Energy-saving machine provided with box-shaped detergent dissolving device

An energy-saving washing machine and dissolving device technology, which is applied to washing machines with containers, washing devices, and other washing machines, can solve the problems of low heat utilization rate and high power consumption, and achieve the purpose of avoiding sealing difficulties, increasing volume, and saving laundry the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

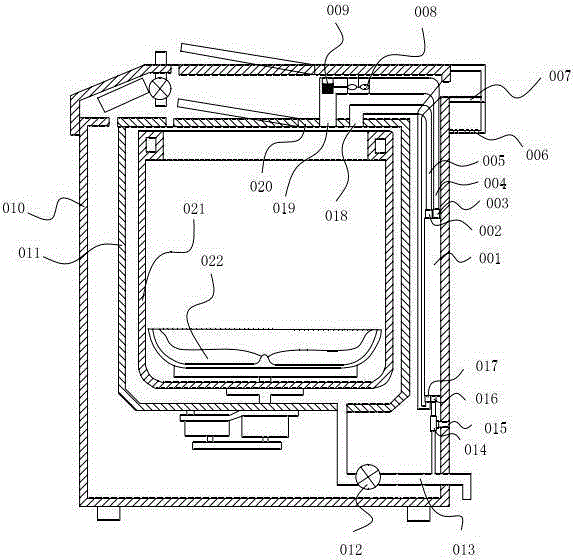

[0028] Such as figure 1 As shown, this embodiment includes a casing 010, an outer cylinder 011, an inner cylinder 021, a pulsator 022, an electric heater 009, a fan 008, and a filter 007. The outer cylinder 011 passes through a plurality of shock absorbers (not shown in the figure) ) is elastically suspended in the casing 010, the inner cylinder 021 is rotatably arranged in the outer cylinder 011, and the pulsator 022 is rotatably mounted on the inner bottom of the inner cylinder 021. A detergent box (not shown in the figure) and a washing powder dissolving device (not shown in the figure) are also arranged above the casing 010 . The detergent box is a conventional design in the prior art. It is located above the casing 010, close to the connection between the casing 010 and the casing cover (not marked). The washing powder dissolving device is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com