Patents

Literature

61results about How to "Shorten laundry time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

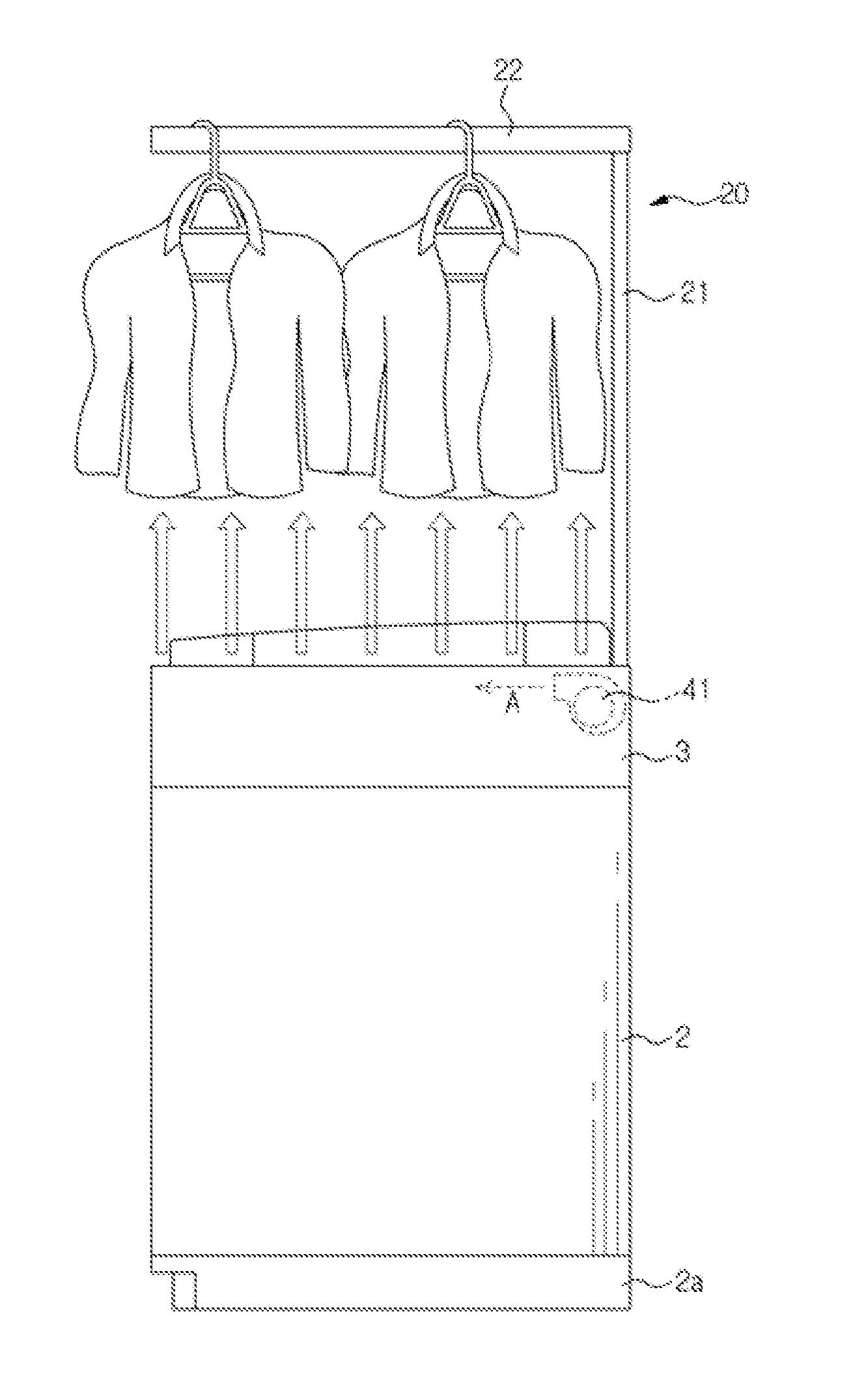

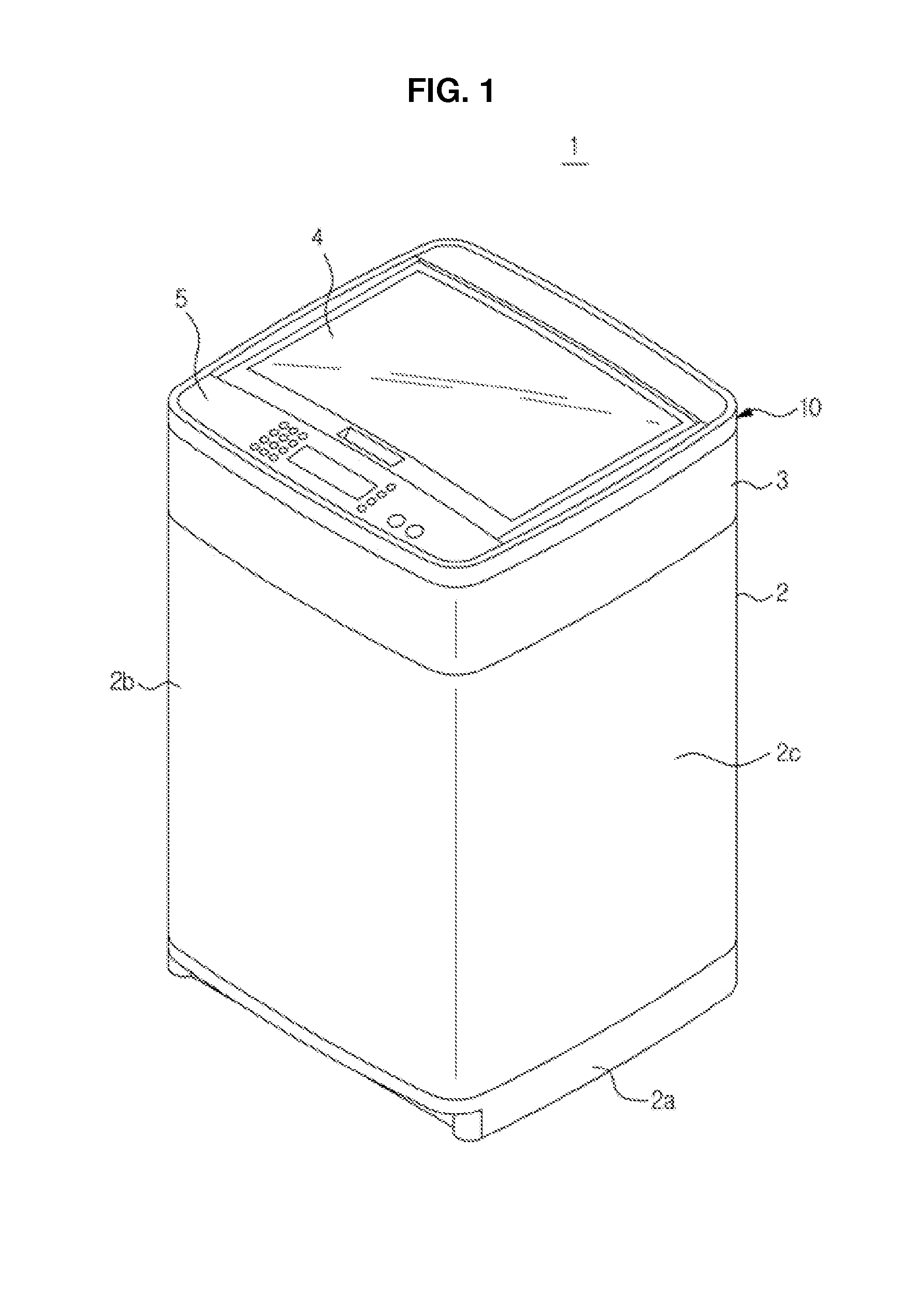

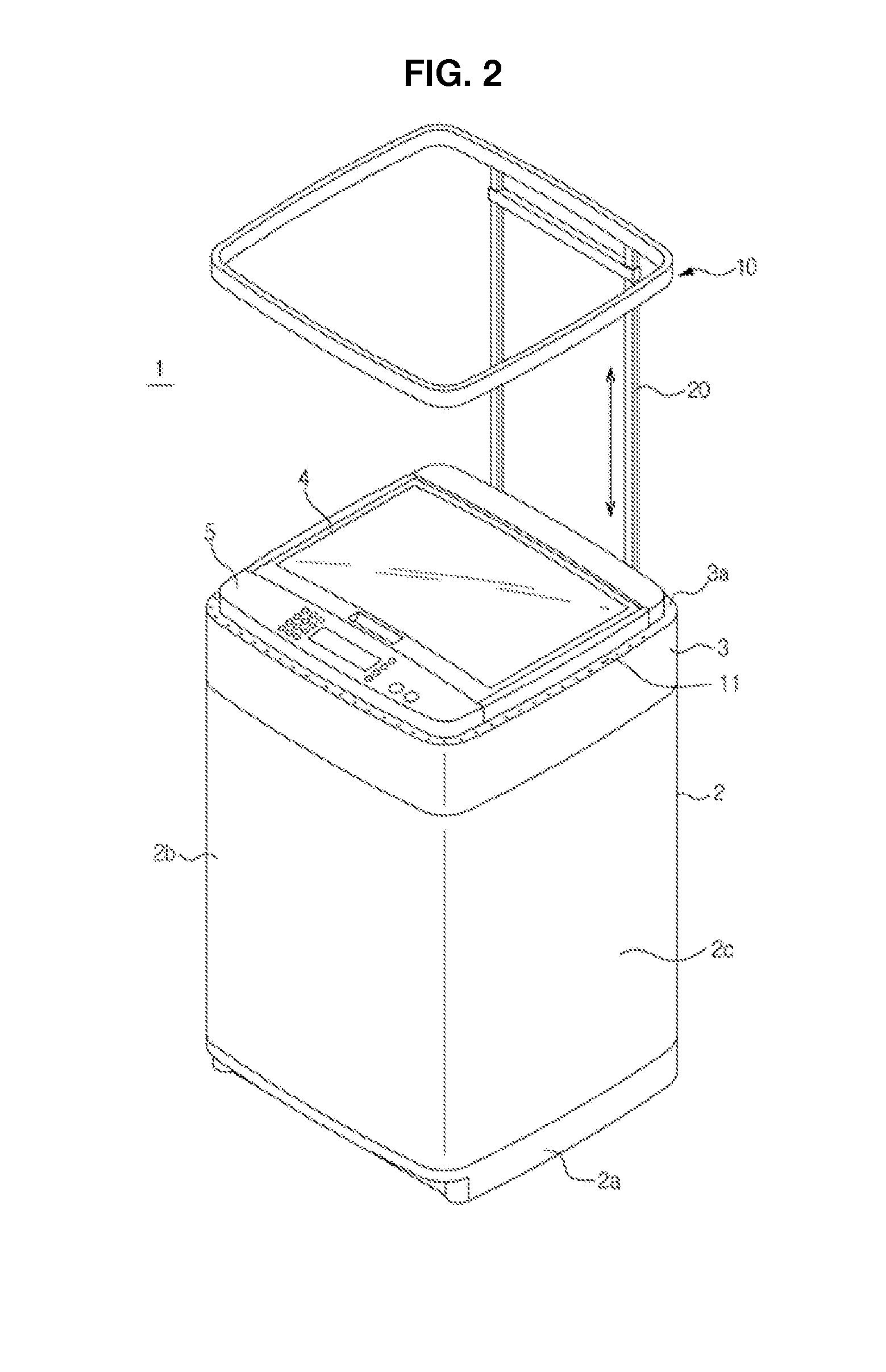

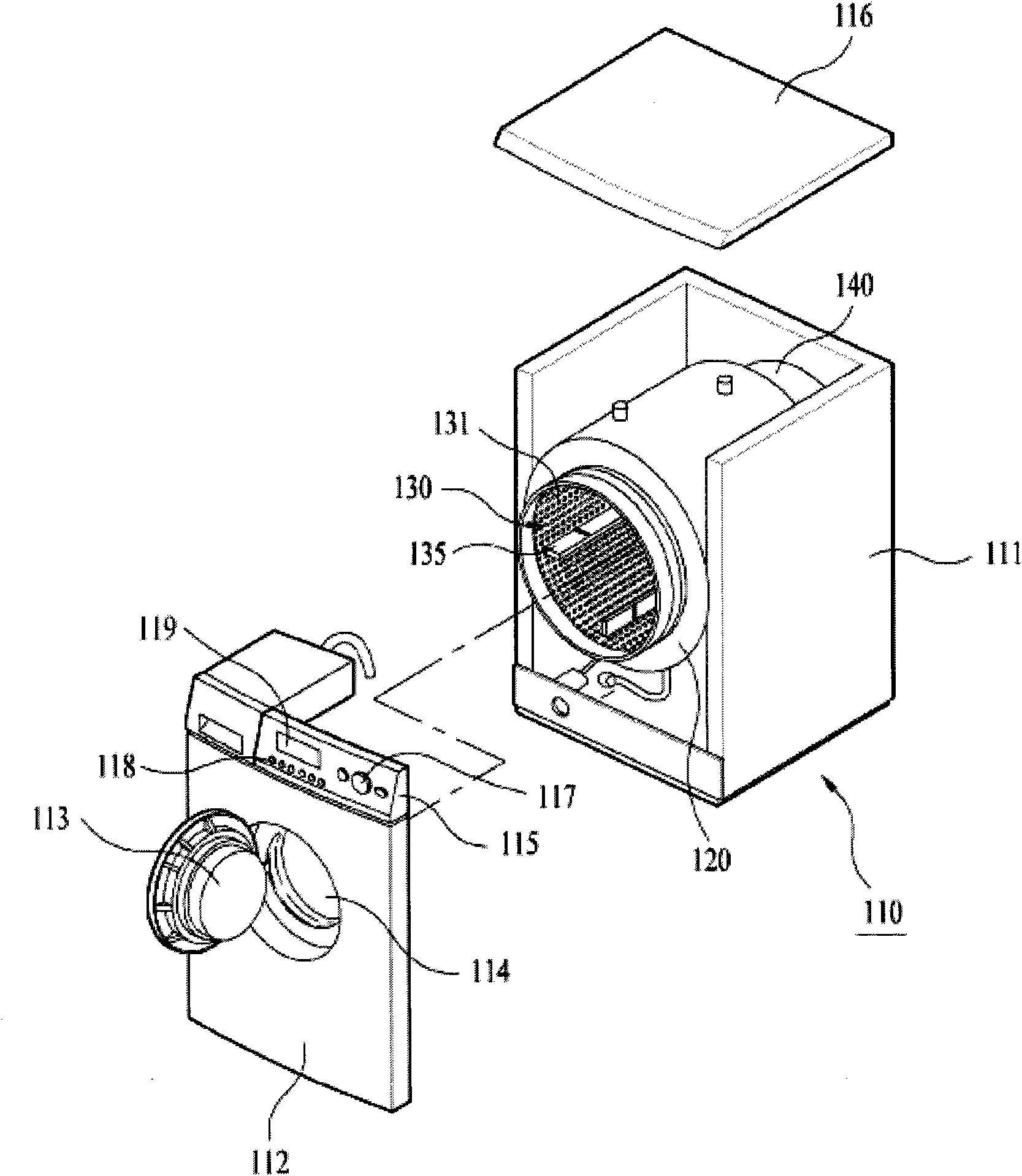

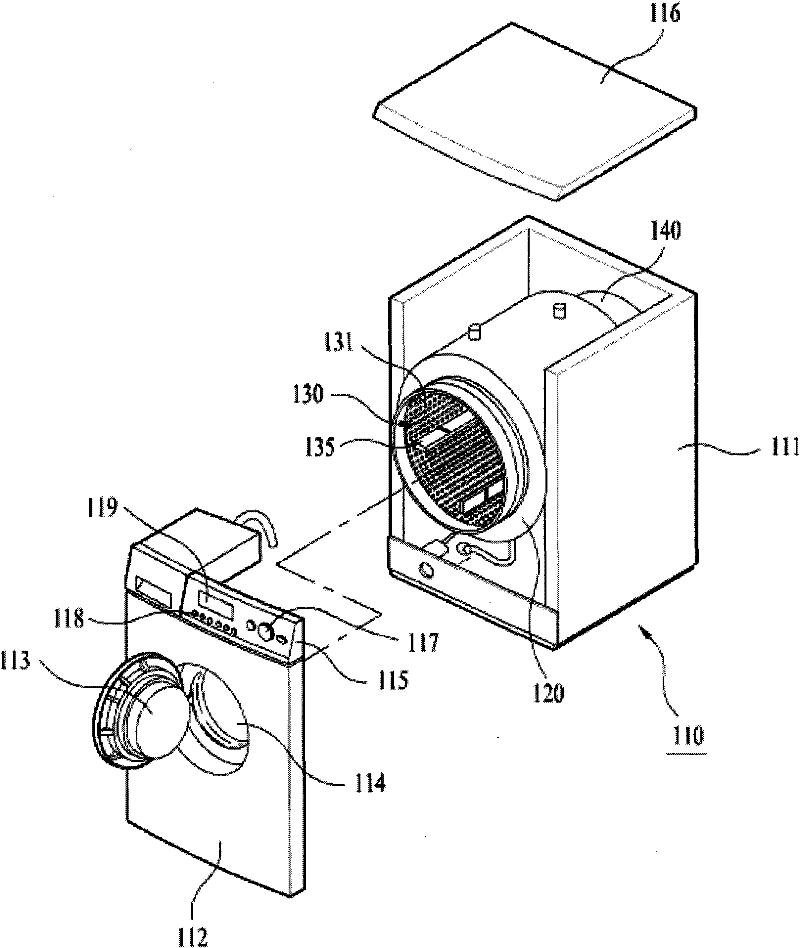

Washing machine having drying apparatus

ActiveUS20150033574A1Shorten laundry timeImprove drying efficiencyAgriculture tools and machinesDrying solid materials with heatDrying timeLaundry

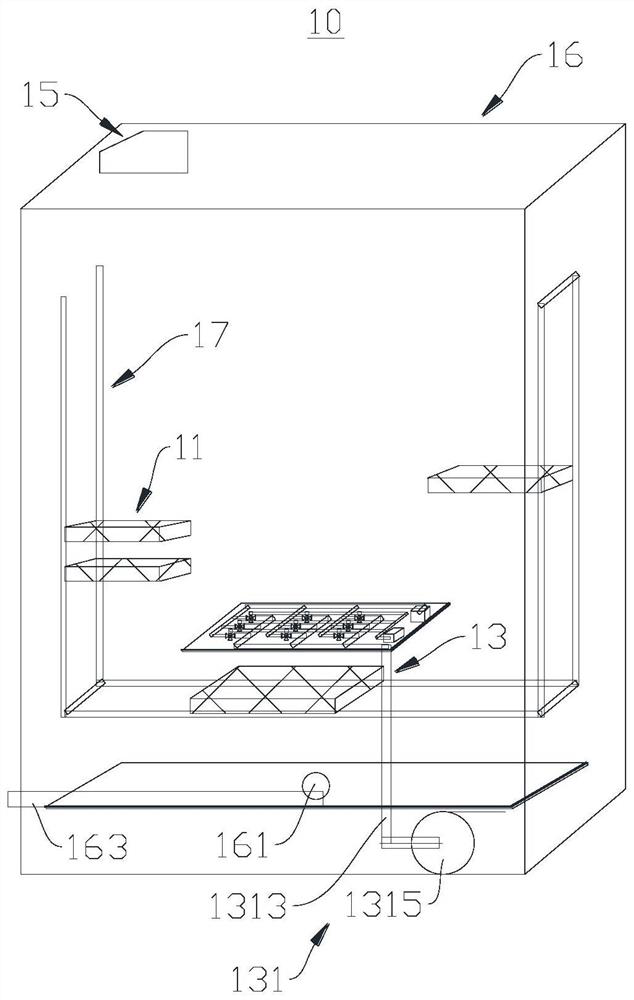

A washing machine having a drying apparatus, which can perform a heated drying operation and shorten a drying time of laundry, is provided. The washing machine having a drying apparatus includes a top cover which is provided in an upper part of a body and has at least one air hole formed in a top surface thereof, a drying duct which is provided in the top cover to supply air heated by a heater provided thereinside to the air hole, and a rack member which is provided to be extractable from the body to hang laundry above the body.

Owner:SAMSUNG ELECTRONICS CO LTD

High-speed washing program of washer

InactiveCN1373248AEffective dissolutionQuick soakControl devices for washing apparatusTextiles and paperWater flowInlet valve

A program for fastly washing clothes in washer includes charging water to level No.1, turning on motor and draining pump, slowly rotating internal drum and pulsator, charging water to half of predefined level, slow streaming water to predefined water level, internal circulating, washing for 3-8 min, smoothing water flow for 10-30 seconds, intermittent extracting water for draining the water in internal drum while stopping internal drum and pulsator for 1-25 min, continuous extracting water for 30-65 seconds, cycling 2-5 times, closing water inlet valve, continuous extracting water for 30-90 seconds, inertial extracting water for 10-40 seconds and braking. It can shorten time by 2 / 3 and save water by 2 / 3.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

