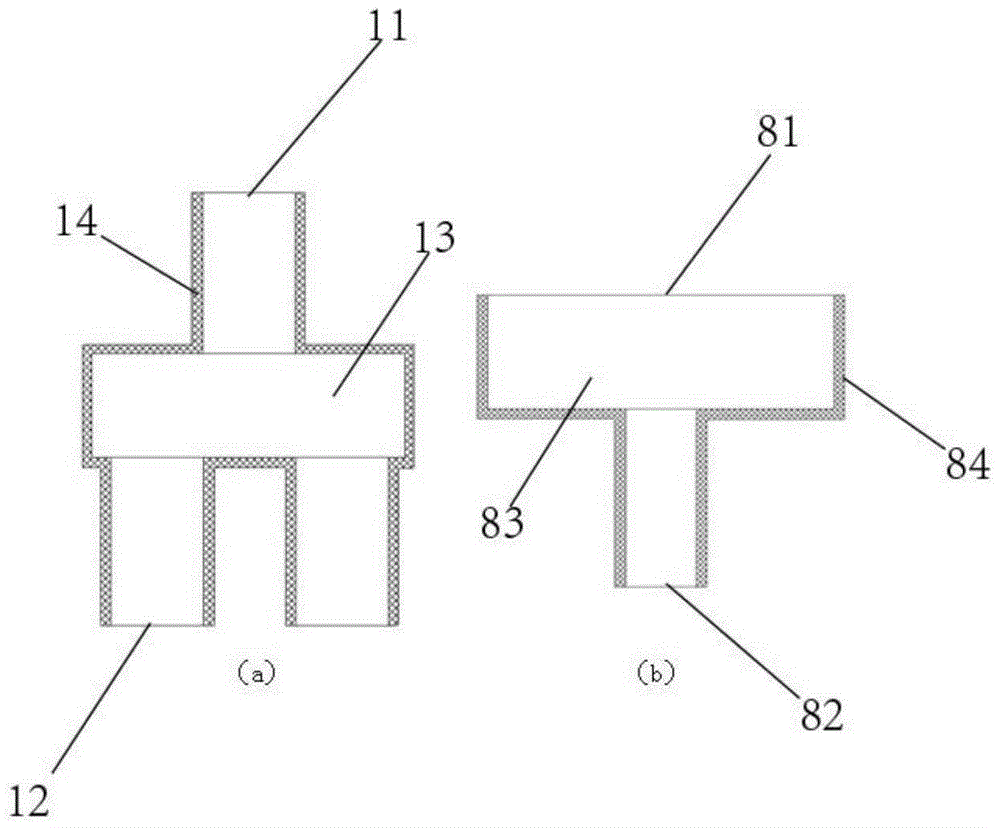

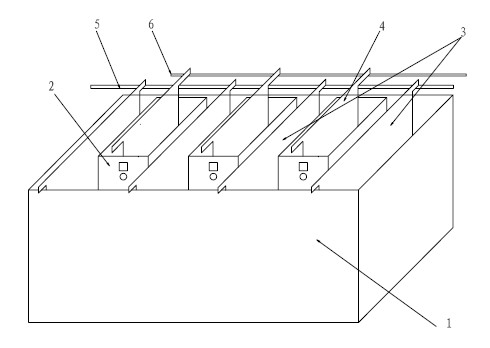

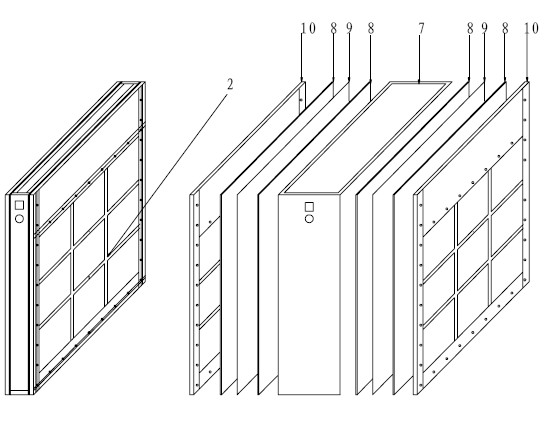

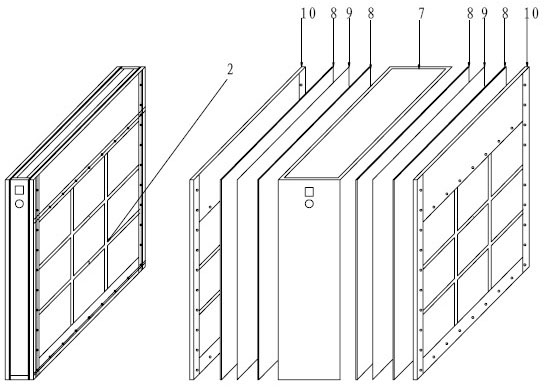

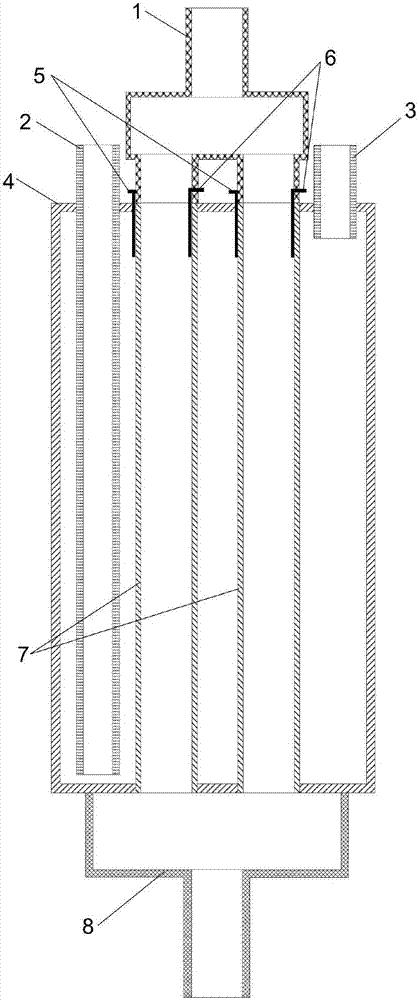

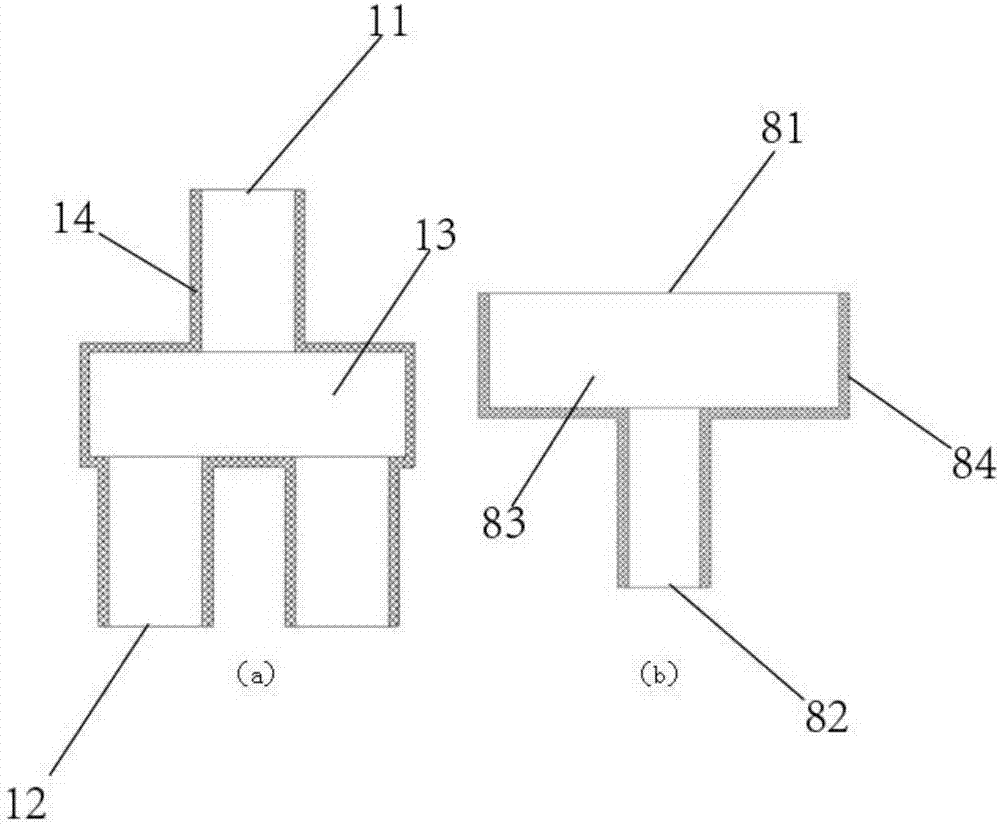

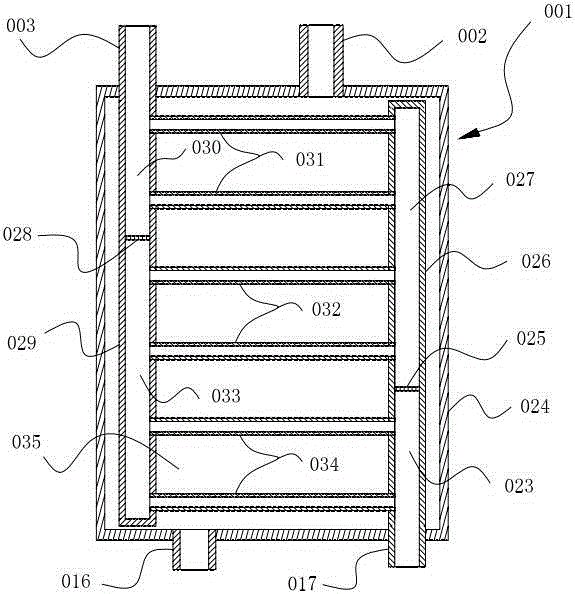

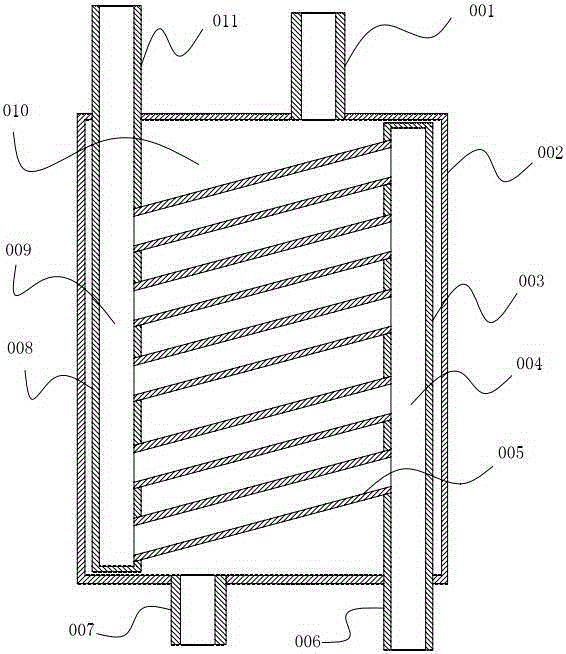

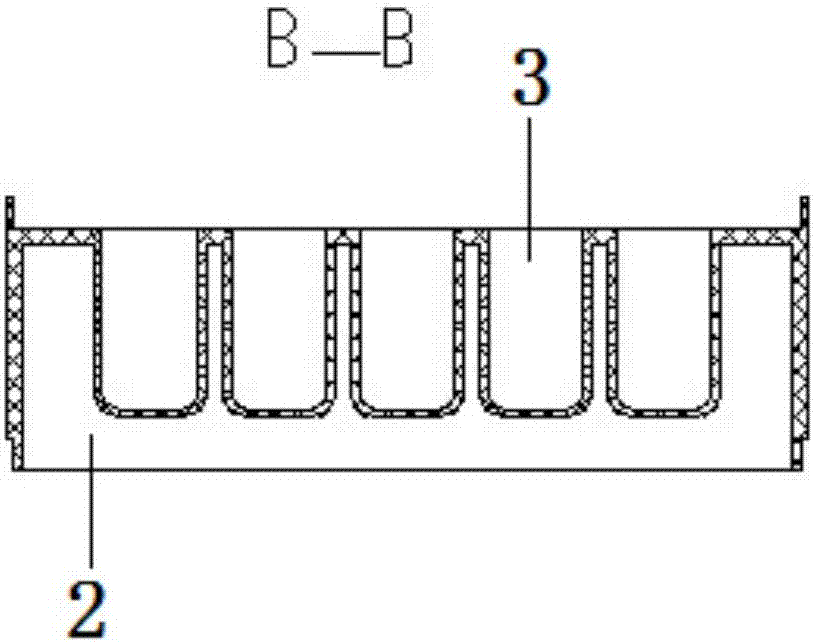

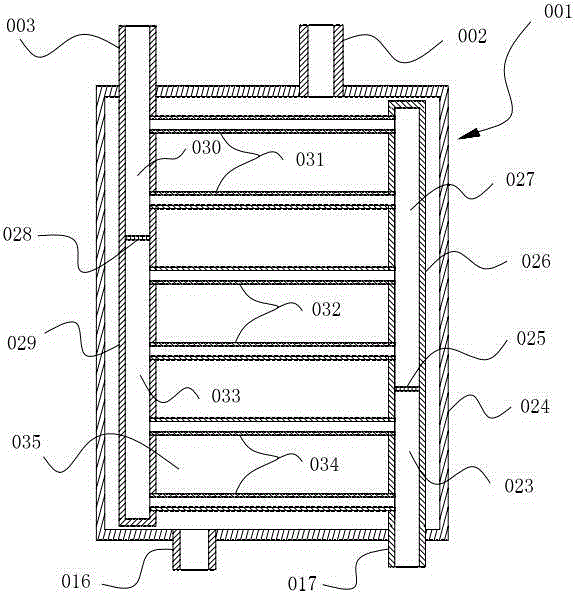

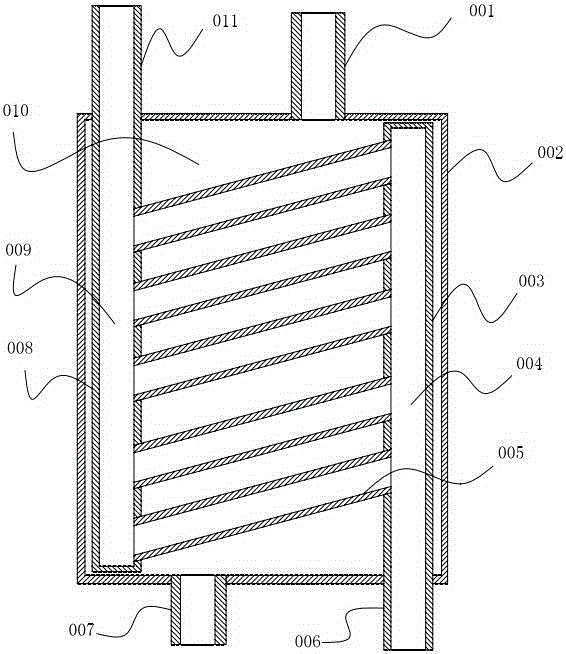

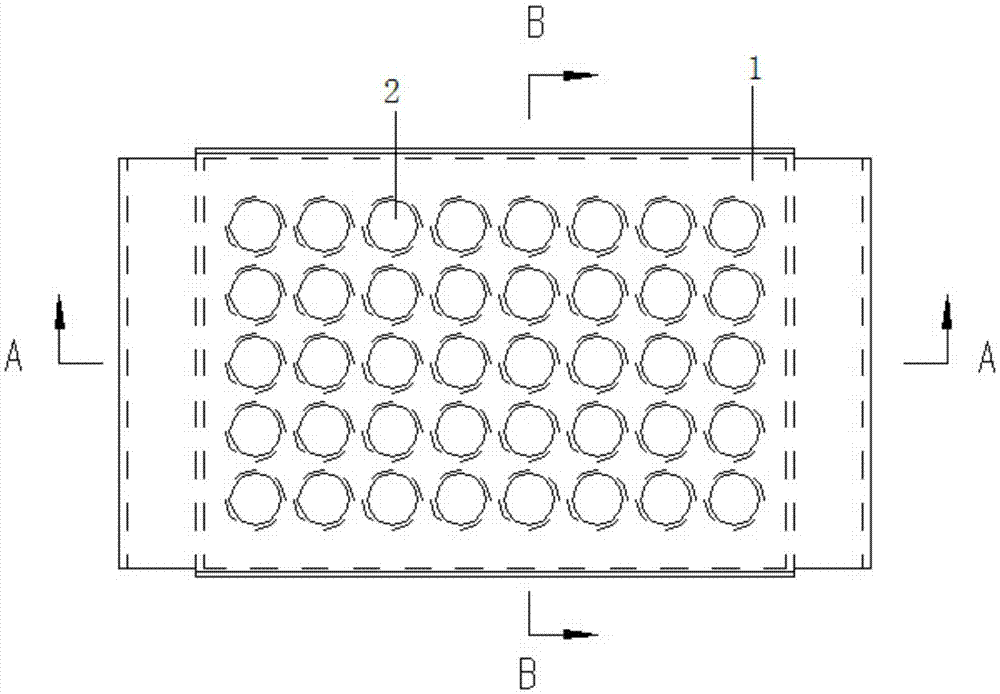

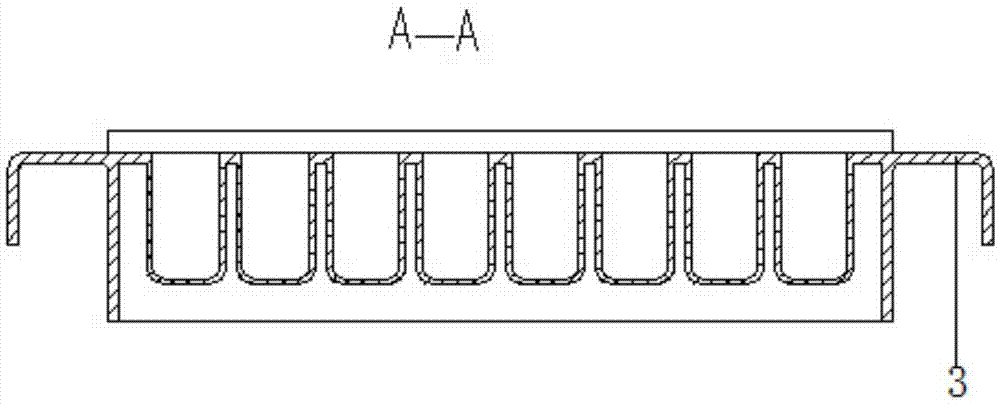

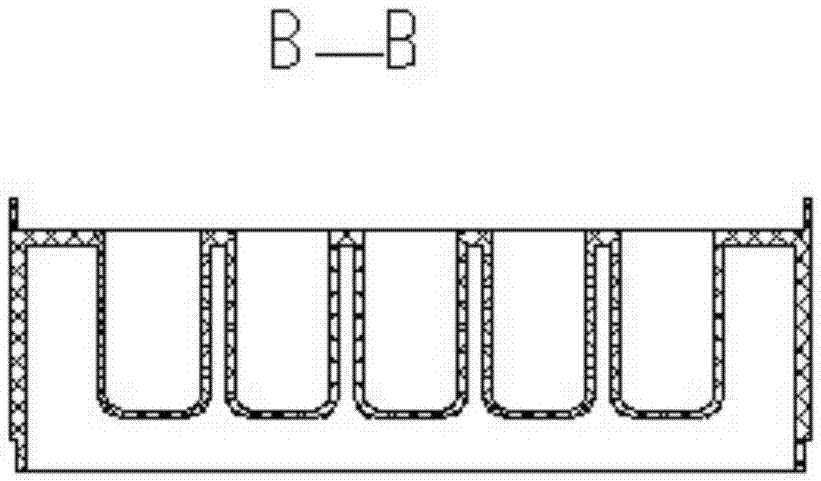

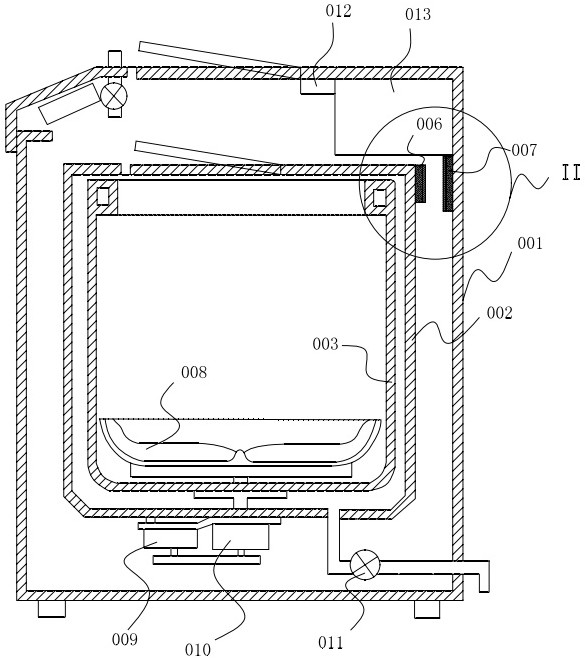

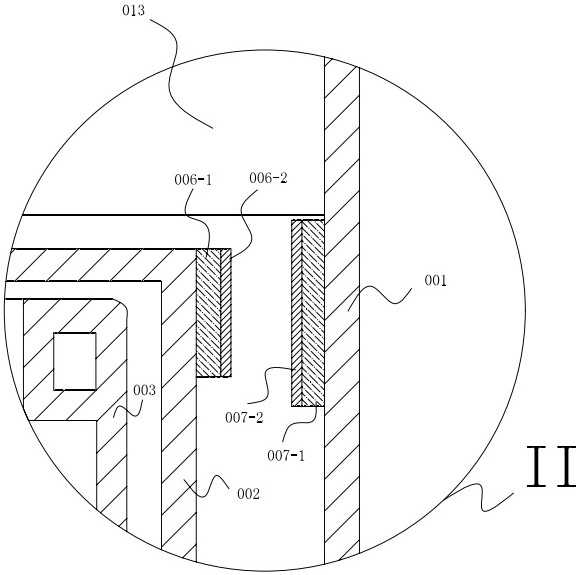

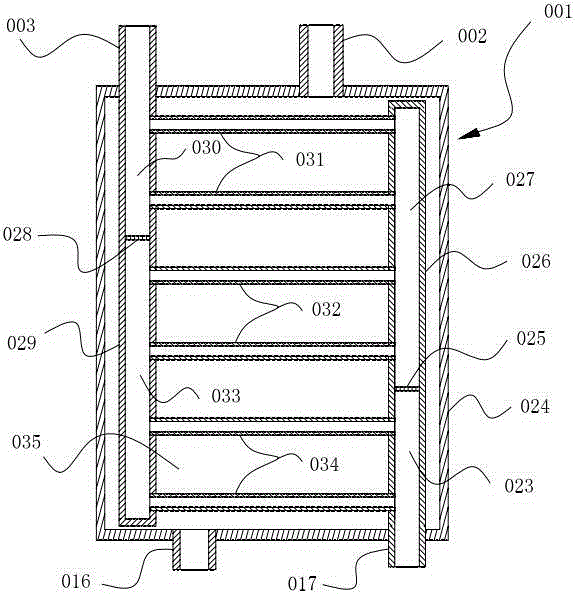

Cell stack of tubular solid oxide fuel cells and preparation method of cell stack

