Distributed automatic-compensation vane vacuum pump

An automatic compensation, vacuum pump technology, applied in the direction of rotary piston type/swing piston type pump components, rotary piston type pumps, and elastic fluid rotary piston type/swing piston type pump combinations, etc., can solve the secondary oil and gas recovery System impact, shortening the service cycle, impervious blade wear and other problems, to achieve the effect of beautiful appearance, increased service life, constant outlet pressure and vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following describes the specific implementation, structure, and structure of a decentralized automatic compensation vane vacuum pump proposed in accordance with the present invention with reference to the accompanying drawings and preferred embodiments. The characteristics and effects are described in detail later.

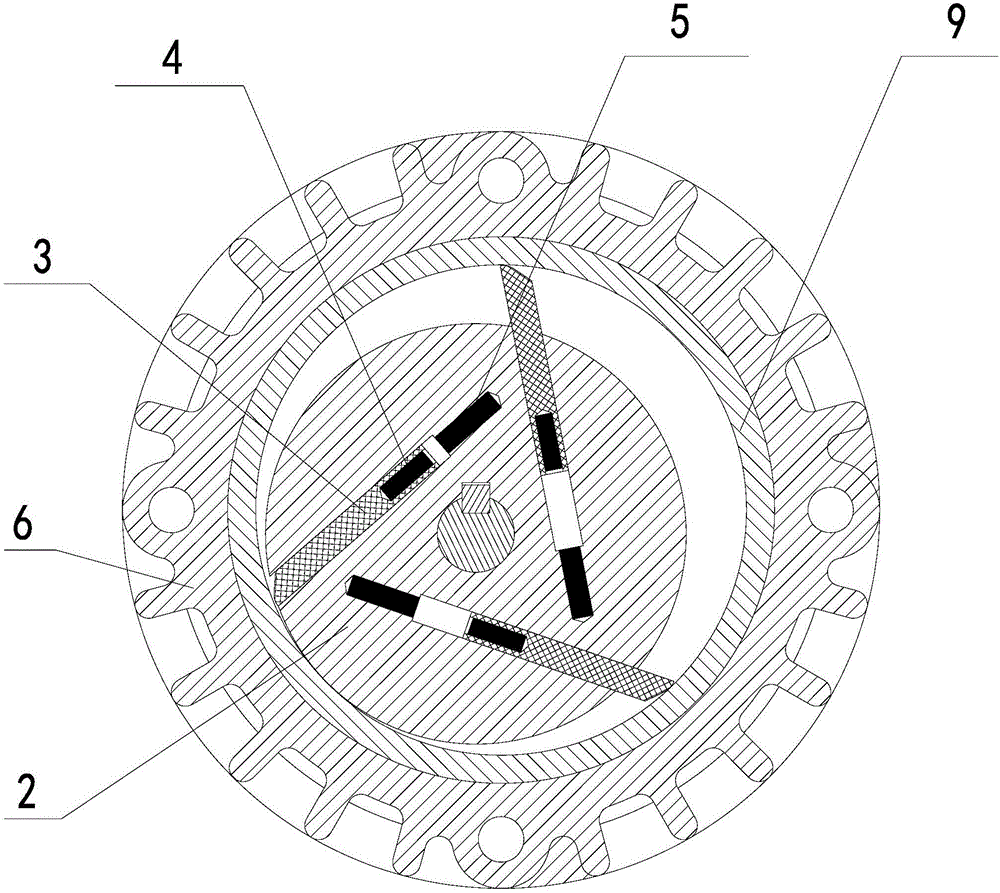

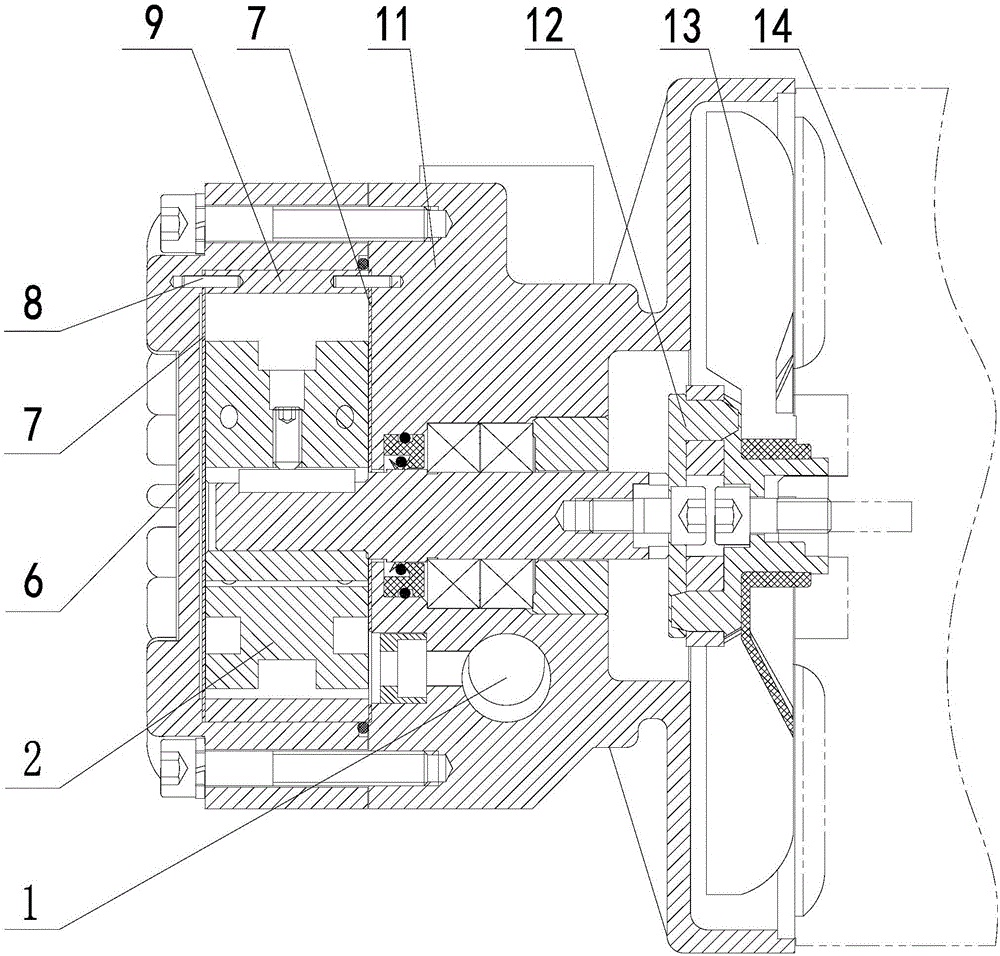

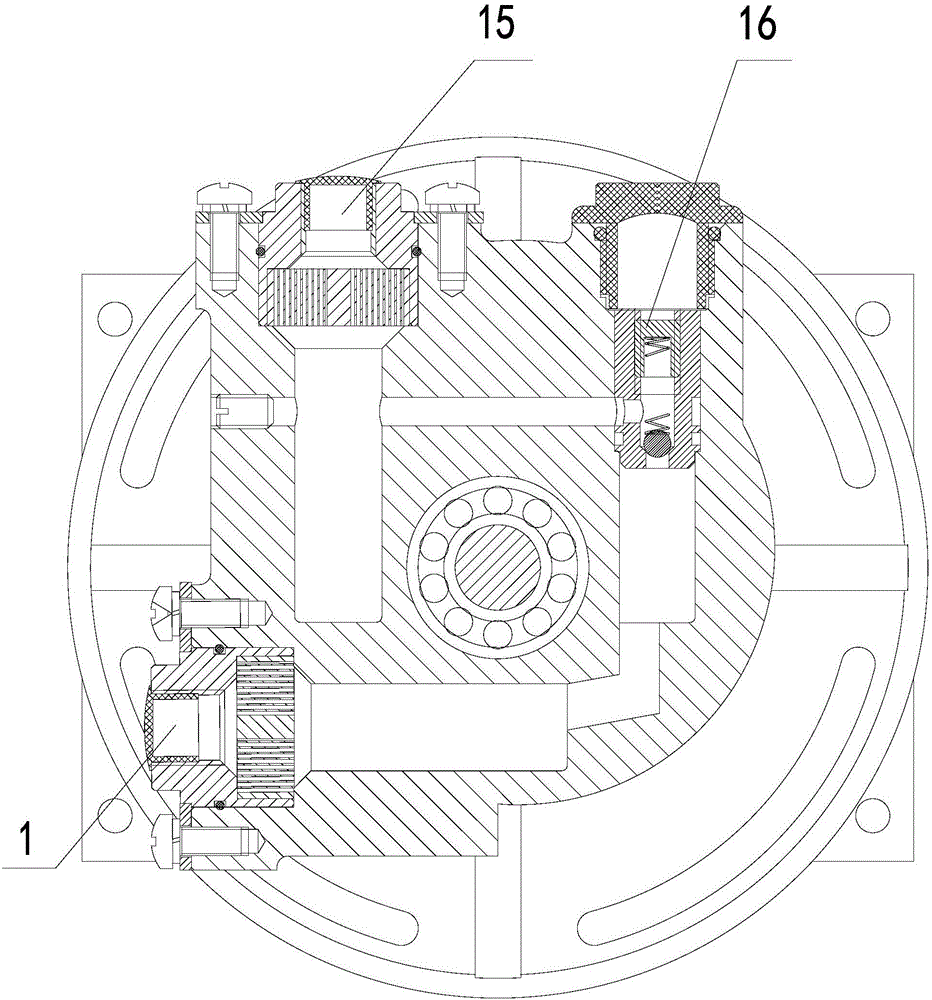

[0041] See figure 1 , figure 2 with image 3 , The present invention is a decentralized automatic compensation vane vacuum pump, the pump body 11 is detachably connected with the explosion-proof motor 14, and the main shaft is connected with the output shaft of the explosion-proof motor 14 through a coupling 12. The rotor 2 inside the vane vacuum pump is provided with a plurality of vane slots, and a vane 3 is placed in each vane slot; the end of each vane 3 is inlaid with a vane magnet 4, and each vane slot is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com