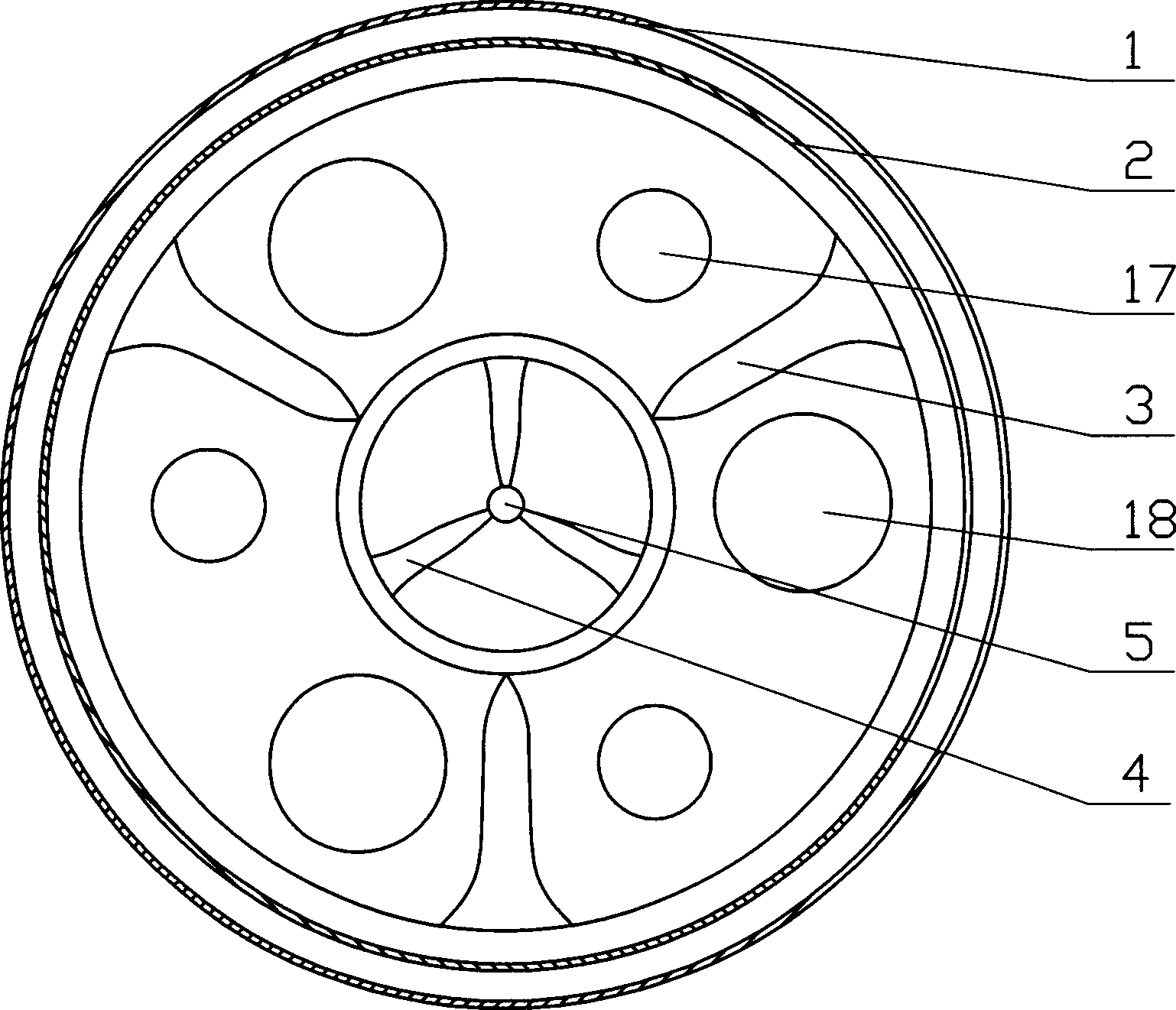

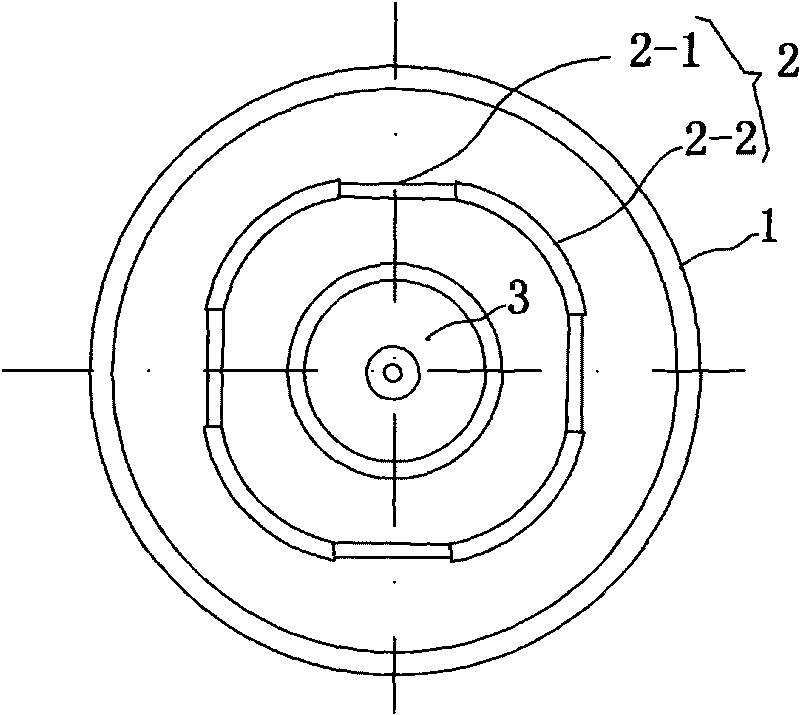

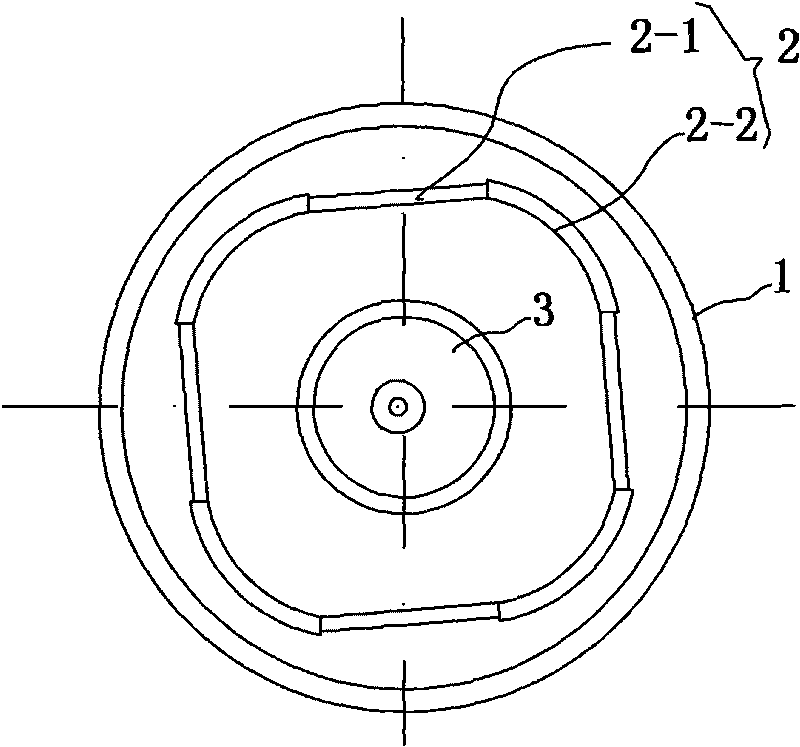

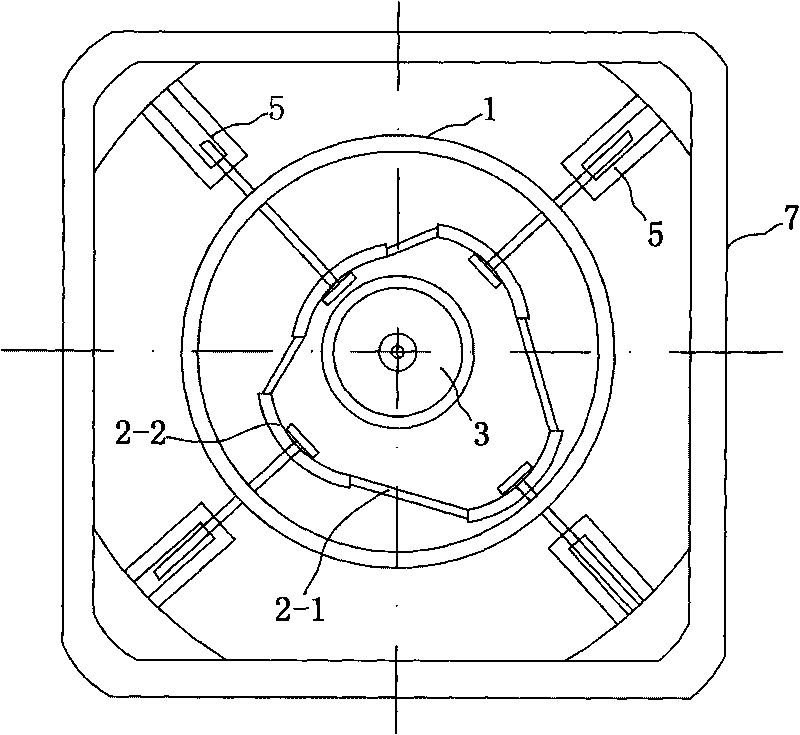

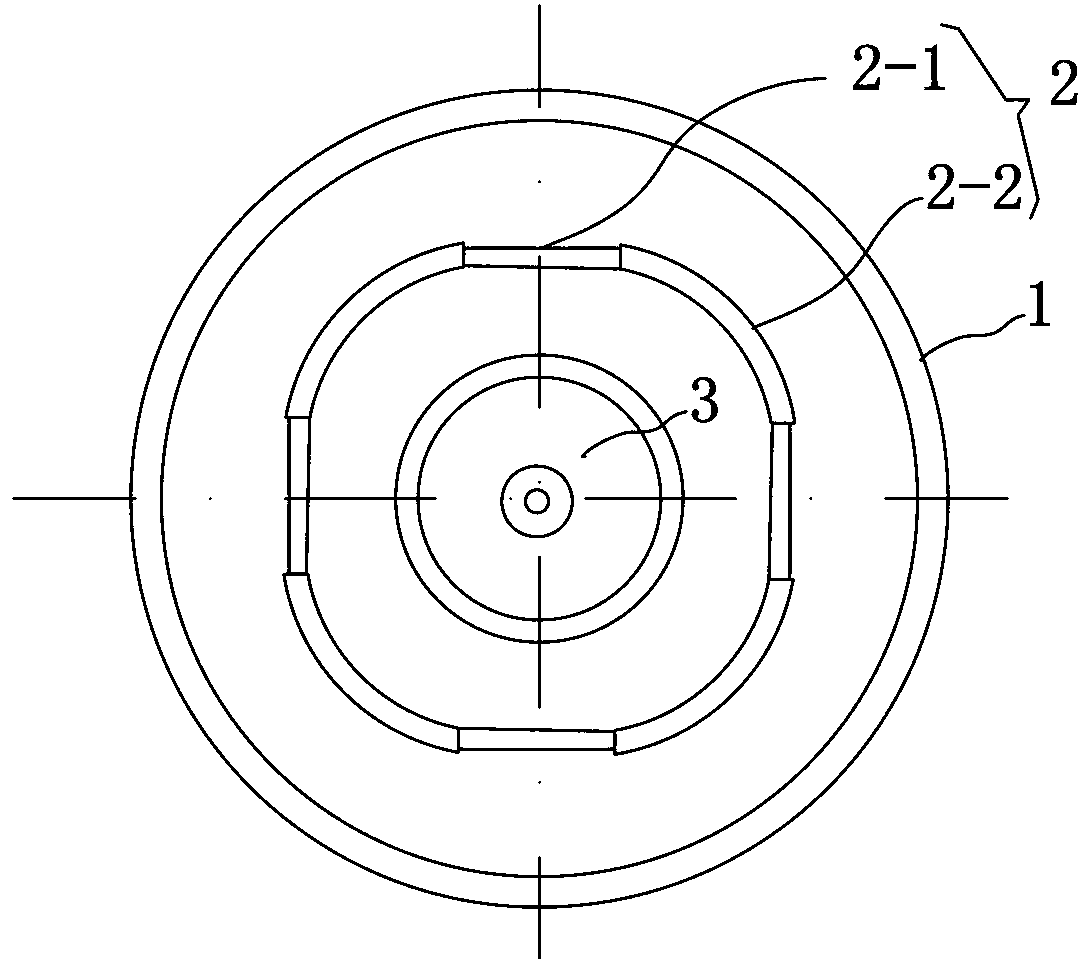

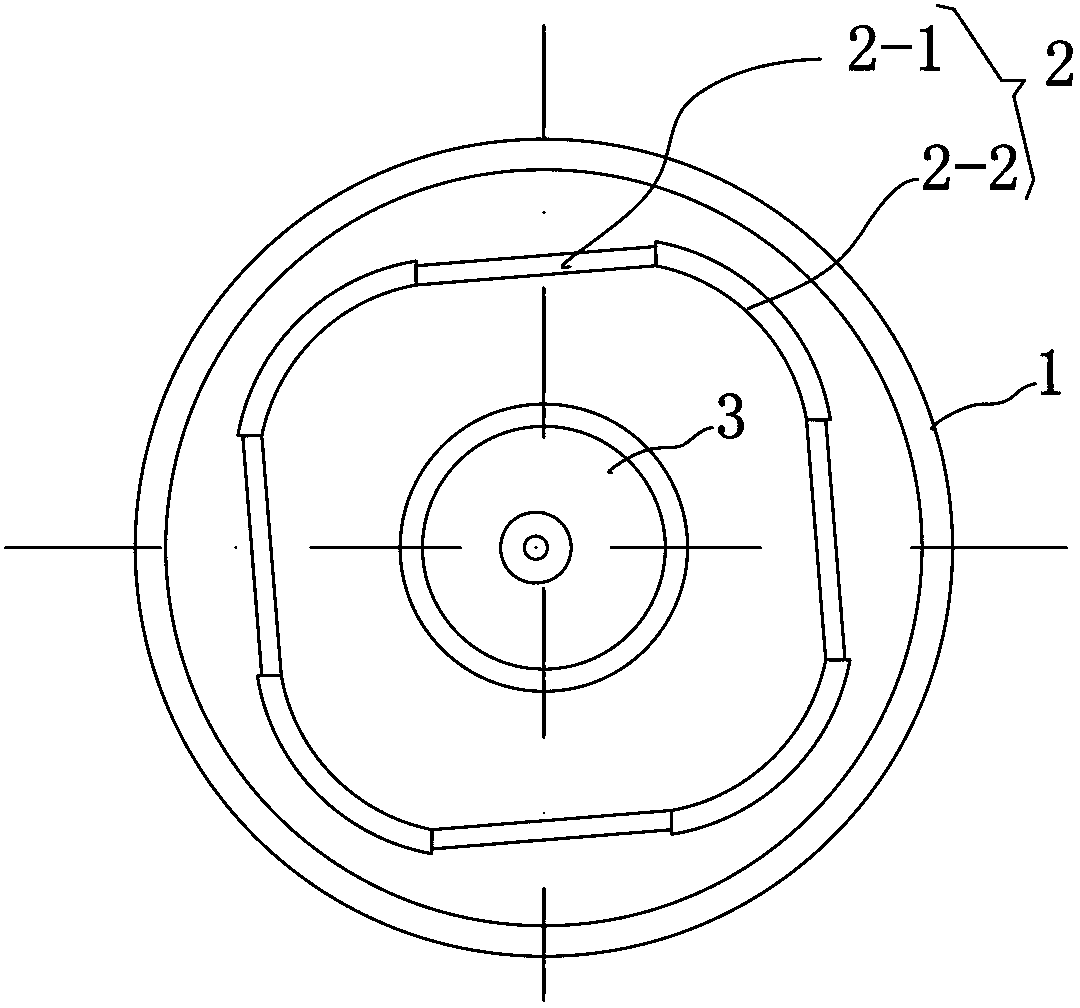

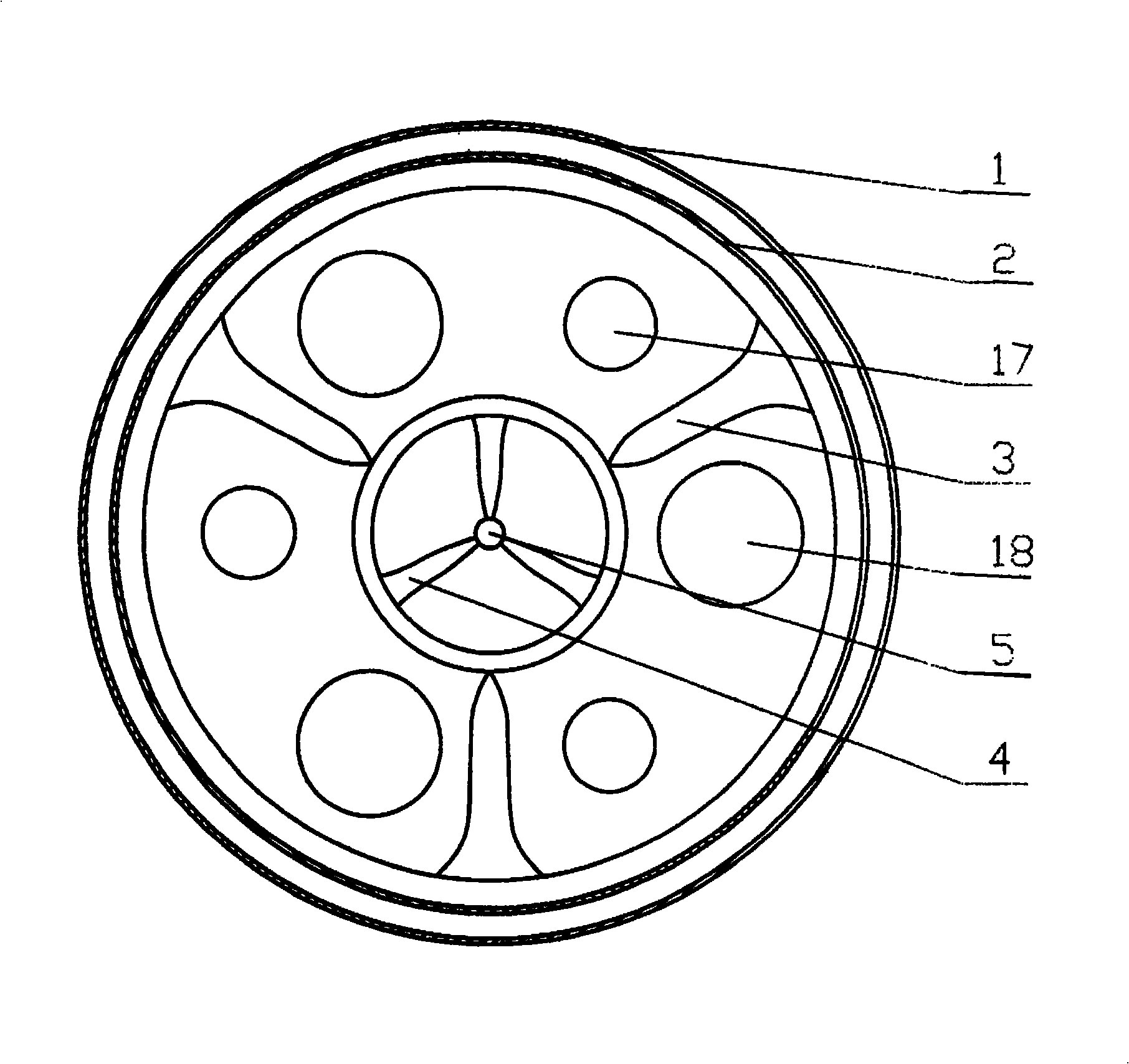

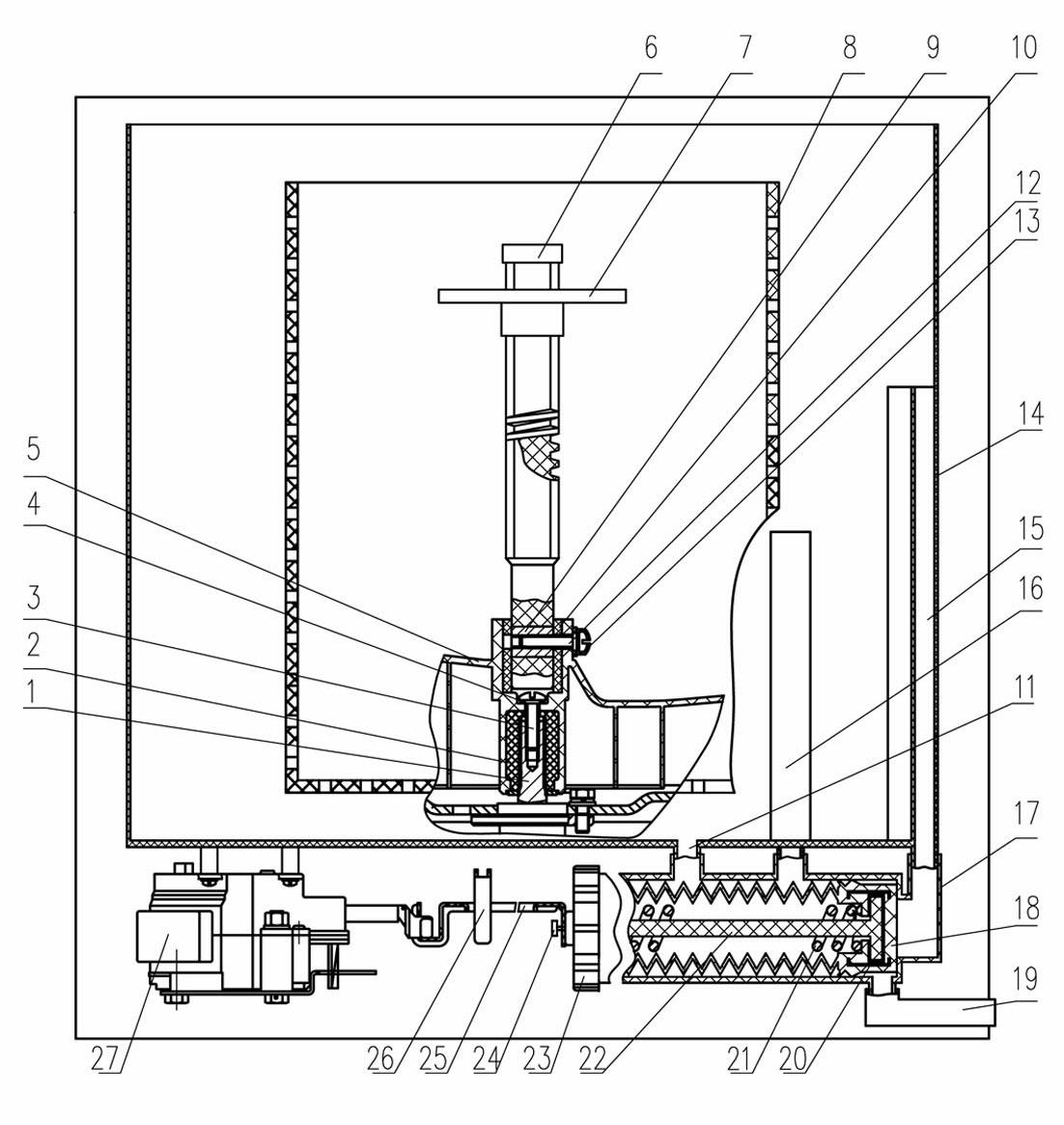

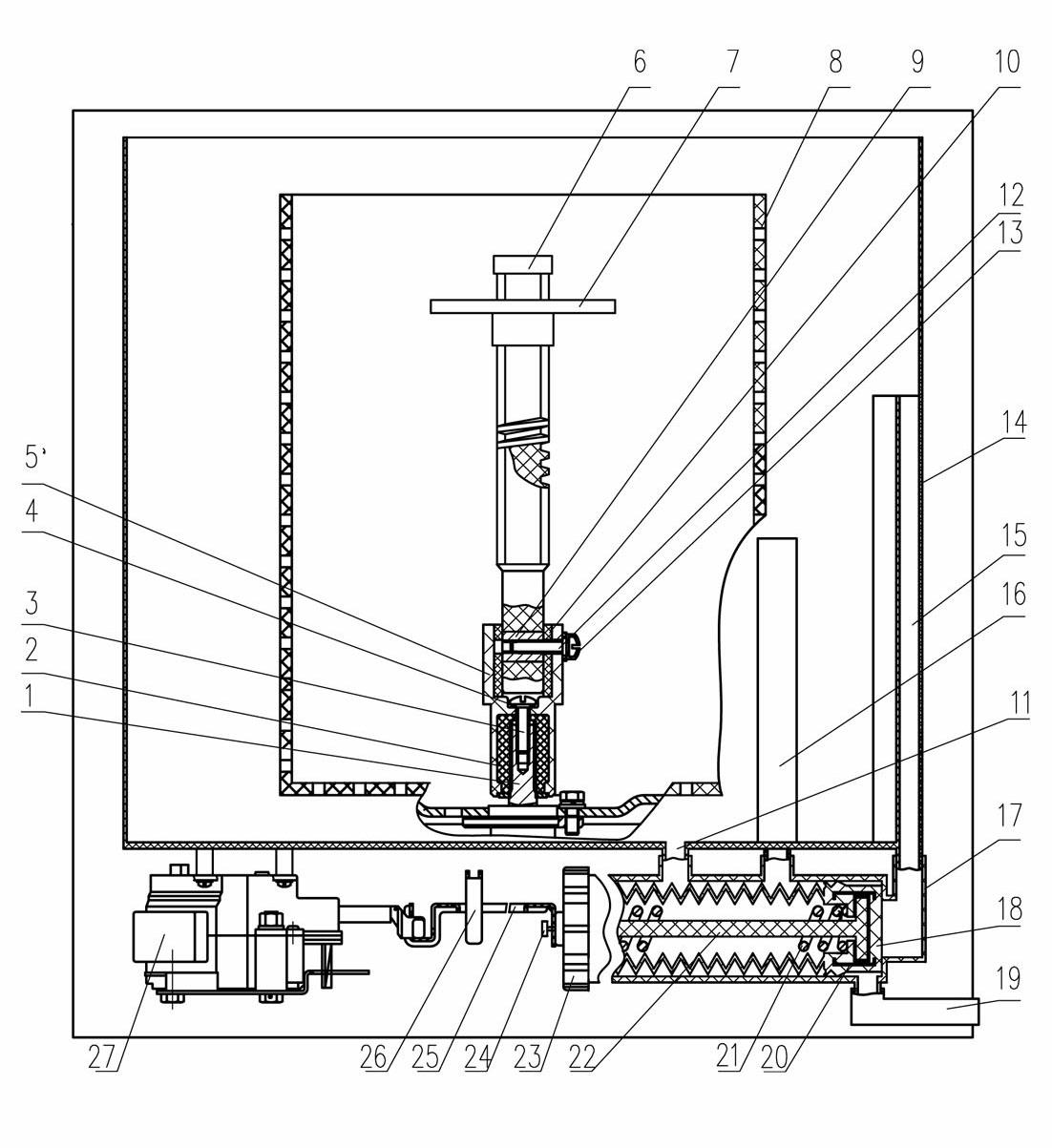

Fully-automatic supersonic washer without detergent

ActiveCN1814893AReduced strength requirementsSimple structureWater/sewage treatmentWashing machine with receptaclesEngineeringFully automatic

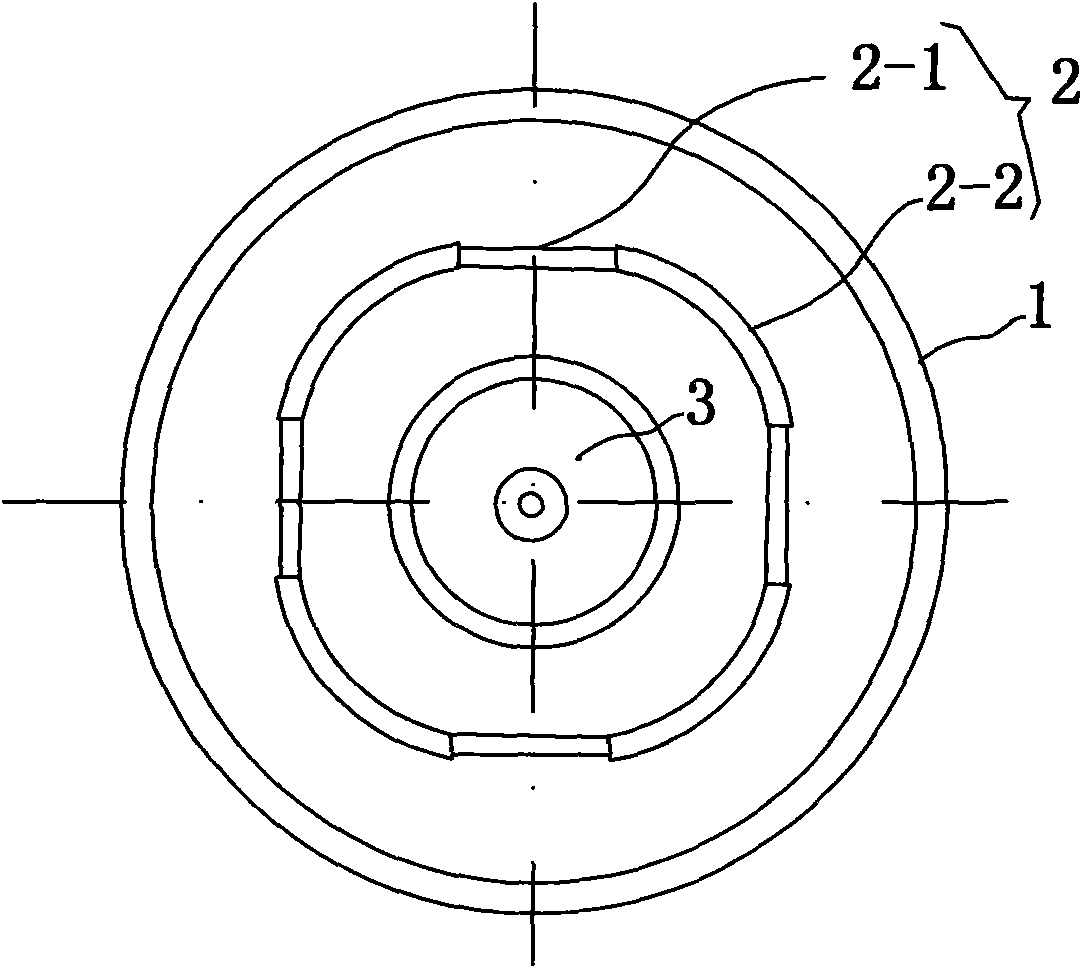

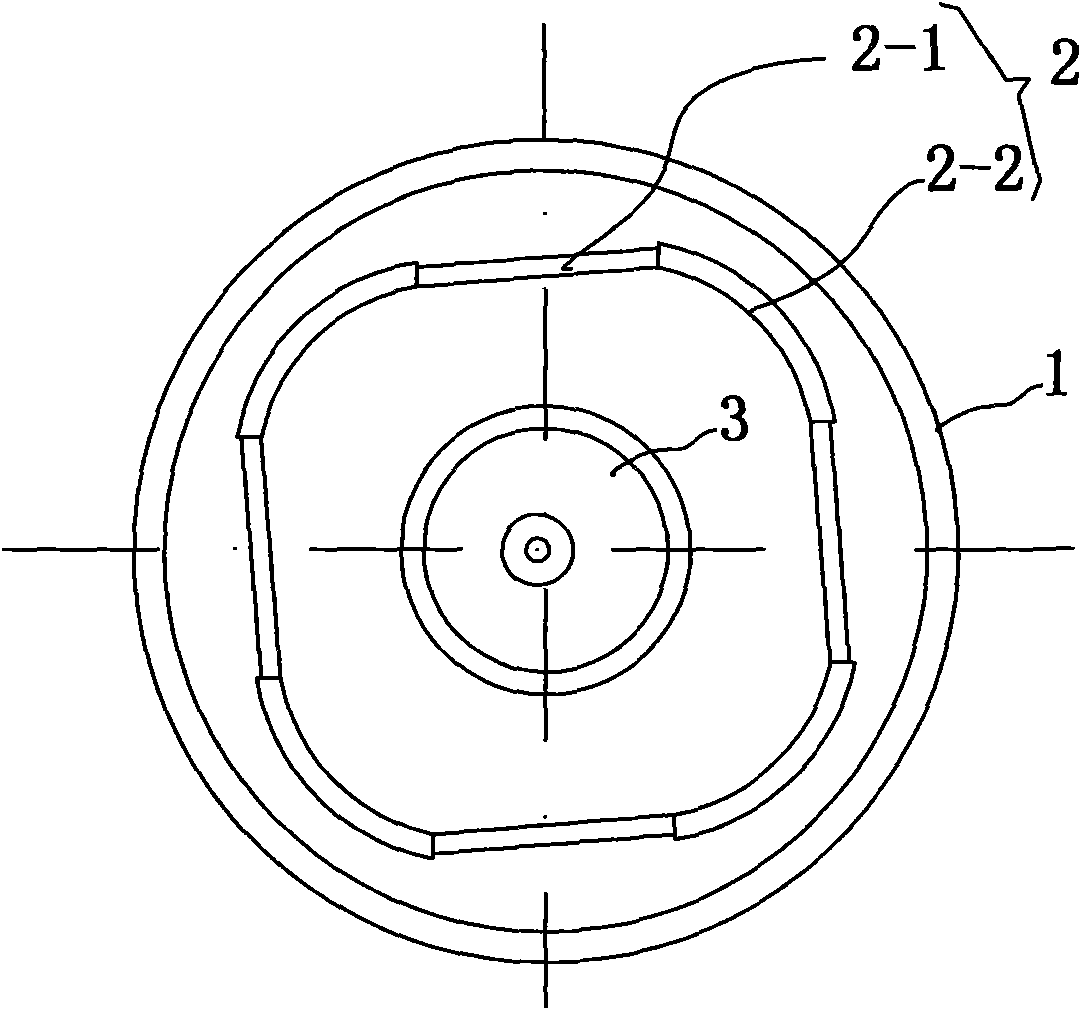

This invention discloses an automatic supersonic washing machine without wash including an outer drum, an inner drum, a wave wheel, an inlet pipe, an electrolyte tank, an inlet electromagnetic valve, an outlet pipe, an outlet electromagnetic valve, a motor, a speed vibrator, a controller, an operating panel and supersonic vibrators, in which, said wave wheel is composed of a large and a small wave wheel set concentrically, said supersonic vibrators are composed of three uniformly distributed vibrators of a horn-type Langevin vibrator and cumulative Longevin supersonic vibrators and said electrolyst tank is set in the inlet pipe.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

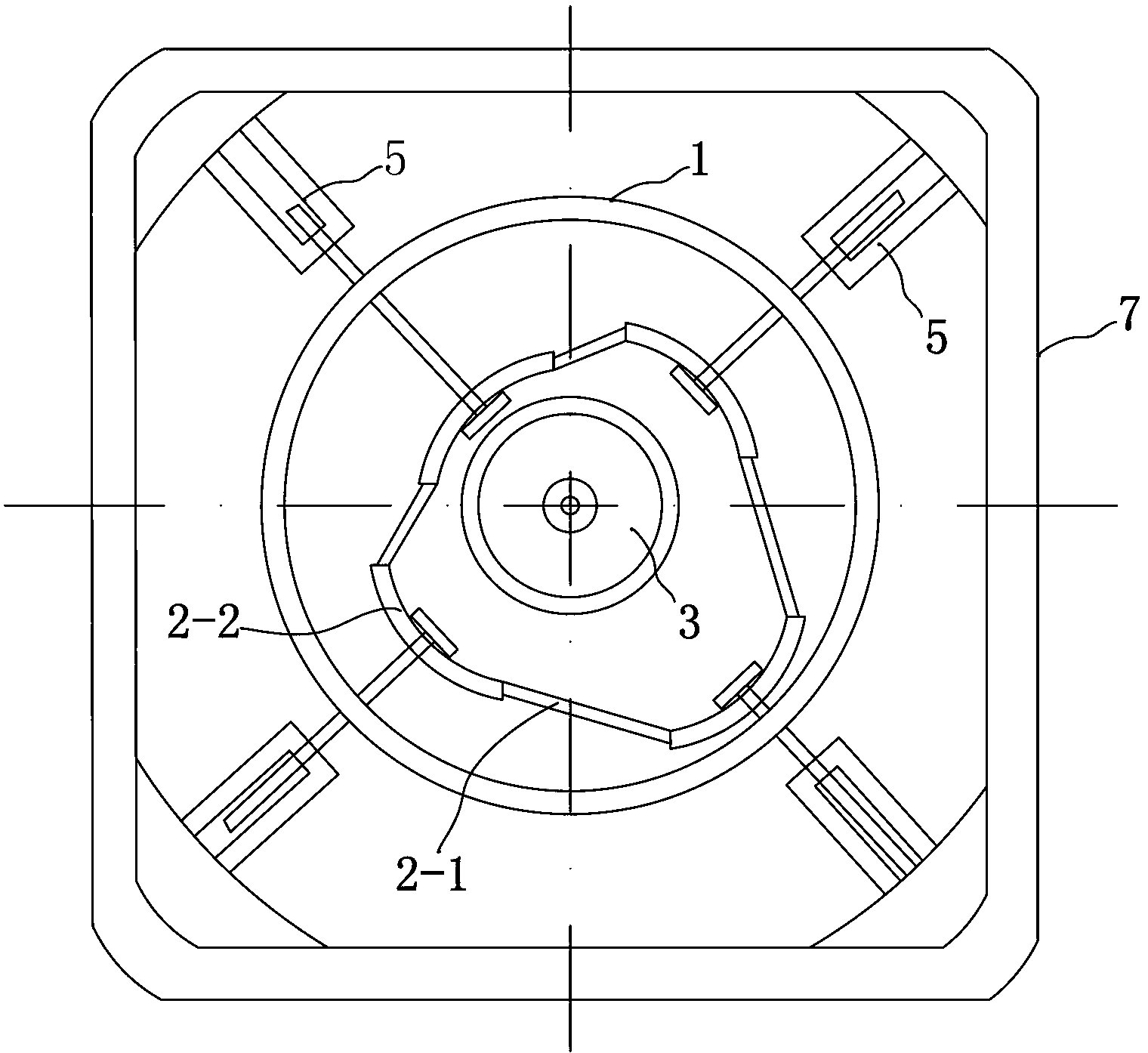

Buoyancy type washing machine impeller capable of lifting washing

ActiveCN101191288AIncrease lift distanceIncrease surface areaWashing machine with receptaclesTextiles and paperImpellerWater level

The invention discloses a buoyancy type washing machine impeller capable of lifting and washing, comprising a wave disc and a plurality of ridgeplates which are arranged on the upper surface of the wave disc; each ridgeplate comprises a ridgeplate matrix which is arranged on the upper surface of the wave disc; the inside of the ridgeplate matrix is hollow and an opening is arranged on the upper surface of the ridgeplate matrix; a groove is formed by the opening and the hollow inside; a ridge beam is arranged inside the groove; the ridge beam can be entirely lifted and descended from the opening, and lifting means can be that the ridge beam is floated off under water by a hollow structure and / or materials of the ridge beam and also can be that the ridge beam is supported by a spring which is arranged inside the groove of the ridgeplate matrix and up-vertically connected with the groove. The structure is automatically arranged on a lifting position when water level is high, and barrier mechanisms are correspondingly arranged on side faces of ridge beams and side faces of grooves in order to increase resistance torsion of water on resisting rotation of the impeller. Moreover, a part of the ridge beams is guaranteed to be always arranged inside the grooves. And the structure is pressed down by the clothes and arranged on a descending position when the water level is low and completely enters into the inside of ridgeplate matrixes, thereby capability of lifting of the impeller is realized, and the washing machine simultaneously has functions of an impeller washing machine and an agitator washing machine.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