InactiveCN105226315AAvoid sealing difficultiesGood for sealing and sinteringFuel cells groupingSolid electrolyte fuel cellsFuel cellsUpper joint

The invention provides a cell stack of tubular solid oxide fuel cells and a preparation method of the cell stack. A fuel cell power generating tube body group is arranged in a cathode casing and consists of fuel cell power generating tube bodies; a cathode air inlet pipe and a cathode air outlet pipe are arranged between the cathode casing and the fuel cell power generating tube bodies; a fuel cell anode air path upper joint is arranged at the upper end of the fuel cell power generating tube body group; a fuel cell anode air path lower joint is arranged at the lower end of the fuel cell power generating tube body group; a cathode terminal is arranged at the contacting part of the outer side of each fuel cell power generating tube body and the cathode casing; an anode terminal is arranged at the contacting part of the inner side of each fuel cell power generating tube body and the cathode casing. The cell stack of the fuel cells is sintered into an integrated ceramic structure, so that the problem that the solid oxide fuel cells are difficult to seal under high-temperature working conditions is avoided, and further assembly and construction of the solid oxide fuel cells are realized more easily.

Owner:TIANJIN UNIV

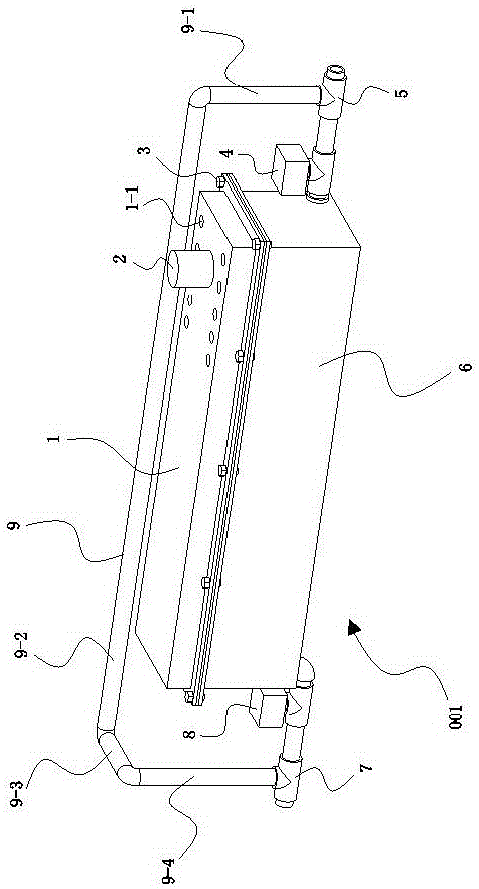

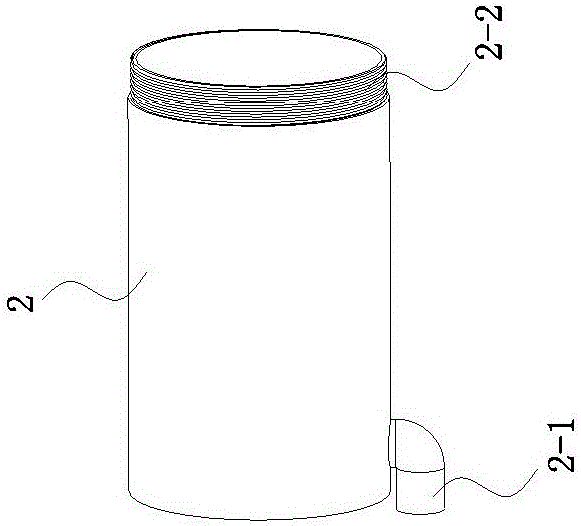

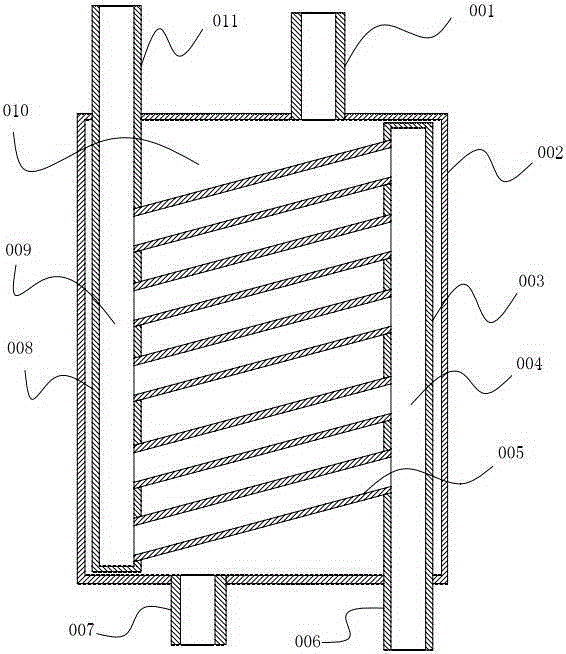

Device for preparing stannous sulfate by electrolysis in mobile cathode chamber

The invention discloses a device for preparing stannous sulfate by electrolysis in a mobile cathode chamber. The device comprises an electrolytic bath and anodes and a cathode arranged in the electrolytic bath, wherein the anodes are arranged on two sides of the cathode respectively; a diaphragm is arranged between the cathode and the anode; and the mobile cathode chamber is formed in the electrolytic unit bath, the mobile cathode chamber is positioned between two adjacent anodes, the mobile cathode chamber comprises a cathode cavity and diaphragm frames, the cathode is positioned in the cathode cavity, the diaphragm frames are arranged on two sides of the cathode cavity, the diaphragms are positioned in the diaphragm frames, and a sealing washer is arranged between the diaphragm frame and the cathode cavity. The invention provides the device for preparing the stannous sulfate by electrolysis in the mobile cathode chamber, which reduces the voltage of the bath, is convenient for diaphragm maintenance and bath maintenance and reduces the processing cost.

Owner:ZHEJIANG UNIV OF TECH

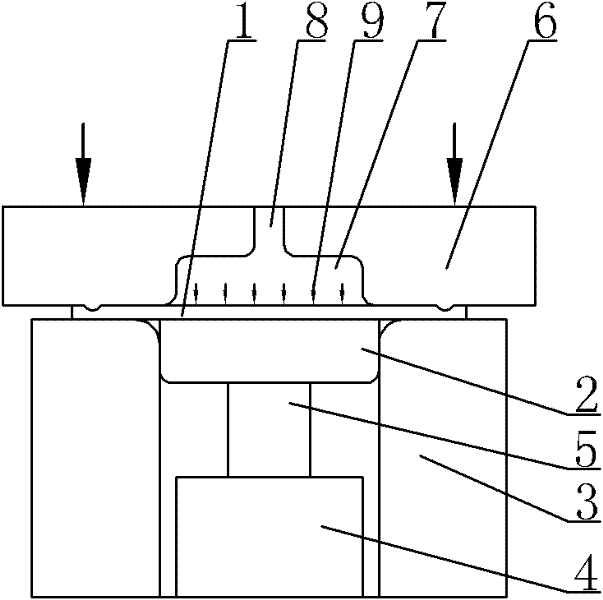

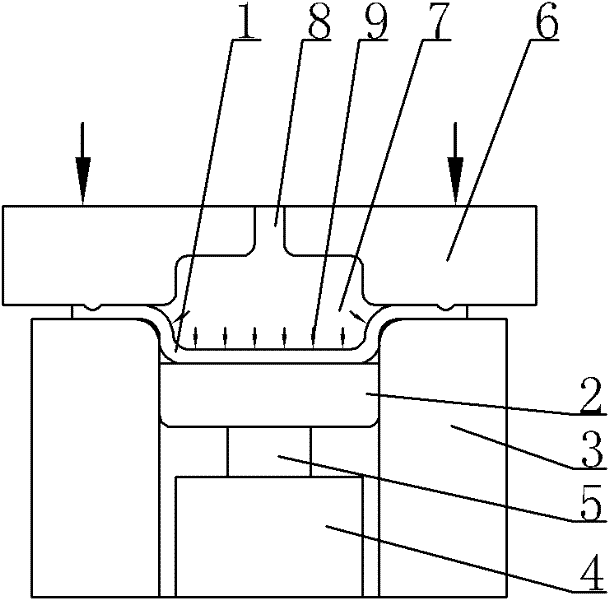

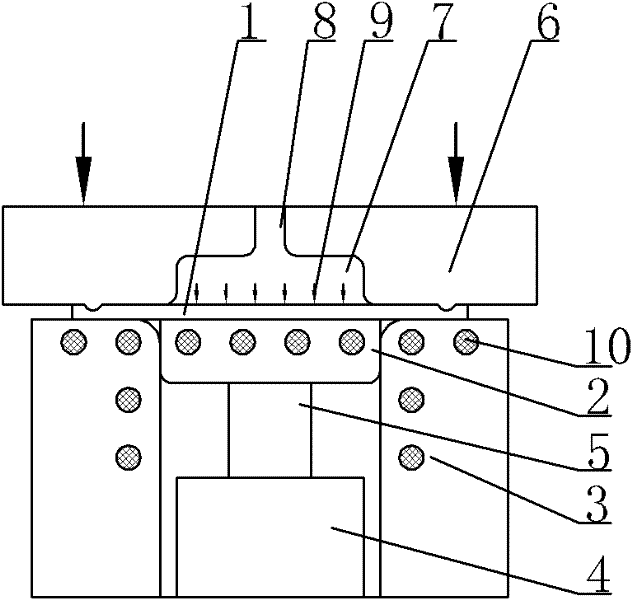

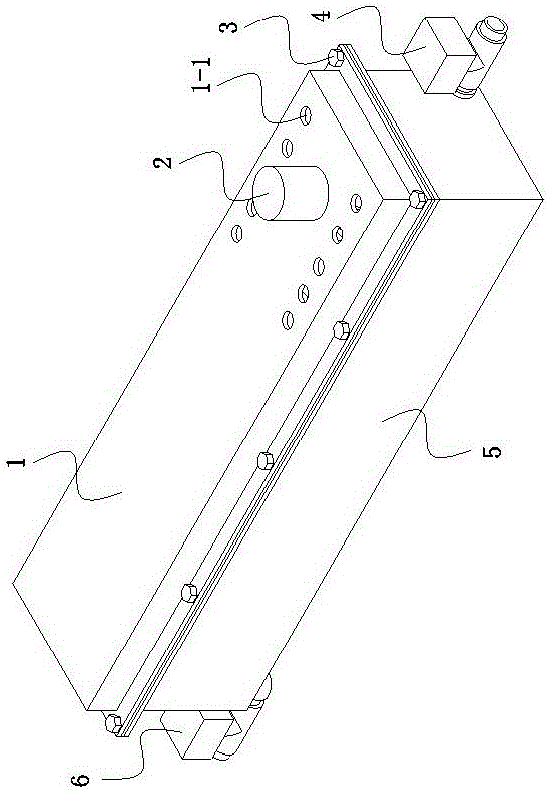

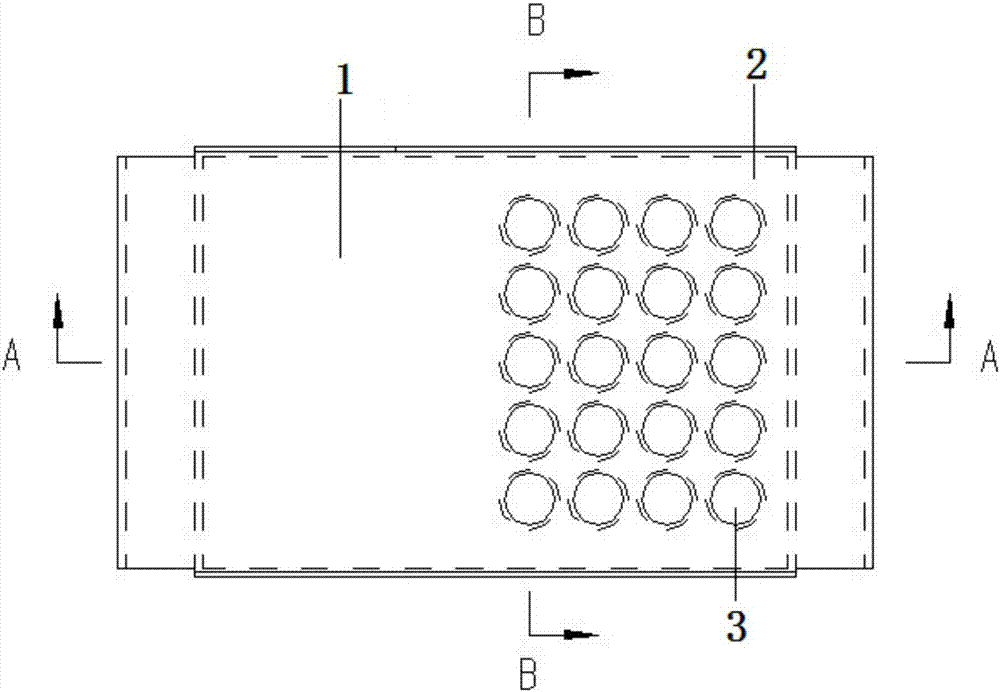

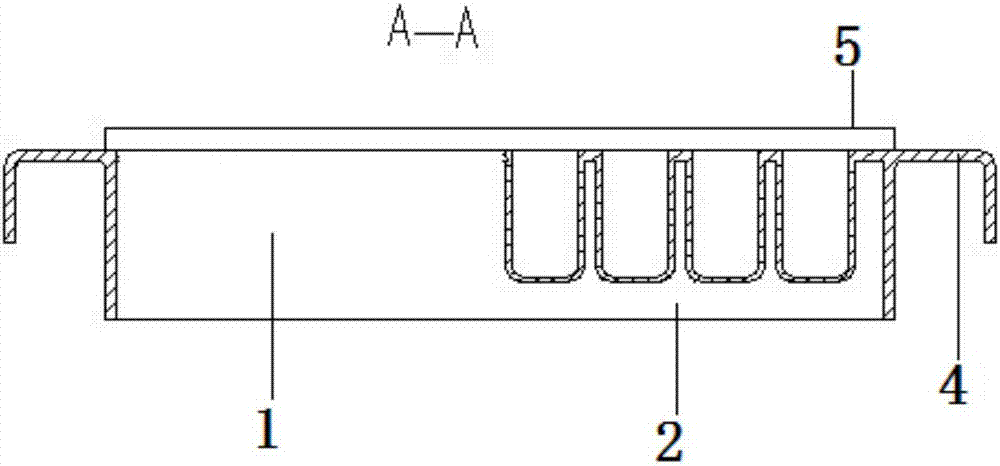

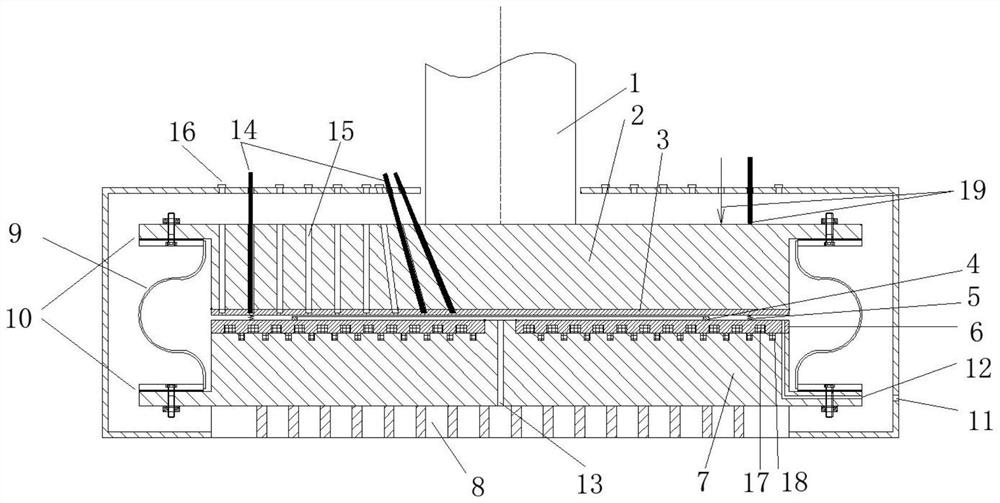

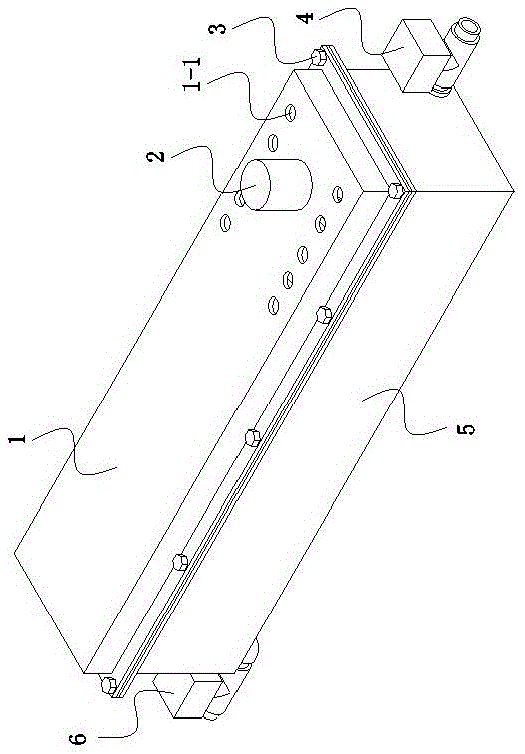

Plate back press forming method utilizing displacement control mode

InactiveCN102513435AAvoid sealing difficultiesLarge amount of deformationHydraulic cylinderDisplacement control

The invention relates to a plate forming method, in particular to a plate back press forming method utilizing a displacement control mode, which solves the problem that the existing plate part forming method is incapable of forming parts high in deformation and complicated in shape. The plate back press forming method includes steps of placing a to-be-formed plate blank on a die holder, regulating position of a plunger rod of a hydraulic cylinder until the upper surface of a die contacts with the lower surface of the to-be-formed plate blank; pressing the to-be-formed plate blank onto the upper surface of the die holder by downward motion of a press plate and reserving a closed cavity between the lower surface of the press plate and the upper surface of the to-be-formed plate blank; injecting high-pressure fluid medium into the cavity though a through hole arranged above the press plate; and moving the die and the to-be-formed plate blank downwards synchronously until the to-be-formed plate blank is formed completely by controlling the plunger rod of the hydraulic cylinder. The plate back press forming method is used for the plate expansion process or the plate drawing forming process.

