Energy-saving pump with ultralow specific speed

A specific speed, energy-saving pump technology, used in pumps, pump devices, pump components, etc., can solve the problems of inability to meet the constant pressure characteristics of the conveying medium, increasing the risk of equipment failure, and reducing the lift of a single-stage pump, achieving a simple and reliable structure. , light weight, reduce hydraulic loss effect

Inactive Publication Date: 2012-07-11

GUANGZHOU GUANGYI PUMP

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these pumps all have some disadvantages: such as multi-stage centrifugal pumps, in order to improve the efficiency of such pumps, the usual way is to reduce the head of the single-stage pump and increase the specific speed Ns of the pump.

Due to the lower head of the single-stage pump, in order to achieve the same high pressure of the pump, it is necessary to increase the number of pump stages (that is, increase the number of pump impellers in series), and the structure of multi-stage pumps with dozens of stages becomes extremely complicated. The total length of the pump (or height) increases, the weight increases, and the cost increases substantially at the same time

The complex multi-stage pump structure increases the risk of equipment failure and troublesome maintenance

In addition, the impeller channel of the pump with low flow rate, high lift and ultra-low specific speed is short and narrow. To process a narrow and long impeller channel, the current process often uses stamping and welding stainless steel plate impellers, which greatly increases the manufacturing cost of the pump; and Due to the axial friction between the impeller and the casing, the vortex pump has a short working life and poor cavitation performance. It is only suitable for working conditions with a lift below 200M and infrequent startup; reciprocating pumps have advantages in conveying small flow and high lift media Certain advantages, higher efficiency than centrifugal pumps, but reciprocating pumps have inevitable disadvantages: unstable flow, poor reliability, frequent maintenance; large vibration, high noise

[0004] To sum up, the above categories of products can no longer meet the requirements of energy saving, low cost, simple structure, and convenient maintenance, and at the same time, they cannot meet the constant pressure characteristics required by the conveying medium.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