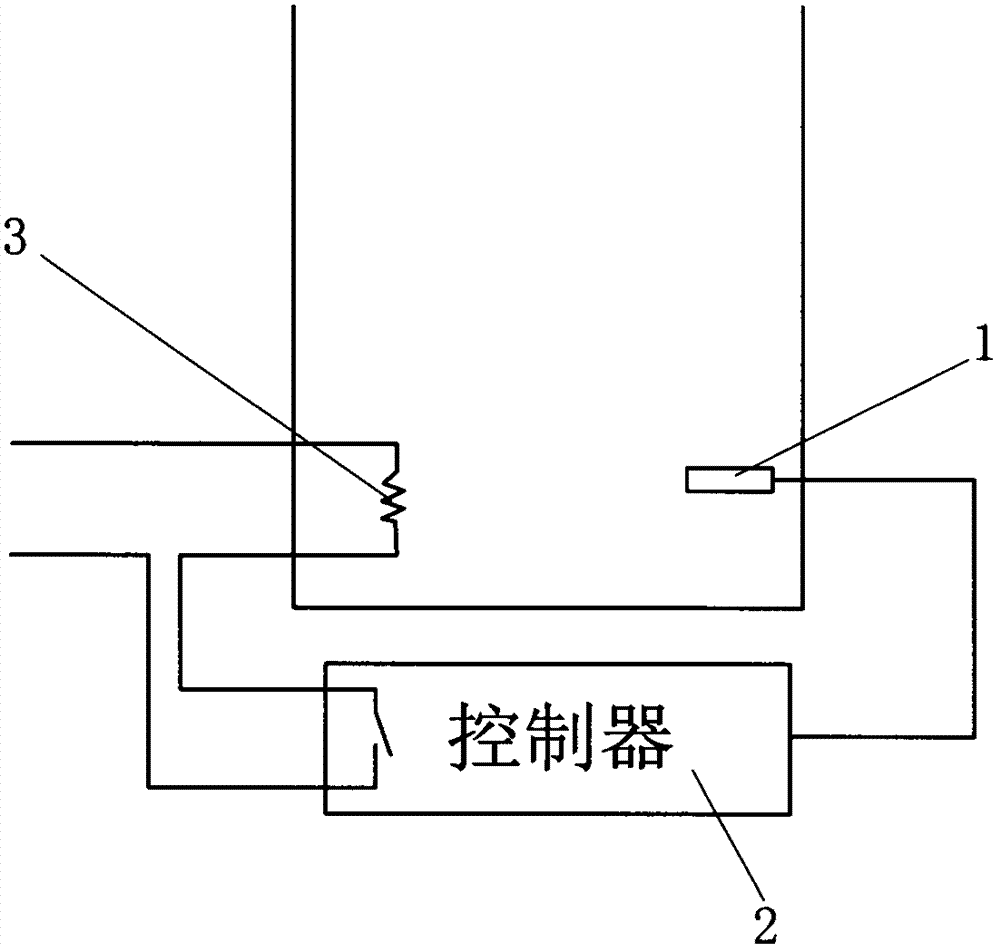

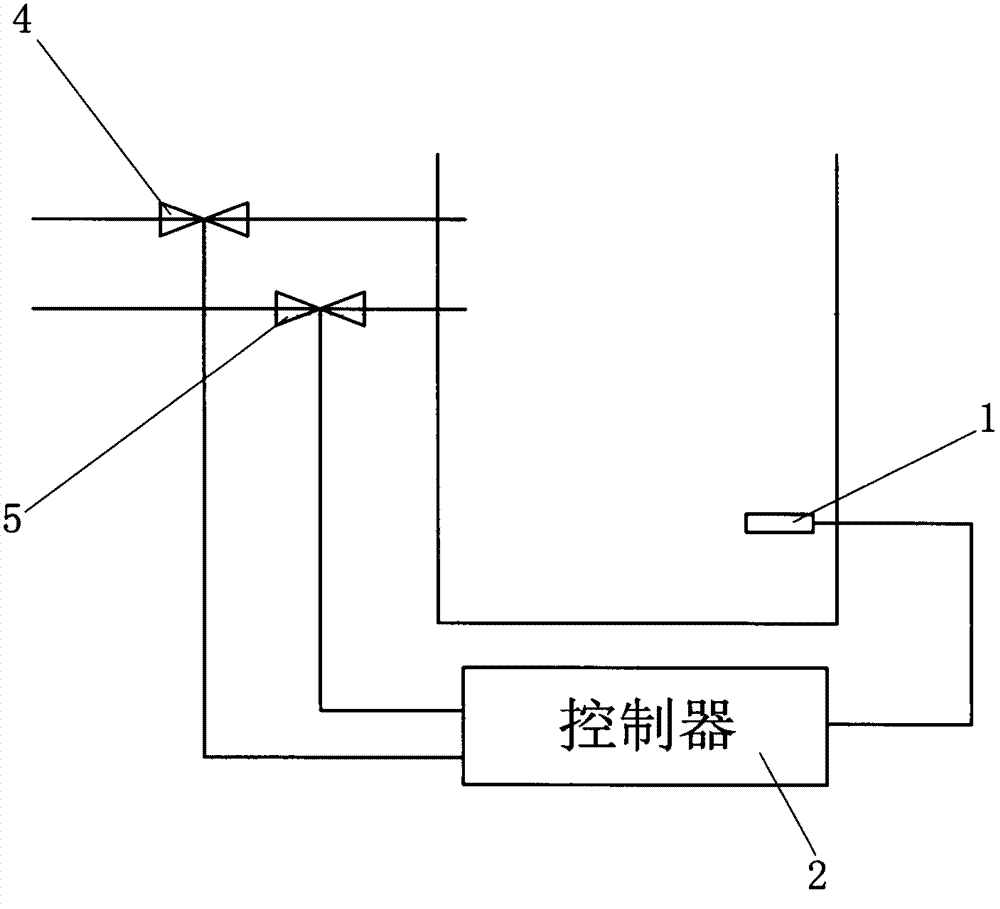

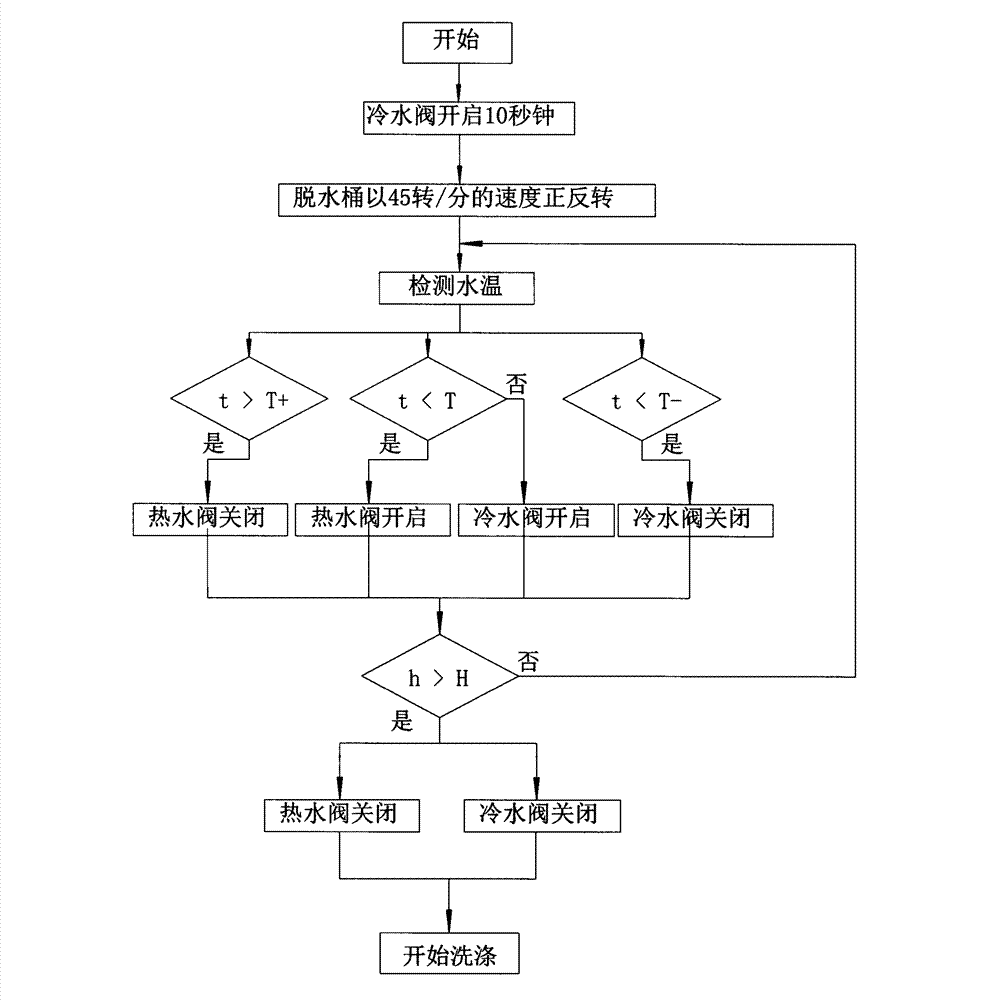

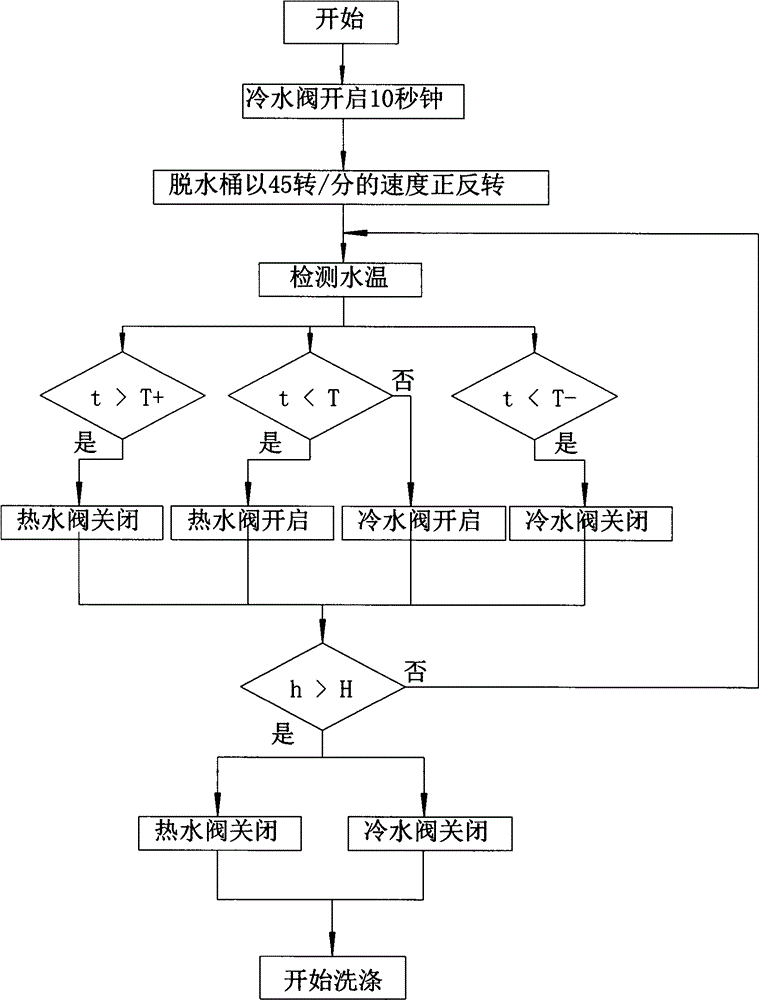

Water temperature control method of cold and hot water double-inlet washing machine

InactiveCN102926170APrecise water temperature controlImprove water temperature control abilityOther washing machinesControl devices for washing apparatusInlet temperatureEngineering

The invention relates to a water temperature control method of a cold and hot water double-inlet washing machine. The water temperature control method is characterized in that a cold water inlet valve and a hot water inlet valve are arranged and are constant-flow water inlet valves, wherein a temperature sensor is arranged in a washing bucket; a controller is used for setting fixed total water inlet time every time of the cold water inlet valve and the hot water inlet valve; the controller calculates a cold water inlet temperature and a hot water inlet temperature according to water temperatures in the washing bucket of the washing machine before and after adding water; then the controller calculates a ratio of desired inlet cold water to desired inlet hot water by using the known cold water inlet temperature, the hot water inlet temperature and the water temperatures in the washing bucket, and converts the ratio into a turn-on time ratio of the cold water inlet valve to the hot water inlet valve every time; and the controller controls the turn-on time of the cold water inlet valve and the hot water inlet valve so as to control the water temperature. According to the water temperature control method of a cold and hot water double-inlet washing machine, the accuracy of water temperature control of the cold and hot water double-inlet washing machine is improved, the washing degree of clothes is increased, the energy consumption is saved, and the washing time is shortened simultaneously.

Owner:WUXI LITTLE SWAN GENERAL APPLIANCE CO LTD

Air washer and washing method thereof

InactiveCN104775271AHigh speedImprove cleanlinessOther washing machinesTextiles and paperWater storageLaundry washing machine

The invention discloses an air washer and a washing method thereof. Stains on clothes are quickly stripped by high pressure vortex air current, ozone is used for sterilizing, disinfecting and decontaminating, the voltage of an air compressor is 220V, and the working pressure is set between 0.4 and 0.7mpA; one end of an inverted U-shaped high pressure pipe on a water storage barrel is communicated with the air compressor through a pressure air electromagnetic valve, and the other end of the U-shaped high pressure pipe is communicated with a gaseous disk at the bottom of the water storage barrel, and 5-8 nozzles are uniformly distributed on the gaseous disk; each nozzle is provided with a nozzle hole and makes air current sprayed from each nozzle hole to be in a vortex shape, the diameter of each nozzle hole is 0.1-0.3mm and the air compressor, the pressure air electromagnetic valve, a water inlet electromagnetic valve and a drain electromagnetic valve are electrically connected with a controller. The air washer has the characteristics of being free from a detergent, free from wear on clothes and free from pollution to the environment, is short in washing time, and the clothes can be cleaned up.

Owner:张才友 +1

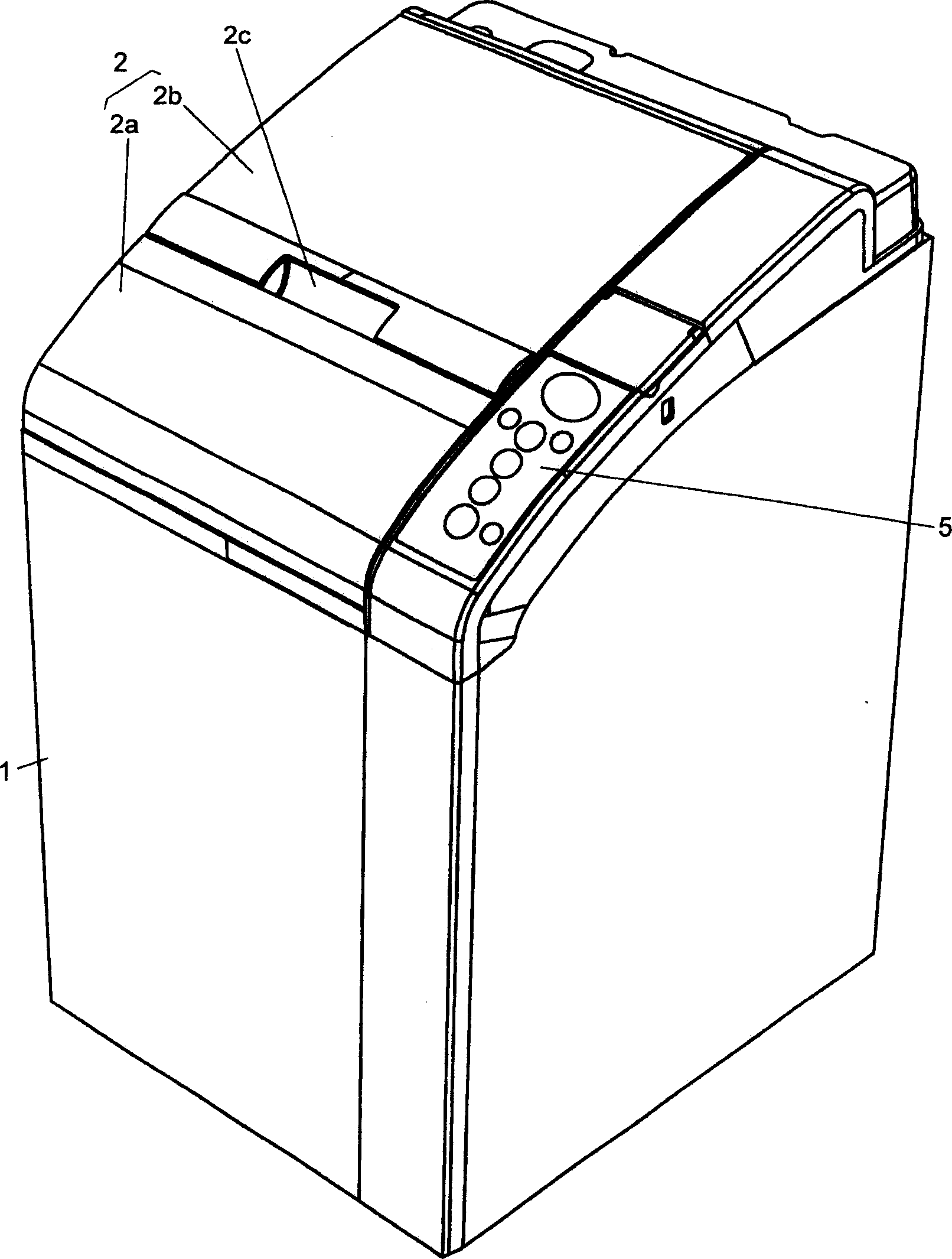

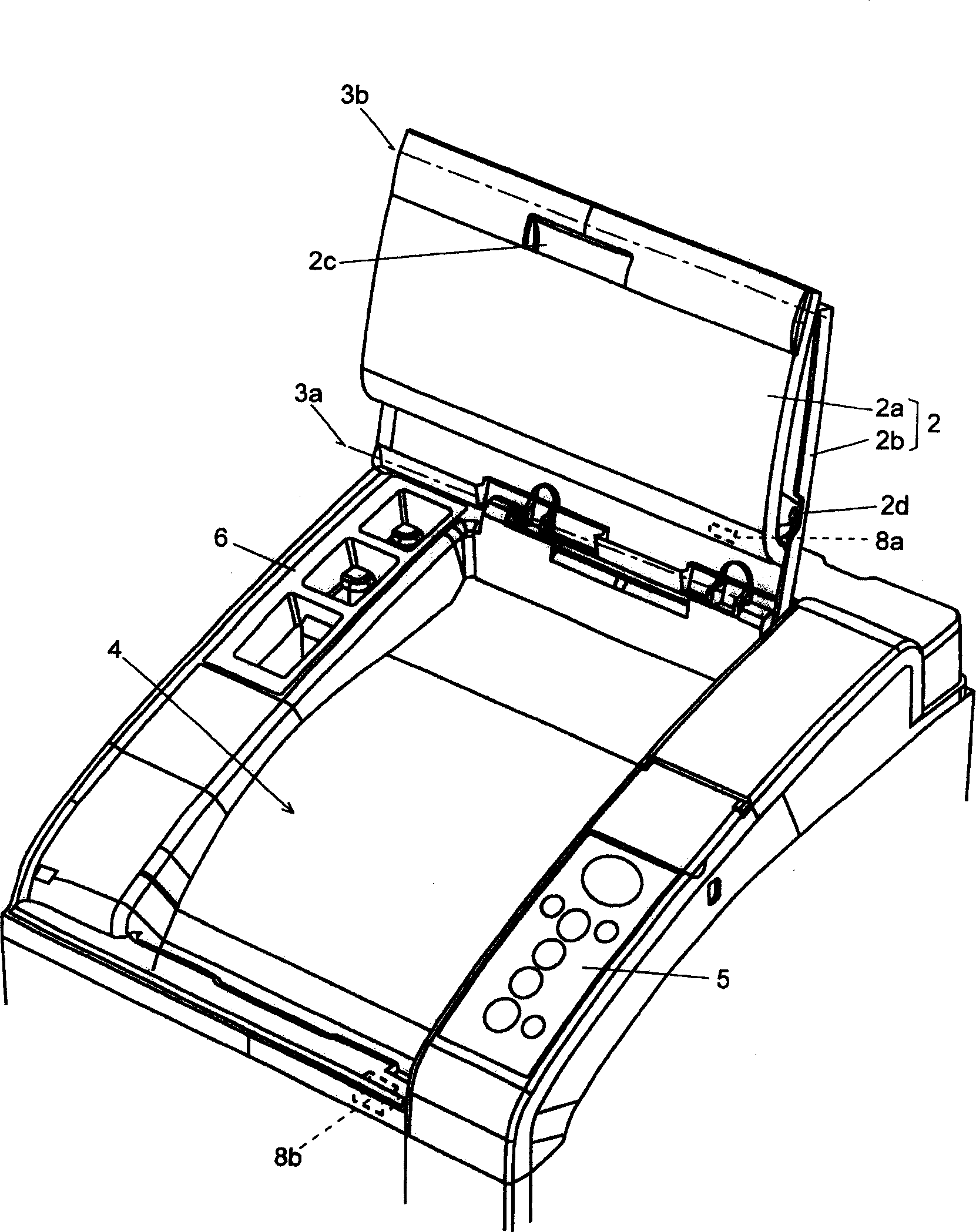

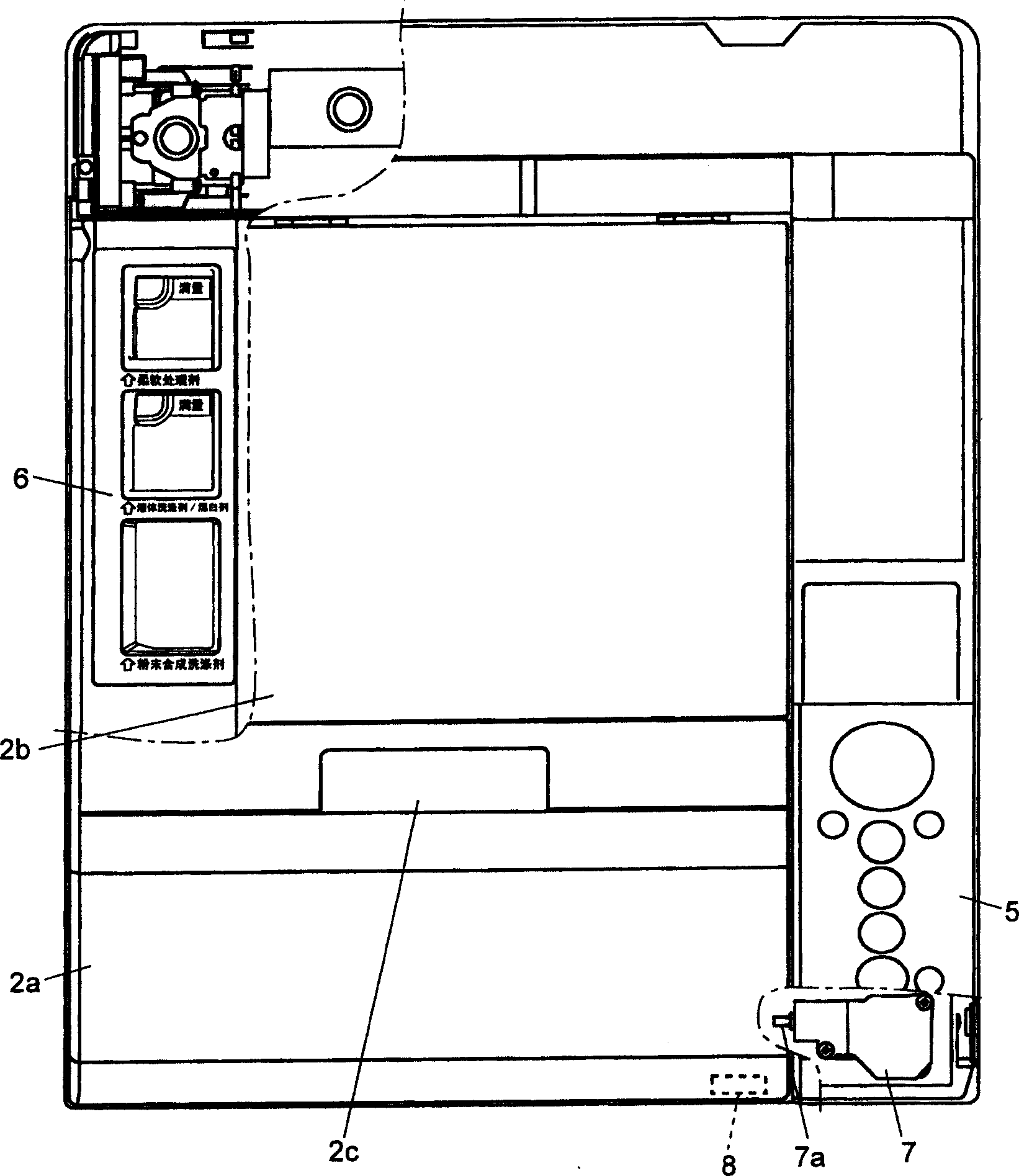

Washer

InactiveCN1626719AAvoid breakingAvoid failureOther washing machinesControl devices for washing apparatusMechanical engineeringEngineering

The invention relates to a washing machine. A detergent container is provided inside a top cover to ensure safety when detergent is received in the detergent container and to improve usability. The drum is rotated and driven in a locked state where the top cover is closed and the opening is prohibited, and the amount of laundry is detected (S2-S6). Then, rotating the drum to the locked position implements the locking of the drum (S7), and unlocking the top cover allows the top cover to be opened (S8). When the load detection is completed, the appropriate detergent amount standard corresponding to the load is known, but the detergent amount standard display is not performed until the top cover is unlocked, but is displayed after the top cover is unlocked (S9). Accordingly, it is possible to prevent the top cover from being opened in a state where the drum is not locked, such as during load detection. In addition, since the user must release the lock of the top cover when seeing the detergent amount standard, it is possible to avoid the situation that the top cover cannot be opened when the user intends to inject detergent in consideration of this situation.