Owner:HARBIN INST OF TECH

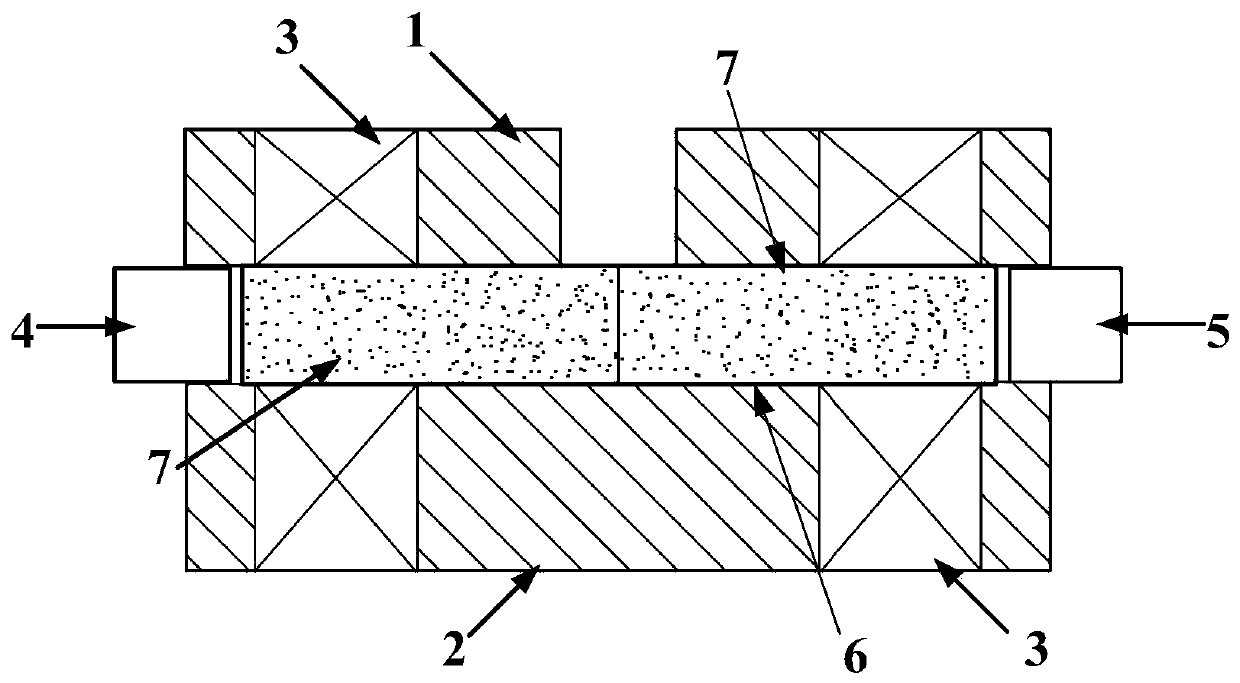

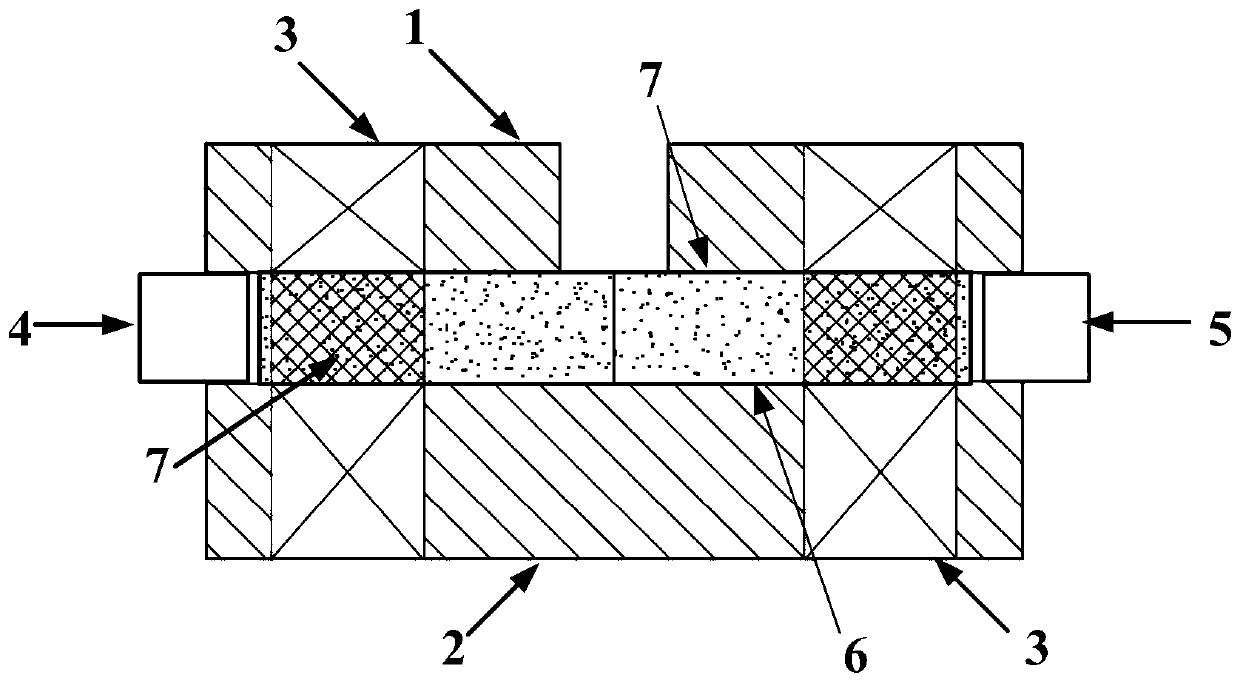

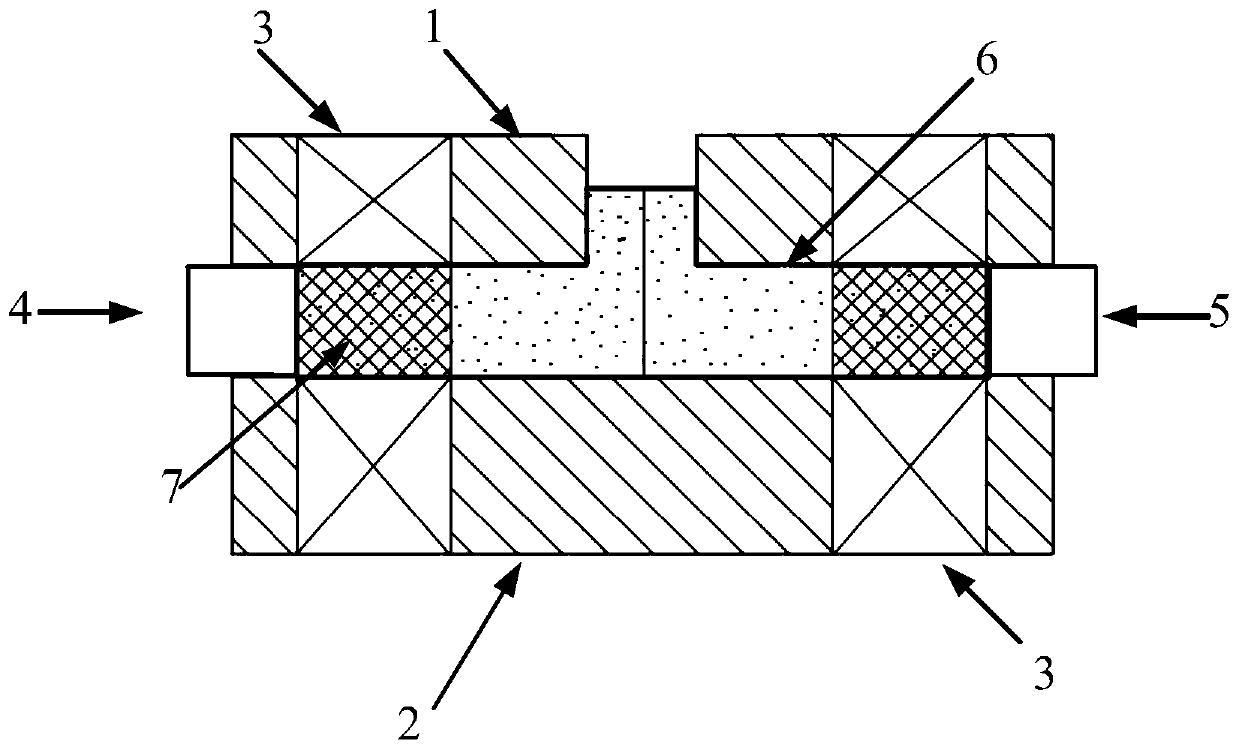

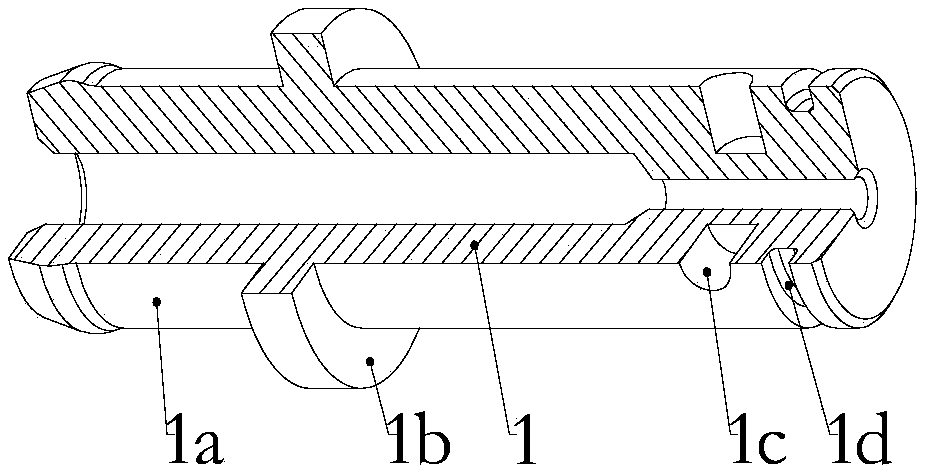

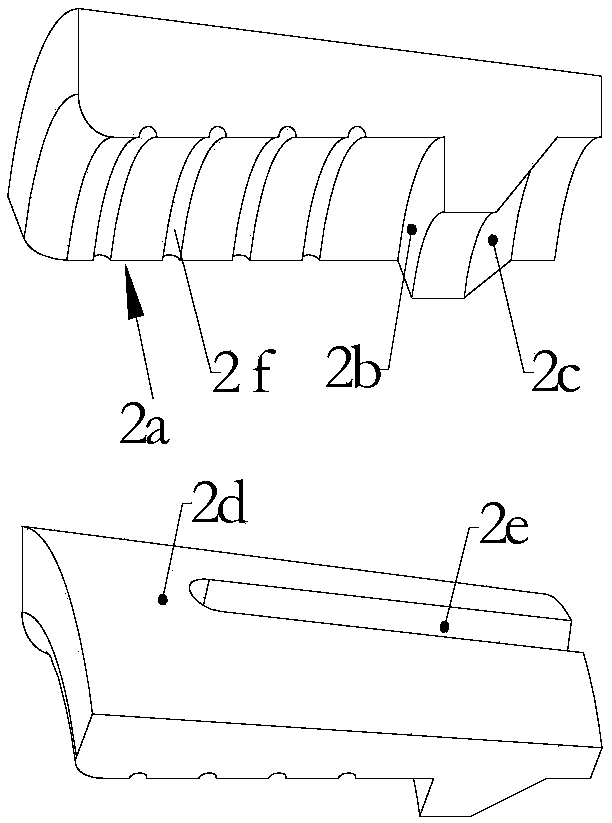

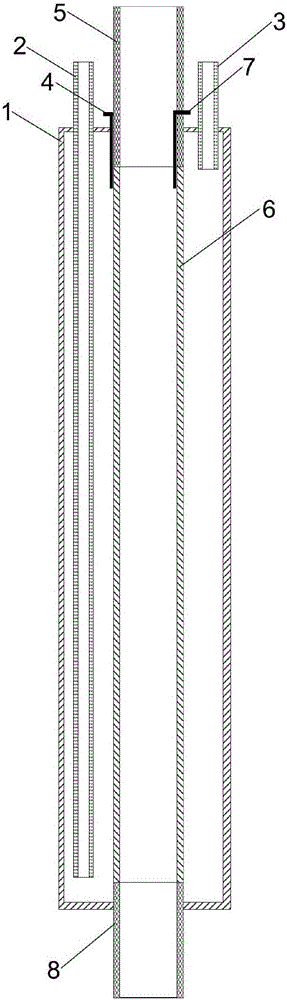

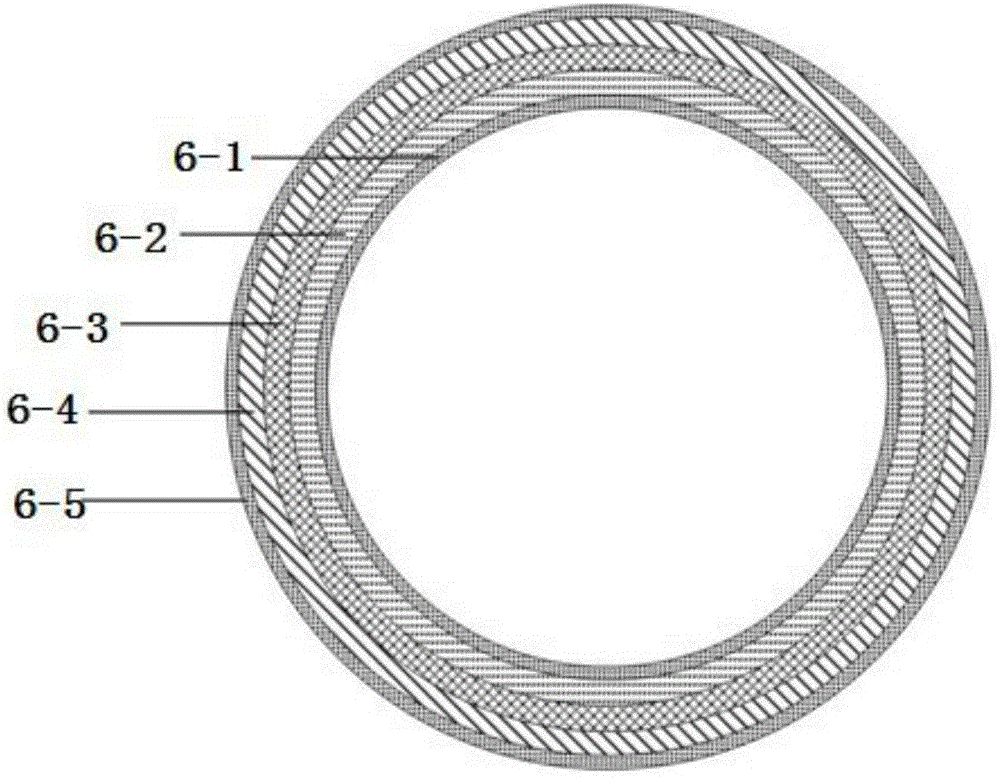

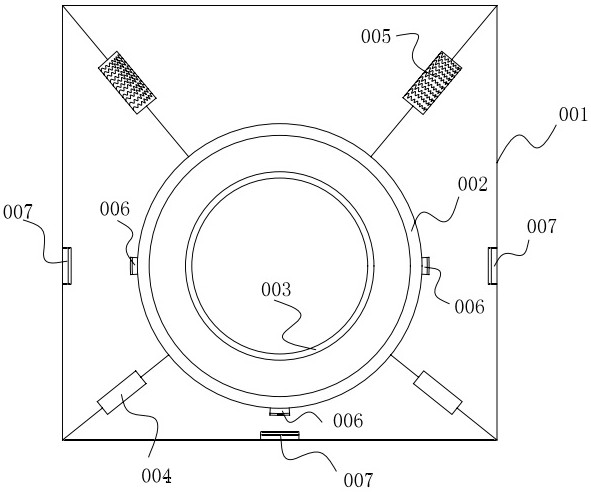

Complex tubular component flexible forming device and method based on magnetorheological elastomer

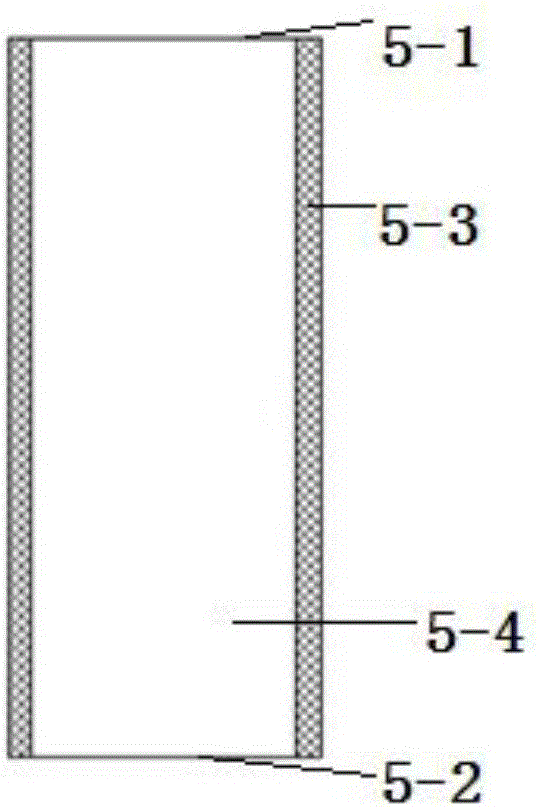

The invention discloses a complex tubular component flexible forming device and method based on a magnetorheological elastomer. The device comprises an upper mould body (1), a lower mould body (2), electromagnetic coils (3), a left punch (4), a right punch (5), an initial tube blank (6) and the magnetorheological elastomer (7). Under the effect of an external magnetic field, the elasticity modulusof different portions of the magnetorheological elastomer changes differently, so that the to-be-formed tube blank is formed in a required shape under the proper elasticity modulus of the magnetorheological elastomer. According to the complex tubular component flexible forming device and method, by means of changing of the elasticity modulus of the magnetorheological elastomer under different magnetic field conditions, the problems that sealing is difficult in the high-pressure forming process of existing complex components, and thin-walled components are prone to cracking in the forming process are solved. The magnetorheological effect of the magnetorheological elastomer is fully achieved, in addition, the equipment is simple, and the production efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

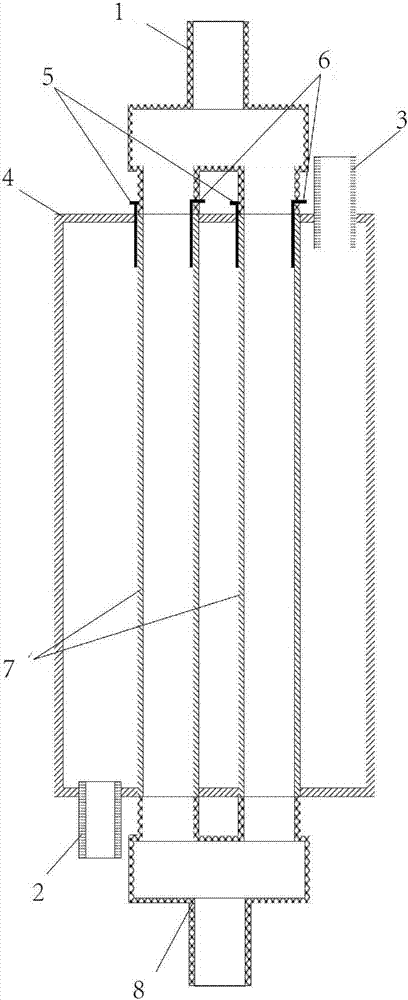

Preparation method of solid oxide fuel cell stack

InactiveCN106887621AAvoid sealing difficultiesGood for sealing and sinteringFuel cells groupingSolid electrolyte fuel cellsFuel cellsUpper joint

The invention provides a preparation method of a solid oxide fuel cell stack. A fuel cell power generation tube body group is arranged in a cathode shell; the fuel cell power generation tube body group is composed of fuel cell power generation tube bodies; a cathode gas inlet tube and a cathode gas outlet tube are arranged between the cathode shell and fuel cell power generation tube bodies; the upper end of the fuel cell power generation tube body group is provided with a fuel cell anode gas path upper joint, and the lower end of the fuel cell power generation tube body group is provided with a fuel cell anode gas path lower joint; the contact between the outer side of each fuel cell power generation tube body and the cathode shell is provided with a cathode terminal; and the contact between the inner side of each fuel cell power generation tube body and the cathode shell is provided with an anode terminal. The sintering-integrated ceramic structure of the fuel cell stack avoids the problem of difficulty in sealing of the solid oxide fuel cells under high-temperature working conditions, so that the solid oxide fuel cells can be further assembled and constructed more easily.

