Device for preparing stannous sulfate by electrolysis in mobile cathode chamber

A technology of stannous sulfate and cathode chamber, which is applied in electrolysis process, electrolysis components, cells, etc., can solve the problems of high voltage of stannous sulfate tank, difficult maintenance of diaphragm tank, high processing cost, etc., so as to reduce the low voltage of the tank and avoid sealing The effect of difficulty and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

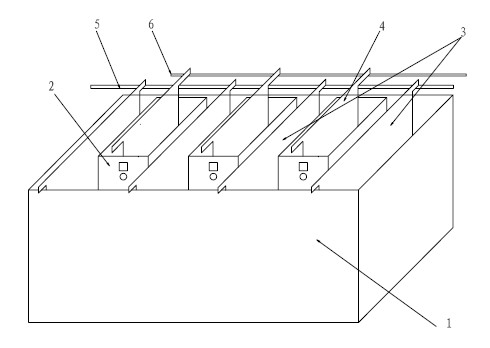

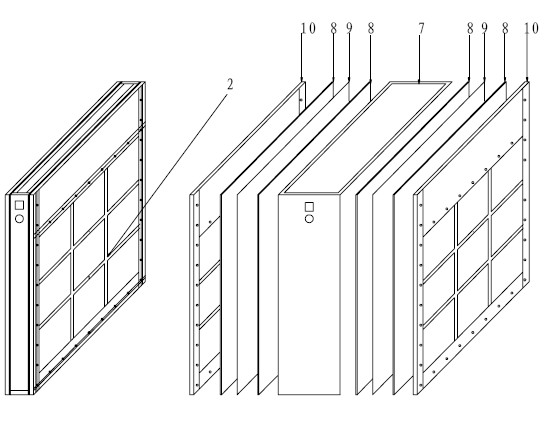

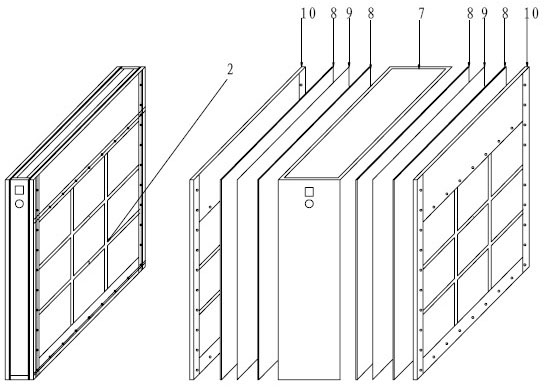

[0030] Example 1: A kind of electrolytic device of electrolytic synthesis of stannous sulfate in mobile cathode chamber, in the attached figure 1 and figure 2In the mobile cathode chamber electrolysis device, the electrolytic cell 1 is a rectangular tank of polypropylene material, and the movable cathode chamber 2 is composed of a cathode chamber 7, a sealing gasket 8, a diaphragm 9 and a diaphragm frame 10, and is fastened by an anti-corrosion nut. The cathode cavity 7 and the diaphragm frame 10 are made of polypropylene material, and the side plates of the cathode cavity 7 and the middle window of the diaphragm frame 10 are opened into a cross frame structure, which is convenient for fixing the diaphragm. Place the three cathode chambers 2 in the rectangular frame of the anode chamber 1, hang three tin plates in the three cathode chambers as cathodes 4; hang tin plates on both sides of the movable cathode chamber 2 as anodes 3, 4 pieces in total. Three cathodes are hung on...

example 2

[0031] Example 2: In the electrolyzer of Example 1, the effective area of the diaphragm window is 0.5m 2 , the thickness of the anode 3 is 2cm and the area is 0.6m 2 , the thickness of the anode 4 is 2cm and the area is 0.6m 2 . Add 10% H in electrolyzer 1 2 SO 4 Solution, add 10% H in 1 active cathode chamber 3 2 SO 4 The solution constitutes two unit electrolyzers, and the unit electrolyzers are connected in parallel. Constant current electrolysis with a current of 300A (each cell current 150A, current density 250A / m 2 ), the electrolyte temperature is controlled at 30-40°C. Electrolysis to SnSO 4 End electrolysis when the content is 180-200g / L, and the cell voltage is 1.5-2.5V. Pump out the anolyte, filter to remove a small amount of precipitate, concentrate in vacuo, and crystallize to obtain SnSO 4 The product has a purity of 99.4%. The current efficiency is 93.1%.

example 3

[0032] Example 3: According to the method of example 2, 10 movable cathode chambers 3 are placed in the electrolyzer 1, and there are 20 unit electrolyzers in total, and each unit electrolyzer is connected in parallel. The anolyte and tank make up the loop, and the catholyte and pump make up the loop. Add 10% H to the anode and catholyte storage tanks 2 SO 4 Solution (anolyte containing crystallization mother liquor), electrolyzed with a constant current of 3000A (single cell current 150A, current density 250A / m 2 ), electrolyte temperature control 30-40 ℃. Electrolysis to SnSO 4 End electrolysis when the content is 180-200g / L, and the cell voltage is 1.5-2.5V. Pump out the anolyte, filter to remove a small amount of precipitate, concentrate in vacuo, and crystallize to obtain SnSO 4 Product, output 1360kg / day, purity 99.4%. The current efficiency is 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com