Owner:SANYO ELECTRIC CO LTD

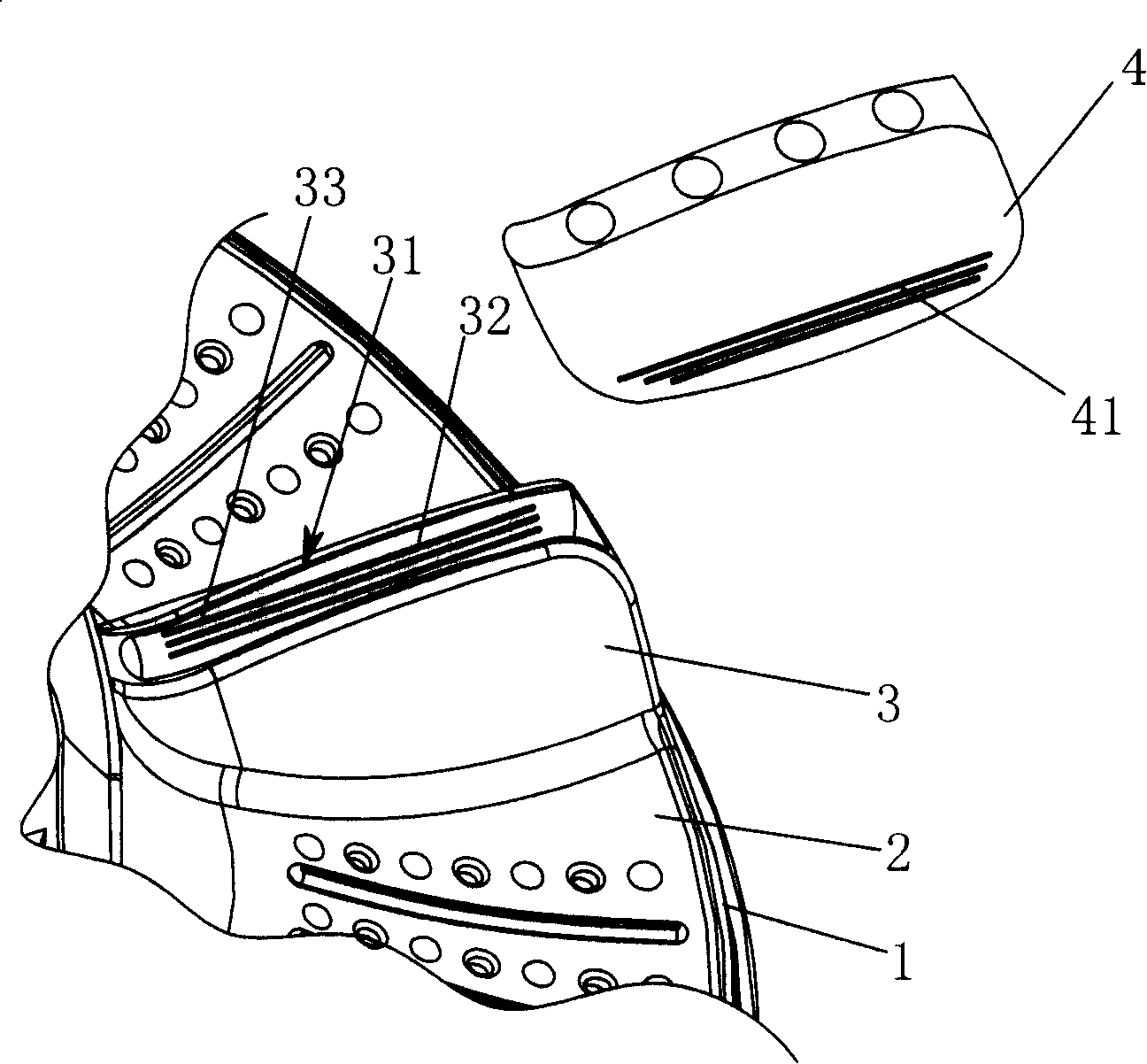

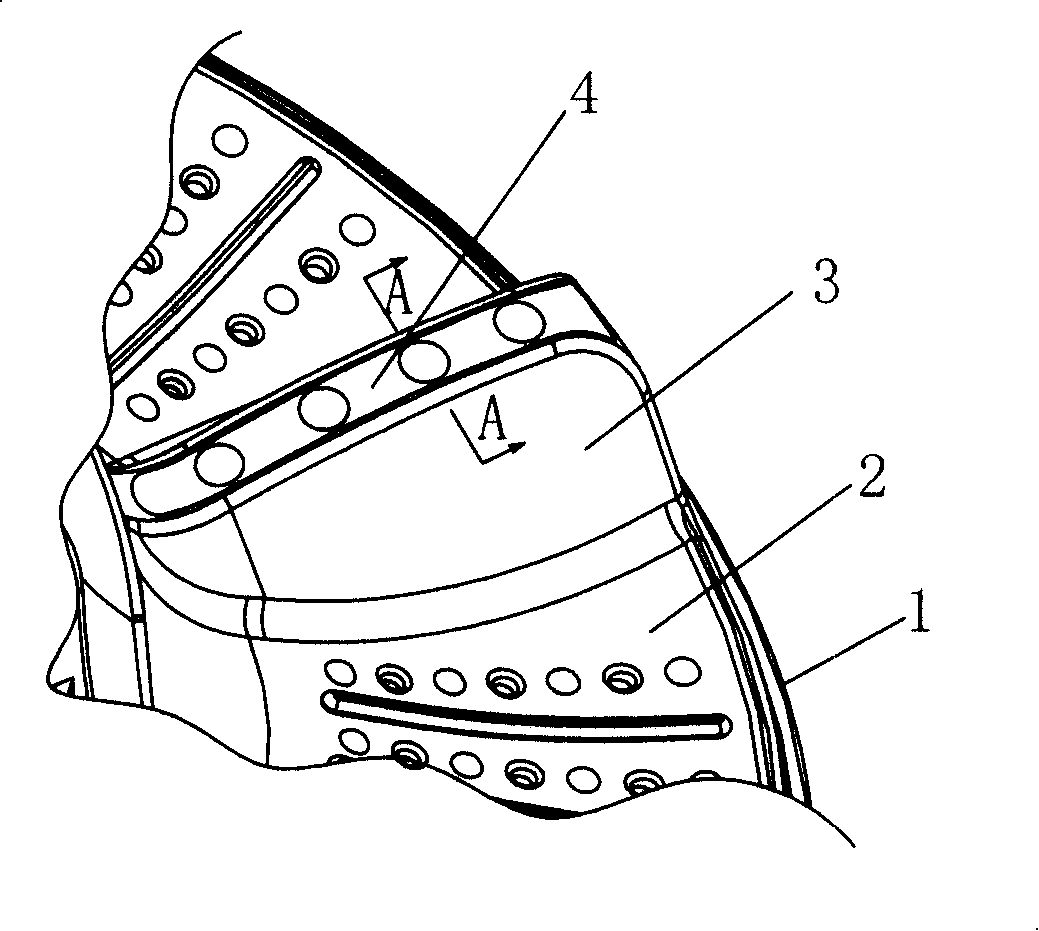

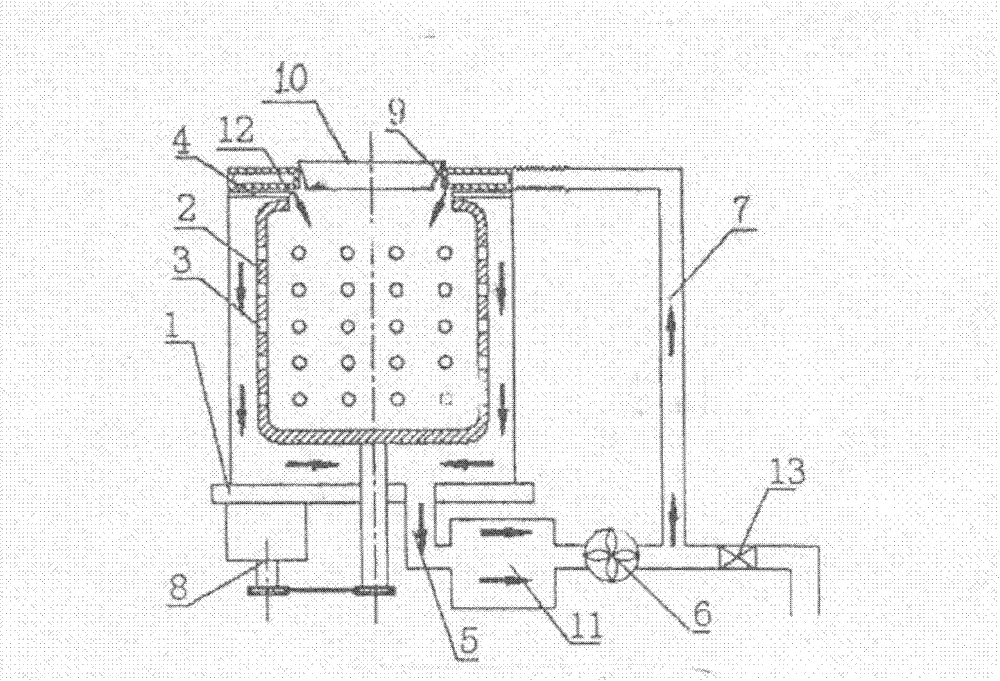

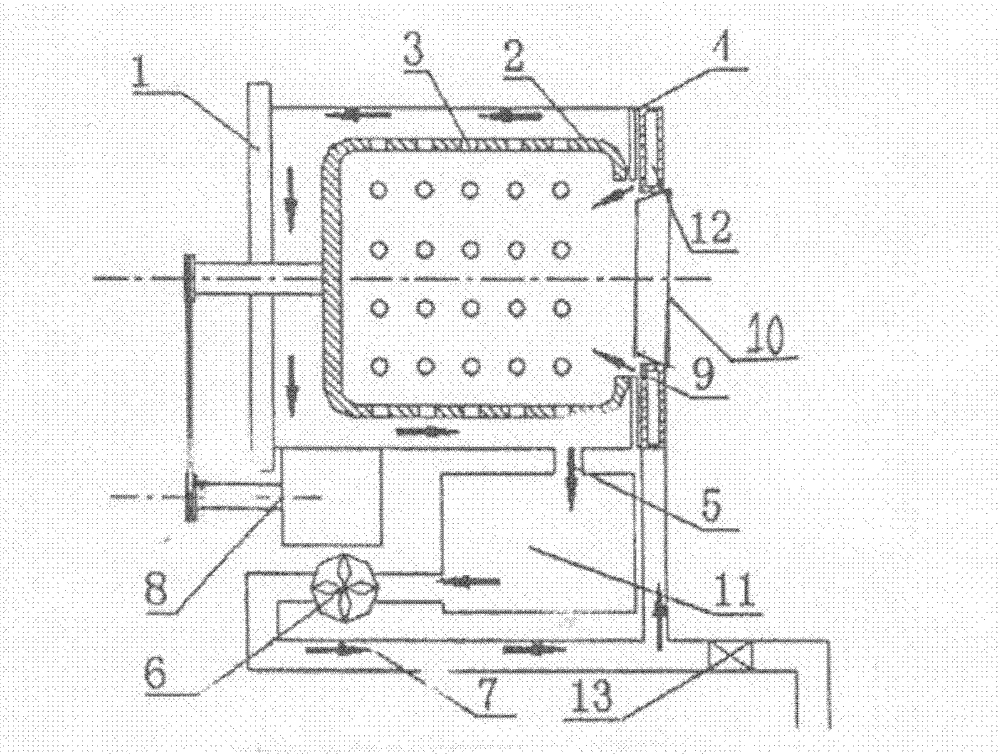

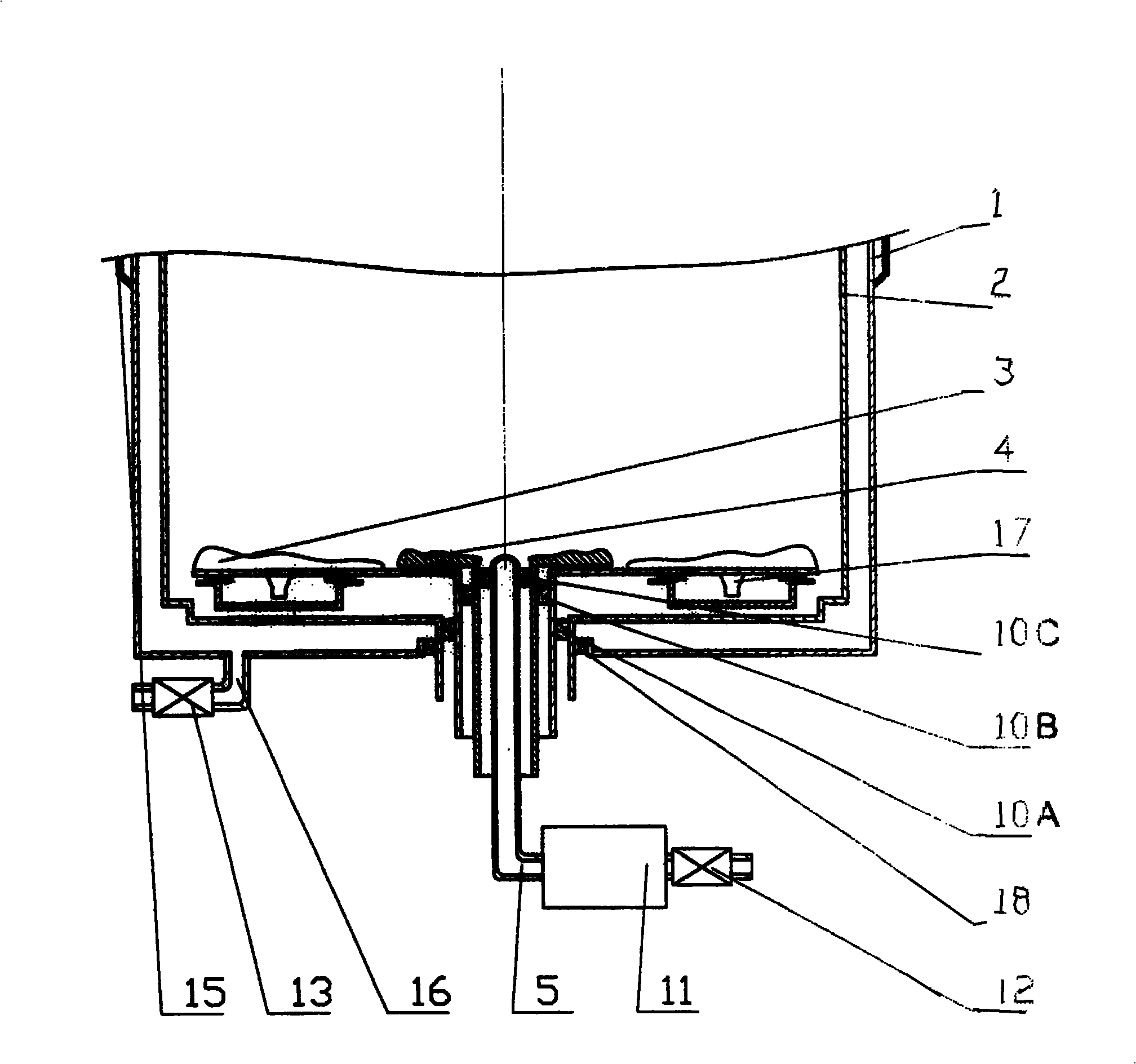

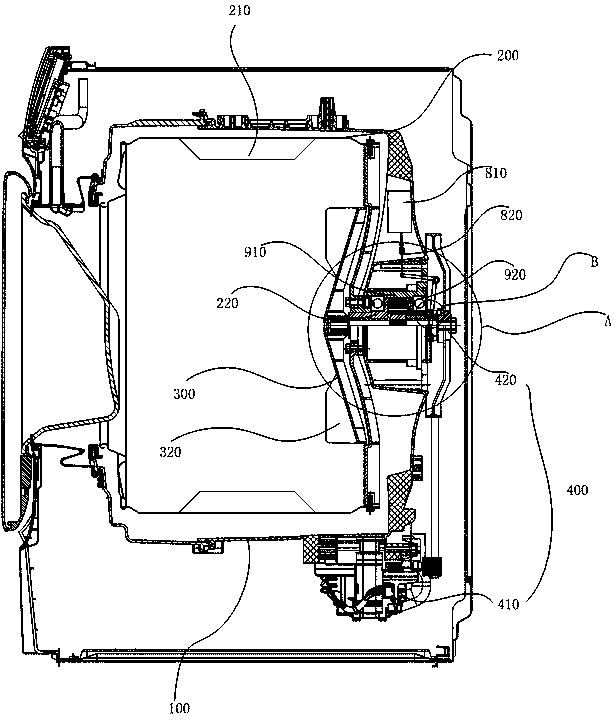

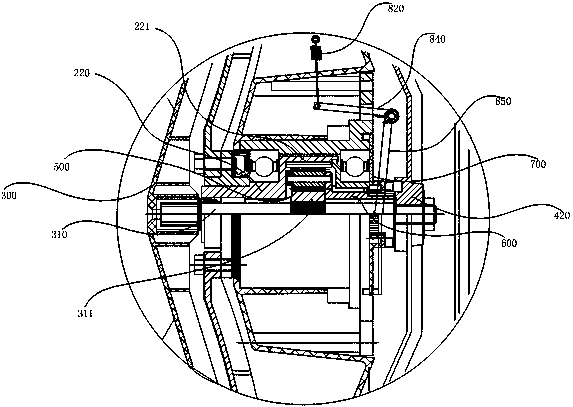

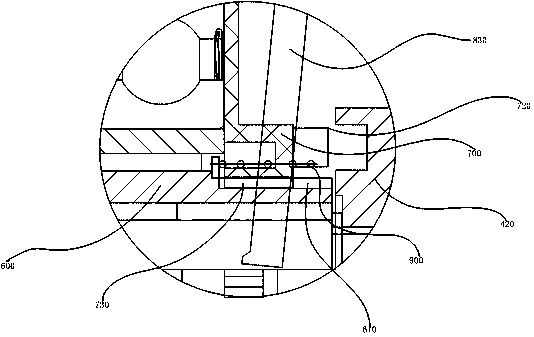

Washing machine and water treatment system using same

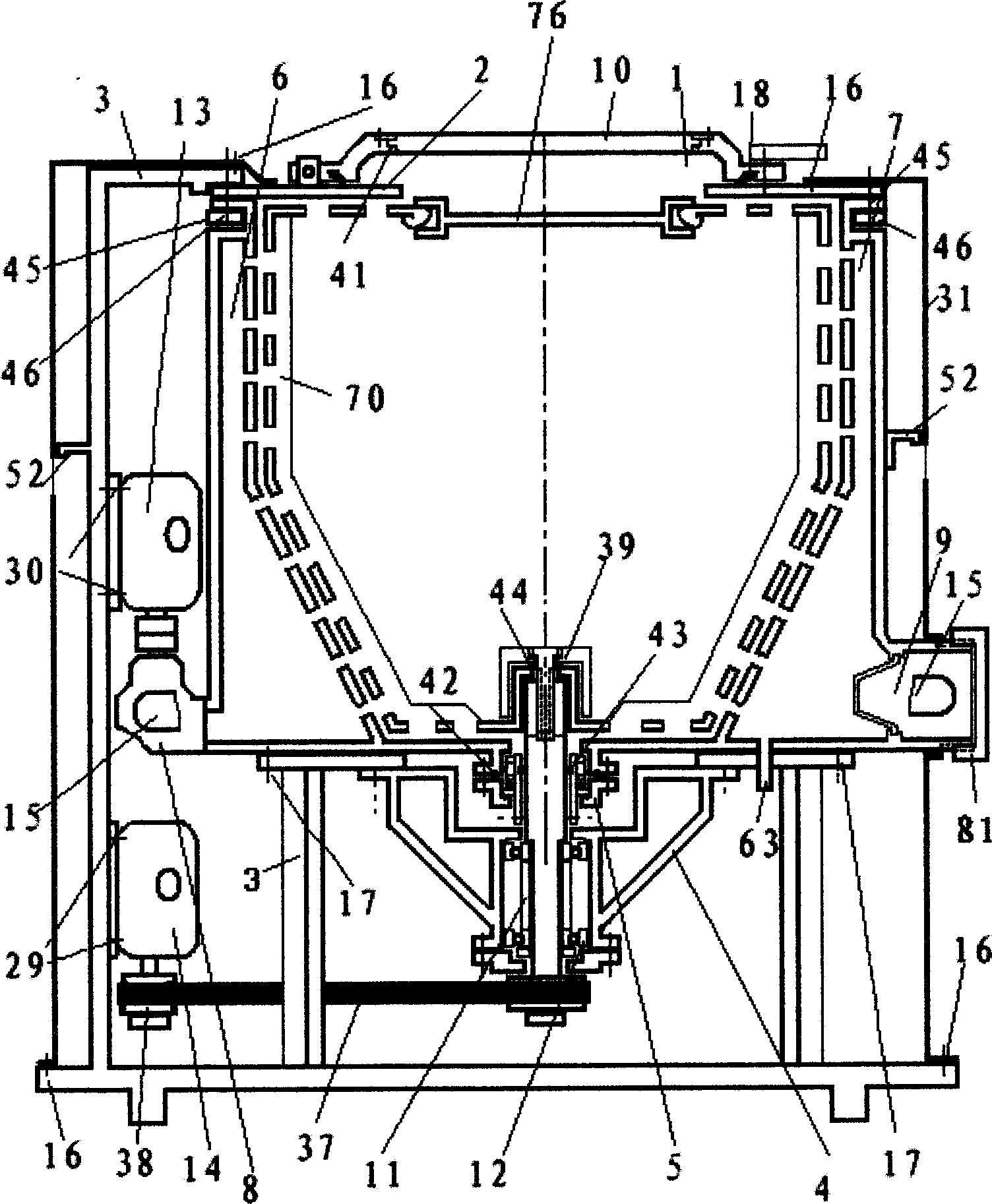

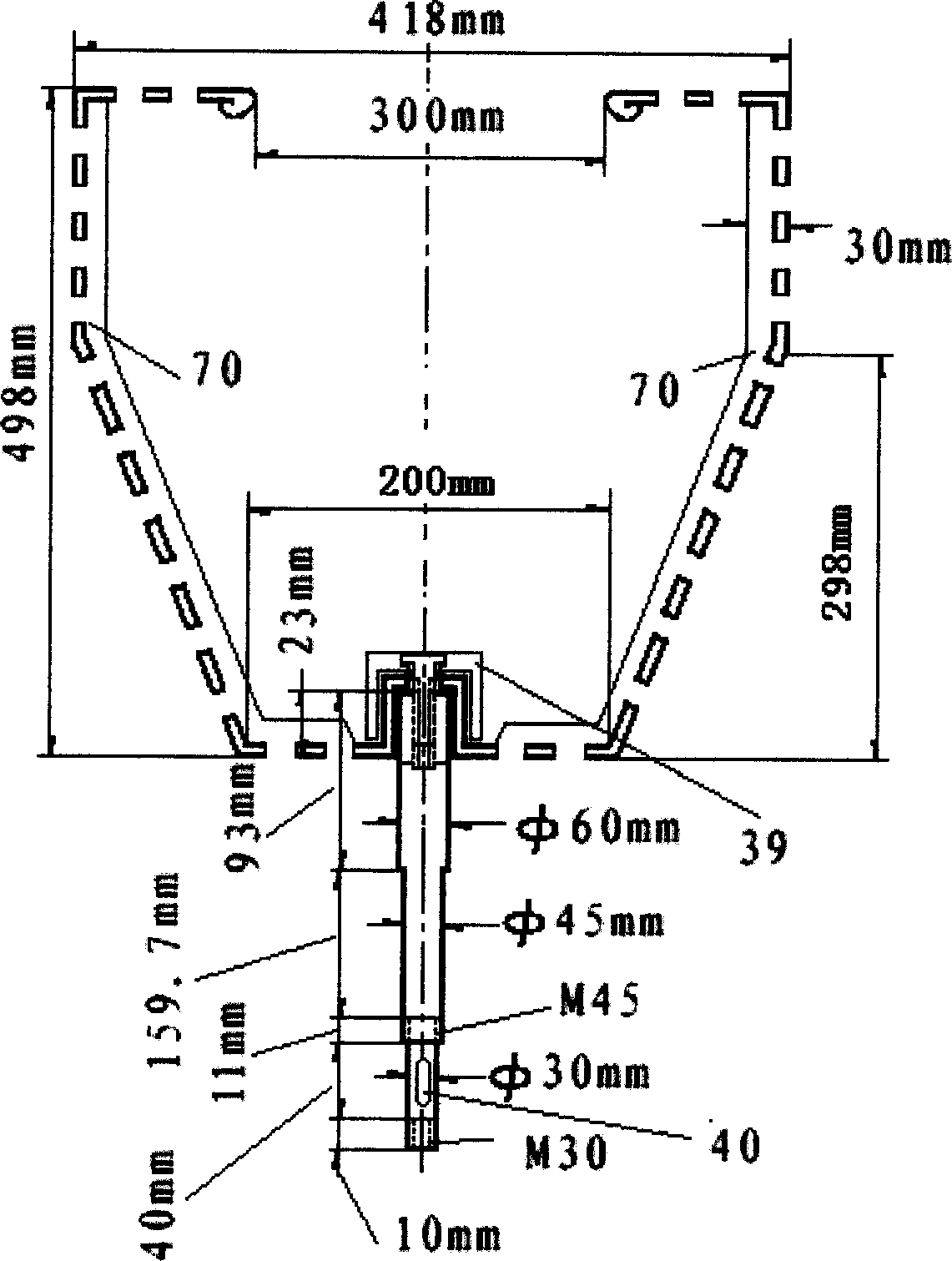

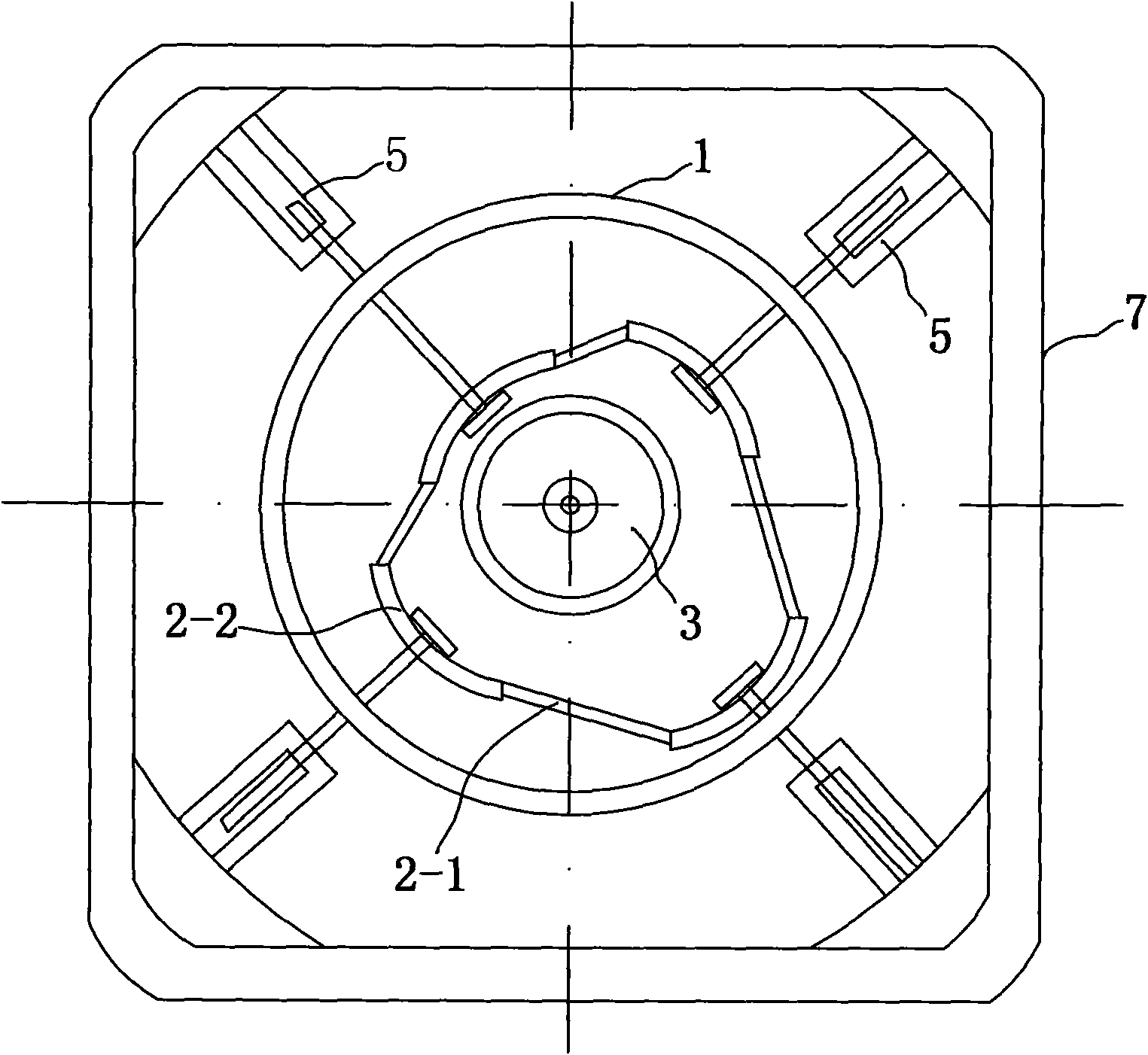

InactiveCN101736549AImprove laundry effectShorten laundry timeOther washing machinesEnergy based wastewater treatmentClutchEngineering

The invention relates to a washing machine and a water treatment system using the washing machine. The washing machine comprises an external drum, an internal drum arranged in the external drum, and a thumb wheel arranged in the internal drum, wherein the thumb wheel is driven by a main motor, and an output shaft of the main motor is connected with the external drum and the internal drum through an electronic clutch; the internal drum comprises at least two pairs of elastic valve bodies and non-elastic valve bodies which are connected together in turn to form a drum body, and through holes which are only opened when the washing machine performs a dewatering process are distributed on wall bodies of the non-elastic valve bodies; each non-elastic valve body is distributed along the outer edge of the thumb wheel and is connected with a connecting rod which is used for controlling the radial displacement of the non-elastic body, and the connecting rod is connected with a driving mechanism; when the washing machine performs a washing process and a rinsing process, along with the rotation of the thumb wheel, the driving mechanism controls each non-elastic valve body to perform quick radial reciprocating displacement through the connecting rod; and when the washing machine performs the dewatering process, along with the rotations of the external drum and the internal drum, the driving mechanism controls each non-elastic valve body to extrude towards the center of the thumb wheel through the connecting rod and releases each non-elastic valve body until the dewatering process is finished. The washing machine can knead and rub clothes in the washing and rinsing processes and can perform dewatering with extruding force in the high-speed rotary dewatering process.

Owner:南通贺禧机械设备贸易有限公司

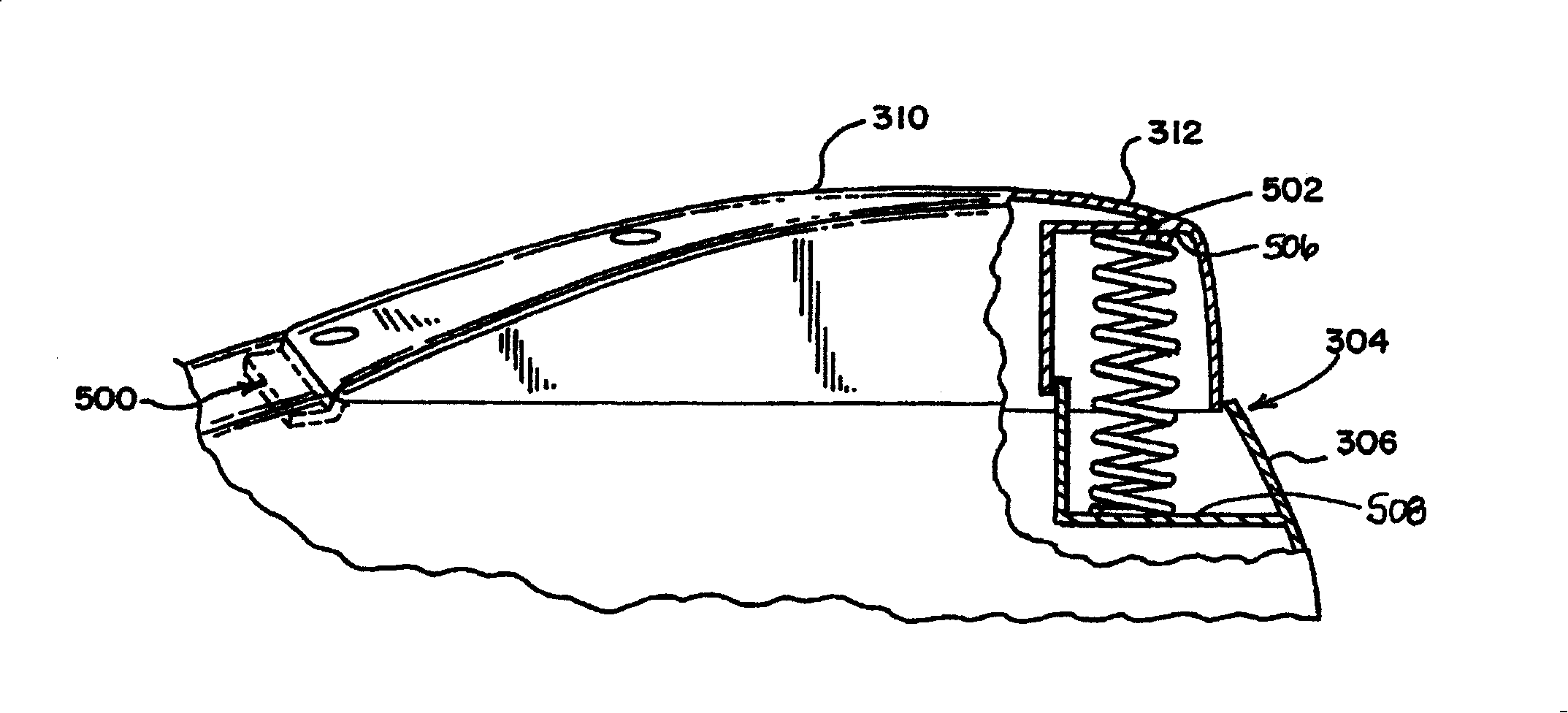

Washing machine as well as method for washing and rinsing thereof

InactiveCN102851915AReduce clothing wear and tearShorten the timeOther washing machinesWashing machine with receptaclesElectricityWater use

The invention provides a method for washing and rinsing of a washing machine. The method is characterized by comprising the following steps of: starting; filling water and spraying the water through a water pump; filling water until all clothes can be soaked; intermittently de-watering, and spraying the water within an intermittent time interval; continuously de-watering; spraying the water through the water pump, intermittently de-watering through a de-watering cylinder, intermittently spraying the water through the water pump, and continuously and repeatedly de-watering for 2-15 times; intermittently de-watering while discharging the water; continuously de-watering while discharging the water; de-watering through using inertia while discharging the water; and stopping. The washing method of the washing machine, provided by the invention, comprises the following steps of: spraying the water to wash while filling the water; spraying the water, intermittently de-watering, and washing through squeezing; and discharging the water, de-watering, and washing through the squeezing. And the rinsing method of the washing machine, provided by the invention, comprises the following steps of: filling and spraying the water for rinsing; spraying the water, de-watering and rinsing through the squeezing; and discharging the water, de-watering and rinsing through the squeezing. The washing machine provided by the invention has the advantages of small water using amount, few washing agents, small electricity consumption, short washing time, small abrasion and high cleaning rate.