Owner:TIANJIN UNIV

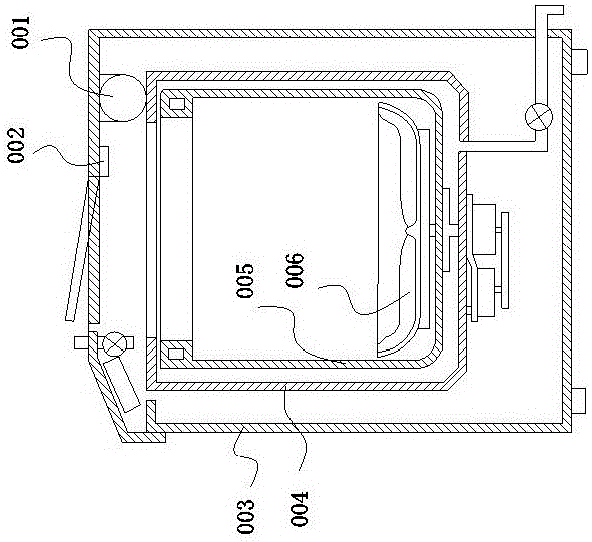

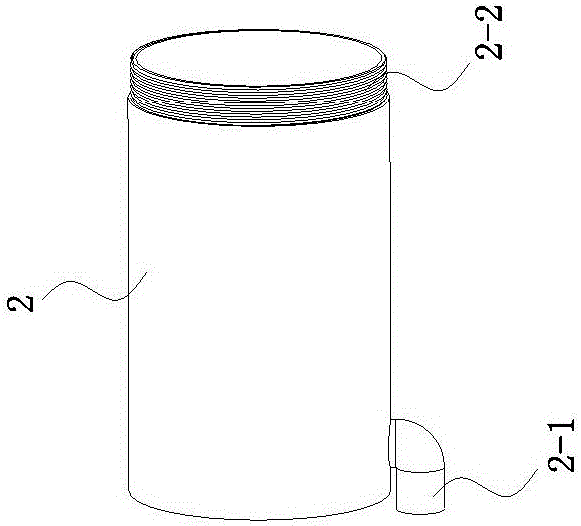

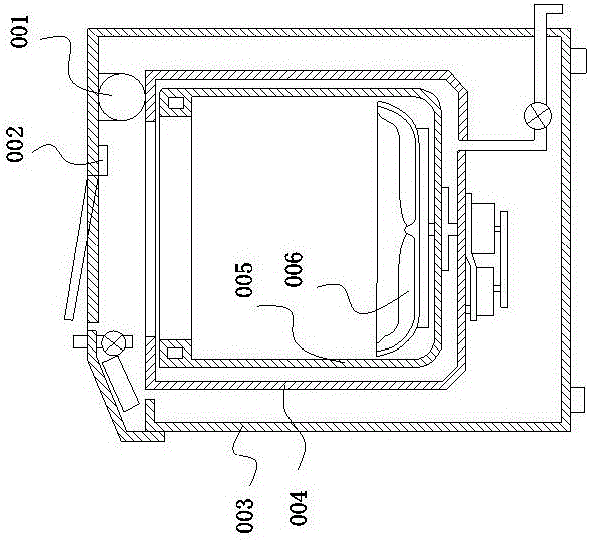

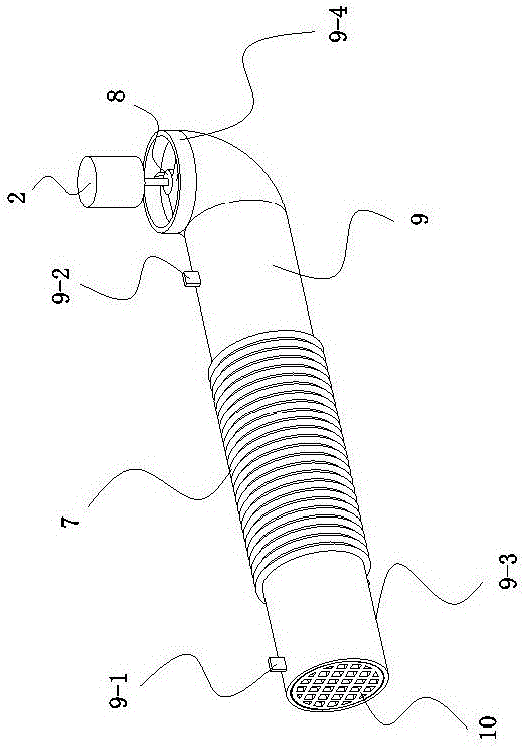

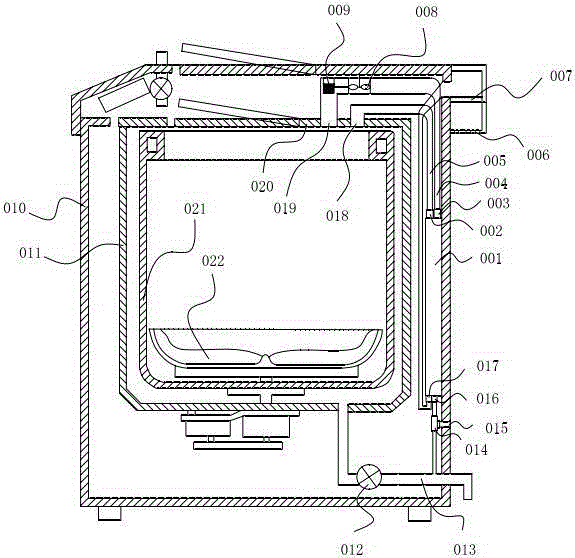

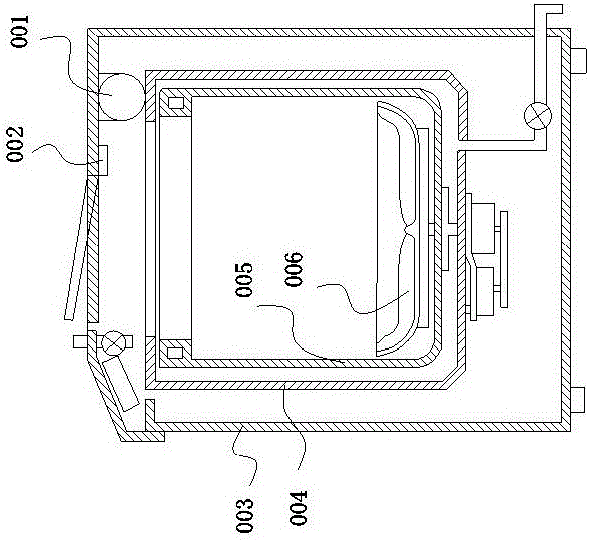

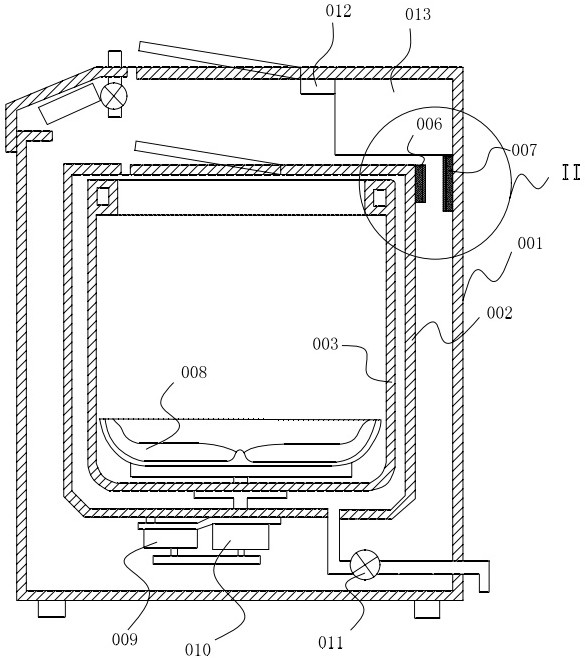

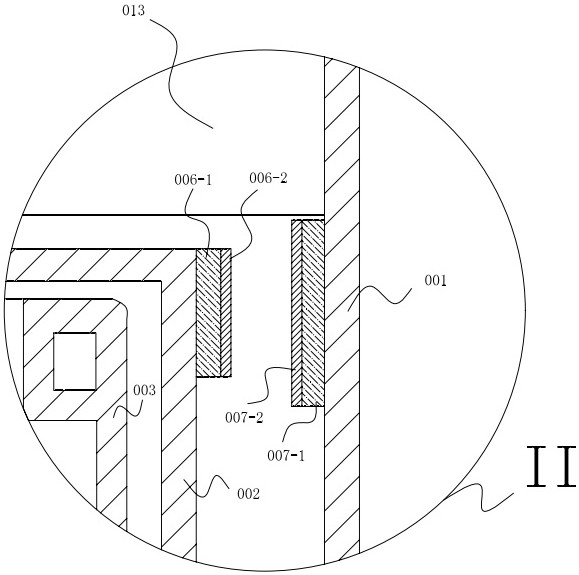

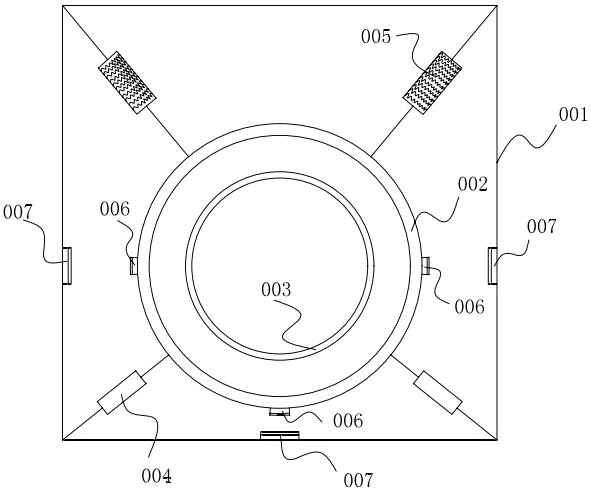

Washing machine with washing powder dissolving device

InactiveCN105113180AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperImpellerWater flow

The invention discloses a washing machine with a washing powder dissolving device. The washing machine comprises a machine shell, an outer tub, an inner tub and an impeller. A detergent box and the washing powder dissolving device are arranged at the upper portion of the machine shell. The washing powder dissolving device comprises a water containing pipe, a guide pipe and a stirrer. The guide pipe is divided into a guide pipe vertical section, a guide pipe elbow section and a guide pipe horizontal section. An electric heating wire is wound around the outer side of the guide pipe horizontal section. A resistance plate is arranged on the inner side of the guide pipe horizontal section. The stirrer comprises a motor and a stirring impeller. The motor is installed above the water containing pipe. An output shaft of the motor penetrates into the water containing pipe and is inserted into the guide pipe vertical section. The stirring impeller is fixedly installed at the lower end of the output shaft of the motor. A water inlet and a water outlet are formed in the water containing pipe. A water inlet electromagnetic valve is installed on the outer side of the water inlet. A water outlet electromagnetic valve is installed on the outer side of the water outlet. The water inlet electromagnetic valve is connected with the detergent box through a water pipe. The water outlet electromagnetic valve is connected with a water pipe for guiding washing water flowing through the water outlet electromagnetic valve into the inner tub. A liquid level sensor and a temperature sensor are arranged in the water containing pipe.

Owner:蒋凤英

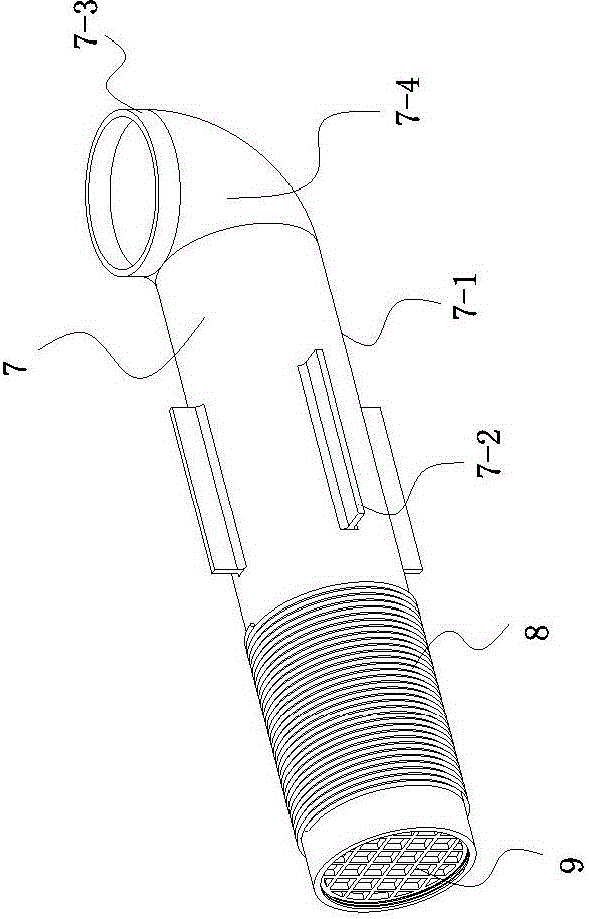

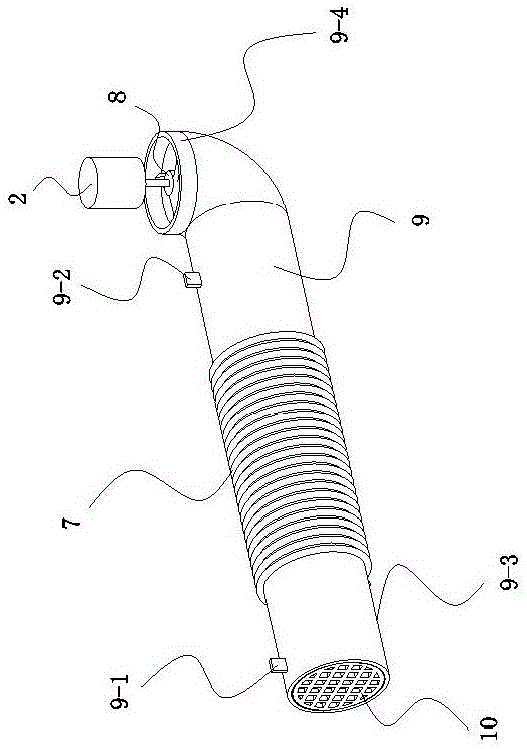

Washing powder dissolving device

InactiveCN105113181AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperImpellerEngineering

The invention discloses a washing powder dissolving device which comprises a water containing pipe, a guide pipe installed in the water containing pipe and a stirrer installed on the water containing pipe. The guide pipe is divided into a guide pipe vertical section, a guide pipe bend section and a guide pipe horizontal section. The lower end of the guide pipe vertical section is integrally connected with the upper end of the guide pipe bend section. The lower end of the guide pipe bend section is integrally connected with the front end of the guide pipe horizontal section. An electric heating wire is wound on the outer side of the guide pipe horizontal section. A resistance plate is disposed on the inner side of the rear end of the guide pipe horizontal section. The stirrer comprises a motor and a stirring impeller. The motor is fixedly installed on the upper portion of the outer side of the water containing pipe. An output shaft of the motor penetrates into the water containing pipe to be inserted into the guide pipe vertical section. The stirring impeller is fixedly installed at the lower end of the output shaft of the motor. The water containing pipe is further provided with a water inlet and a water outlet. A water inlet electromagnetic valve is installed on the outer side of the water inlet. A water outlet electromagnetic valve is installed on the outer side of the water outlet. A liquid level sensor and a temperature sensor are further disposed in the water containing pipe.

Owner:蒋凤英

Energy-saving machine provided with box-shaped detergent dissolver

InactiveCN105200727AIncrease volumeAvoid sealing difficultiesOther washing machinesWashing machine with receptaclesImpellerWater pipe

The invention discloses an energy-saving machine provided with a box-shaped detergent dissolver. The energy-saving washing machine is characterized in that a detergent dissolving device is arranged at the upper part of a case, and a heat exchanger is arranged in the case; a wet and hot air inlet, a cold air outlet, a wet and hot air outlet and a cold air inlet are formed in the heat exchanger; the cold air outlet, a fan, an electric heater and a warm air supply port are connected through a pipeline, a wet and hot air exhaust port is connected with the wet and hot air inlet through a pipeline, the wet and hot air outlet is connected with a tee joint through a pipeline, and the tee joint is connected with an exhaust port and a drain pipe through a pipeline respectively; the cold air inlet is connected with a filter and an air suction port through a pipeline. The detergent dissolving device comprises a box, a guiding pipe and a stirrer, wherein a water inlet and a water outlet are formed in the box, and a water inlet solenoid valve and a water outlet solenoid valve are mounted on the outer sides of the water inlet and the water outlet respectively; the water inlet solenoid valve is connected with a detergent box through a water pipe; the guiding pipe is fixed in the box, stirring impellers of the stirrer are inserted into the guiding pipe, and a liquid level sensor is further arranged in the box.

Owner:耒阳市亲民电子商务有限公司

Washing machine provided with washing powder dissolving device

InactiveCN105113185AImprove solubilityIncrease volumeOther washing machinesTextiles and paperImpellerPulp and paper industry

Owner:蒋凤英

Washing machine with detergent dissolution device

InactiveCN105133257AImprove solubilitySimple structureOther washing machinesTextiles and paperImpellerSolenoid valve

The invention discloses a washing machine with a detergent dissolution device. The washing machine comprises a machine casing, an outer barrel, an inner barrel and an impeller. A detergent box and the detergent dissolution device are arranged on the upper portion of the machine casing. The detergent dissolution device comprises a water containing pipe, a guide pipe installed in the water containing pipe and a stirrer installed on the water containing pipe. The stirrer comprises a motor and a stirring impeller, the motor is fixedly installed above the outer side of the water containing pipe, an output shaft of the motor penetrates into the water containing pipe to be inserted in the guide pipe, the stirring impeller is fixedly installed at the lower end of the output shaft of the motor, the water containing pipe is further provided with a water inlet and a water outlet, a water inlet solenoid valve is installed on the outer side of the water inlet, and a water outlet solenoid valve is installed on the outer side of the water outlet. The water inlet solenoid valve is connected with the detergent box through a water pipe, the water outlet solenoid valve is connected with a water pipe for leading washing water flowing through the water outlet solenoid valve into the inner barrel, and a liquid level sensor is further arranged in the water containing pipe.

Owner:蒋凤英

Washing powder dissolving device

InactiveCN105113184AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperEngineeringStructural engineering

The invention discloses a washing powder dissolving device. The washing powder dissolving device comprises a box body, a guiding pipe and a stirrer. A water inlet used for leading washing water into the box body is formed in the right side of the box body, and a water inflow electromagnetic valve is installed on the outer side of the water inlet. A water outlet used for discharging the washing water in the box body is formed in the bottom of the box body, and a water outflow electromagnetic valve is installed on the outer side of the water outlet. The guiding pipe is detachably and fixedly arranged in the box body and composed of a vertical segment, an elbow segment and a horizontal segment, the lower end of the vertical segment and the upper end of the elbow segment are integrally connected, and the lower end of the elbow segment and the front end of the horizontal segment are integrally connected; an electric heating wire is wound on the outer side the horizontal segment, and a resistance plate is arranged on the inner side is arranged at the rear end of the horizontal segment. The stirrer comprises a motor and a stirring impeller, the motor is fixedly installed above the outer side of the box body, and the lower end of a motor output shaft penetrates into the box body through a shaft hole formed in the upper portion of the box body and is inserted into the vertical segment of the guiding pipe. The stirring impeller is fixed to the lower end of the motor output shaft. A liquid level sensor and a temperature sensor are further arranged on the inner side of the box body.