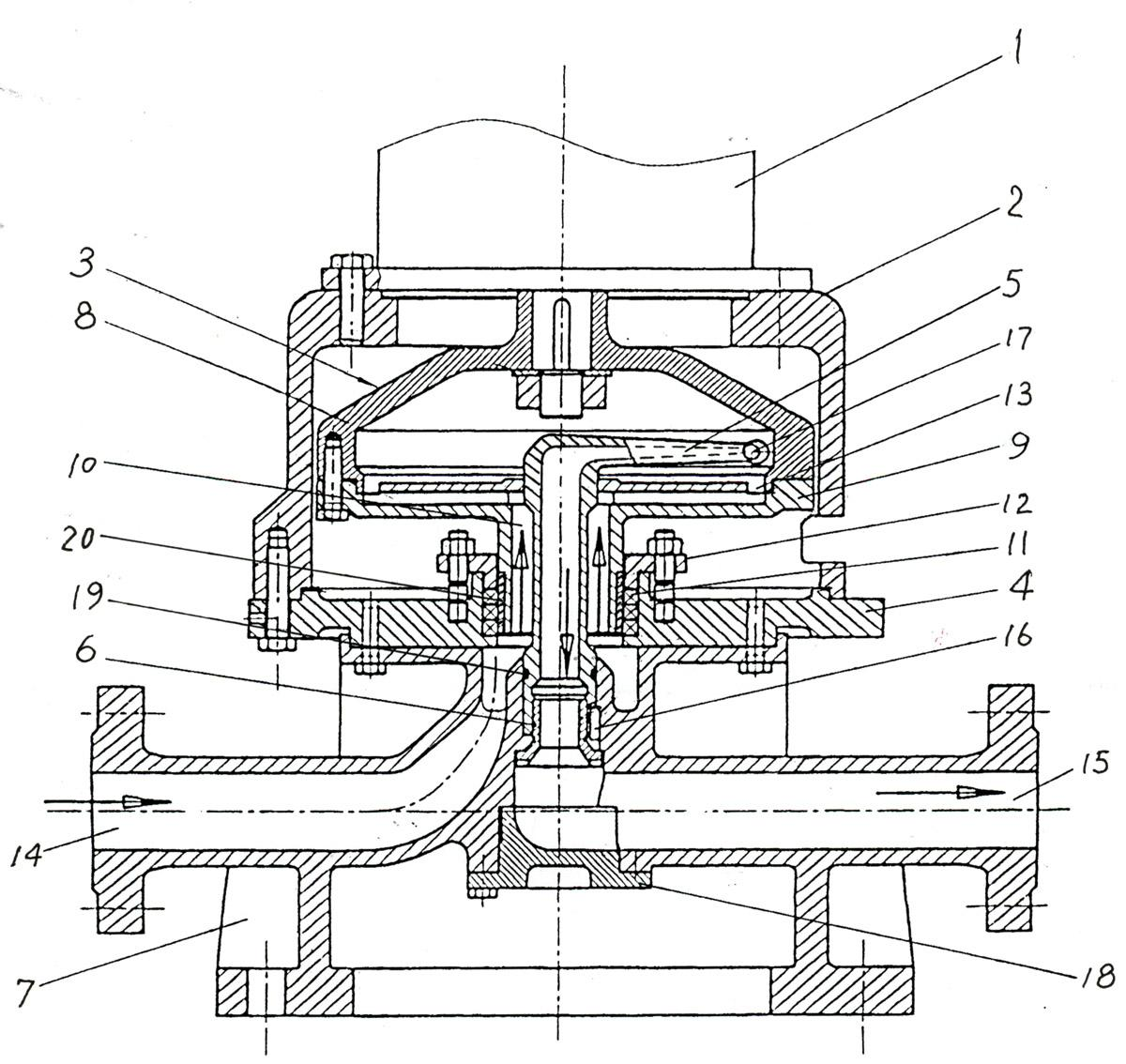

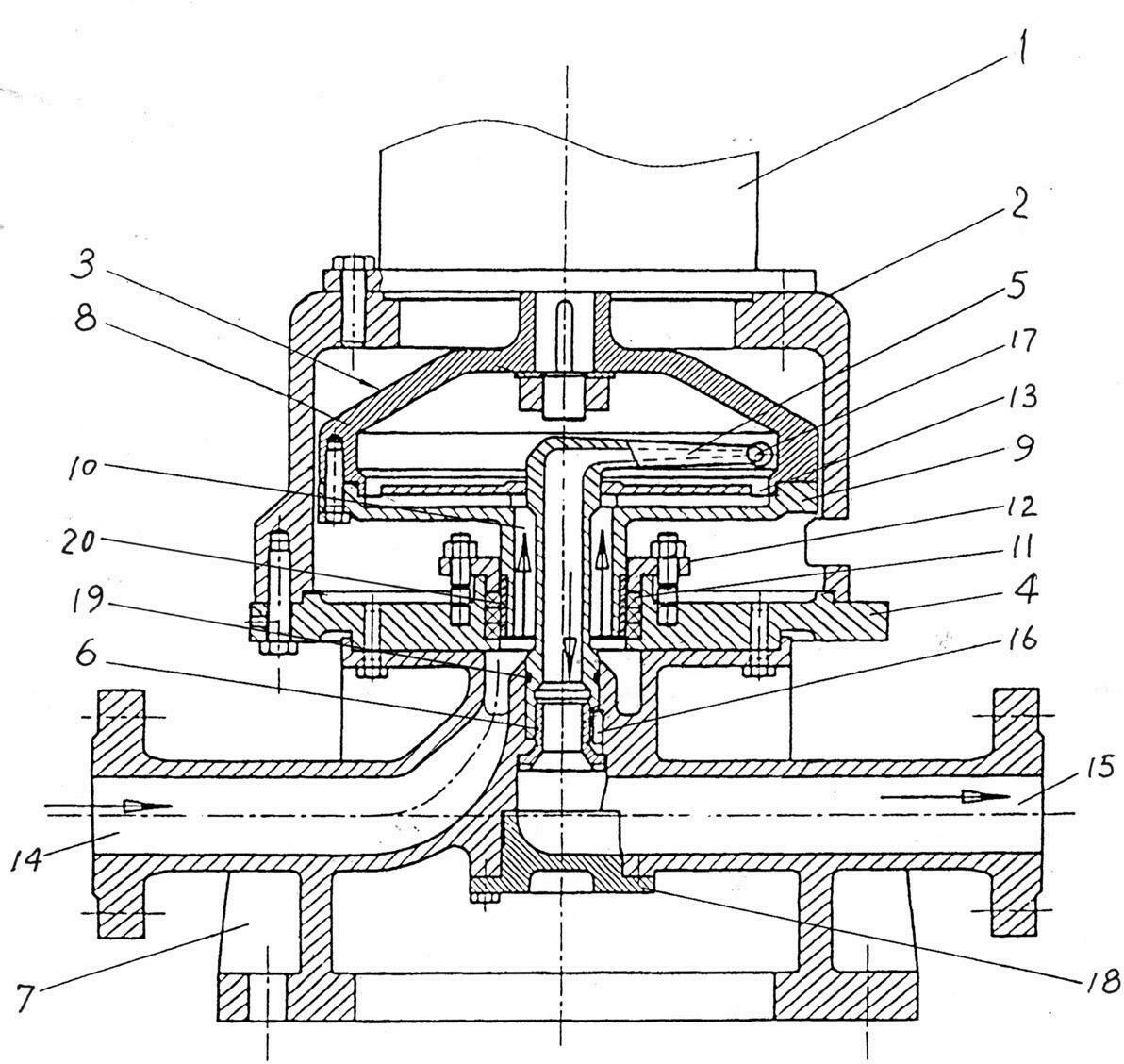

[0026] Embodiment 1. The water inlet pipe 14 and the water outlet pipe 15 of the base 7 are placed symmetrically and horizontally in the base 7 .

Embodiment 2

[0027] Embodiment 2. An O-shaped sealing ring 19 is arranged between the liquid collecting pipe 5 and the center hole of the base 7 .

Embodiment 3

[0028] Embodiment 3. An inspection cover 18 is provided at the lower end of the center hole of the base 7 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an energy-saving pump with ultralow specific speed, which is characterized in that a rotor consisting of a pump body and an impeller is mounted in a cavity formed by a top cap and a connecting plate, the upper end of the rotor is connected with a motor, the lower end of the rotor is arranged in a center hole of the connecting plate through a hollow shaft of the impeller, a circular water outlet is arranged at the outer edge of the impeller, a base is connected with the connecting plate, a vertical pipe of an inverted-L-shaped water collection pipe is arranged in the hollow shaft of the impeller, the lower portion of the vertical pipe is fixed to the center hole of the base by a positioning sleeve in a threaded connection manner, a flat key is arranged between the positioning sleeve and the center hole, a cross pipe of the water collection pipe is arranged above the impeller, a water inlet is arranged at the outer end of the cross pipe, a water inlet pipe at the base is communicated with the hollow shaft, and a water outlet pipe is communicated with the water collection pipe. The energy-saving pump is simple in structure, reliable in running, low in flow, high in lift, high in performance adaptability and efficiency and reliable in sealing performance, and is particularly suitable for occasions having requirements for low flow, high lift and constant pressure.

Description

technical field [0001] The invention relates to the technical field of pumps, in particular to an ultra-low specific speed energy-saving pump, which is especially suitable for use in occasions with small flow rate, high lift and constant pressure conveying medium. Background technique [0002] The pump is a machine that converts the mechanical energy of the prime mover into liquid energy through the impeller. The specific speed of the pump Ns is an important parameter used to quantify the performance of the pump. The lower the specific speed of the pump, the smaller the pump flow and the higher the lift at a certain speed. . The lower the specific speed, the shorter the flow path of the pump and the lower the pump efficiency will be. For the pump with a specific speed Ns≤30, it is usually called an ultra-low specific speed pump. Small flow and high head centrifugal pumps are used in small boiler water supply, fire protection stability, It is widely used in petrochemical, ch...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04D13/06F04D29/22F04D29/42F04D29/08

Inventor 刘龙珍黄思

Owner GUANGZHOU GUANGYI PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com