Owner:林贤华 +1

Pressure circulating washing machine with forced jet water flow

InactiveCN1487138ALarge amount of laundryThe production process is not complicatedWashing machine with receptaclesTextiles and paperWater circulationHigher Power

The pressure circulating washing machine has one increased forced water circulating system in the cylinder, and the whole washing process is completed in the sealed cylinder and the forced water circulating system. The water flow of the washing machine has relatively high power and the direction inversely to clothing motion and the cylinder always changes its rotation direction for constant impact to clothing. The beneficial effects include raised clothing detergency and shortened washing time, and the present invention provides one kind of new washing mode and new un-complicated washing machine.

Owner:乔向东

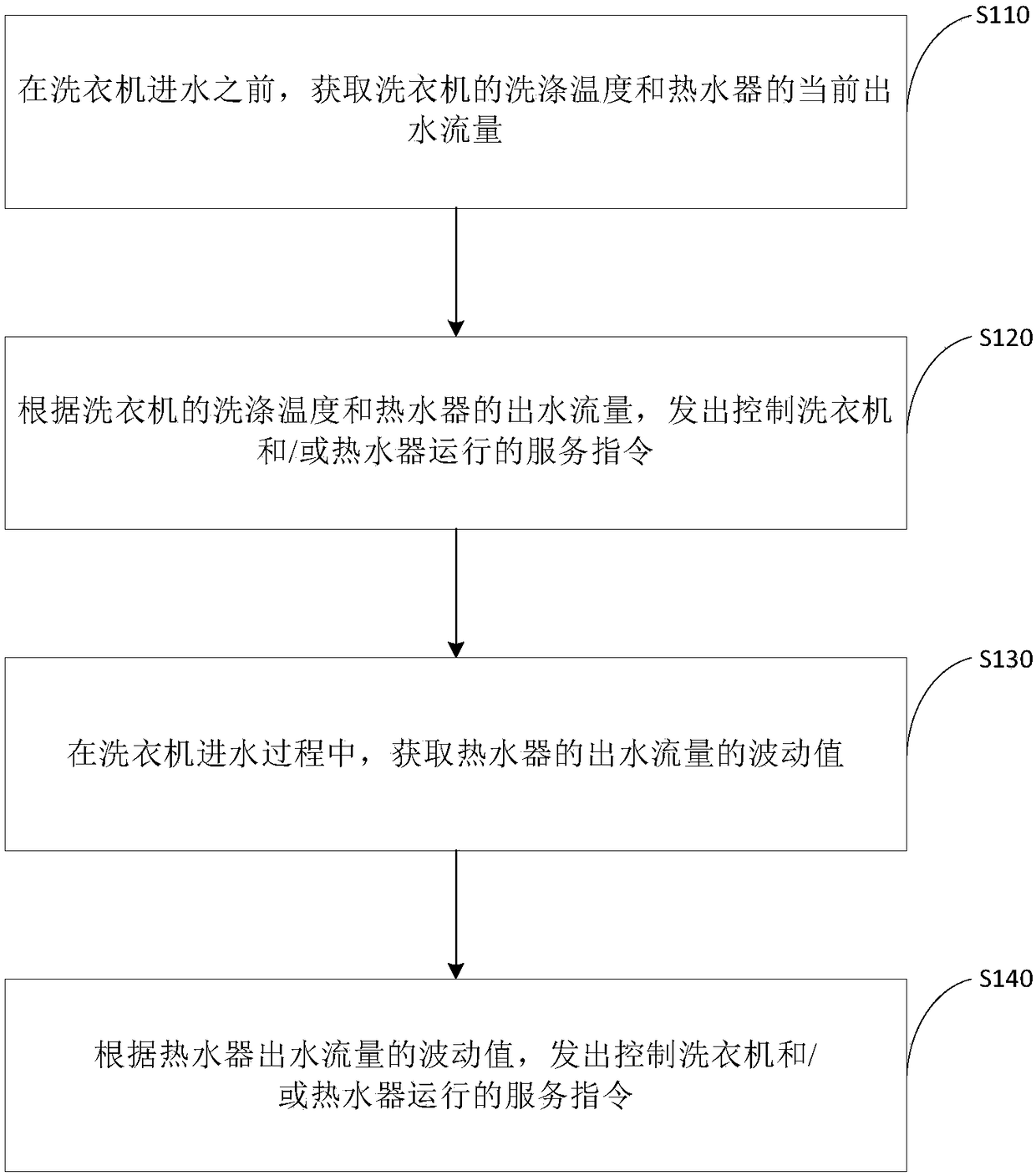

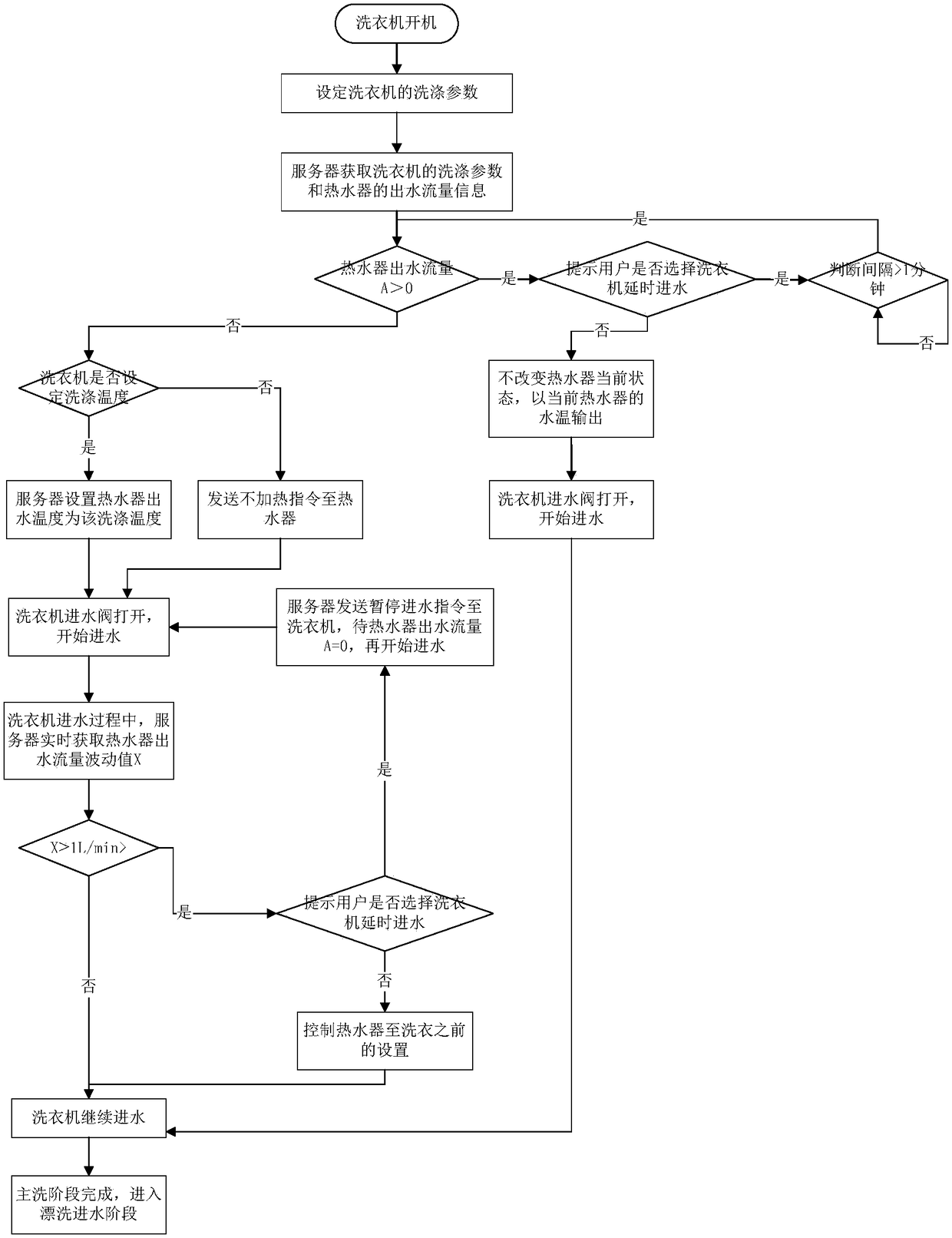

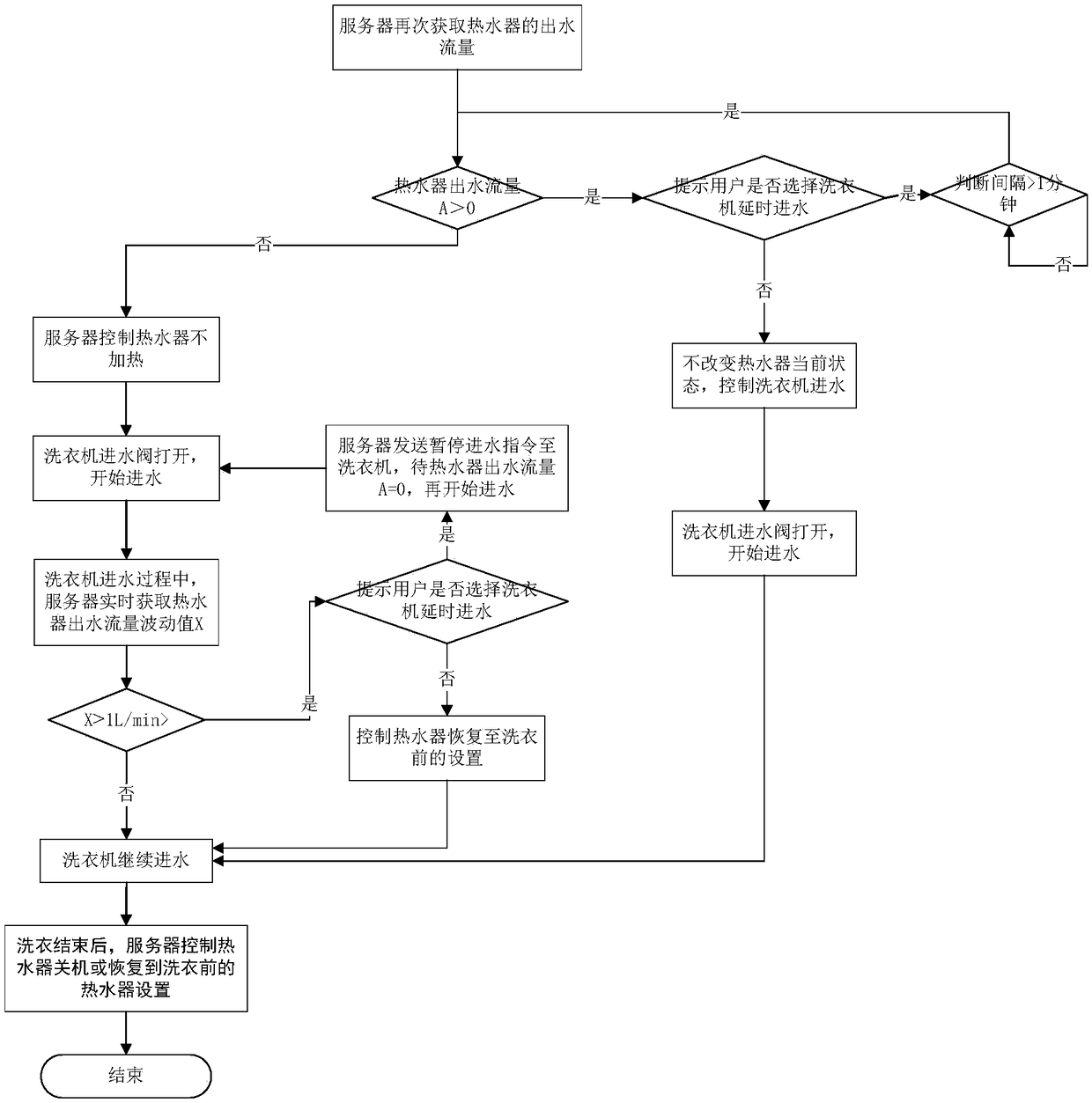

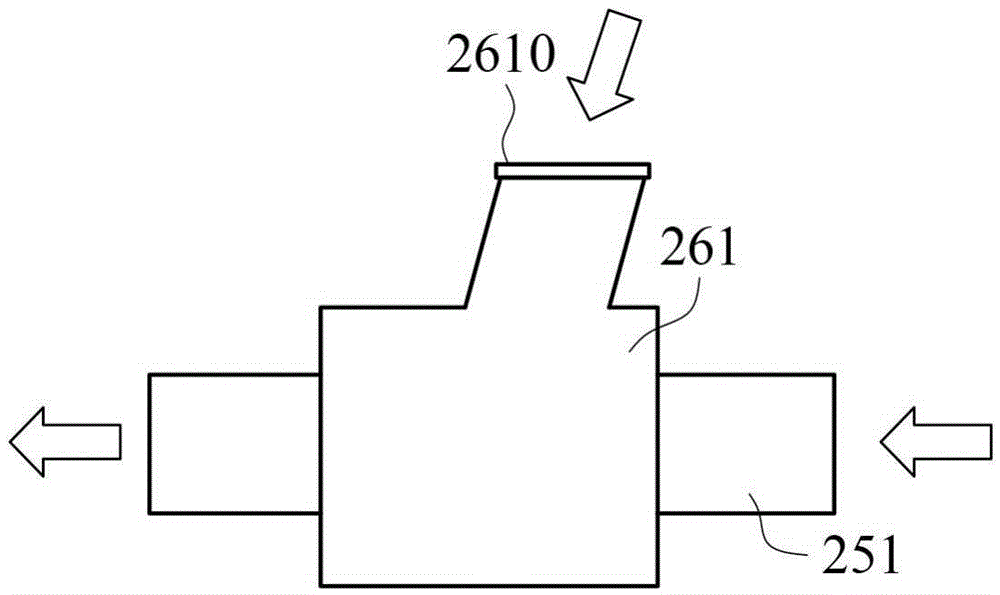

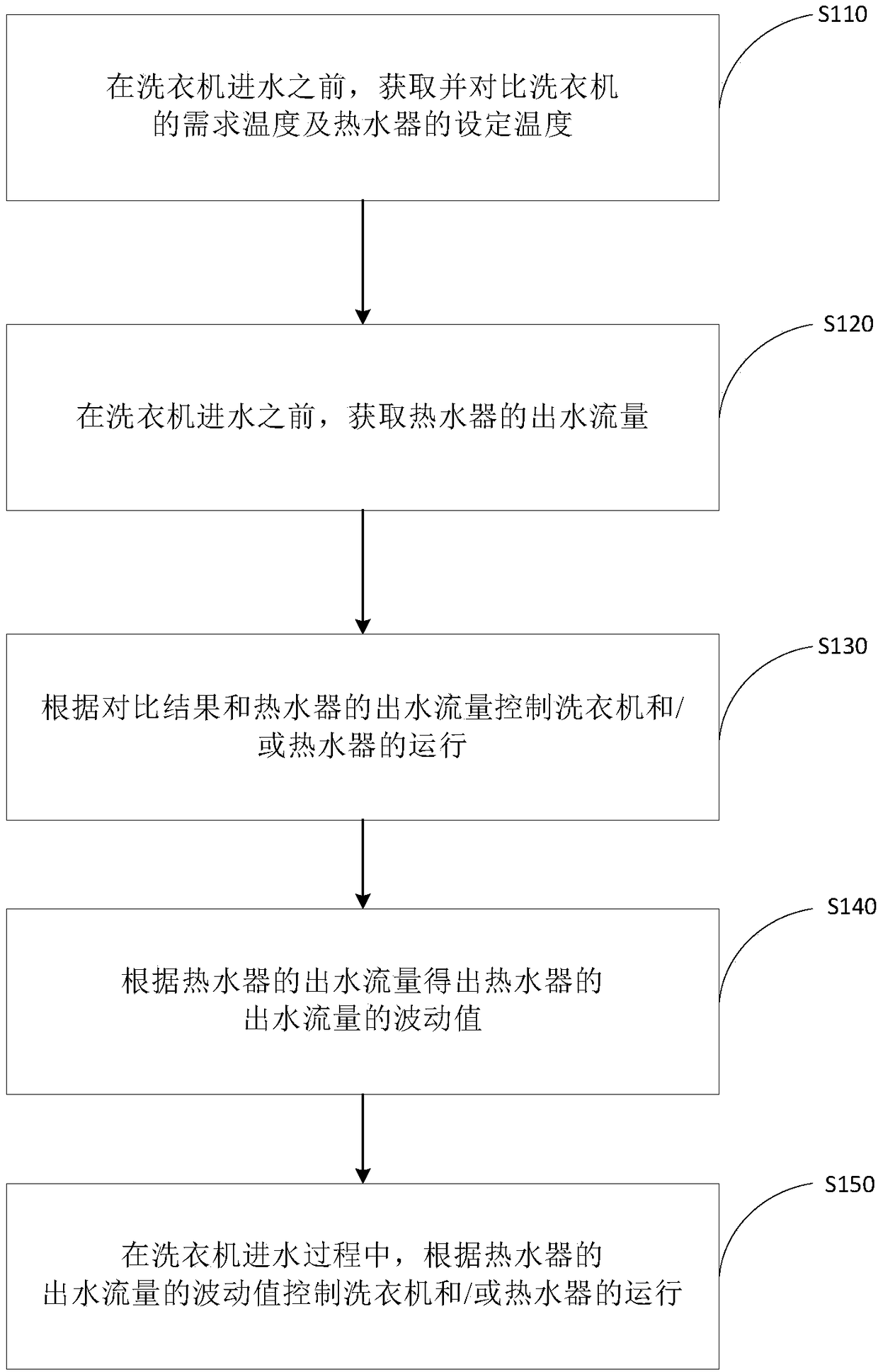

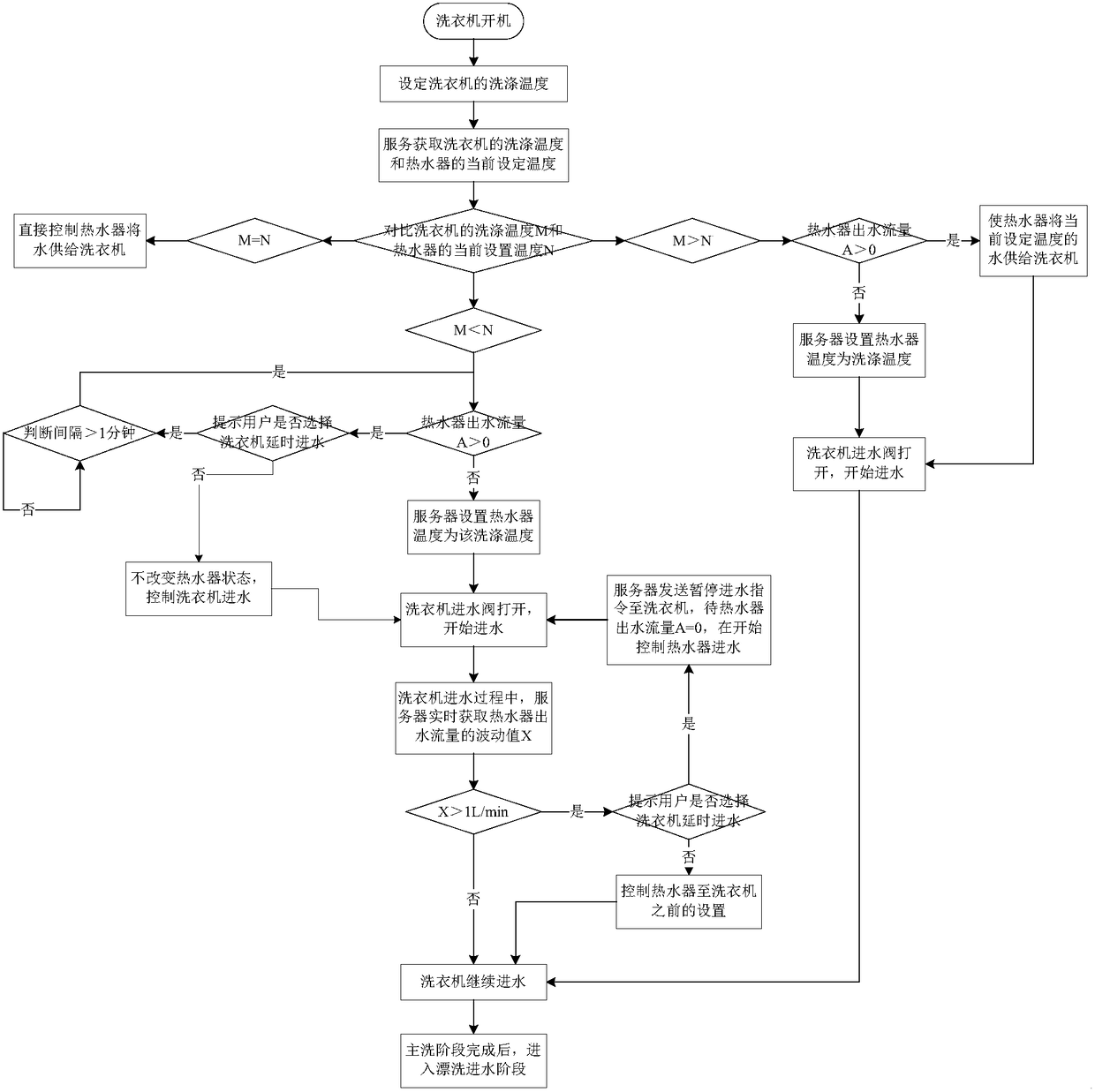

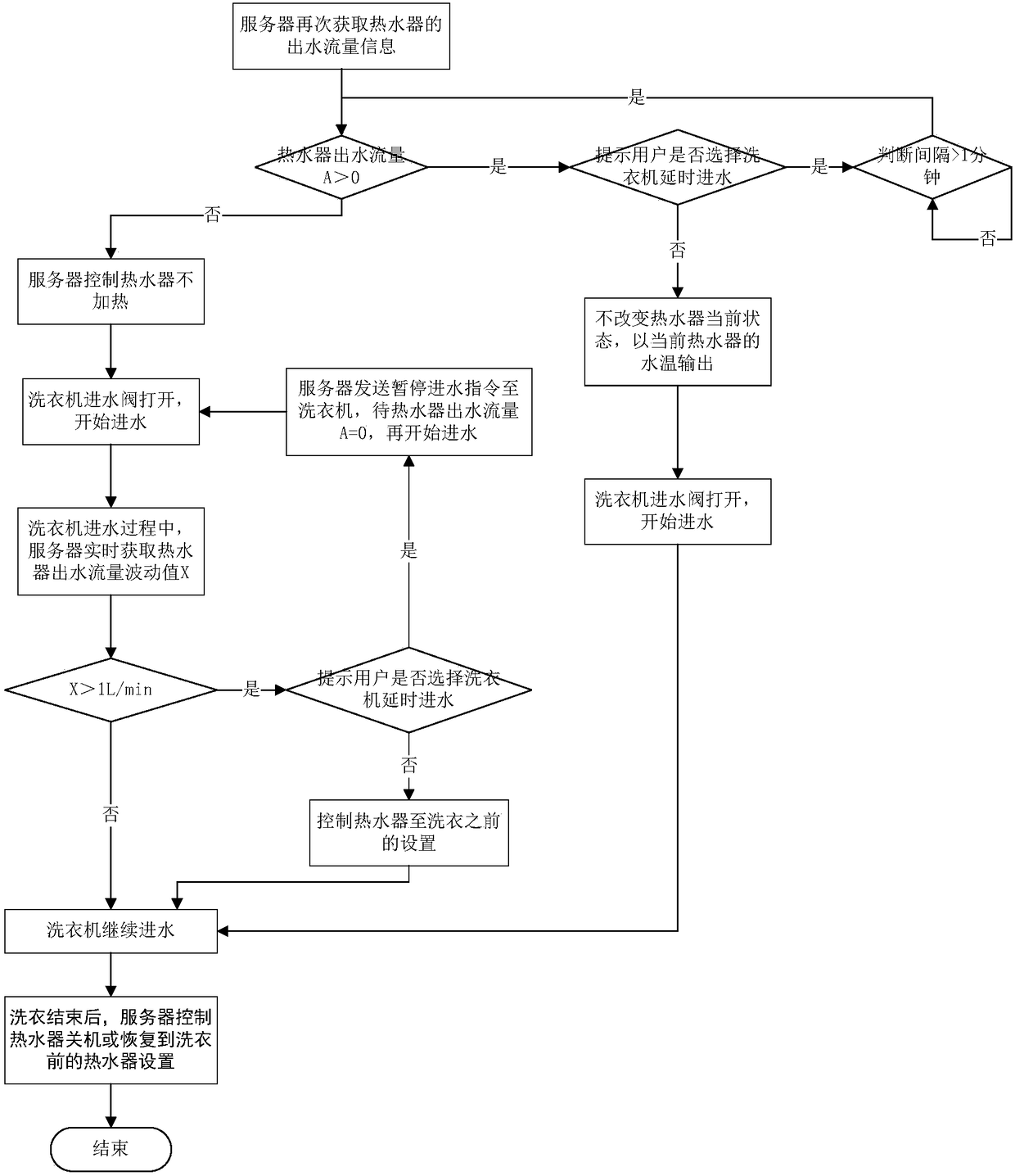

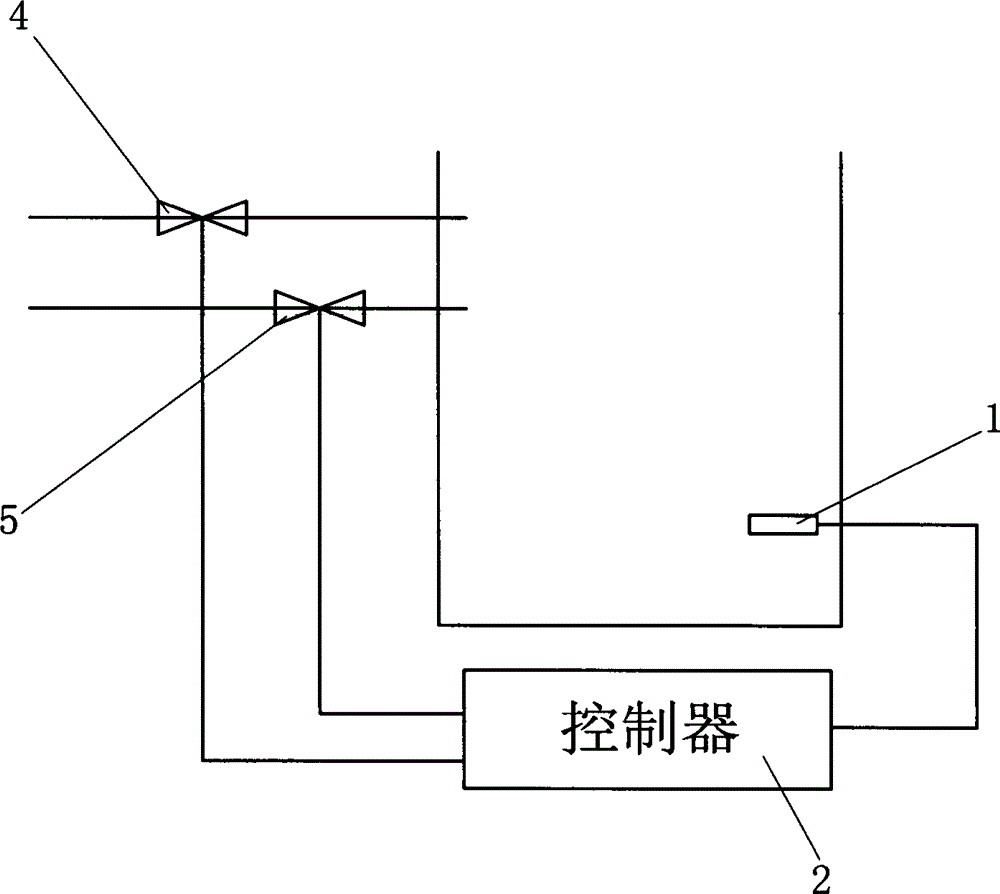

Cooperative control system and method for water consumption equipment and water heater

ActiveCN108572567AShorten laundry timeImprove user experienceFluid heatersProgramme control in sequence/logic controllersControl modeEngineering

The invention belongs to the technical field of household electrical appliances, and specifically relates to a cooperative system and method for water consumption equipment and a water heater. The invention aims to solve a problem that the existing water heater is relatively single in control mode. To this end, the cooperative control method comprises the steps of obtaining the outlet water flow of the water heater in the water inflowing process of the water consumption equipment; obtaining a fluctuation value of the outlet water flow of the water heater according to the outlet water flow of the water heater; and controlling the operation of the water consumption equipment and / or the water heater according to the fluctuation value of the outlet water flow of the water heater. Through the cooperative control for the water consumption equipment and the water heater, the cooperative control method avoids a problem of collision among multiple sets of water consumption equipment when usingthe water heater while meeting hot water utilization of the water consumption equipment through comparing the fluctuation value of the outlet water flow of the water heater with a preset value in thewater inflowing process.