Owner:蒋凤英

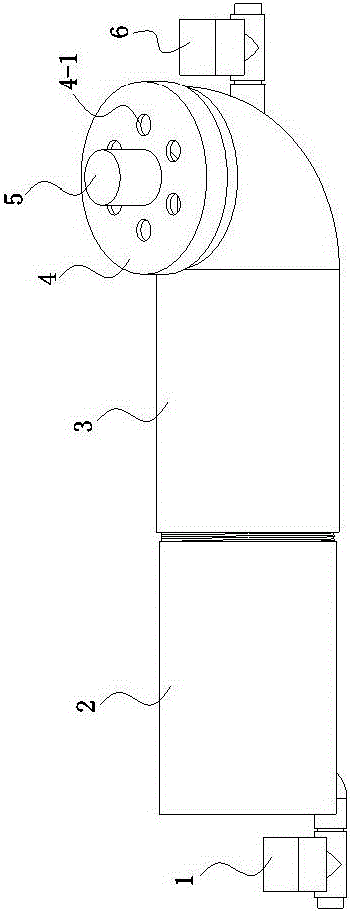

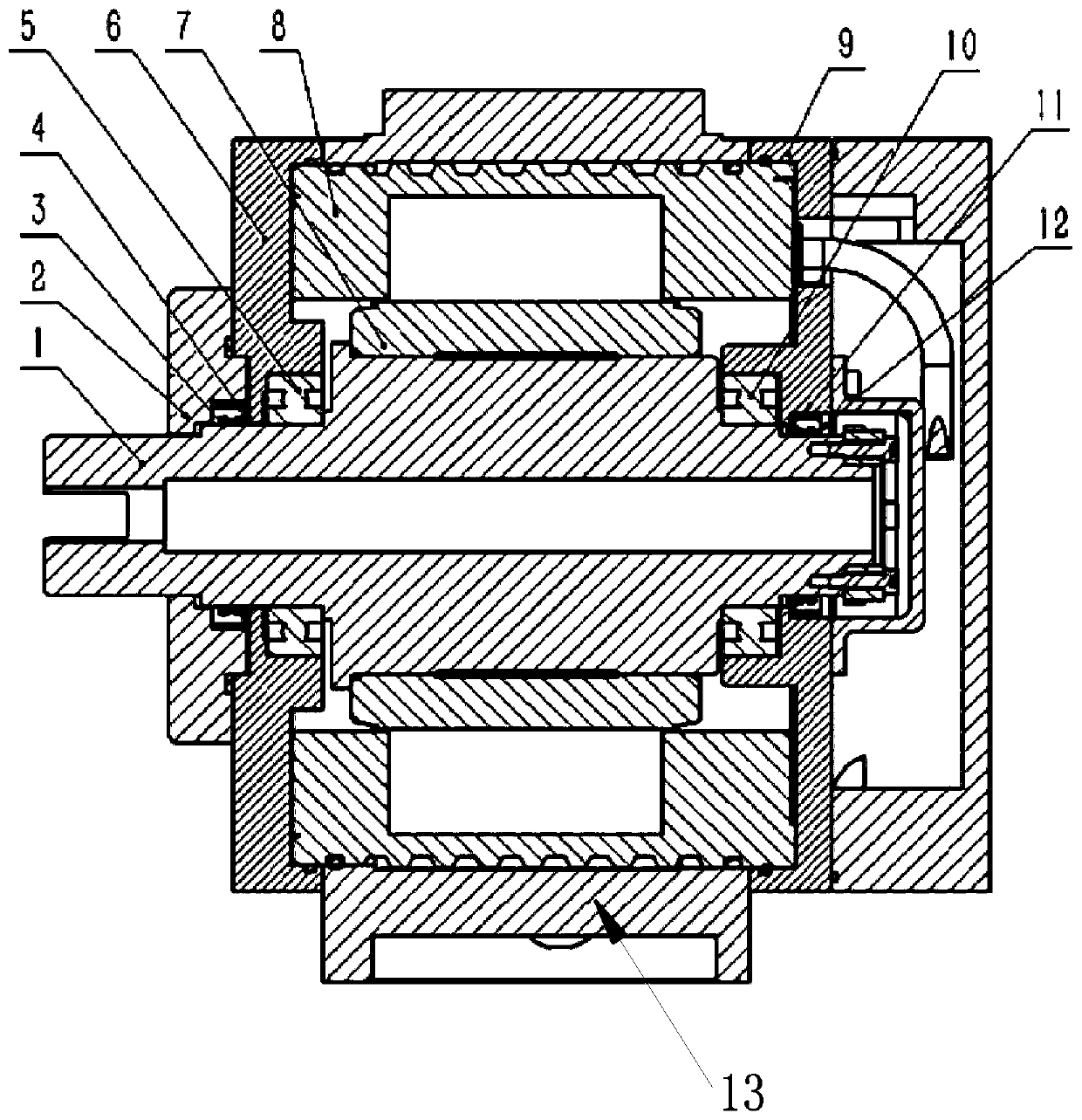

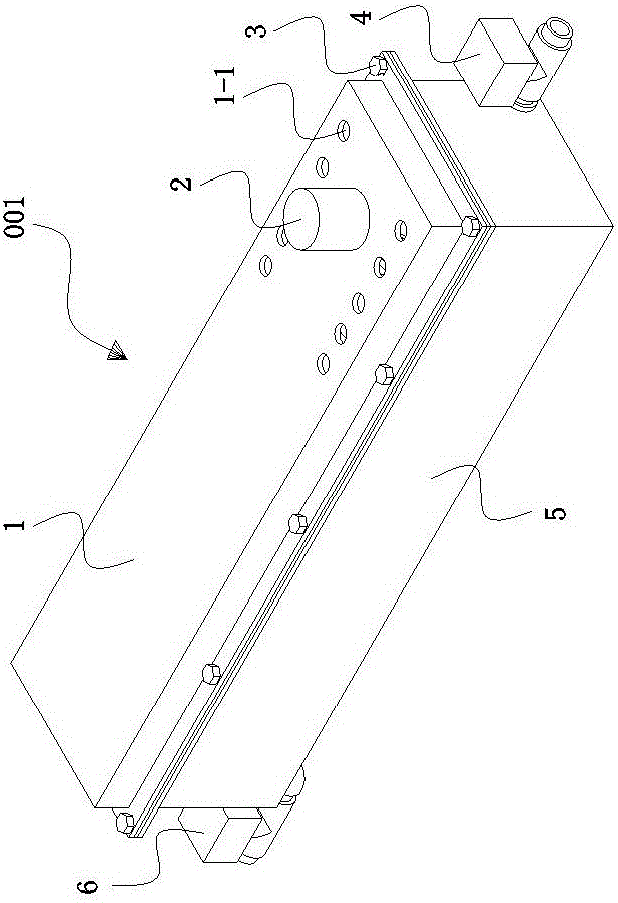

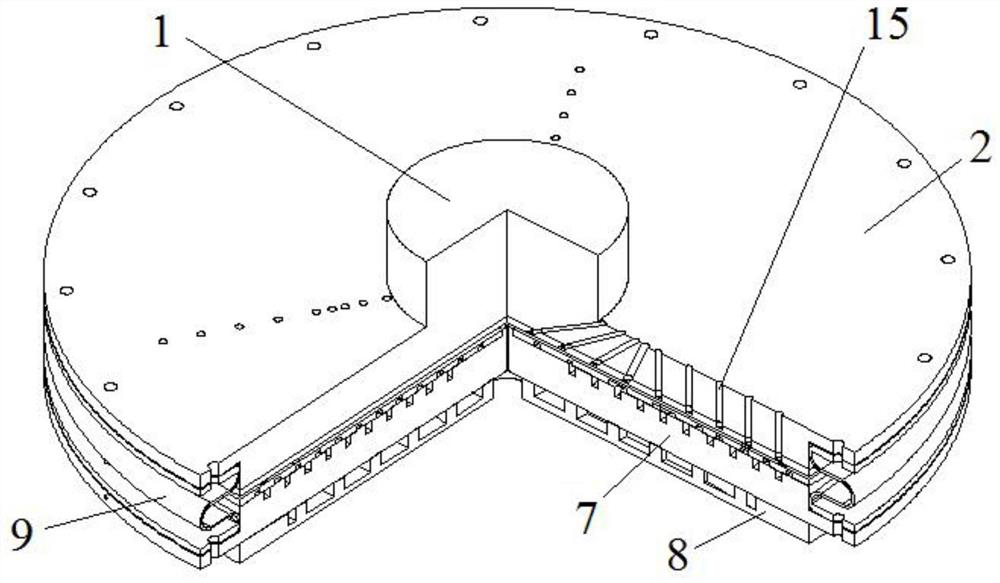

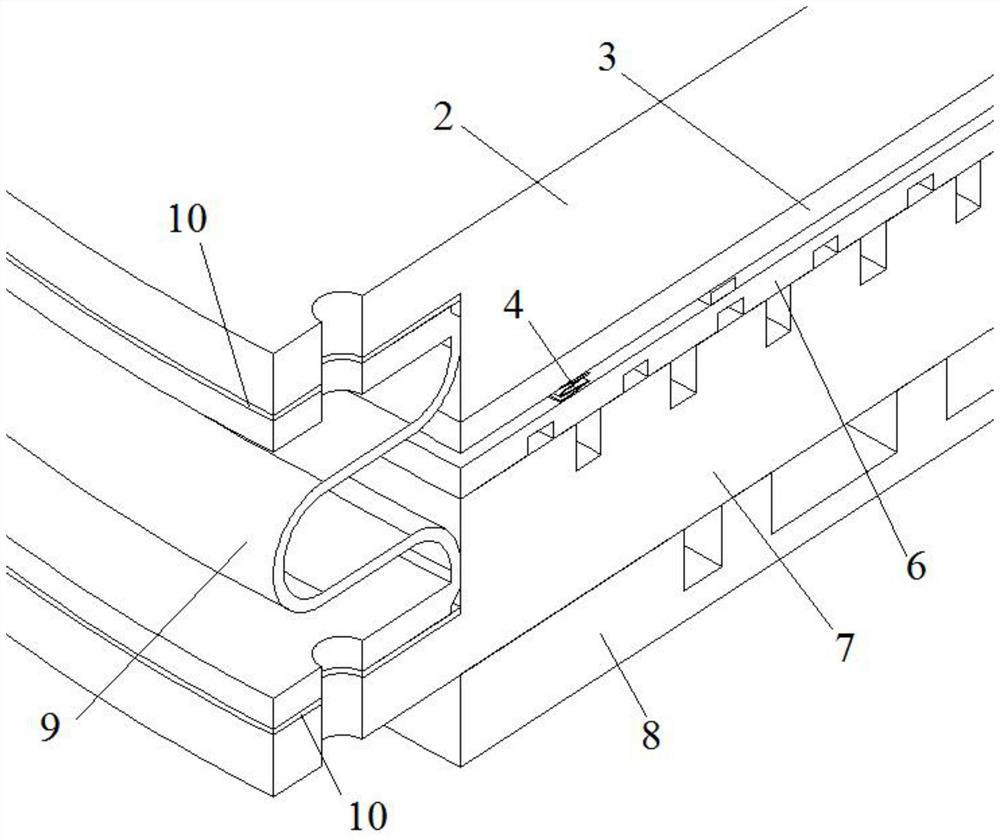

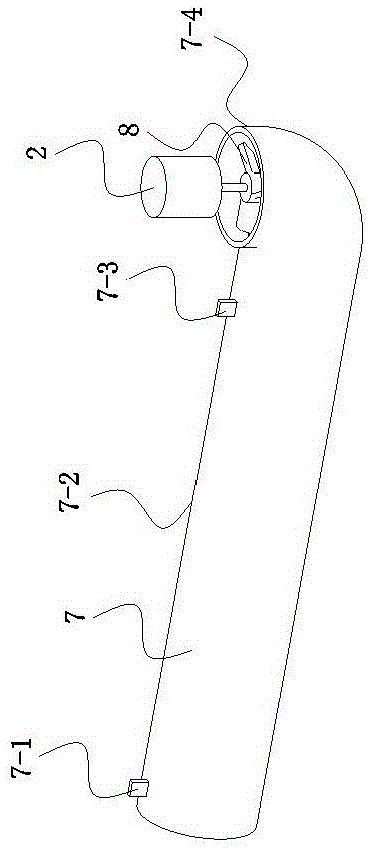

Motor shaft surface coating structure applied to power tool turret

PendingCN111313597AAvoid sealing difficultiesExtended service lifeAuxillary equipmentSupports/enclosures/casingsElectric machineryStructural engineering

The invention relates to a motor shaft surface coating structure applied to a power tool turret. The motor shaft surface coating structure comprises a main shaft, a front bearing and a rear bearing, wherein the front bearing and the rear bearing are assembled on the two sides of the main shaft. The main shaft is supported by the front bearing and the rear bearing at the two ends and forms axial positioning; the outer side of the front bearing and the outer side of the rear bearing are connected with a front flange plate and a rear flange plate respectively; the front flange plate and the rearflange plate are mounted at two ends of the main shaft box; an end cover is installed on the outer side of the front flange plate; a front oil seal and a rear oil seal are installed in the end cover and the rear flange plate respectively; oil seal lips of the front oil seal and the rear oil seal are in contact with the outer circle of the main shaft and are in sliding friction with the outer circle of the main shaft; a front wear-resistant coating and a rear wear-resistant coating are respectively arranged on contact areas of the main shaft and the front oil seal and the main shaft and the rear oil seal. According to the invention, the coating structure is compact in structure; the problem that the main shaft is difficult to seal due to the fact that the main shaft box is arranged in a cutter head structure is solved; and the service life of the sealing structure can be greatly prolonged especially when the main shaft rotates at high speed.

Owner:PINGHU HAICHEN MACHINE

Environment-friendly plastic woven bag

ActiveCN111254876AAvoid interferenceImprove production efficiencyDamsBagsAgricultural engineeringStructural engineering

The invention relates to the technical field of woven bags, in particular to an environment-friendly plastic woven bag. The environment-friendly plastic woven bag comprises a woven bag main body and aplacing frame for placing the woven bag main body, wherein the placing frame comprises a base, two ends of the upper surface of the base are respectively provided with supporting columns, the upper ends of the two supporting columns are connected with an annular mounting plate, two ends of the annular mounting plate are respectively provided with a first mounting through hole, a connecting rod isfixedly connected in each first mounting through hole, the upper end part of each connecting rod penetrates through the corresponding first mounting through hole, the bottom end of each connecting rod is fixedly connected with a supporting plate, and an opening of the woven bag main body is provided with two woven bag through holes which are matched with the connecting rods. According to the environment-friendly plastic woven bag, sandy soil can be added into the woven bag main body by a single person, and in the process of adding the sandy soil, the woven bag main body can be effectively prevented from deforming and interfering with the filling of the sandy soil. Therefore, the manufacturing efficiency of flood control bags is effectively improved, and the flood control effect is improved.

Owner:温州耀弘塑业有限公司

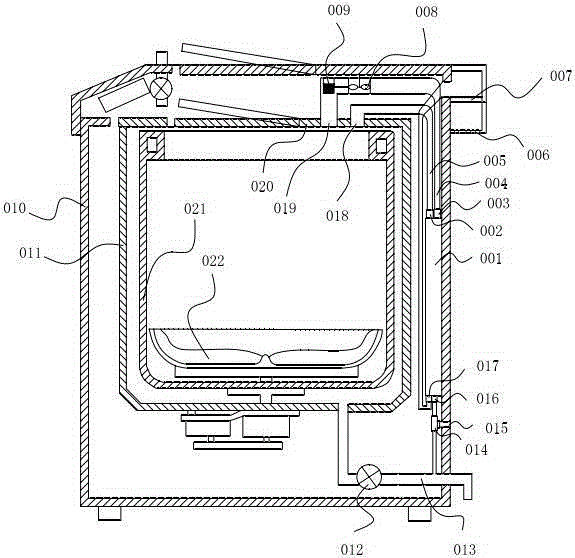

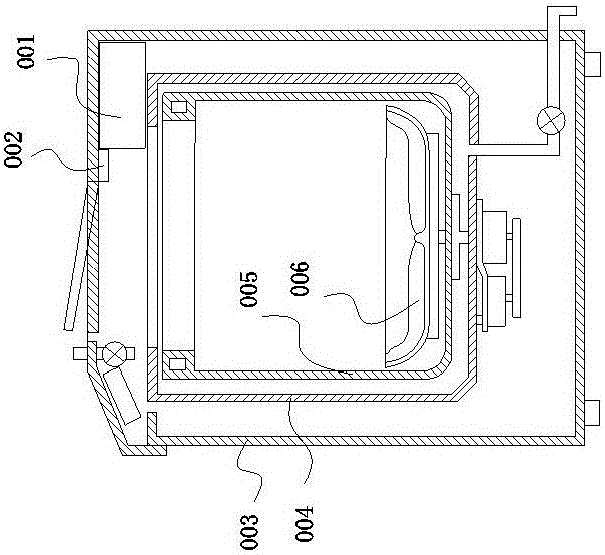

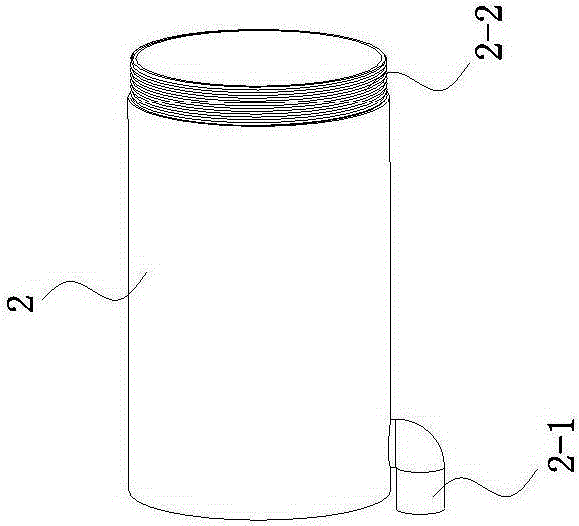

Culture medium apparatus provided with anaerobic device, and culturing method

InactiveCN107312702AMinus aliquot stepsGuaranteed tightnessBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologyCulture mediums

The invention relates to the technical field of microbial culture, and concretely relates to a culture medium apparatus provided with an anaerobic device, and a culturing method. The problems of provision of an effective anaerobic environment in the anaerobic culture process, and complicated sterilization and subpackaging extraction during culture experiments of a large amount of microbes are solved in the invention, and the problems of cross pollution between / among different culture media and the bacterial pollution risk brought in the culture medium packaging process are also prevented. The apparatus is disclosed against the problems during the storage of a liquid culture medium and can conveniently provide the anaerobic environment. The culture medium apparatus provided with the anaerobic device is a closed container, the closed container comprises a culture medium storage space and an anaerobic bag storage space; the culture medium storage space mutually communicates with the anaerobic bag storage space; and the closed container is provided with a seal membrane structure.

Owner:杭州至高生物科技有限公司

Washing machine provided with washing powder dissolving device

InactiveCN105113183AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses a washing machine provided with a washing powder dissolving device. The washing machine comprises a machine shell, an outer cylinder, an inner cylinder and an impeller. A detergent box and the washing powder dissolving device are arranged above the machine shell. The washing powder dissolving device comprises a box body, a guide pipe and a stirrer. A water inlet and a water outlet are formed in the box body. The outer side of the water inlet is provided with a water inlet electromagnetic valve, the water inlet electromagnetic valve is connected with the detergent box through a water pipe, and the outer side of the water outlet is provided with a water outlet electromagnetic valve. The guide pipe is fixed into the box body and divided into a vertical segment, an elbow segment and a horizontal segment. The lower end of the vertical segment and the upper end of the elbow segment are integrally connected, and the lower end of the elbow segment and the front end of the horizontal segment are integrally connected. Heating wires are wound around the outer side of the horizontal segment, and the inner side of the horizontal segment is provided with a resistance plate. The stirrer comprises a motor and a stirring impeller. The motor is fixed above the box body, and the lower end of an output shaft of the motor is arranged in the box body in a penetrating mode through a shaft hole and inserted into the vertical segment of the guide pipe. The stirring impeller is fixed to the lower end of output shaft of the motor. The inner side of the box body is further provided with a liquid level sensor and a temperature sensor.

