Washing powder dissolving device

A technology of dissolving device and washing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

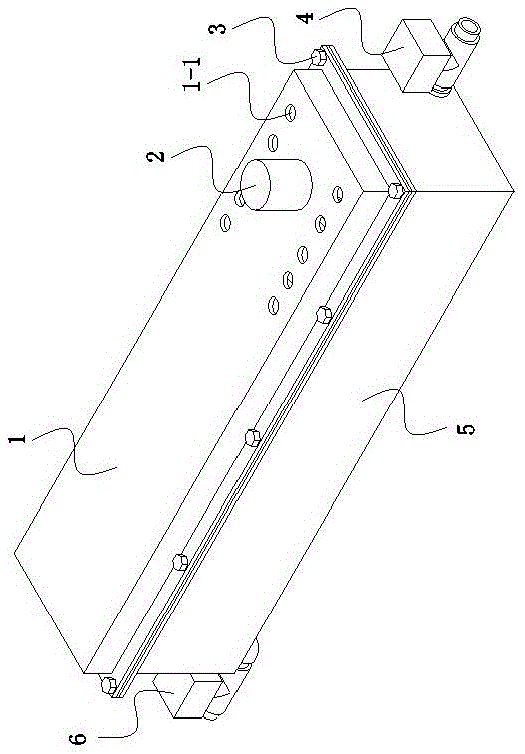

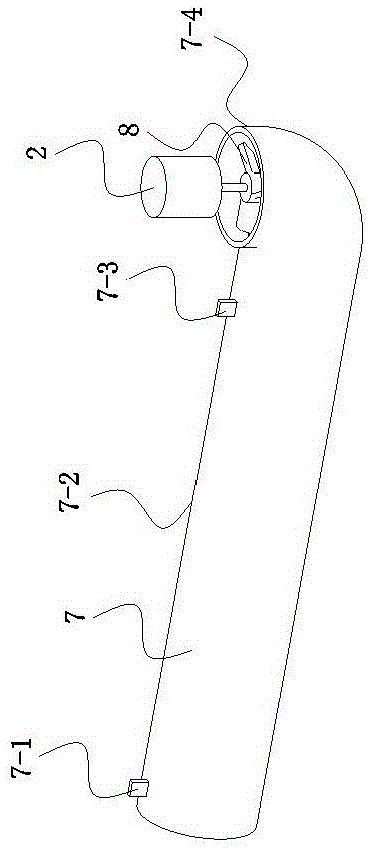

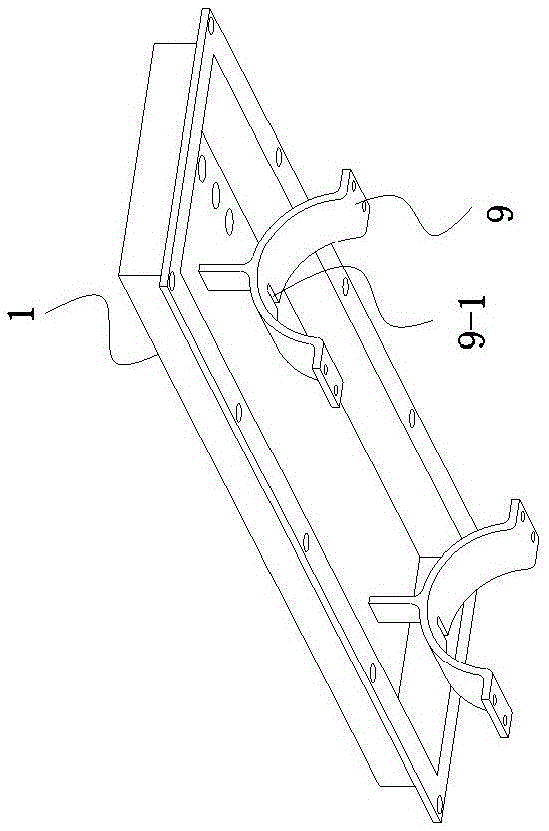

[0021] Such as Figure 1~5 As shown, the present embodiment includes a box body, a guide pipe 7 and an agitator. The box body is in the shape of a cuboid, and it includes a box body 5 and a box cover 1, and the box body 5 and the box cover 1 are fixedly connected by bolts 3. A cushion layer 12 for sealing the joint between the box cover 1 and the box body 5 is also provided between the box cover 1 and the box body 5 . The top of the box cover 1 is also provided with a plurality of through holes 1-1 connecting the inner space of the box body with the outer space of the box body. A liquid level sensor (not shown) is also provided inside the box body.

[0022] The so-called "seal the joint between the lid 1 and the box body 5" refers to the anti-leakage treatment to prevent washing water from flowing out from the joint between the lid 1 and the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com