Owner:上海海尔洗涤电器有限公司 +1

Washing machine provided with washing powder dissolving device

InactiveCN105113185AImprove solubilityIncrease volumeOther washing machinesTextiles and paperImpellerPulp and paper industry

Owner:蒋凤英

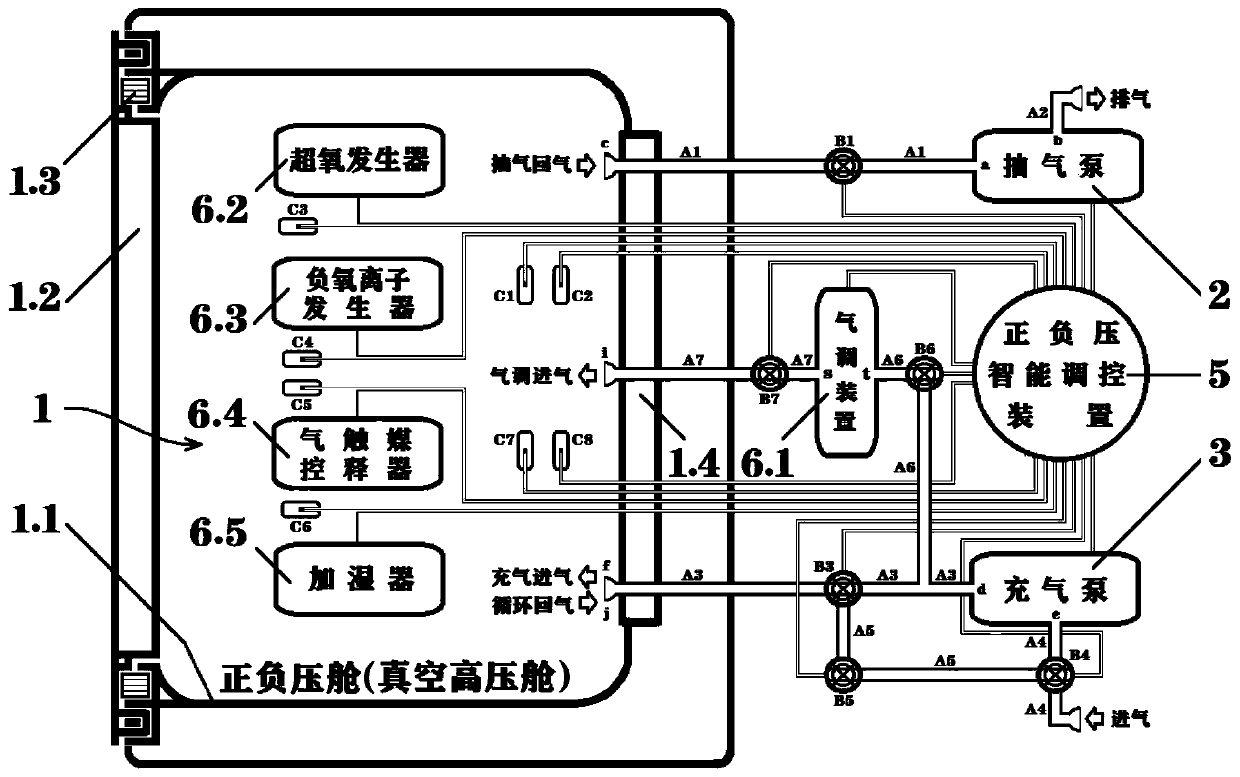

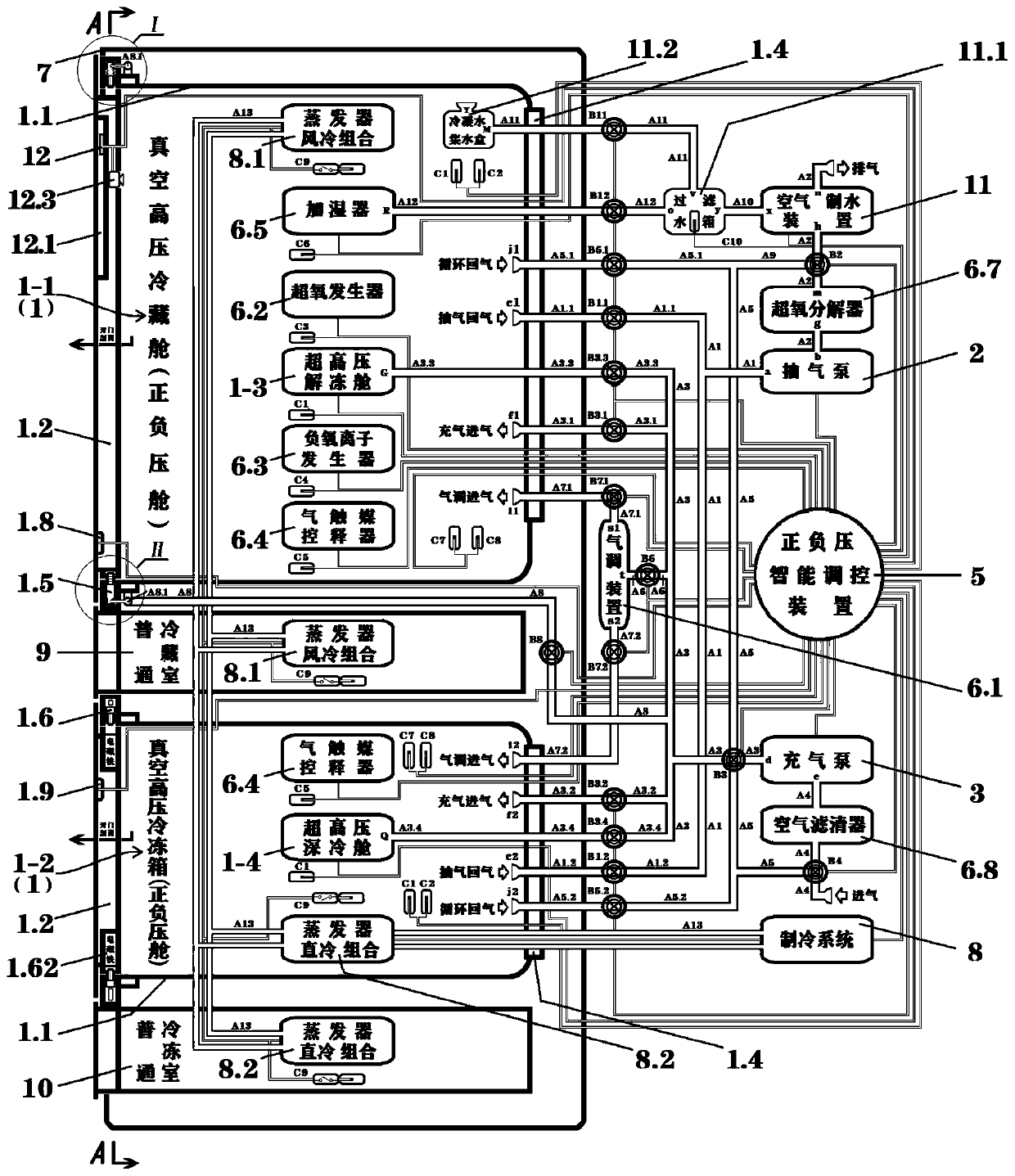

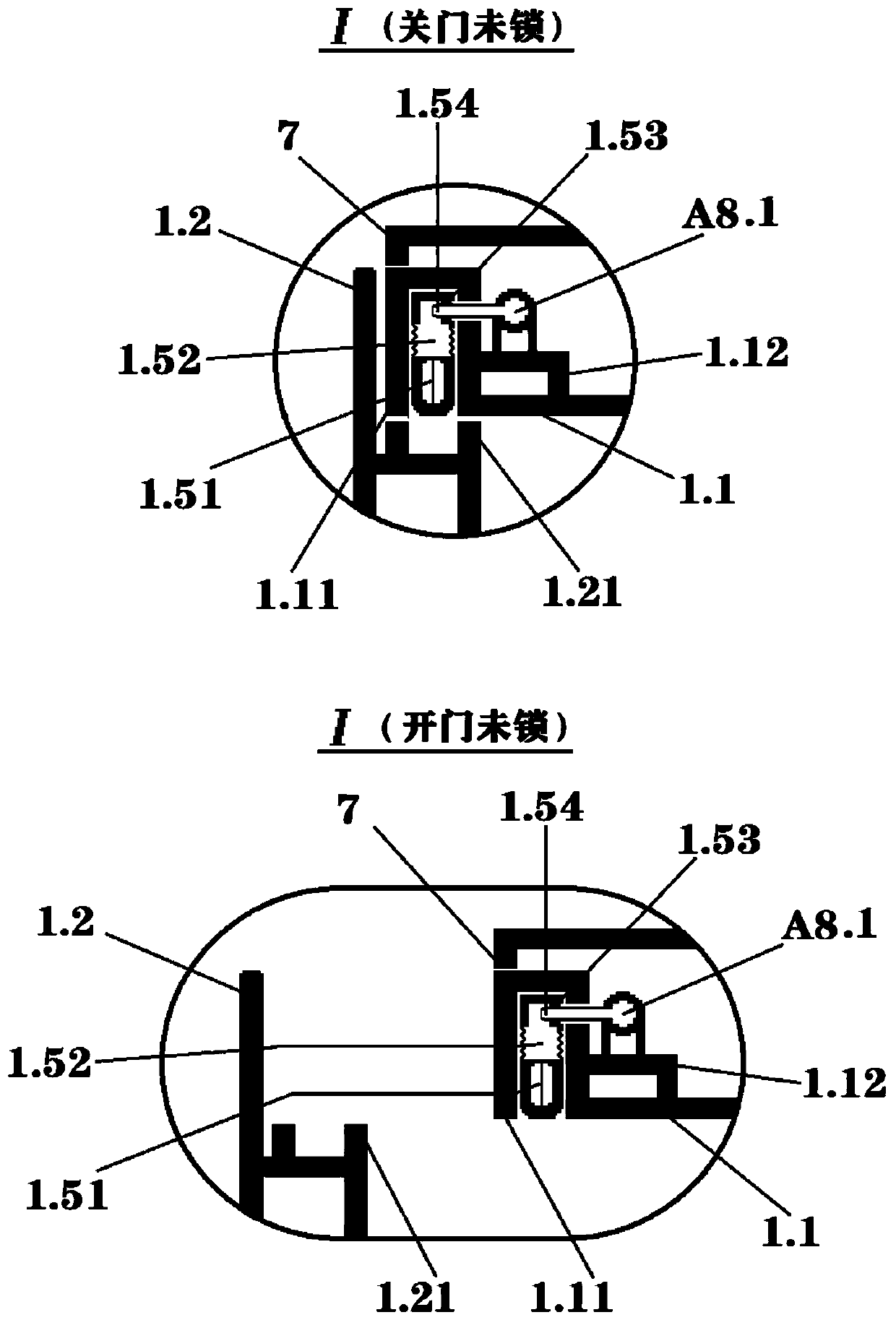

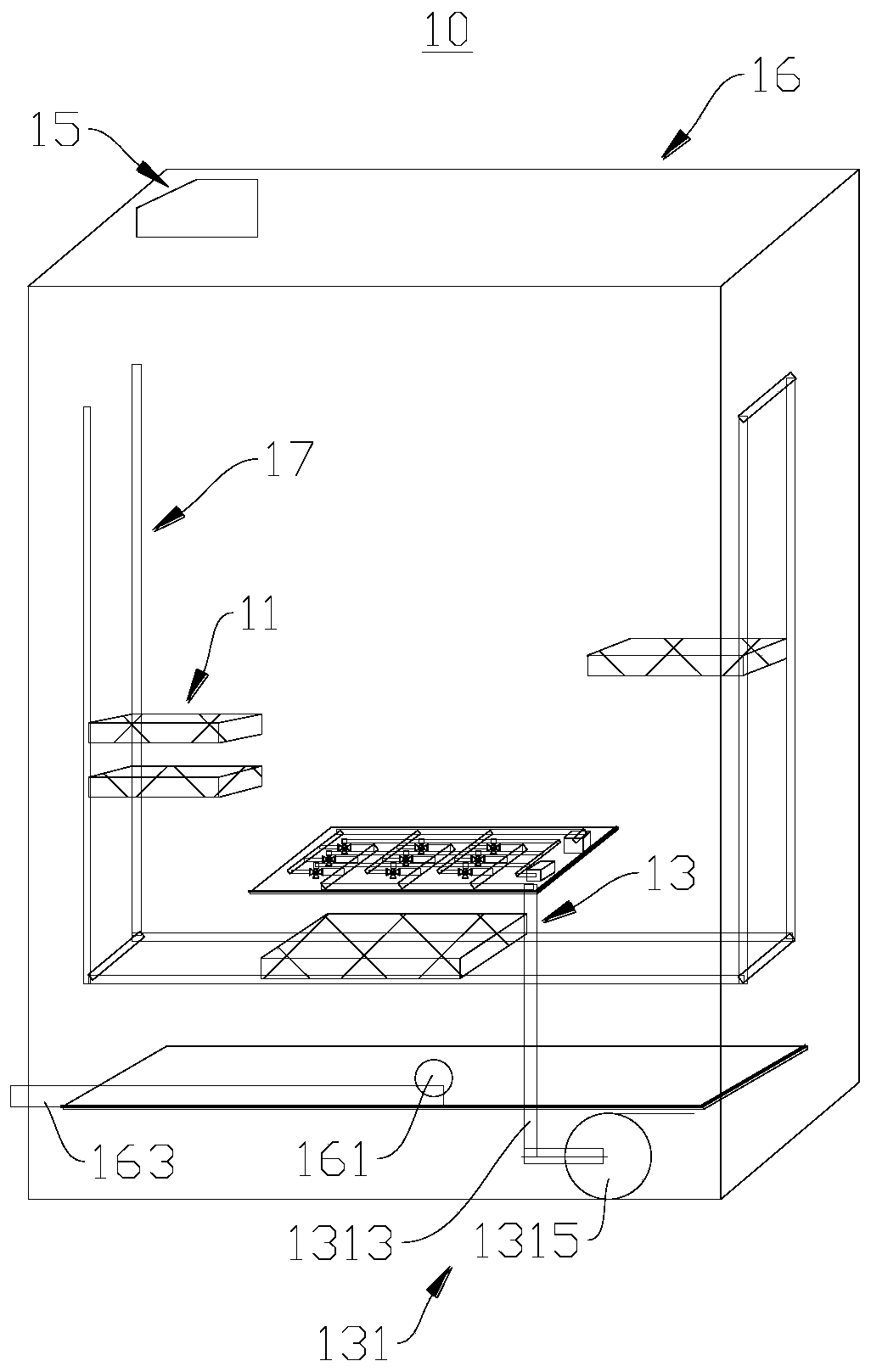

Positive-negative pressure system, operation method thereof and positive-negative pressure electric appliance using system

PendingCN111562804ASolve the technical problem of irreversible quality damageInhibition of activityWashing controlling processesDomestic stoves or rangesLaundry washing machineMicrowave oven

The invention relates to a positive-negative pressure system, an operation method thereof and a positive-negative pressure electric appliance using the system. The positive-negative pressure electricappliance comprises: a positive-negative pressure refrigerator, a positive-negative pressure washing machine, a vacuum dish washing and fruit-vegetable cleaning machine, a super-oxygen washing range hood, a positive-negative pressure oven fryer microwave oven, a positive-negative pressure fresh-keeping compartment, a positive-negative pressure fresh-keeping warehouse and a positive-negative pressure module cabinet. According to the technical principle and the basic operation method of the positive-negative pressure system, air flow is regulated and controlled through positive and negative pressure, or multiple effective loads like ozone, air catalysts, negative ions, air-conditioned gas and water are carried for orderly getting in and out of the positive-negative pressure cabins or staying, and needed influences are exerted on objects therein. Accordingly, multiple technologies like vacuum, high pressure, ozone, catalysts, controlled atmosphere fresh-keeping, negative ions, disinfection and purification, humidification and dehumidification, air water production and low-temperature storage are regulated and integrated through the positive-negative pressure system and are combined and applied to the positive-negative pressure electric appliance, a breathing function is given to the electric appliance, and a positive-negative pressure electric appliance subdivision field is developed for upgrading and updating existing electric appliances and traditional technologies.

Owner:郑伯昂

Washing machine and clothes washing method

ActiveCN110670294AReduce weightAvoid noiseOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention relates to the technical field of household appliances, in particular to a washing machine and a clothes washing method. The washing machine comprises a clothes container for containingclothes, a spraying device for washing clothes by spraying, and a control device; the control device controls the spraying device to drive a pressure jetting device to jet a high-pressure water flow to to-be-washed clothes placed in the clothes container, and thus, the clothes can be cleaned effectively through the high-pressure water flow, time for washing is shortened, noise generated by a motored drum can be avoided, and dirt hiding between the outer tub and the inner tub in use of the conventional drum washing machines can be prevented effectively; further, the clothes in the clothes container can be washed in a targeted manner, bacterial cross-infection between different clothes caused in mixing of washing of the conventional washing machine and staining of other clothes due to easy-to-fade clothes are both avoided effectively; arrangement of weights is omitted, so that the washing machine is light, and is convenient to move and transport, and the like.

Owner:GREE ELECTRIC APPLIANCES INC +1

Washing machine capable of rubbing clothes

ActiveCN103276550AAvoid pollutionReduce loadOther washing machinesEnergy based wastewater treatmentElectric machineryRadial displacement

The invention relates to a washing machine which comprises an outer barrel, an inner barrel arranged in the outer barrel and a poking wheel arranged in the inner barrel. The poking wheel is driven by a main motor, and an output shaft of the main motor is connected with the outer barrel and the inner barrel through an electronic clutch. The washing machine is characterized in that the inner barrel comprises at least two pairs of elastic petal bodies and non-elastic petal bodies which are sequentially connected to form a through body. Through holes opened only when the washing machine executes a dewatering program are distributed on the wall bodies of the non-elastic petal bodies. The non-elastic petal bodies are distributed along the outer edge of the poking wheel and connected with a connection rod used for controlling radial displacement of the non-elastic petal bodies, and the connection rod is connected with a driving mechanism. When the washing machine executes a washing or rinsing program, the driving mechanism controls the non-elastic petal bodies to move quickly and radially in a reciprocating mode through the connection rod along with rotating of the poking wheel.

Owner:桐乡佳车科技股份有限公司

Fully-automatic supersonic washer without detergent

ActiveCN100451211CIncrease concentrationNot easy to tangleWater/sewage treatmentWashing machine with receptaclesEngineeringFully automatic

This invention discloses an automatic supersonic washing machine without wash including an outer drum, an inner drum, a wave wheel, an inlet pipe, an electrolyte tank, an inlet electromagnetic valve, an outlet pipe, an outlet electromagnetic valve, a motor, a speed vibrator, a controller, an operating panel and supersonic vibrators, in which, said wave wheel is composed of a large and a small wave wheel set concentrically, said supersonic vibrators are composed of three uniformly distributed vibrators of a horn-type Langevin vibrator and cumulative Longevin supersonic vibrators and said electrolyst tank is set in the inlet pipe.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