Owner:蒋凤英

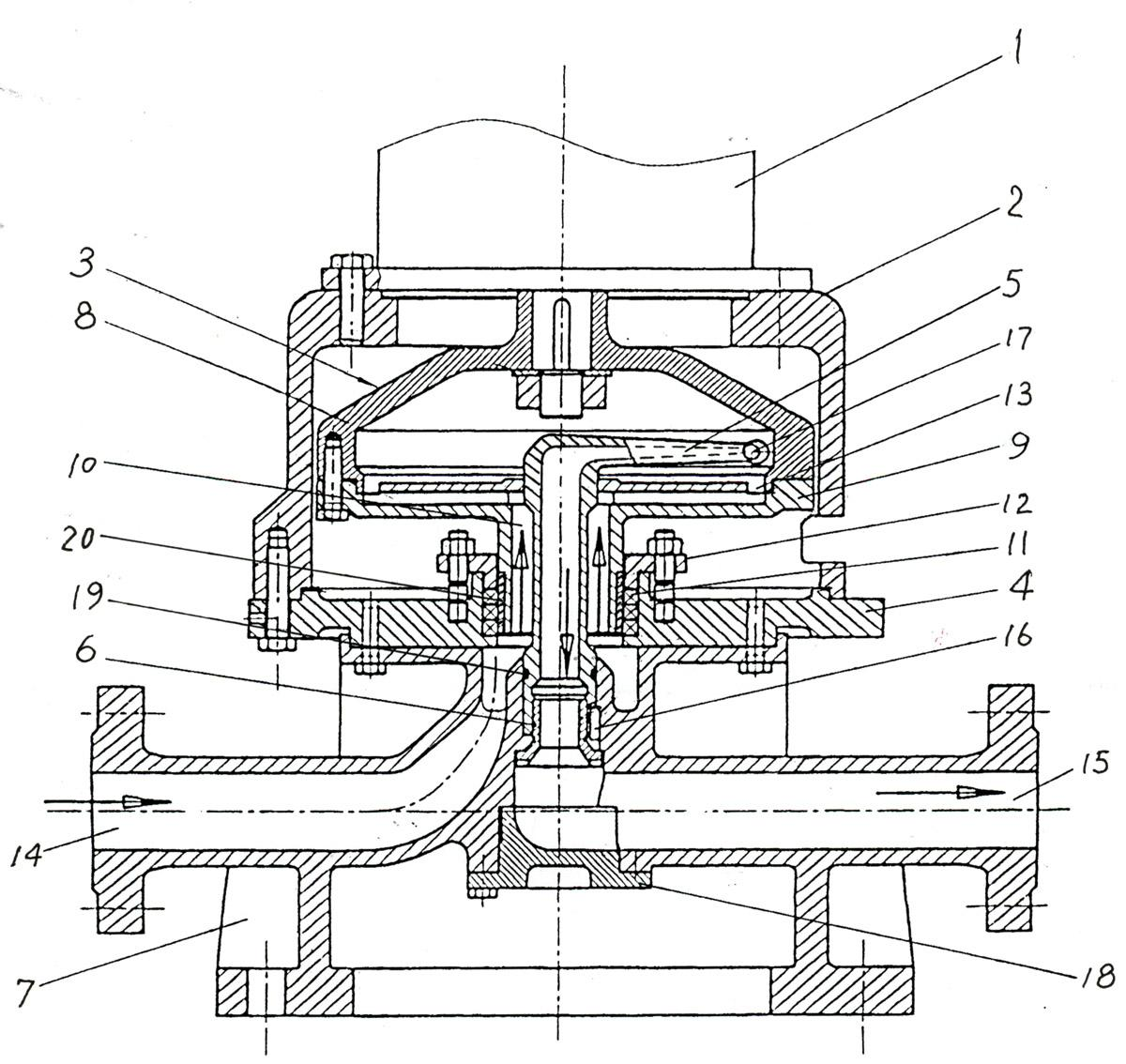

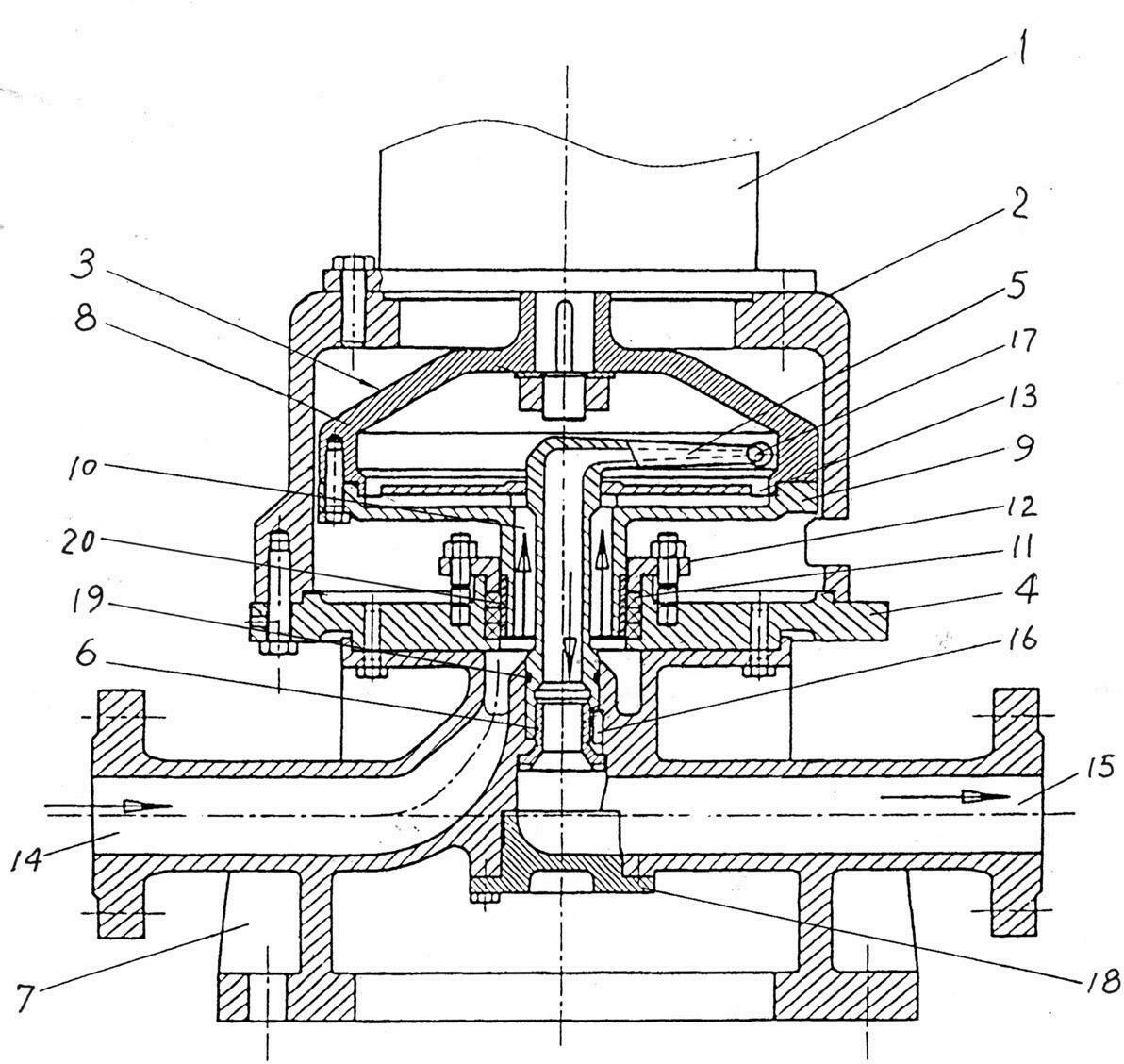

Energy-saving pump with ultralow specific speed

InactiveCN102562608AConstant outlet pressureSmall starting torquePump componentsPump installationsImpellerElectric machinery

The invention discloses an energy-saving pump with ultralow specific speed, which is characterized in that a rotor consisting of a pump body and an impeller is mounted in a cavity formed by a top cap and a connecting plate, the upper end of the rotor is connected with a motor, the lower end of the rotor is arranged in a center hole of the connecting plate through a hollow shaft of the impeller, a circular water outlet is arranged at the outer edge of the impeller, a base is connected with the connecting plate, a vertical pipe of an inverted-L-shaped water collection pipe is arranged in the hollow shaft of the impeller, the lower portion of the vertical pipe is fixed to the center hole of the base by a positioning sleeve in a threaded connection manner, a flat key is arranged between the positioning sleeve and the center hole, a cross pipe of the water collection pipe is arranged above the impeller, a water inlet is arranged at the outer end of the cross pipe, a water inlet pipe at the base is communicated with the hollow shaft, and a water outlet pipe is communicated with the water collection pipe. The energy-saving pump is simple in structure, reliable in running, low in flow, high in lift, high in performance adaptability and efficiency and reliable in sealing performance, and is particularly suitable for occasions having requirements for low flow, high lift and constant pressure.

Owner:GUANGZHOU GUANGYI PUMP

Energy-saving washing machine with box-shaped washing powder quick dissolving device

InactiveCN105177933AImprove solubilityFast dissolution rateOther washing machinesTextiles and paperCold airLaundry washing machine

The invention discloses an energy-saving washing machine with a box-shaped washing powder quick dissolving device. The washing machine is characterized in that a washing powder dissolving device is arranged on a case; a heat exchanger is arranged in the case; a hot and humid air inlet, a cold air outlet, a hot and humid air outlet and a cold air inlet are formed in the heat exchanger; the cold air outlet, a fan, an electric heater and a warm air feeding hole are connected by a pipeline; a hot and humid air discharge outlet is connected with the hot and humid air inlet by a pipeline; the cold air inlet is connected with a filter and an air suction inlet by a pipeline; the washing powder dissolving device comprises a box, a guide pipe and a stirrer; a water inlet solenoid valve and a water outlet solenoid valve are installed outside a water inlet and a water outlet in the box respectively; the water inlet solenoid valve and the water outlet solenoid valve are respectively connected with a water inlet tee joint and a water outlet tee joint by water pipes; the water inlet tee joint is connected with a detergent box by a water pipe; the water inlet and outlet tee joints are connected by a branch water pipe; a heating wire is wound outside a horizontal section of the guide pipe; a drag plate is arranged in the horizontal section; a stirring impeller of the stirrer is inserted in a vertical section; and a liquid level sensor and a temperature sensor are also arranged in the box.

Owner:耒阳市亲民电子商务有限公司

Washing machine with washing powder dissolving device

InactiveCN105113178AImprove solubilityIncrease volumeOther washing machinesTextiles and paperImpellerEngineering

The invention discloses a washing machine with a washing powder dissolving device. The washing machine comprises a machine shell, an outer tub, an inner tub and an impeller. A detergent box and the washing powder dissolving device are arranged at the upper portion of the machine shell. The washing powder dissolving device comprises a water containing pipe, a guide pipe arranged in the water containing pipe, and a stirrer arranged on the water containing pipe. The stirrer comprises a motor and a stirring impeller. The motor is fixedly installed above the outer side of the water containing pipe. An output shaft of the motor penetrates into the water containing pipe and is inserted into the guide pipe. The stirring impeller is fixedly installed at the lower end of the output shaft of the motor. A water inlet and a water outlet are formed in the water containing pipe. A water inlet electromagnetic valve is installed on the outer side of the water inlet. A water outlet electromagnetic valve is installed on the outer side of the water outlet. The water inlet electromagnetic valve is connected with a water inlet three-way joint through a water pipe. The water inlet three-way joint is connected with the detergent box through a water pipe. The water outlet electromagnetic valve is connected with a water outlet three-way joint through a water pipe. The water inlet three-way joint is connected with the water outlet three-way joint through a branch water pipe. A liquid level sensor is arranged in the water containing pipe.

Owner:蒋凤英

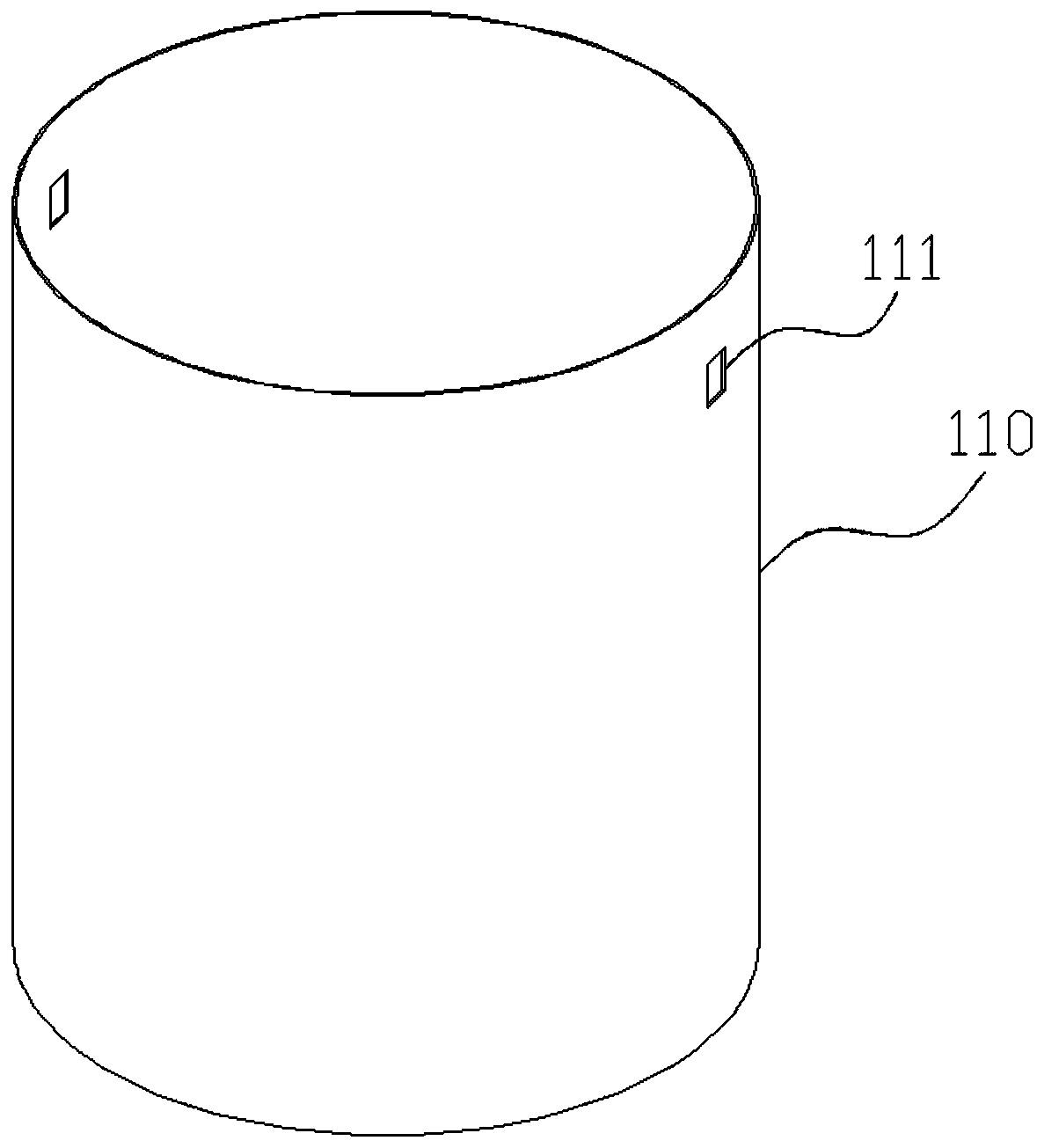

Culture medium storage apparatus

InactiveCN107236663AMinus aliquot stepsGuaranteed tightnessBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologyCross infection

The invention relates to the technical field of microbial culture, specifically relates to a culture medium storage apparatus, and aims to overcome the problem of trouble in sterilization and sub-package and extraction of the culture medium in a microbial culture experiment with a huge amount of sample size, prevent from the problem of cross infection between different culture mediums and avoid the microbiological contamination risk in the culture medium sub-package process; for solving the problems existing in the liquid culture medium storage, the invention provides the culture medium storage apparatus; the culture medium storage apparatus comprises a culture medium storage container and a sealing film structure arranged on the culture medium storage container; and the culture medium storage container is 2-10ml in volume.

