Low-noise washing machine with box-shaped detergent dissolver

A washing powder and dissolver technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of short buffer distance of the sponge layer, easy damage of the sponge layer, and large vibration of the casing, so as to reduce vibration and fully dissolve , the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

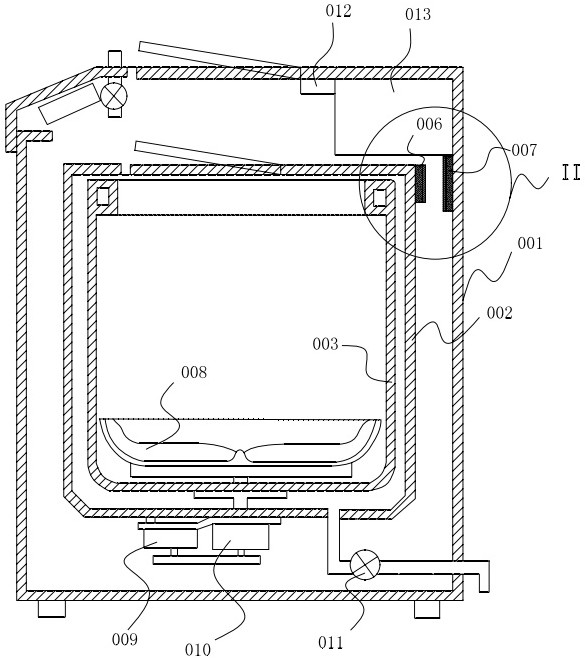

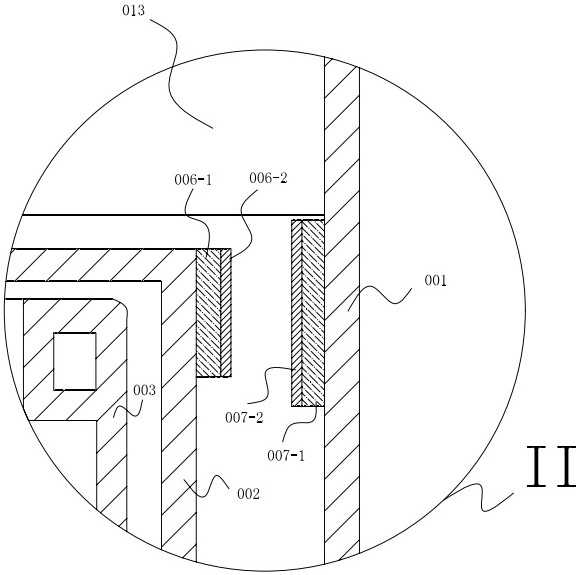

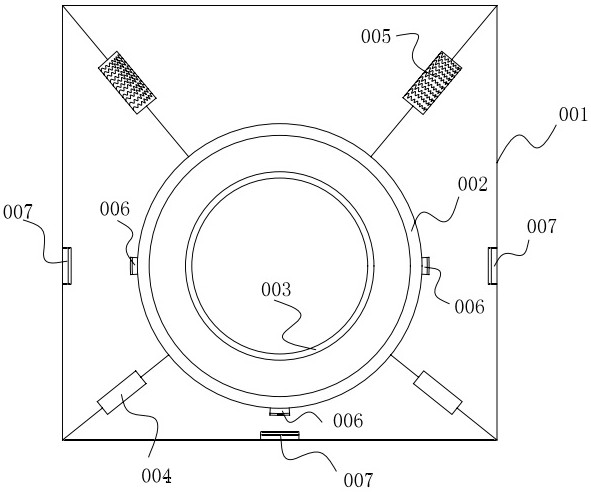

[0027] Such as figure 1 , image 3 As shown, this embodiment includes a casing 001, an outer cylinder 002, an inner cylinder 003, and a pulsator 008. The outer cylinder 002 is suspended on the In the casing 001, the inner cylinder 003 is rotatably installed on the inner side of the outer cylinder 002, and the pulsator 008 is rotatably installed on the inner bottom of the inner cylinder 003, and a detergent box 012 and a washing powder dissolving device are arranged above the casing 001 013. Two rotating shafts (not shown) for driving the rotation of the inner cylinder 003 and the pulsator 008 pass through the outer cylinder 002 from the outside of the bottom of the outer cylinder 002, and are fixedly connected with the inner cylinder 003 and the pulsator 008 respectively. The driving motor 009, the clutch 010, the drain valve 011, and the drain motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com