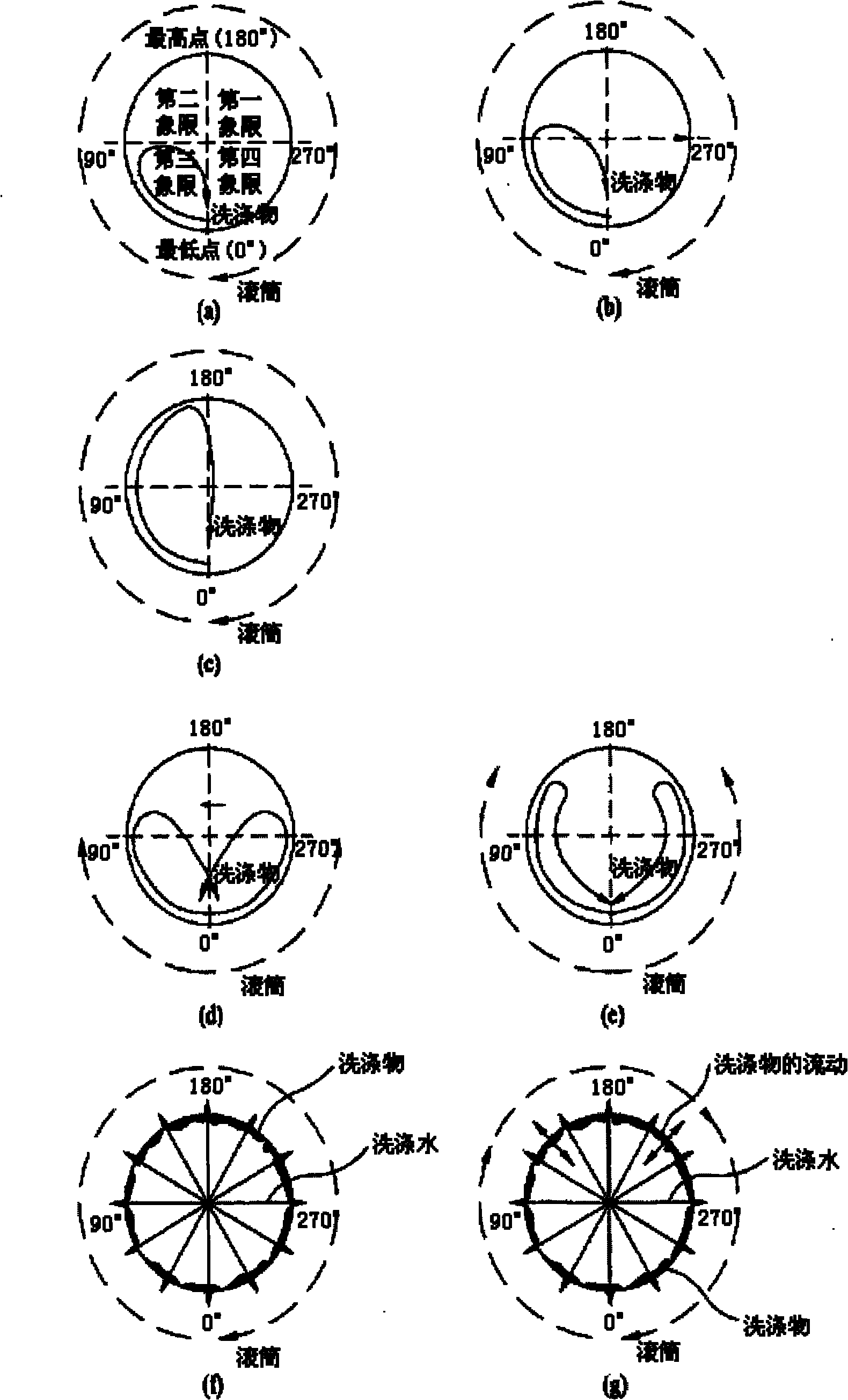

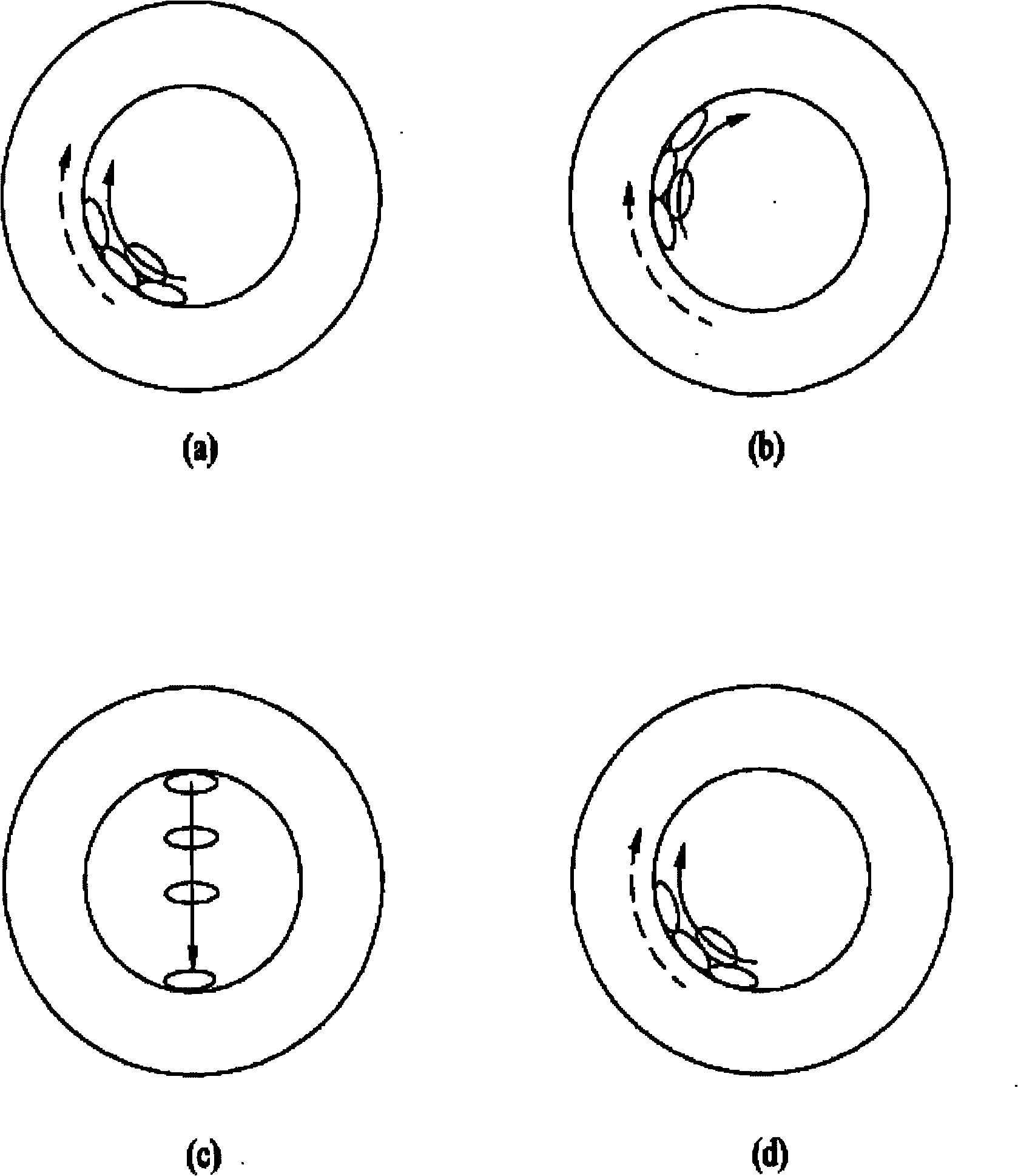

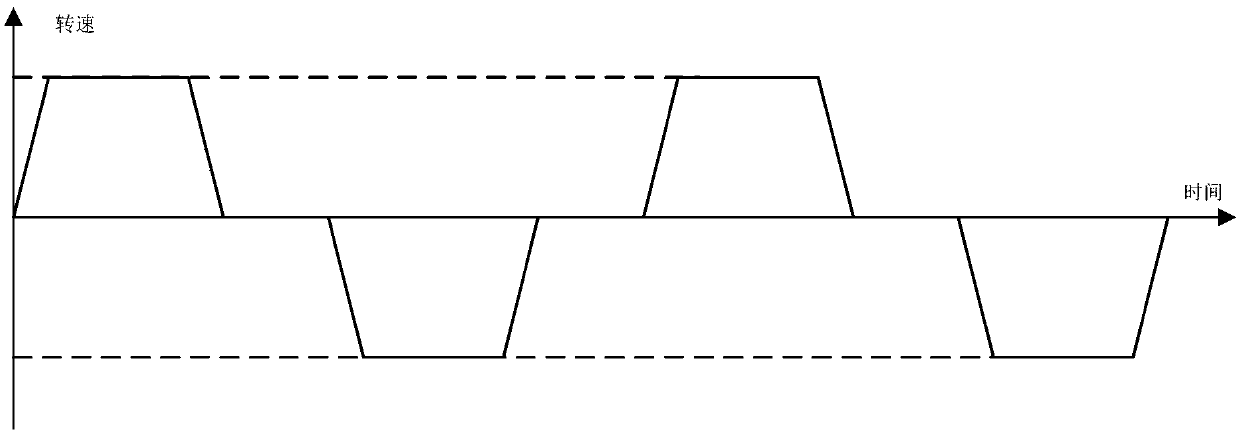

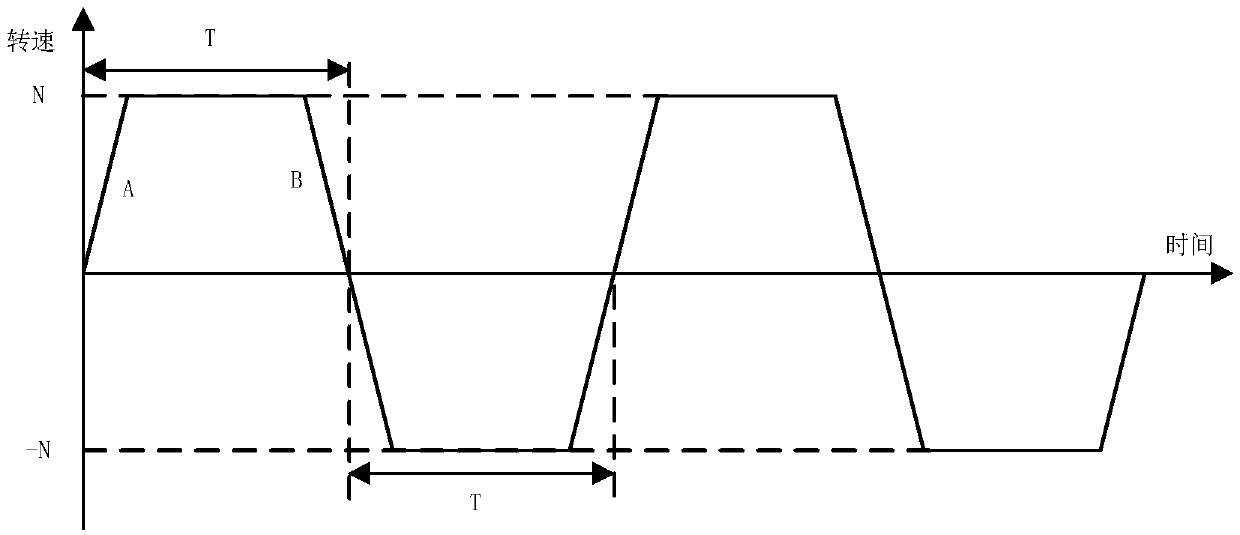

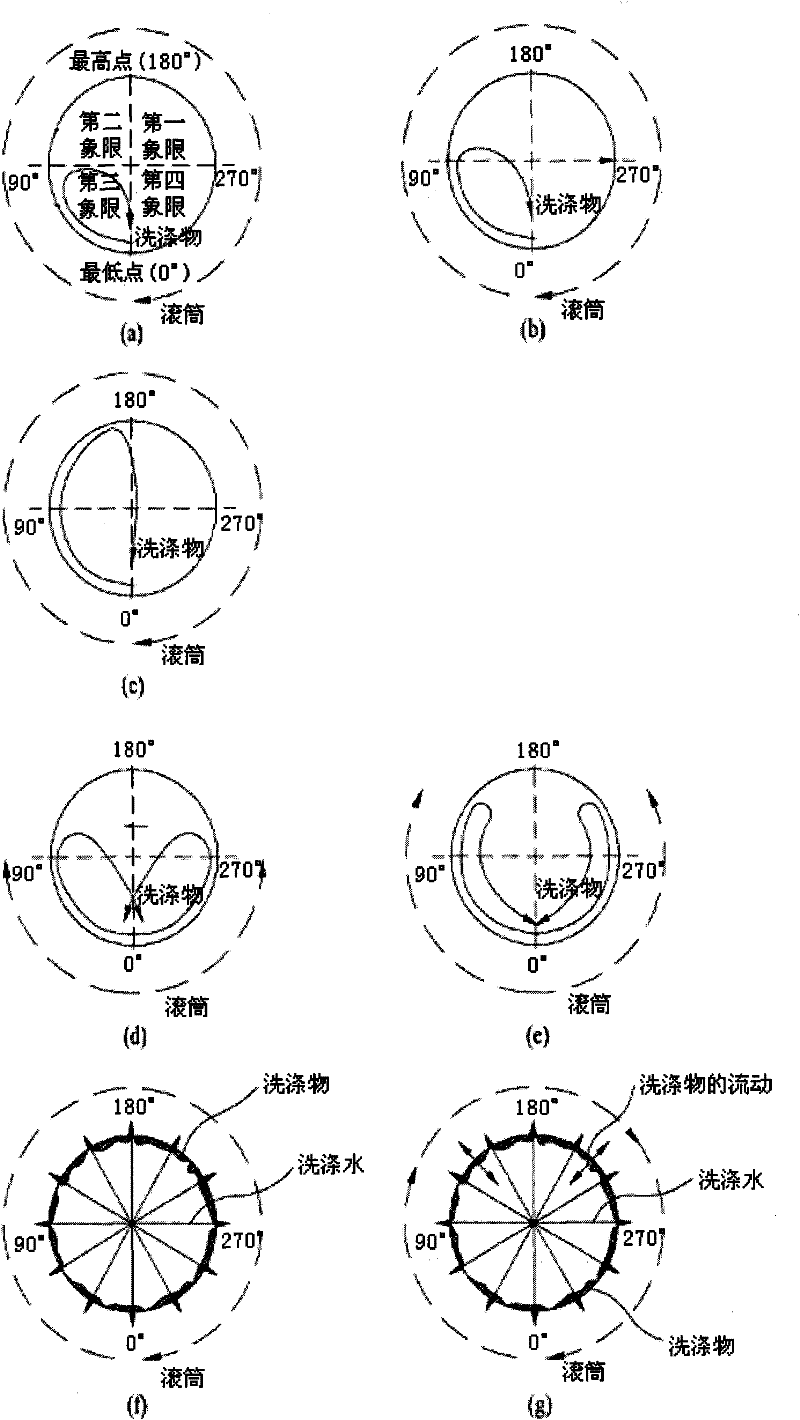

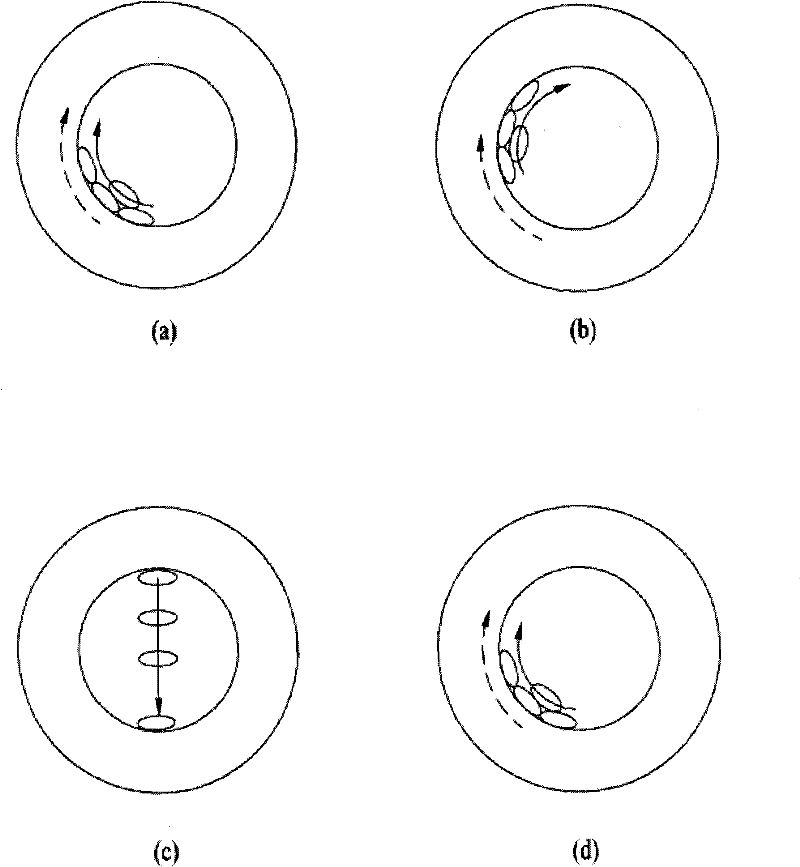

Control method of laundry device

InactiveCN101818433AImprove laundry efficiencyShorten laundry timeControl devices for washing apparatusWashing machine with receptaclesProcess engineering

The invention discloses a control method of a laundry device, more particularly relates to a control method of a laundry device, capable of diversifying the roller driven motion to achieve convenient use and meet the demand of various users. According to the invention, the control method of the laundry device includes: a washing stroke comprising a washing step of supplying the washing water for a washing tub or a roller to wash the washings and a draining step of discharging the washing water, characterized in that in the draining step, the roller driven motion for relapsing to performing the operation for lifting the washings and then falling down in the roller is performed.

Owner:NANJING LG PANDA APPLIANCES

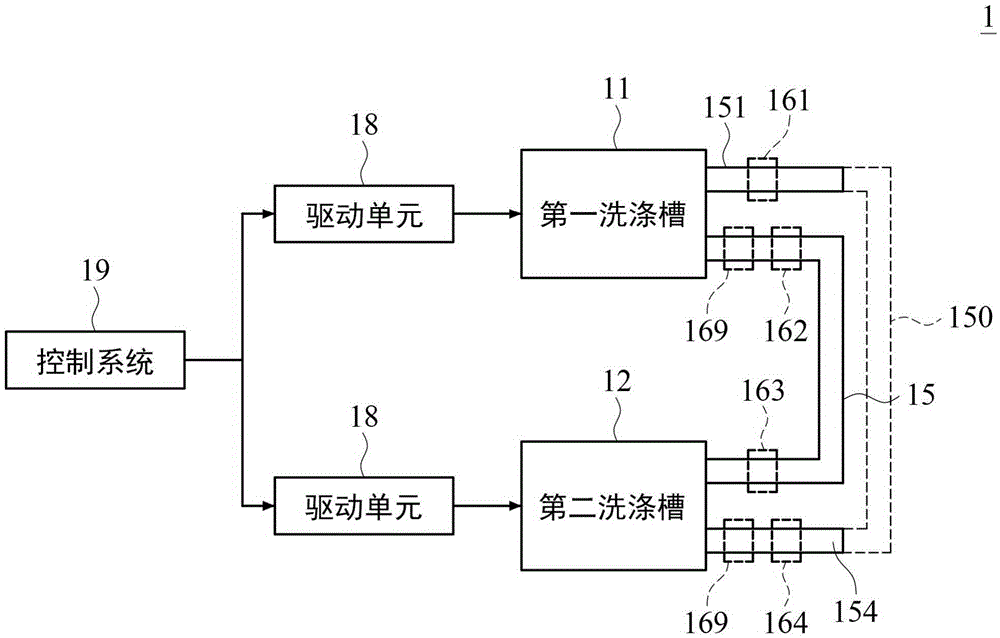

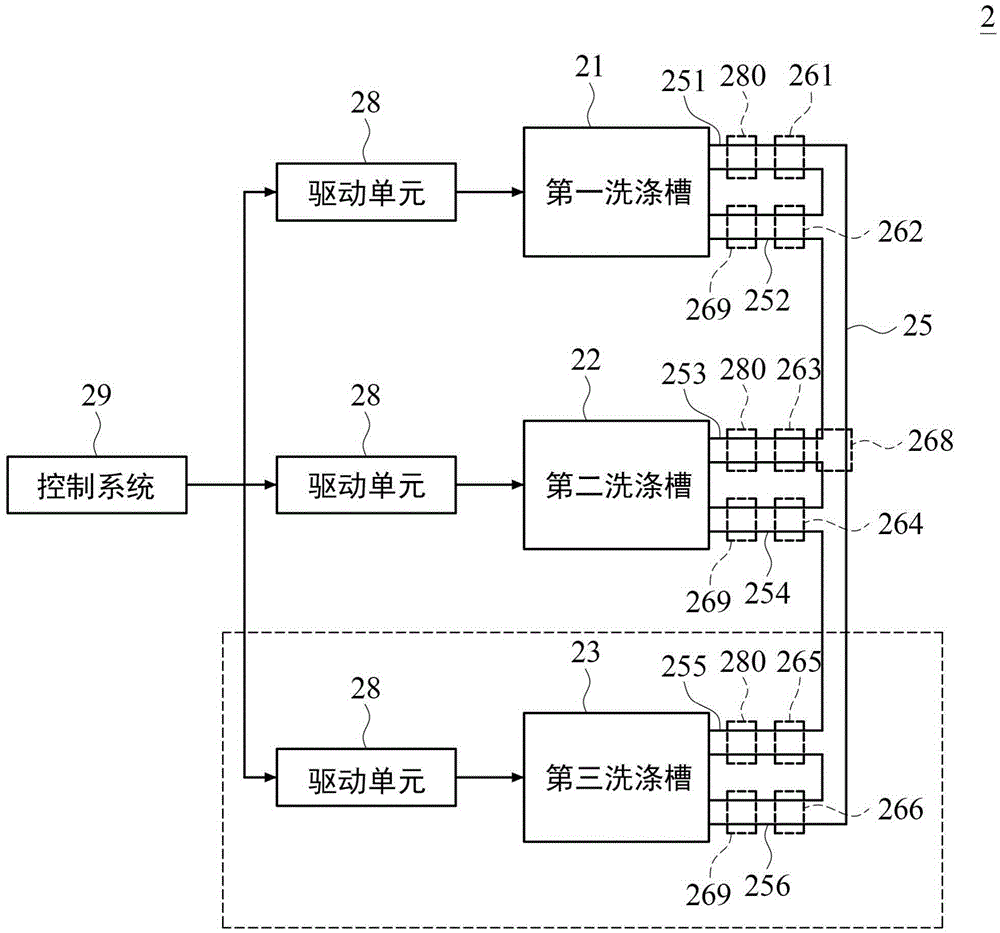

Multi-tank clothes washing device and method

InactiveCN105386272ASave spaceSave waterOther washing machinesTextiles and paperProcess engineeringLotion

The invention discloses a multi-tank clothes washing device and method. The multi-tank clothes washing device at least comprises two or more washing tanks, such as the first washing tank and the second washing tank. The method includes the steps that multiple washings are placed in the first washing tank and the second washing tank respectively, a washing medium is placed in the first washing tank, and a first washing procedure is started in the first washing tank. The washing medium used in the first washing tank can be partially or wholly drained and conveyed to be supplied to the second washing tank to be continuously used, a second washing procedure is completed, and finally the washing medium is drained outside. The washing medium can be recycled, so that the purposes of saving time, labor and space of washing equipment are achieved, and the environment-friendly effects of reducing lotion and reducing pollution are achieved.

Owner:周晓璇

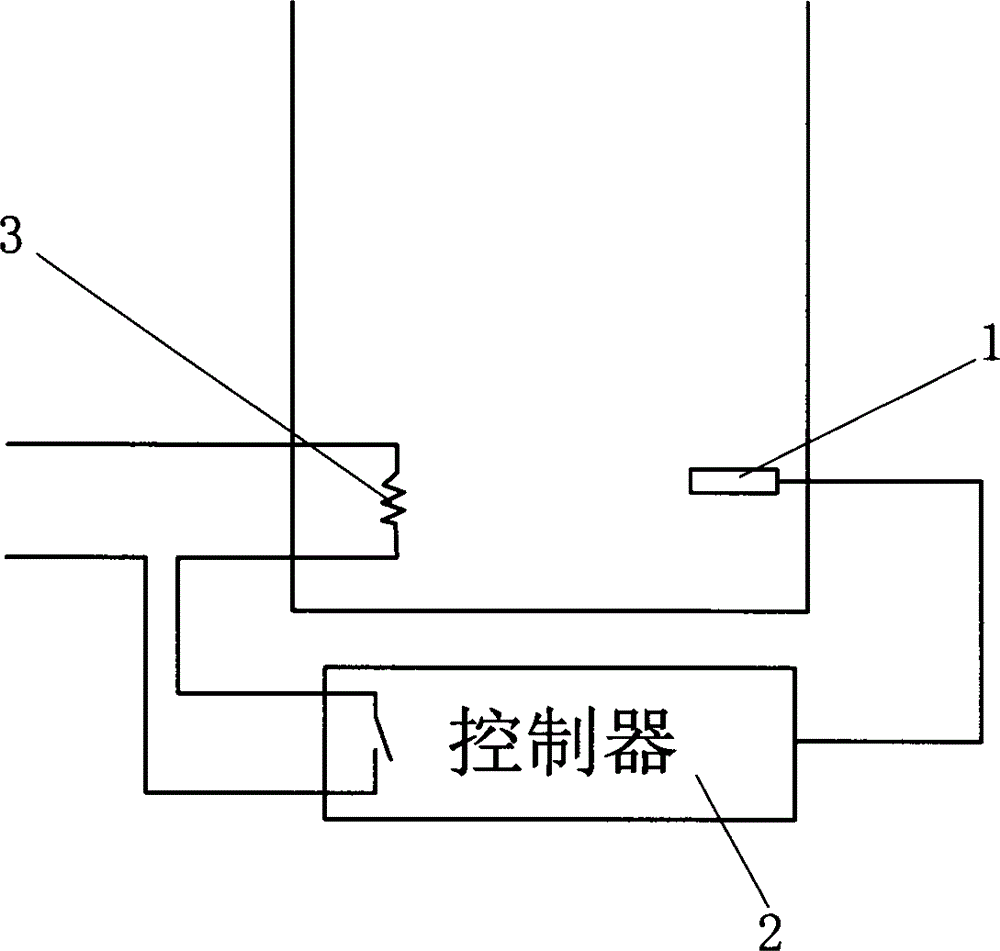

Cooperative control system and method for water consumption equipment and water heater

ActiveCN108572566AShorten laundry timeImprove user experienceFluid heatersProgramme control in sequence/logic controllersControl modeEngineering

The invention belongs to the technical field of household electrical appliances, and specifically relates to a cooperative control system and method for water consumption equipment and a water heater.The invention aims to solve a problem that the existing water heater is relatively single in control mode. To this end, the cooperative control method comprises the steps of obtaining a required temperature of the water consumption equipment before water flows into the water consumption equipment; obtaining a set temperature of the water heater before water flows into the water consumption equipment; and comparing the required temperature of the water consumption equipment with the set temperature of the water heater, and controlling the operation of the water consumption equipment and / or thewater heater according to the comparison result. Through the cooperative control for the water consumption equipment and the water heater, the cooperative control method avoids a problem of collisionamong multiple sets of water consumption equipment when using the water heater while meeting hot water utilization of the water consumption equipment through comparing the set temperature of the water heater with the required temperature of the water consumption equipment before water flows into the water consumption equipment.

Owner:上海海尔洗涤电器有限公司 +1

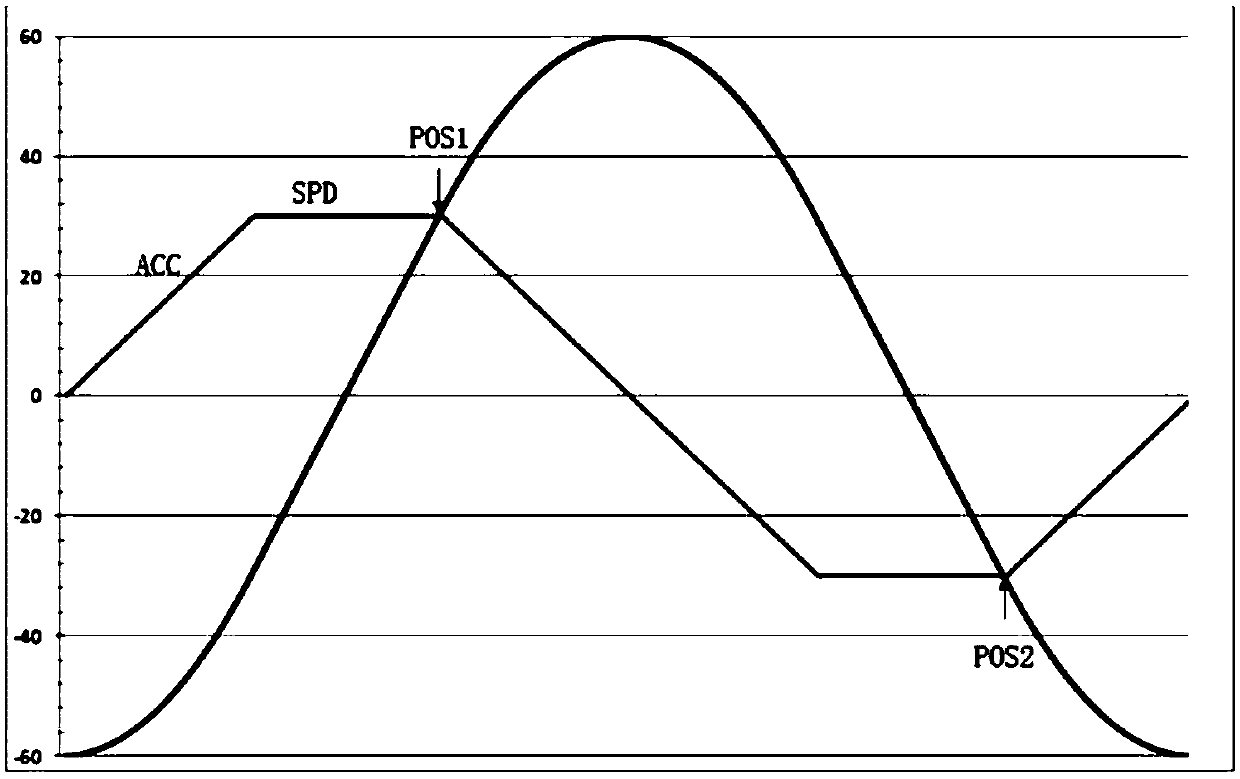

Drum washing machine, control method and control device of drum washing machine and computer readable storage medium

ActiveCN111118821AImprove uniformityPrevent sinkingControl devices for washing apparatusTextiles and paperLaundry washing machineControl engineering

The present invention provides a drum washing machine, a control method and control device of the drum washing machine and a computer readable storage medium. The control method comprises the following steps of controlling a motor to rotate; acquiring a maximum position [theta]max and a minimum position [theta]min of the motor or a drum in a cycle; and setting parameters [theta]1 and [theta]2 which meet the following equations respectively: [theta]1=[theta]1+[theta]-[theta]max and [theta]2=[theta]2-[theta]min, and returning to the step of controlling the motor to rotate, wherein [theta]1 on the left side of the equation [theta]1=[theta]1+[theta]-[theta]max and [theta]1 on the right side of the equation [theta]1=[theta]1+[theta]-[theta]max represent a first preset position in a next cycle of the one cycle and a first preset position in the one cycle respectively, [theta] is a maximum preset position of the motor or the drum, and [theta]2 on the left side of the equation [theta]2=[theta]2-[theta]min and [theta]2 on the right side of the equation [theta]2=[theta]2-[theta]min represent a second preset position in the next cycle of the one cycle and a second preset position in the one cycle. The control method provided by the invention can reduce abrasion to clothes.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

High-speed washing program of washer

InactiveCN1205373CEffective dissolutionQuick soakControl devices for washing apparatusTextiles and paperSoft waterWater flow

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Control method for laundry device

InactiveCN101812789BAvoid damageImprove washing efficiencyOther washing machinesControl devices for washing apparatusSpinsEngineering

This invention discloses a control method for laundry device, more concretelly relates to an easy used method for diversificating the drive actions of the roller, and meeting the required of varied users. The control method for laundry device according this invention includes the followed steps: Procedure 1: The user chooses the needed procedure from the multiple operation modes. Procedure 2: washing course. Procedure 3: cleaning course. Procedure 4: dehydrating course. Where, in order to untie the washing bag and dehydrate the clothing the cleaning course is performed through repeated spin motion in regular time and finished through stopped interval dehydrating course.