Owner:HANGZHOU GAOZHENG MEDICAL TECH CO LTD

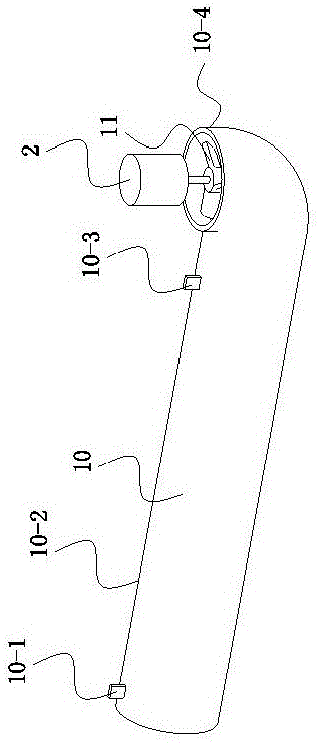

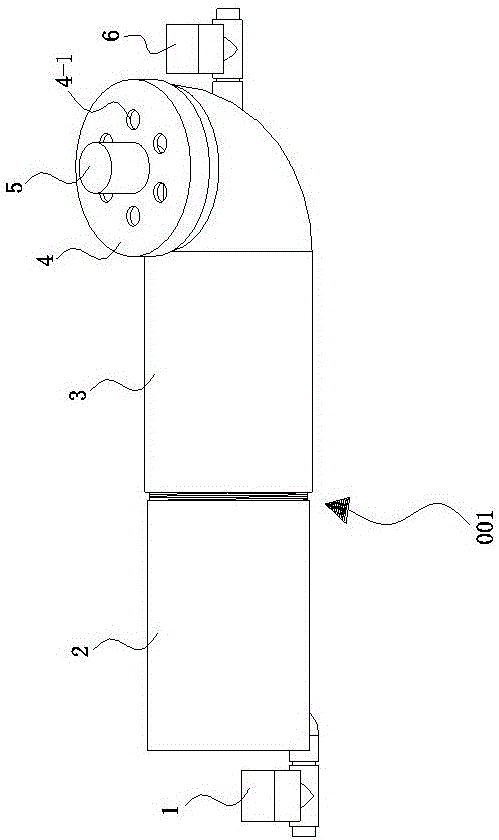

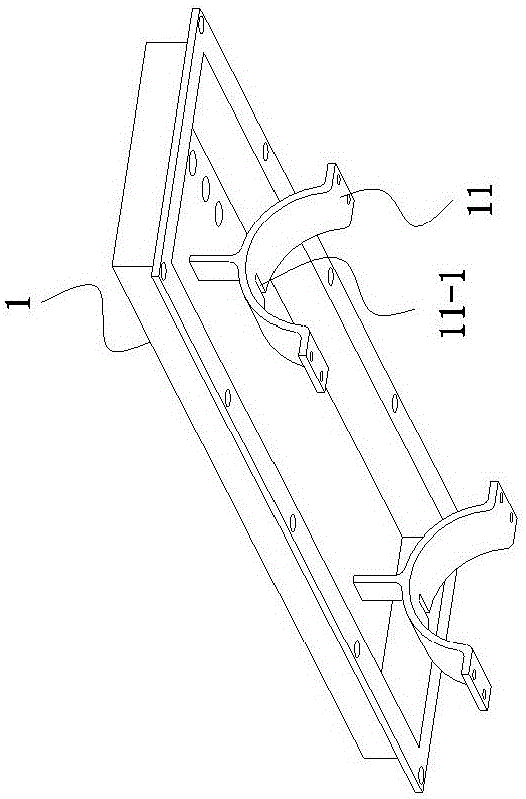

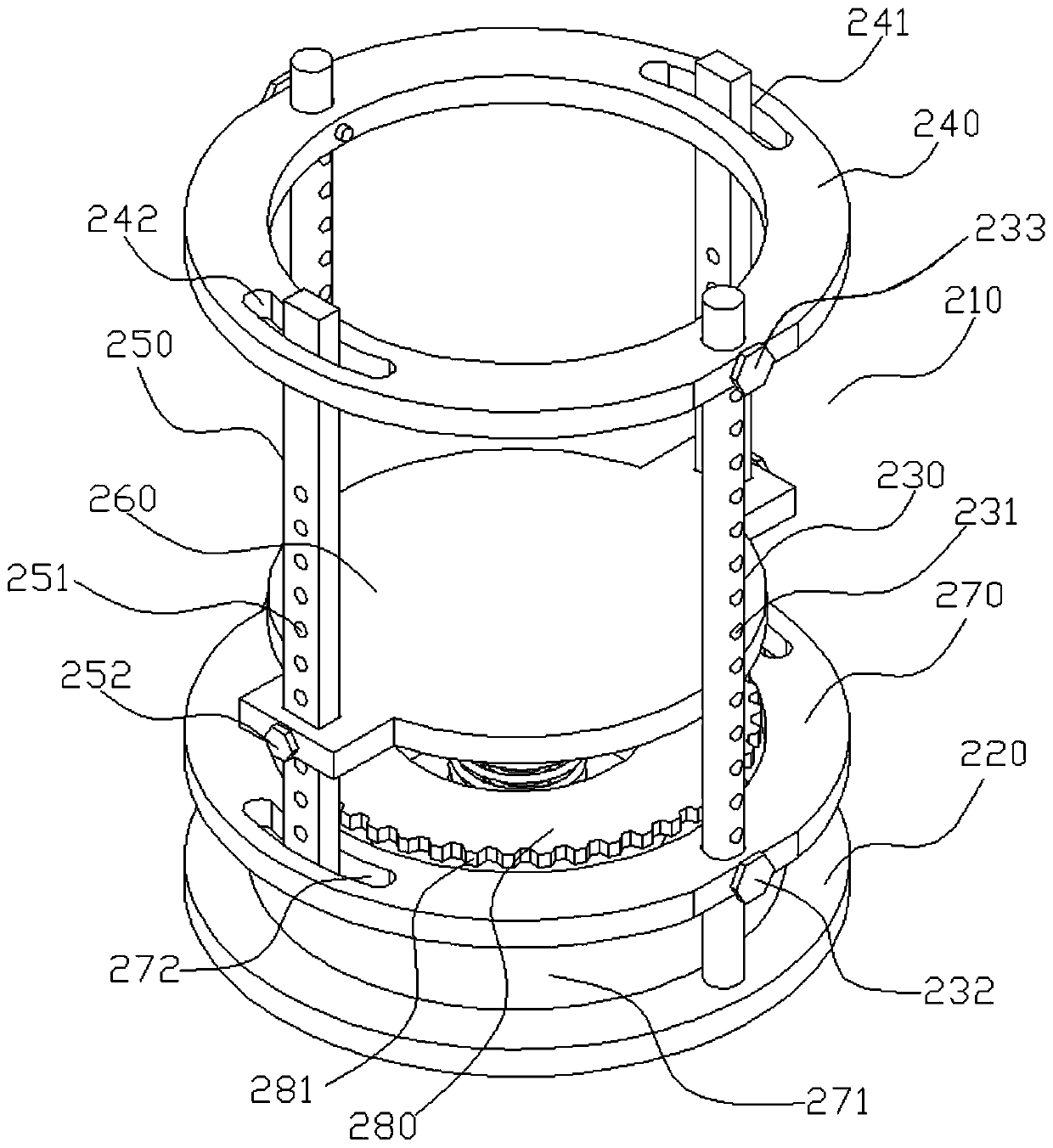

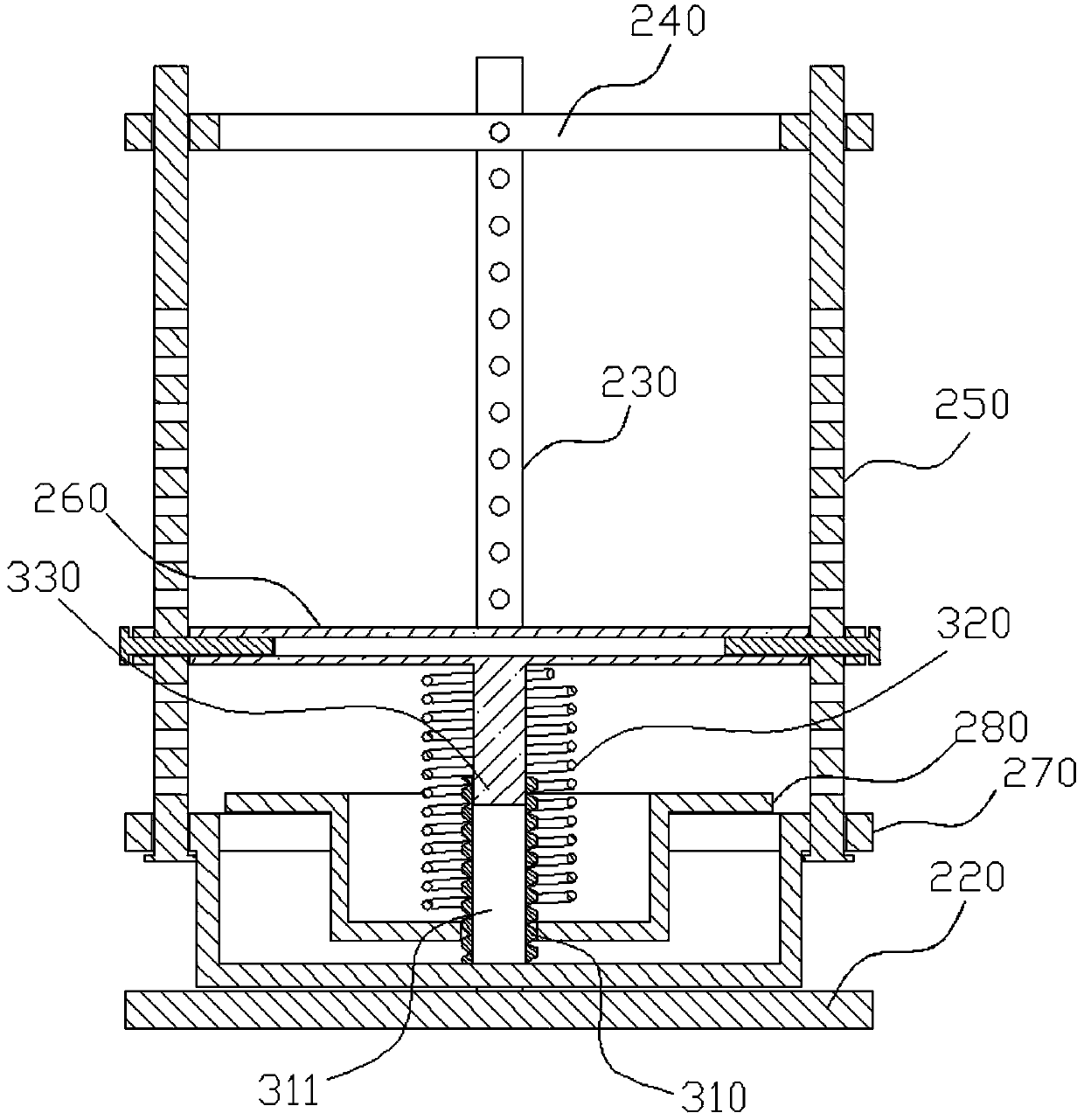

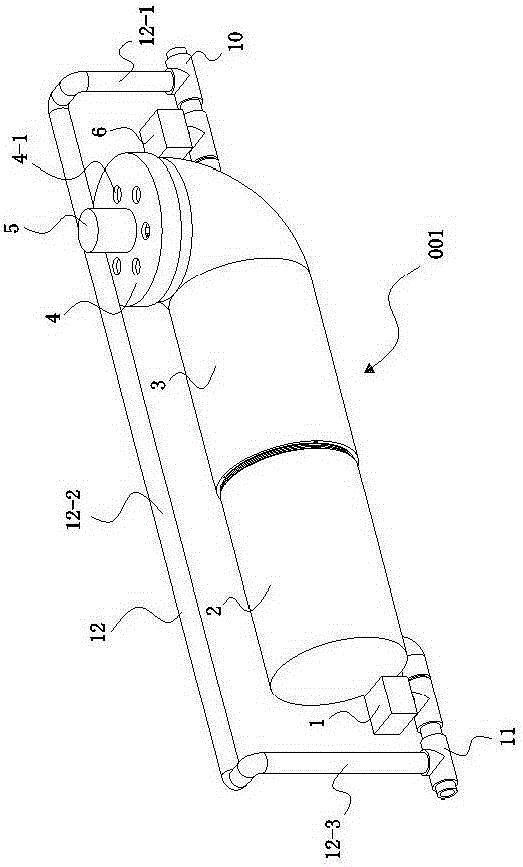

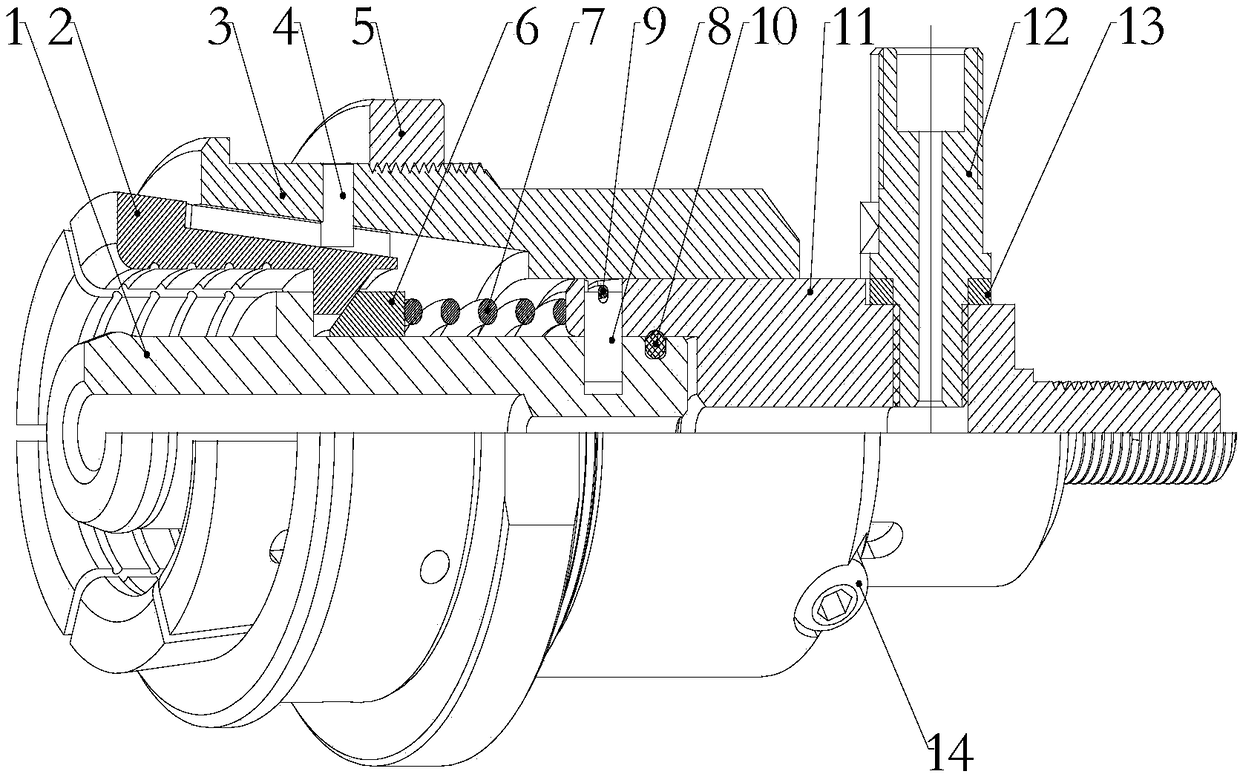

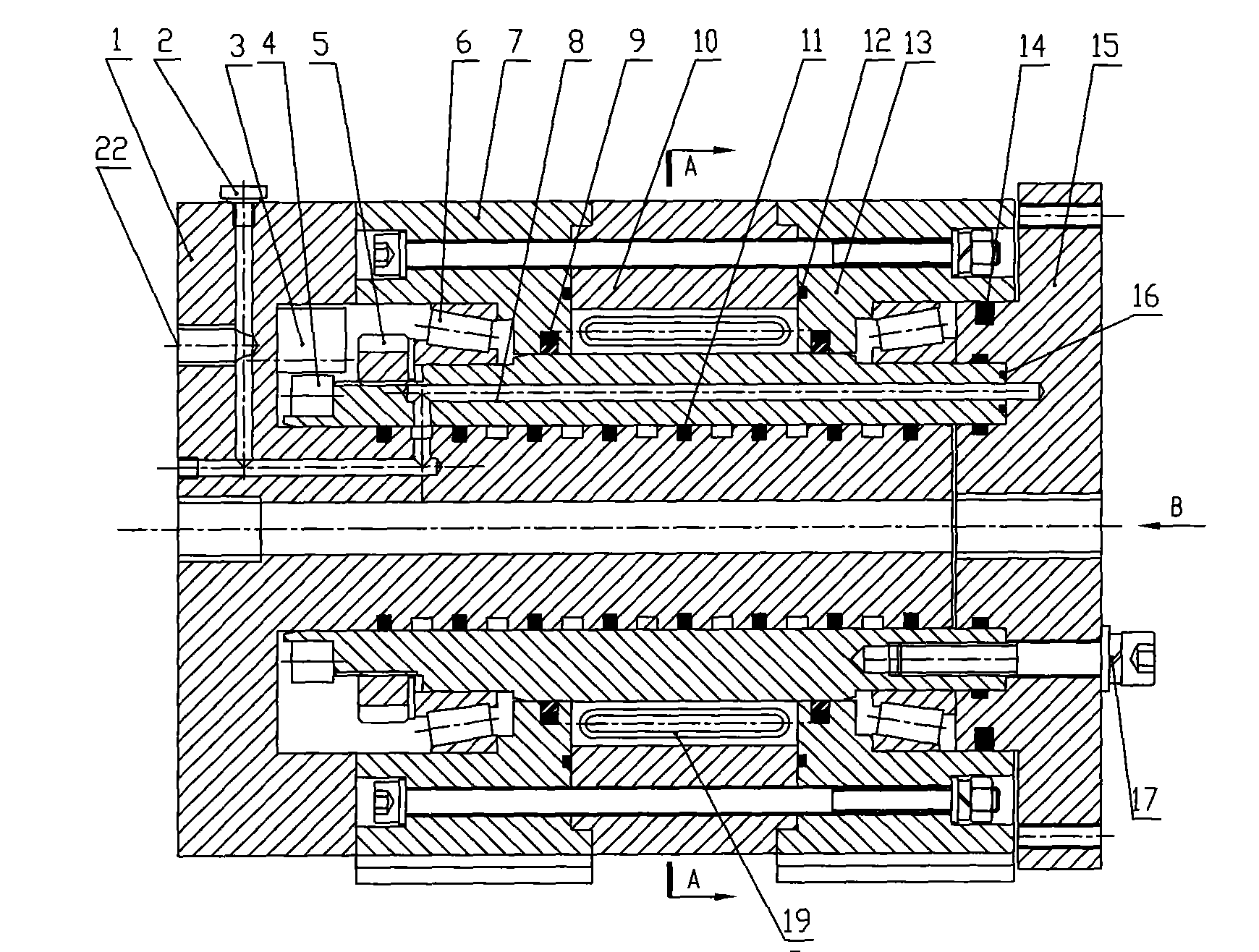

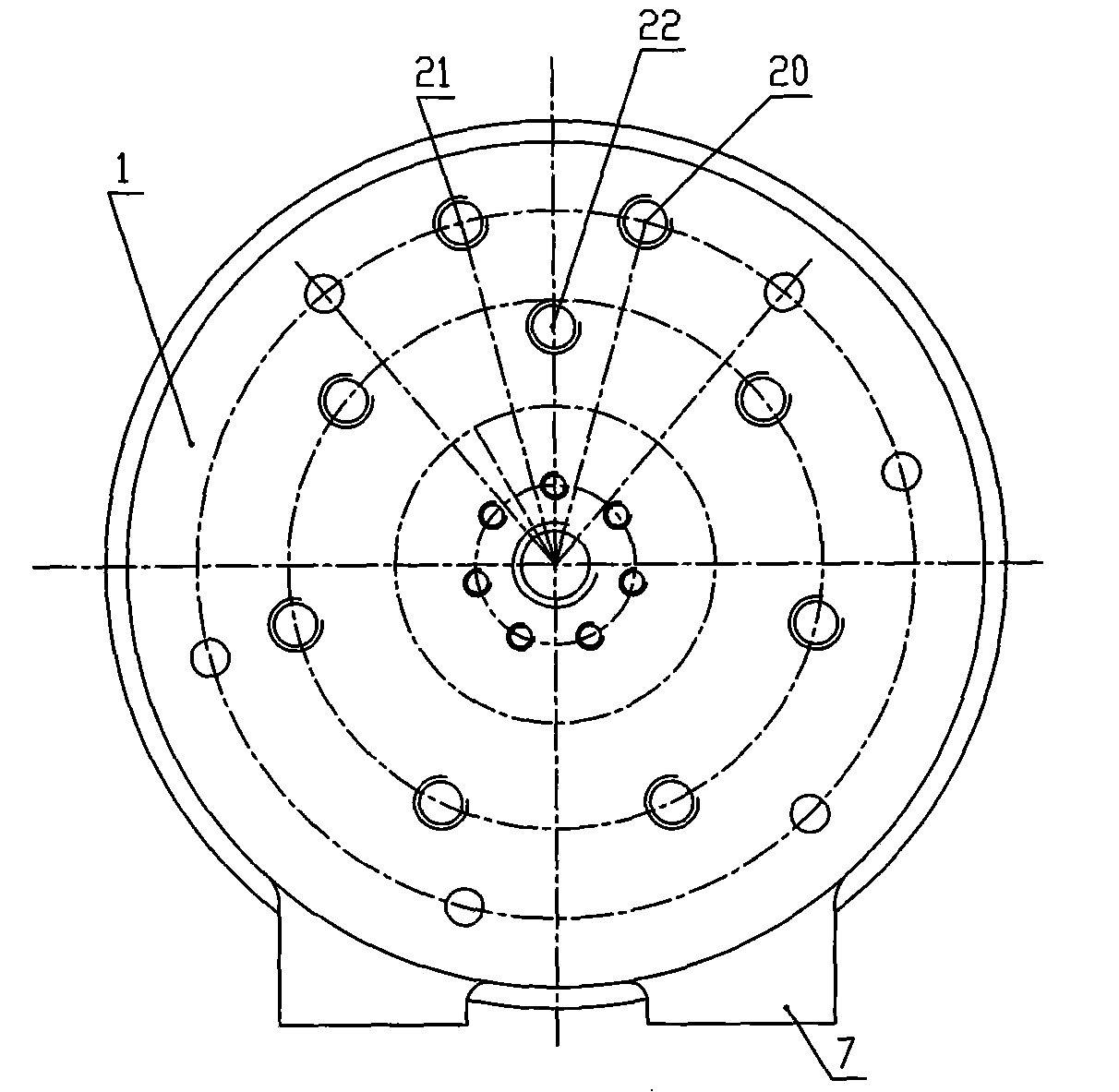

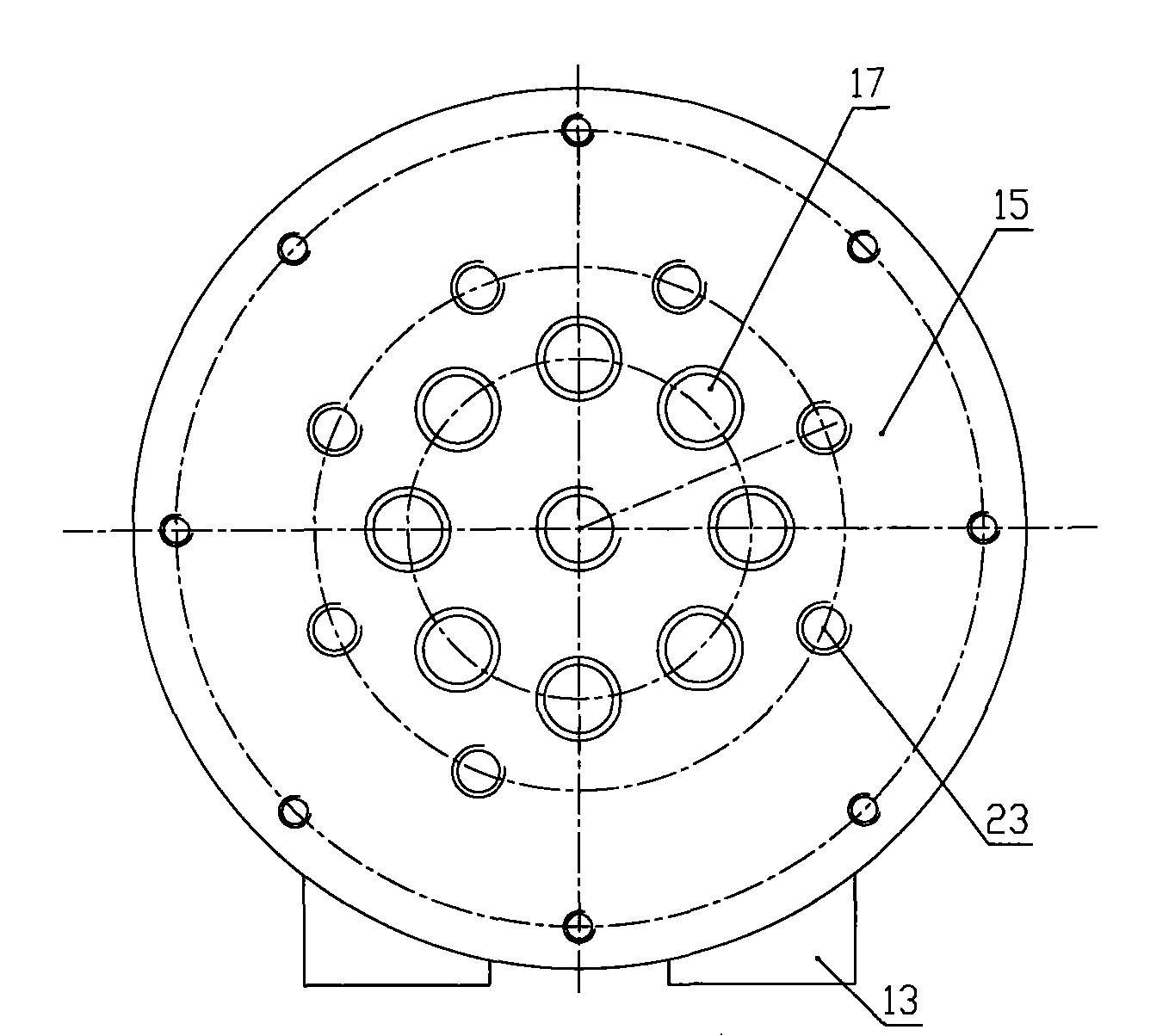

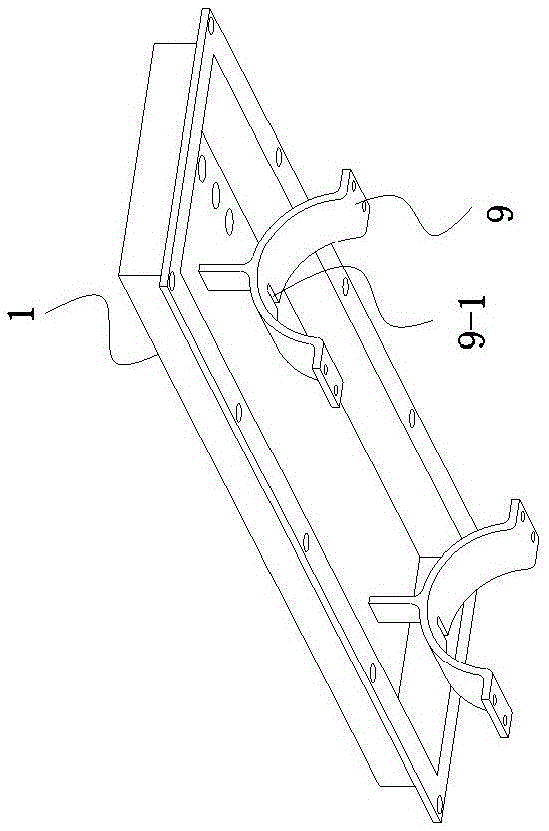

Clamping device for workpiece air tightness inspection

ActiveCN106985093BAvoid sealing difficultiesSafe and reliable clampingWork holdersFluid-tightness measurement using fluid/vacuumAir tightnessEngineering

The invention relates to a clamping device for workpiece airtightness testing. The clamping device comprises a hollow shaft, a sliding rod, a clamping mechanism, a pressing sleeve, a sliding sleeve and a compression restoration part. A first limiting part is arranged on the outer circumferential surface of one end of the hollow shaft. A ventilating hole is formed in one end of the sliding rod. The clamping mechanism surrounds the hollow shaft. A spaced space is formed between the clamping mechanism and the hollow shaft in the radial direction. A radial protrusion is arranged on the inner wall surface of the clamping mechanism. A tapered surface is arranged at the end, departing from the first limiting mechanism, of the radial protrusion. At least one part of an inner hole of the pressing sleeve is a tapered hole. The outer circumferential surface of the clamping mechanism is a tapered surface. One end of the pressing sleeve is sleeved with the clamping mechanism, and the tapper surface of the pressing sleeve is matched with the tapered surface of the clamping mechanism. The hollow shaft is sleeved with the sliding sleeve, and the radial protrusion is clamped between the first limiting part and the sliding sleeve. One end of the compression restoration part abuts against the sliding sleeve or is connected with the sliding sleeve, and the other end of the compression restoration part abuts against a sliding rod or is connected with the sliding rod. The clamping device for workpiece airtightness testing has the advantage that clamping is easy.

Owner:常州市盛士达汽车空调有限公司

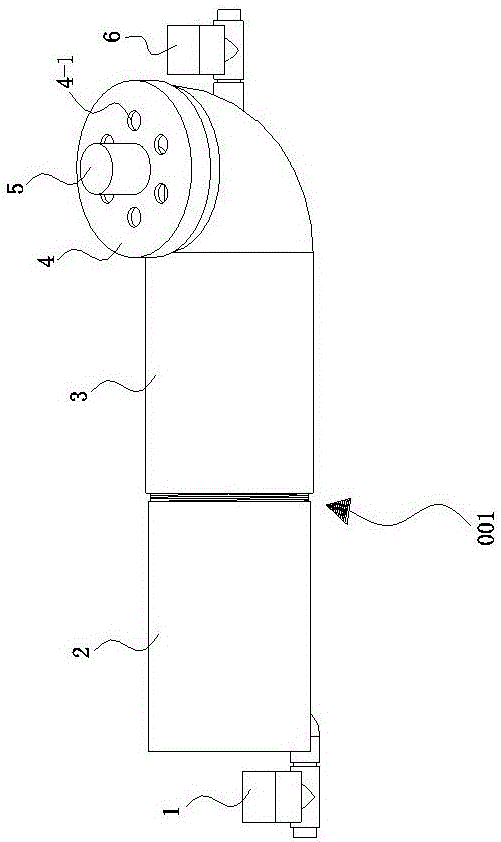

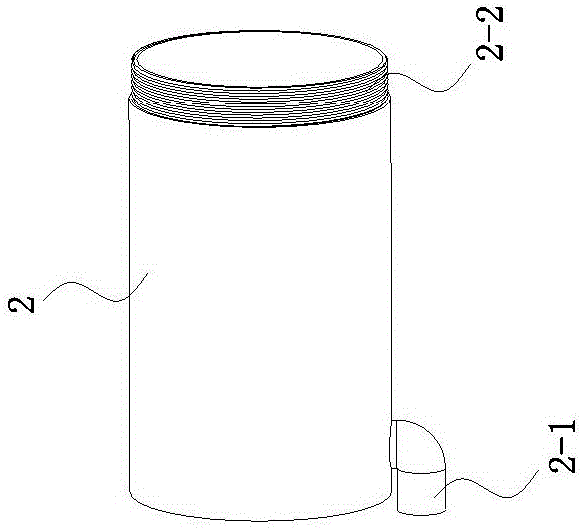

Tube-type solid oxide fuel cell monocell and preparation method thereof

InactiveCN105070935AGood for sealing and sinteringEasy to assemble and buildFinal product manufactureSolid electrolyte fuel cellsEngineeringOxide

The invention discloses a tube-type solid oxide fuel cell monocell and a preparation method thereof. In the tube-type monocell, a fuel cell generation tube body is arranged in a cathode shell, a cathode air inlet tube and a cathode air outlet tube are arranged between the cathode shell and the fuel cell generation tube body, an upper connector of the fuel cell generation tube body is arranged at the upper end of the fuel cell generation tube body, a lower connector of the fuel cell generation tube body is arranged at the lower end of the fuel cell generation tube body, and a cathode binding post and an anode binding post are arranged at a position where the fuel cell generation tube body and the cathode shell are in contact. With the adoption of a ceramic sealing sintering technique, all components of the fuel cell monocell are sealed and sintered to form an integrated ceramic structure, the problem of difficulty in sealing of all components of the solid oxide fuel cell in a high-temperature working condition is avoided, and the solid oxide fuel cell is further easy to assemble and build.

Owner:TIANJIN UNIV

Oil path built-in swivel motor for underwater manipulator

InactiveCN101499693BAvoid interferenceCompact structureStructural associationMechanical energy handlingUnderwater manipulatorEngineering

The invention provides a swing motor which is provided with a built-in oil passage and used for an underwater manipulator. The swing motor comprises a swing motor shaft core, a left end cover, a stator, a rotor, a vane, a right end cover, an output flange, a sensor and a conical roller bearing; one end of the left end cover is fixedly connected with the swing motor shaft core and the other end thereof is fixedly connected with the stator; the other end of the stator is fixedly connected with the right end cover; the left end cover, the stator and the right end cover are respectively provided with a cavity; the rotor is arranged in the cavity and can rotate in the circumferential direction; one end of the rotor is fixedly connected with the output flange; the vane is fixedly connected withthe external round surface of the rotor; the sensor is arranged at one end of the rotor; the reading head of the sensor is arranged in the cavity of the motor shaft core and fixedly connected with the motor shaft core; the conical roller bearing is sleeved on the external round surface of the rotor; the motor shaft core, the rotor and the output flange are provided with an oil passage respectively. The swing motor has compact structure and light weight, simultaneously avoids the interference with the environmental article due to the exteriorization of the oil pipe and increases the operation range of the manipulator.

Owner:HARBIN ENG UNIV

Low-noise washing machine with box-shaped detergent instant dissolver

InactiveCN112111934AMake the most of idle spaceReduce instantaneous impulseOther washing machinesTextiles and paperLaundry washing machineAgitator

The invention discloses a low-noise washing machine with a box-shaped detergent instant dissolver. The low-noise washing machine comprises a machine shell, an outer barrel, an inner barrel and an impeller, and a detergent box and a detergent dissolving device are arranged on the machine shell; a first permanent magnet is arranged at the upper end of the outer side of the outer barrel, a second permanent magnet is arranged on the inner side of the machine shell, and the two permanent magnets are magnetically arranged oppositely; the detergent dissolving device comprises a box body, a guide pipeand a stirrer, a water inlet and a water outlet are formed in the box body, a water inlet electromagnetic valve and a water outlet electromagnetic valve are arranged outside the water inlet and the water outlet, the water inlet electromagnetic valve is connected with the detergent box through a water pipe, and the water outlet electromagnetic valve is connected with a water pipe for guiding waterinto the inner barrel; the guide pipe is installed in the box body, the outer side of the guide pipe is wound with an electric heating wire, and the inner side of the guide pipe is provided with a resistance plate; the stirrer comprises a motor and a stirring impeller, the lower end of an output shaft of the motor penetrates into the box body through a shaft hole formed in the upper portion of the box body and is inserted into the guide pipe, and the stirring impeller is fixed to the lower end of the output shaft of the motor; and a liquid level sensor and a temperature sensor are further arranged on the inner side of the box body.

Owner:杨汉友

A sealing ring test device with deformation error compensation

ActiveCN110879139BReduce heat exchangeHigh measurement accuracyMachine part testingMaterial strength using tensile/compressive forcesMechanical energyEngineering

The invention discloses a sealing ring test device with deformation error compensation, which comprises an upper connecting plate and a lower connecting plate, the top of the upper connecting plate is fixedly connected with the bottom of the upper pressure plate, and the lower connecting plate is placed on the lower pressure plate. And the lower connecting plate is facing the upper connecting plate, the sealing ring test piece is placed on the top surface of the lower connecting plate, the sealing ring is connected between the edge of the upper platen and the edge of the lower platen, and the bottom surface of the lower connecting plate is also The main electric heating wire is set, and the top of the sealing ring test piece is in close contact with the bottom of the upper connecting plate; the high-pressure air inlet pipe passes through the lower pressure plate and the lower connecting plate to communicate with the high-pressure cavity, and the internal pressure ventilation pipe passes through the lower pressure The disc communicates with the inner cavity. The sealing ring test device with deformation error compensation of the present invention reduces the thermal energy, mechanical energy and high-pressure gas energy required for the sealing ring test, improves the measurement accuracy of the loading force and deformation of the test piece, and improves the controllability of the pressure ring force.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Low-noise washing machine with box-shaped detergent dissolver

InactiveCN112111935AMake the most of idle spaceReduce instantaneous impulseOther washing machinesTextiles and paperImpellerLaundry washing machine

The invention discloses a low-noise washing machine with a box-shaped detergent dissolver. The low-noise washing machine comprises a machine shell, an outer barrel, an inner barrel and an impeller, and a detergent box and a detergent dissolving device are arranged on the machine shell. A first permanent magnet is arranged at the upper end of the outer side of the outer barrel, a second permanent magnet is arranged on the inner side of the shell, and the first permanent magnet is magnetically opposite to the second permanent magnet. The detergent dissolving device comprises a box, a guide pipeand a stirrer, a water inlet and a water outlet are formed in the box, a water inlet electromagnetic valve and a water outlet electromagnetic valve are installed outside the water inlet and the wateroutlet, the water inlet electromagnetic valve is connected with the detergent box through a water pipe, and the water outlet electromagnetic valve is connected with a water pipe for guiding water intothe inner barrel. The guide pipe is installed in the box, the stirrer comprises a motor and stirring impellers, the motor is fixedly installed on the upper part of the outer side of the box, the lower end of an output shaft of the motor penetrates into the box through a shaft hole in the upper part of the box and is inserted into the guide pipe, and the stirring impellers are fixed to the lower end of the output shaft of the motor. A liquid level sensor is further arranged on the inner side of the box.

Owner:赵端英

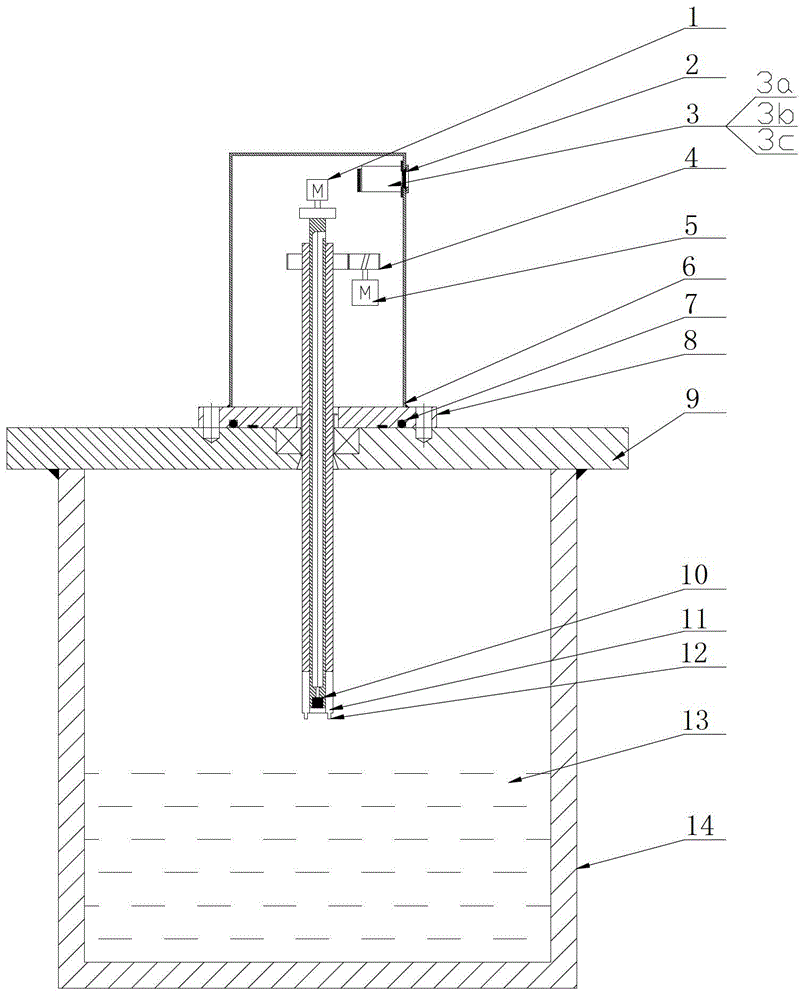

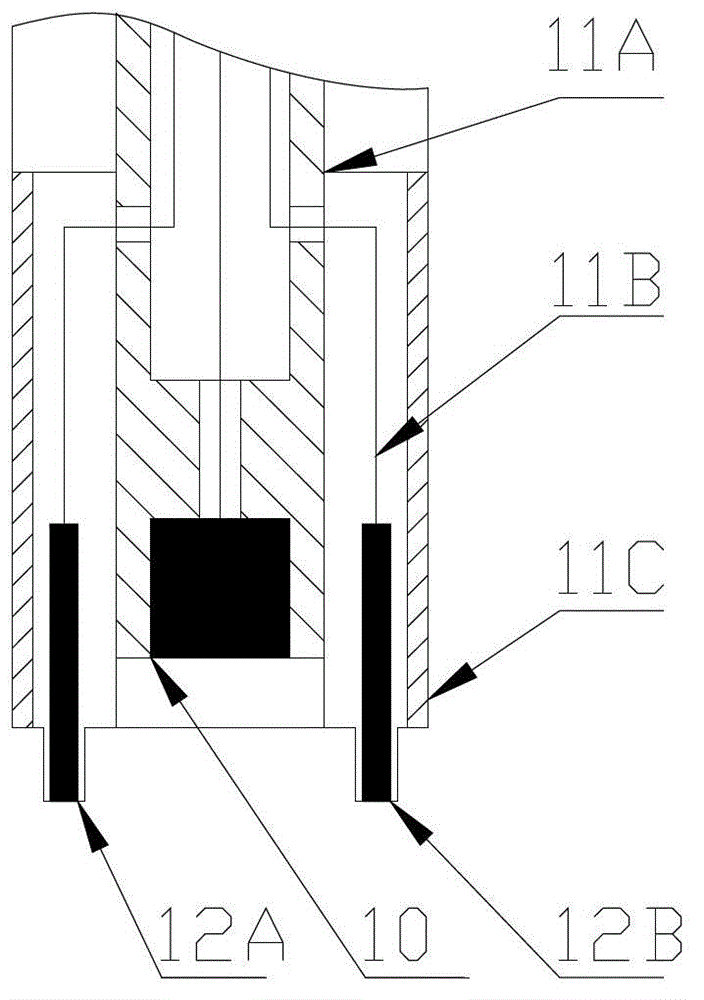

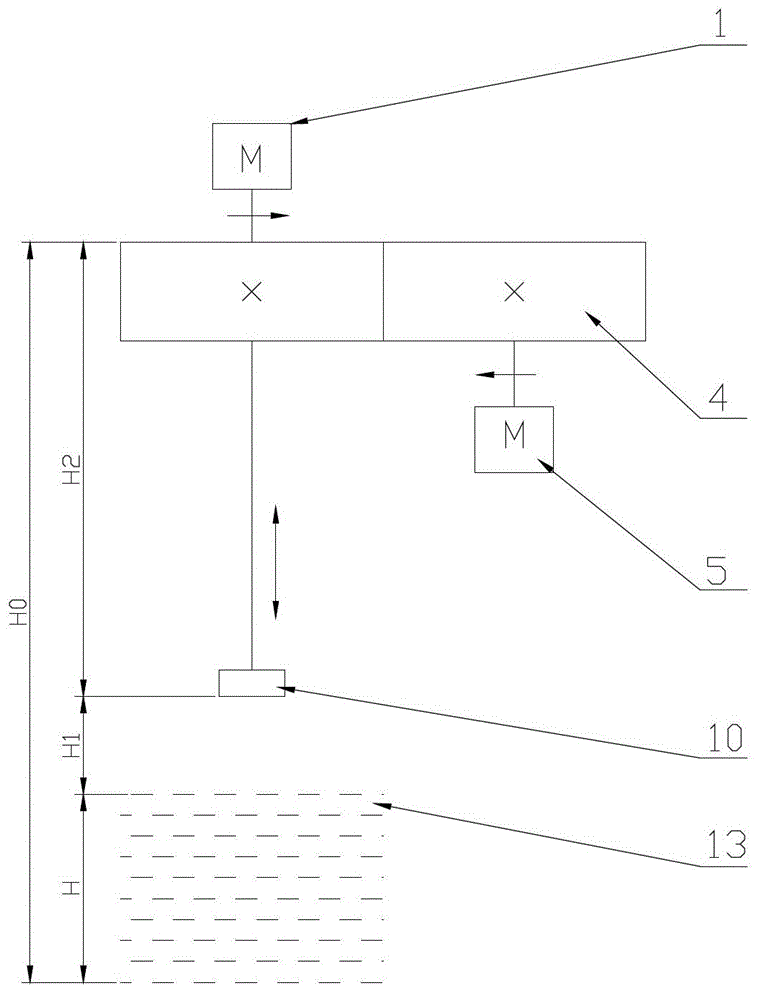

Non-contact type single-point liquid metal liquid level measurement device

InactiveCN102914343BHigh measurement accuracySimple structureTesting/calibration apparatusMachines/enginesMeasurement deviceEngineering

The invention discloses a non-contact type single-point liquid metal liquid level measurement device, which consists of a sensing probe, a lifting casing pipe, a liquid level probe, a direct-current stepping motor, an upper flange plate, a lower flange plate, a sealing shell, a meshing gear, a sealing element, a signal processing system, a motor driving system and a wireless transmission system, wherein the sensing probe detects the free liquid level of detected liquid metal; and the stepping motor is controlled by a corresponding control algorithm to drive the lifting casing pipe to lift, thereby keeping the sensing probe always in non-contact with the liquid level of detected liquid metal to realize non-contact measurement; the maximum detection distance between the sensing probe and the liquid level of detected liquid metal can be automatically calibrated by the liquid level probe, and the liquid level can be prevented from contacting with the sensing probe; and the sealing element can ensure the tightness of a measured container and is suitable for measuring the metal liquid level of the pressure container. The liquid level device can measure the liquid level of the liquid metal of which the temperature is up to 600DEG C, can be used for a long time, and has the advantages of high reliability and good sensitivity and accuracy, and is suitable for the accurate non-contact measurement of the high-temperature liquid metal liquid level.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Energy-saving machine provided with box-shaped detergent dissolving device

InactiveCN105200729AIncrease volumeAvoid sealing difficultiesOther washing machinesWashing machine with receptaclesAgricultural engineeringWater pipe

The invention discloses an energy-saving machine provided with a box-shaped detergent dissolving device. The energy-saving washing machine is characterized in that the detergent dissolving device is arranged at the upper part of a case, and a heat exchanger is arranged in the case; a wet and hot air inlet, a cold air outlet, a wet and hot air outlet and a cold air inlet are formed in the heat exchanger; the cold air outlet, a fan, an electric heater and a warm air supply port are connected through a pipeline, a wet and hot air exhaust port is connected with the wet and hot air inlet through a pipeline, and the cold air inlet is connected with a filter and an air suction port through a pipeline. The detergent dissolving device comprises a box, a guiding pipe and a stirrer, wherein a water inlet and a water outlet are formed in the box, and a water inlet solenoid valve and a water outlet solenoid valve are mounted on the outer sides of the water inlet and the water outlet respectively and are connected with a water inlet tee joint and a water outlet tee joint through water pipes respectively; the water inlet tee joint and a detergent box are connected through a water pipe, and the water inlet tee joint and the water outlet tee joint are connected through a branch water pipe; a liquid level sensor is further arranged in the box.

Owner:耒阳市亲民电子商务有限公司

Washing powder dissolving device

InactiveCN105113187AImprove solubilityAchieve complete dissolutionOther washing machinesTextiles and paperImpellerEngineering

The invention discloses a washing powder dissolving device. The washing powder dissolving device comprises a box body, a guiding pipe and a stirrer. A water inlet used for leading washing water into the box body is formed in the right side of the box body, and a water inflow electromagnetic valve is installed on the outer side of the water inlet. A water outlet used for discharging the washing water in the box body is formed in the bottom of the box body, and a water outflow electromagnetic valve is installed on the outer side of the water outlet. The guiding pipe is detachably and fixedly arranged in the box body and composed of a vertical segment, an elbow segment and a horizontal segment, and the vertical segment and the horizontal segment are connected through the elbow segment. The stirrer comprises a motor and a stirring impeller, the motor is fixedly installed above the outer side of the box body, and the lower end of a motor output shaft penetrates into the box body through a shaft hole formed in the upper portion of the box body and is inserted into the vertical segment of the guiding pipe. The stirring impeller is fixed to the lower end of the motor output shaft. A liquid level sensor is further arranged on the inner side of the box body. The washing powder dissolving device can fully use the idle space of a washing machine, and therefore washing powder can be fully dissolved.

Owner:蒋凤英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com