Owner:NANJING LG PANDA APPLIANCES

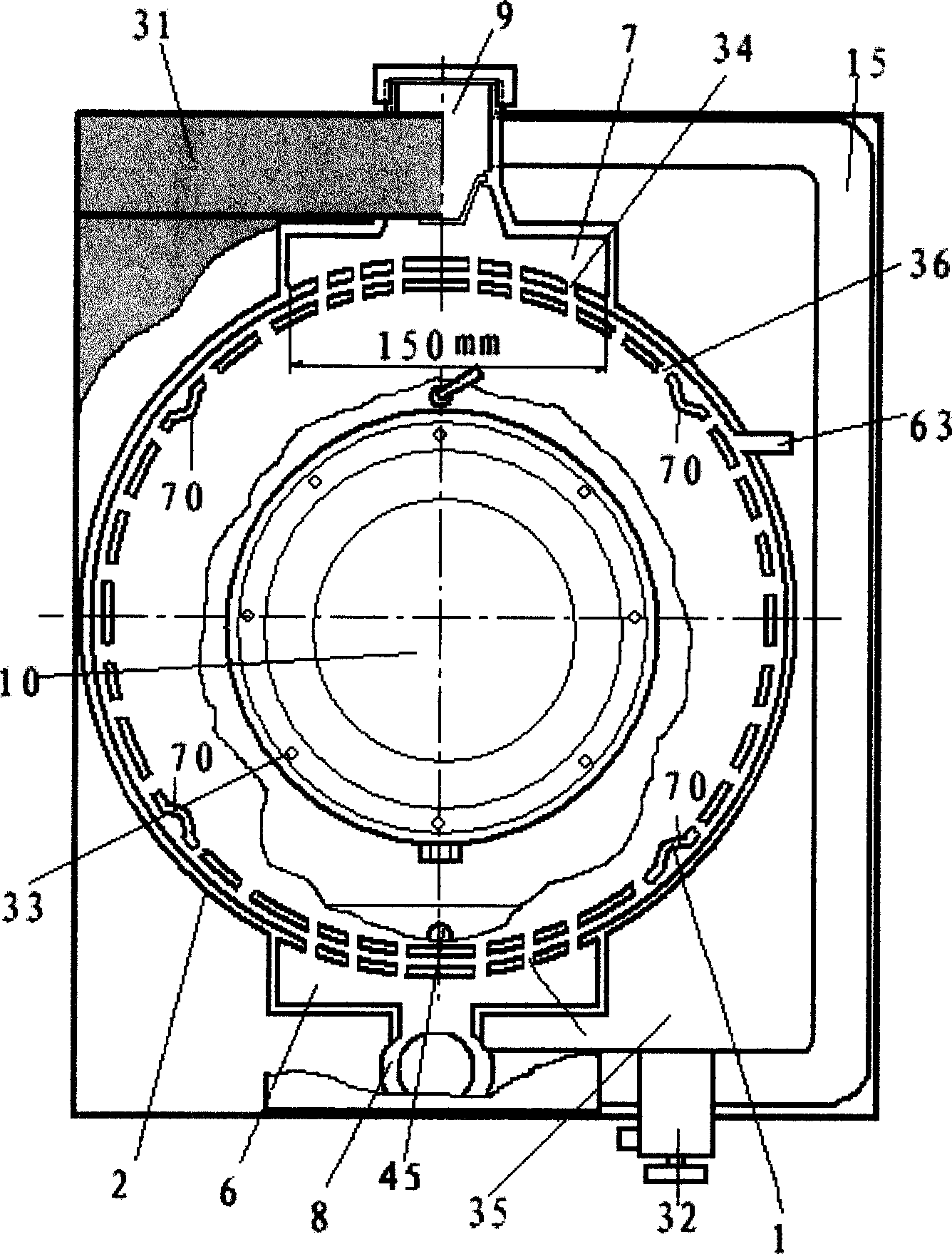

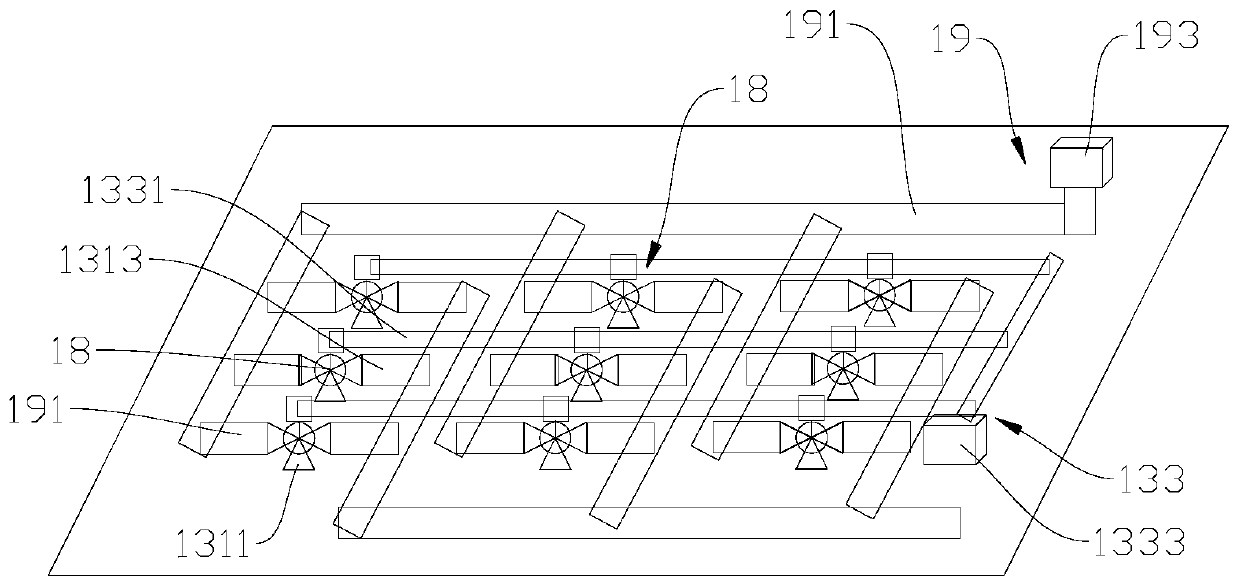

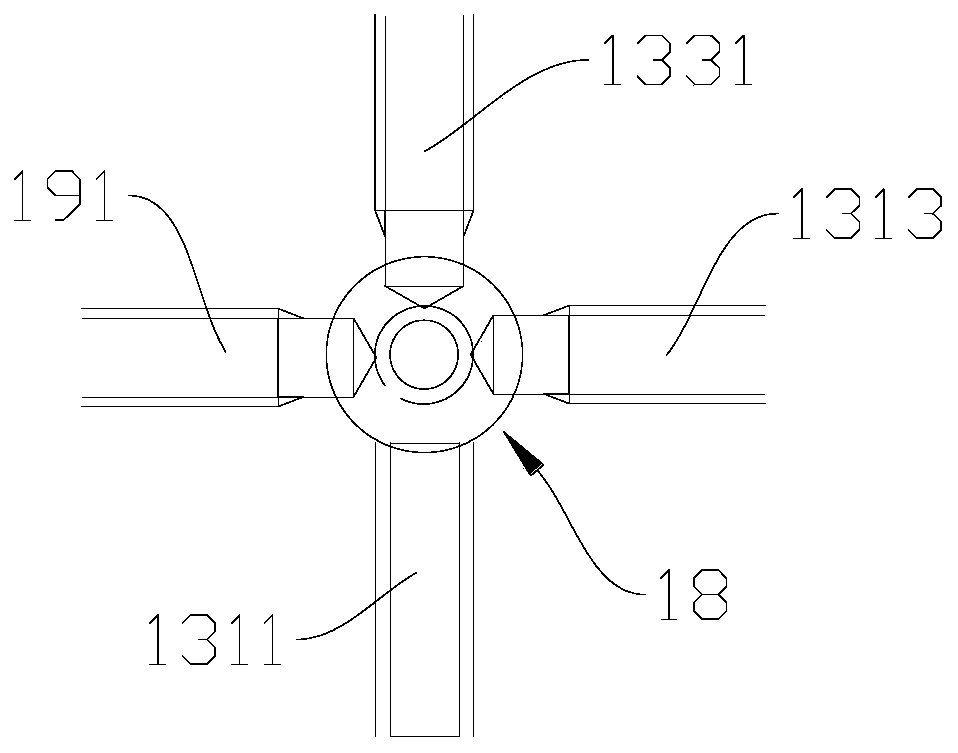

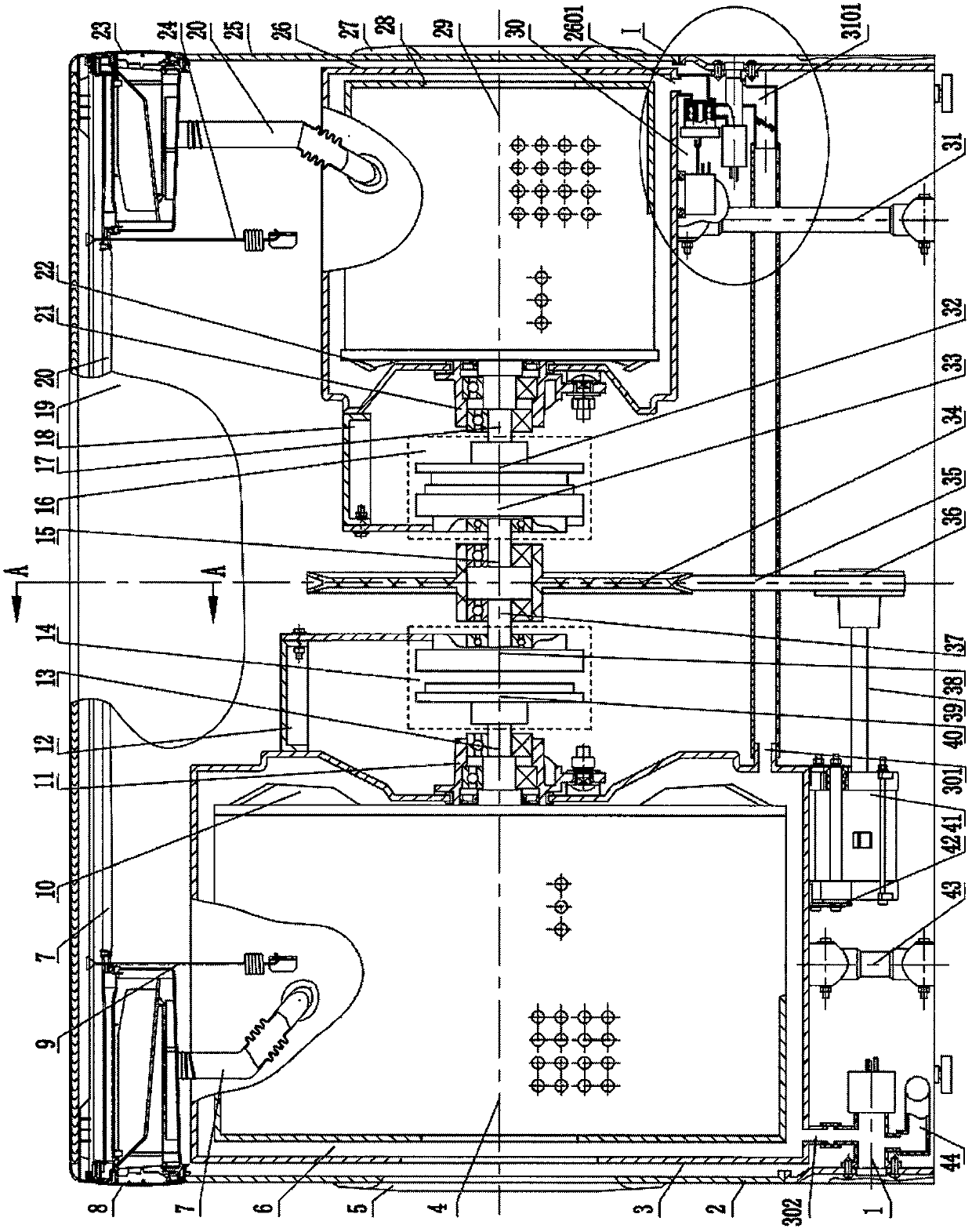

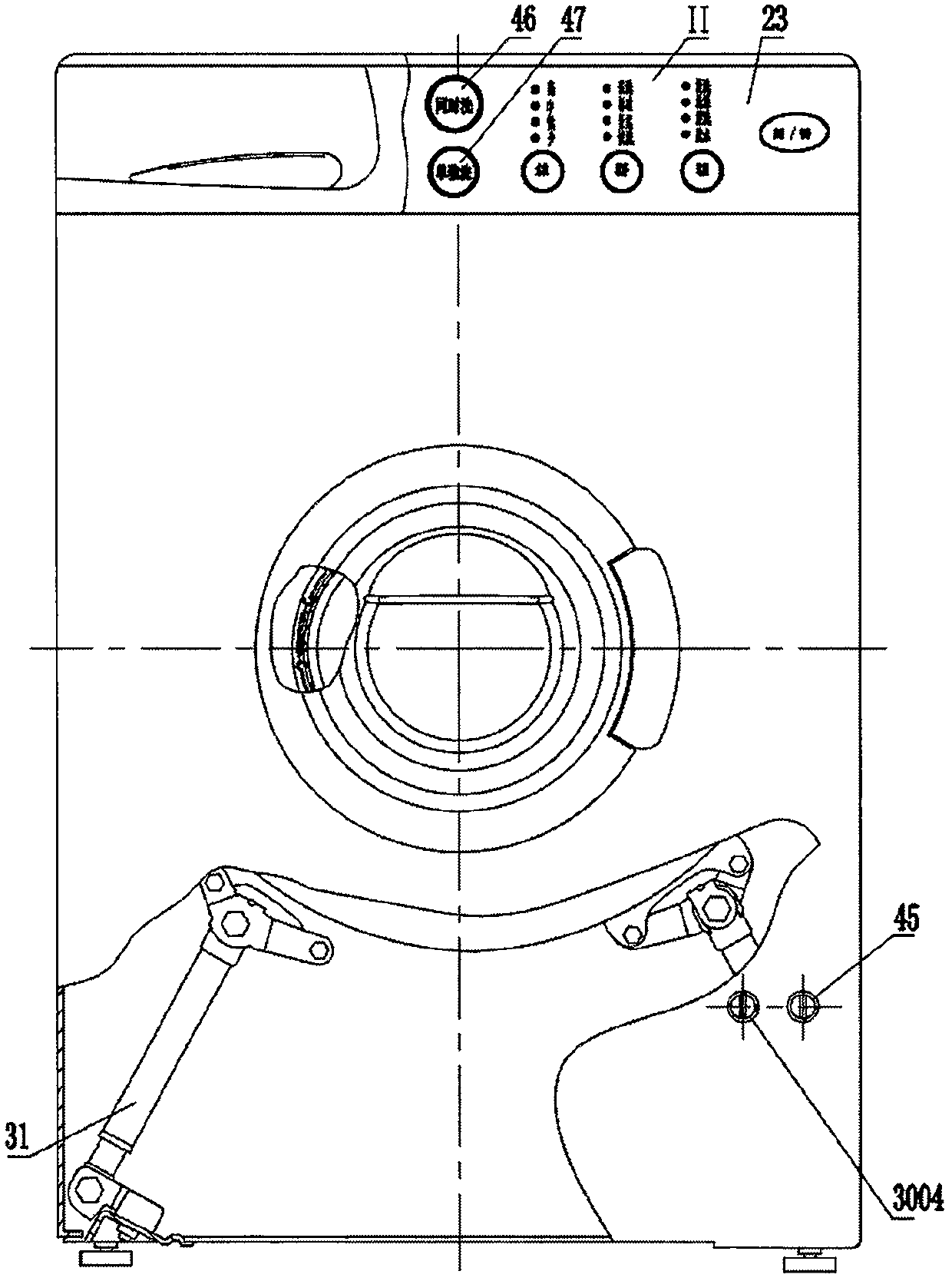

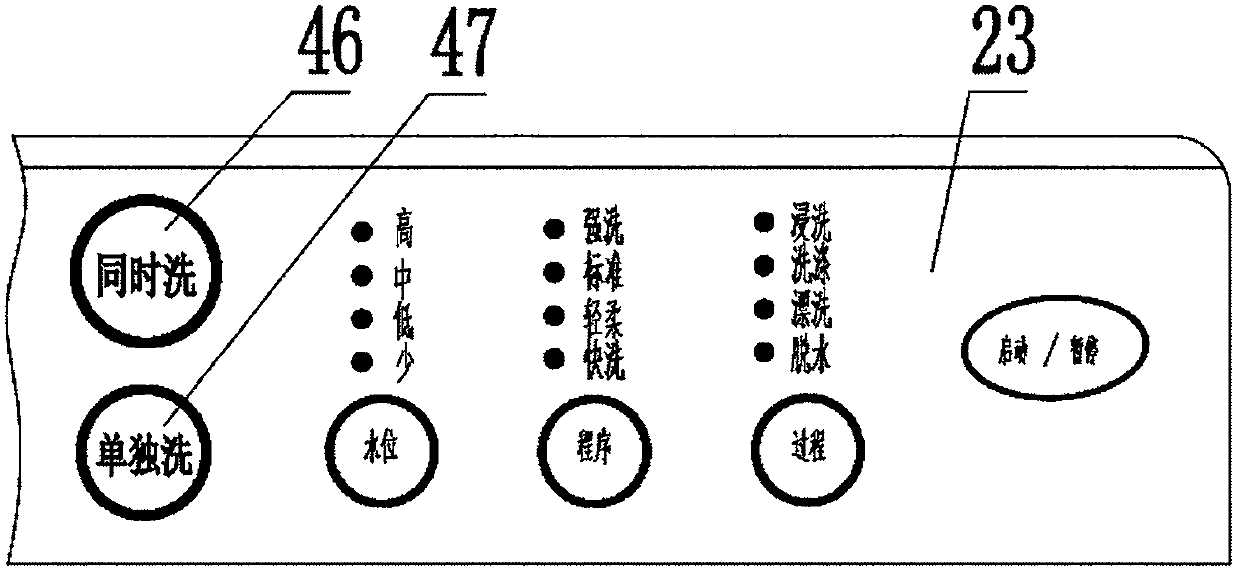

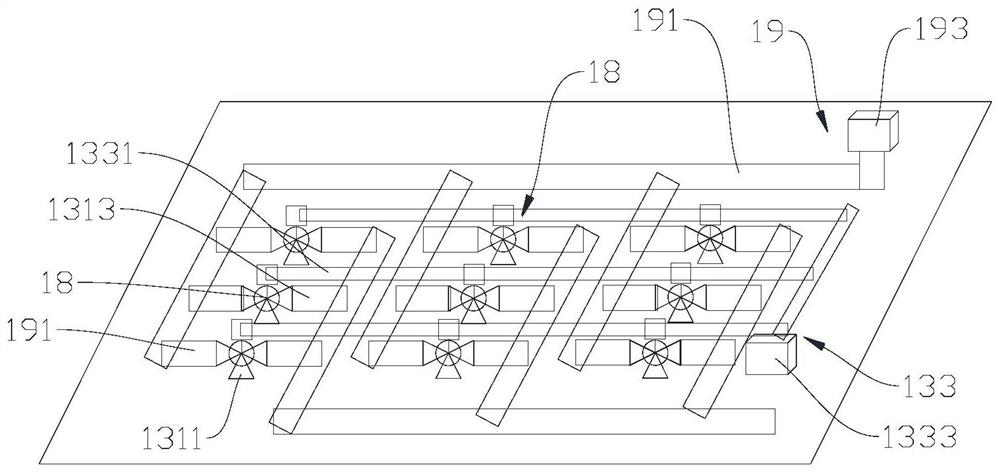

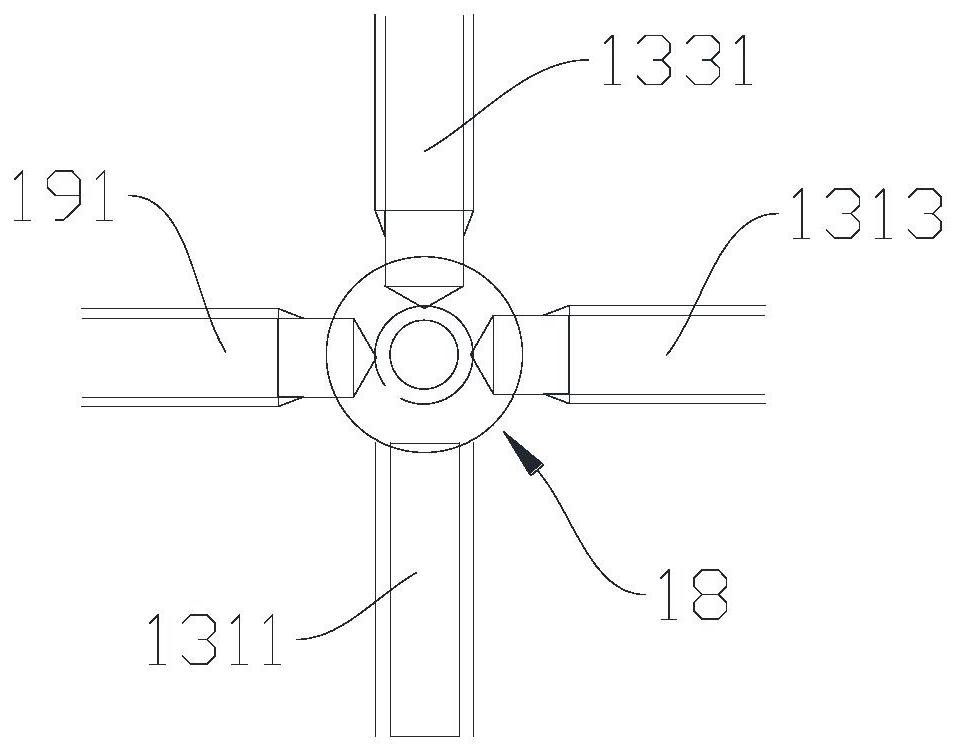

Roller washing machine with simultaneous washing function and method for implementing simultaneous washing

PendingCN107858807AReasonable structural designShorten laundry timeOther washing machinesControl devices for washing apparatusWater savingElectromagnetic clutch

The invention provides a roller washing machine with a simultaneous washing function and a method for implementing simultaneous washing. The roller washing machine comprises a tank body shell and a pair of inner and outer drum assembles. The two sides of the tank body shell are each provided with an operation panel and a front door cover. The operation panel and the front door cover are provided with a washing machine program controller and a glass bowl door respectively. The pair of inner and outer drum assembles are hung on a front upper beam and a rear upper beam of the tank body shell in aback-to-back mode. The lower portions of the inner and outer drum assembles are supported by supporting spring assemblies. A pair of electromagnetic clutches are fixedly installed on outer drums of the corresponding sides of the inner and outer drum assemblies respectively. The input ends of the electromagnetic clutches are each connected with a belt wheel transmission mechanism which can drive the corresponding electromagnetic clutch to rotate, and the output ends of the electromagnetic clutches are fixedly connected with inner drum assembly shafts of the corresponding sides of the inner andouter cylinder assemblies respectively. A water-saving drainage assembly is fixed to the outer drum of the corresponding side, and the input pipe opening and the output pipe opening of the water-saving drainage assembly are communicated with the water outlet and the water inlet of the outer drum of the corresponding side respectively. The roller washing machine is equivalent to two washing machines and simultaneously washes clothes, water produced when washing is completed in one machine is discharged into the other machine to be repeatedly used, under-clothes and outer clothes can be simultaneously and separately washed, and water and time are saved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Rubbing clothing sphere technology of washing machine

InactiveCN101509185AReduce energy consumptionDouble the efficiency and quality of laundryWashing apparatusTextiles and paperChemical reactionRotation function

A washing machine scrubbing ball technique is an updated prearranged physical laundry technique which is suitable for total popularization and application in the field of the washing machine and is closely related to laundry efficiency and quality of the washing machine; a technique for internally arranging the scrubbing ball in a washing box of the washing machine is to manufacture a round ball which has a diameter smaller than a horizontal radius of the washing box, which is free from toxic and side chemical reactions in overall material thereof and flexible in the texture of exterior and interior, which has a mass appreciably lighter or equal to the mass of clothes after entering the water, or which can be suspended in upper and middle aqueous layers, the surface of the ball can be or be similar with the material of rough flexible cloth fabrics in order to be liable to adhere to the clothes in the water upon the action, therefore, the ball is disposed within the water injection washing box to cooperate with the water-whirling rotation of auto-rotation functions of the washing machine so as to generate, by means of depending on and then applying the force, reverse resistance collisional friction on the washed clothes, thus forming the scrubbing washing on the washed clothes.

Owner:杨建忠

Full-automatic washing machine for removing fluff and suspended matters and washing method thereof

InactiveCN102493153AReduce wearShorten laundry timeOther washing machinesWashing machine with receptaclesUnit devicePulp and paper industry

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

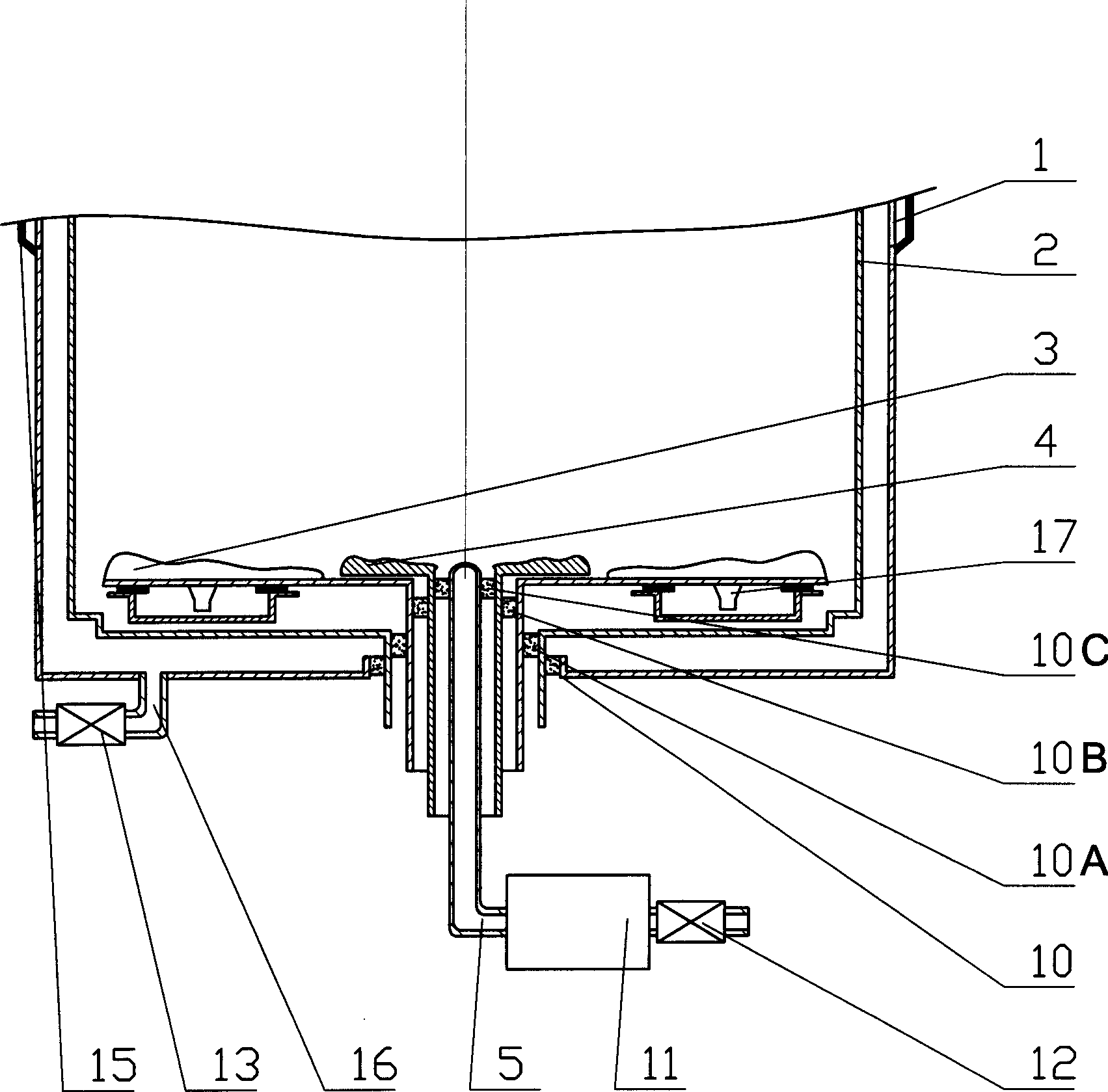

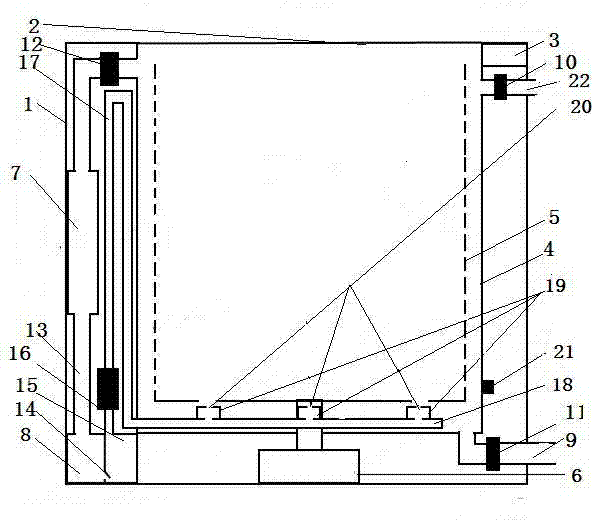

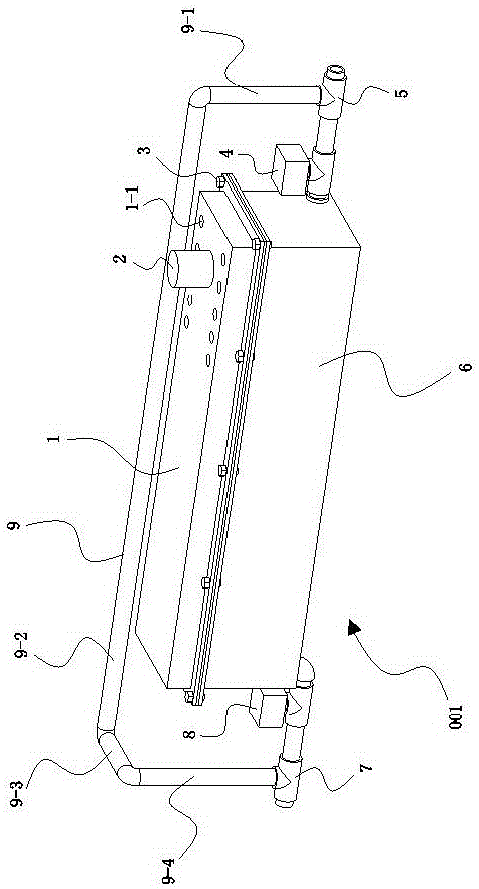

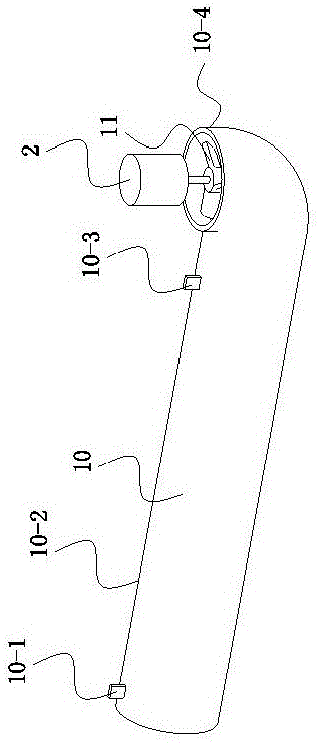

Water-saving washing machine

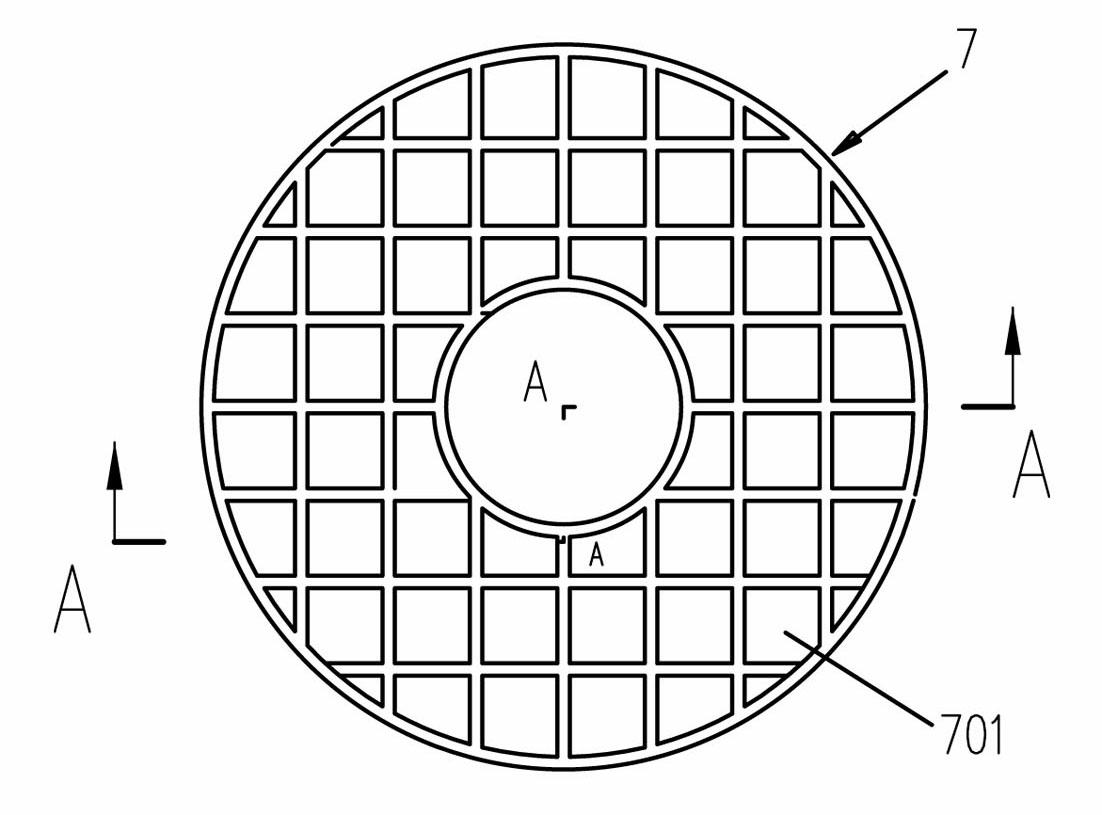

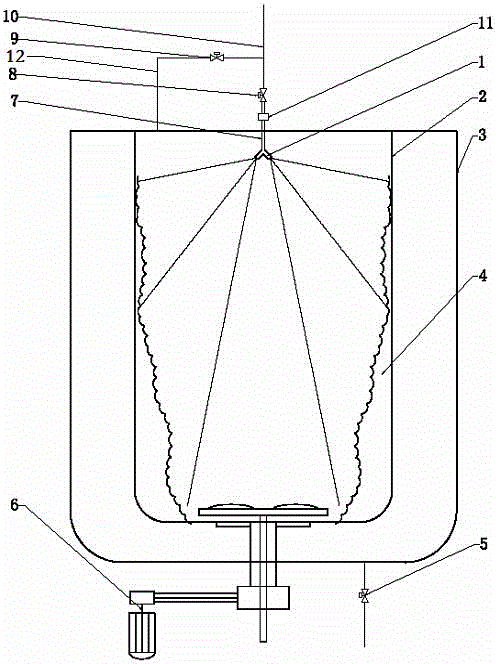

InactiveCN104372563ADoes not affect the washing effectReduce the amount of waterOther washing machinesWashing machine with receptaclesElectricityWater saving

The invention relates to a water-saving washing machine. The water-saving washing machine comprises a spray nozzle (1), an inner barrel (2), a rinsing water inlet pipe (7), a water inlet manifold (10) and a washing water inlet pipe (12). The water inlet manifold (10) is connected with the washing water inlet pipe (12) and the rinsing water inlet pipe (7). A rinsing water inlet valve (8) and a pressurization pump (11) are arranged on the rinsing water inlet pipe (7). The outlet end of the rinsing water inlet pipe (7) is connected with the spray nozzle (1). According to the water-saving washing machine, dirty water of clothes is washed away through circulating atomization and rinsing. Due to the fact that clothes are only wetted in each time of rinsing, the required water amount is small, the water amount required for the whole rinsing process is smaller than the water amount required for each time of rinsing of a traditional washing machine, the water consumption is greatly lowered, electricity is saved, and meanwhile the washing time can be effectively shortened.

Owner:荣先奎

Water temperature control method of cold and hot water double-inlet washing machine

InactiveCN102926170BPrecise water temperature controlImprove water temperature control abilityOther washing machinesControl devices for washing apparatusInlet valveEngineering

The invention relates to a water temperature control method of a cold and hot water double-inlet washing machine. The water temperature control method is characterized in that a cold water inlet valve and a hot water inlet valve are arranged and are constant-flow water inlet valves, wherein a temperature sensor is arranged in a washing bucket; a controller is used for setting fixed total water inlet time every time of the cold water inlet valve and the hot water inlet valve; the controller calculates a cold water inlet temperature and a hot water inlet temperature according to water temperatures in the washing bucket of the washing machine before and after adding water; then the controller calculates a ratio of desired inlet cold water to desired inlet hot water by using the known cold water inlet temperature, the hot water inlet temperature and the water temperatures in the washing bucket, and converts the ratio into a turn-on time ratio of the cold water inlet valve to the hot water inlet valve every time; and the controller controls the turn-on time of the cold water inlet valve and the hot water inlet valve so as to control the water temperature. According to the water temperature control method of a cold and hot water double-inlet washing machine, the accuracy of water temperature control of the cold and hot water double-inlet washing machine is improved, the washing degree of clothes is increased, the energy consumption is saved, and the washing time is shortened simultaneously.

Owner:WUXI LITTLE SWAN GENERAL APPLIANCE CO LTD

Drum washing machine

PendingCN110965265AGood washing effectReverse rotationOther washing machinesTextiles and paperRotational axisEngineering

The invention discloses a drum washing machine. The drum washing machine comprises an outer barrel, an inner barrel, a stirring component, a driving device, a transmission part, a connecting piece anda shifting assembly, wherein the inner barrel is arranged inside the outer barrel and the inner wall of the inner barrel is provided with a lifting rib; the stirring component is rotationally arranged on the rear wall of the inner barrel; the driving device is in transmission connection with the stirring component through a rotating shaft; the transmission part is fixed on a mounting frame and matched with the rotating shaft and a main shaft connected with the inner barrel, can do reverse rotation opposite to rotation of the rotating shaft when the rotating shaft rotates, and rotates in the same direction as the main shaft; the connecting piece is in sliding connection with the mounting frame; the shifting assembly is matched with the connecting piece; when the shifting assembly applies force to the connecting piece, the connecting piece can be separated from the driving device and the driving device can drive the stirring component to rotate for driving the inner barrel to rotate reversely; and when the connecting piece is connected with the driving device, the driving device can drive the stirring component and the inner barrel to rotate in the same direction through self rotation. By means of the washing machine, the problem of the poor washing effect of an existing drum washing machine is solved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Washing machine and water treatment system using same

InactiveCN101736549BAvoid pollutionReduce loadOther washing machinesEnergy based wastewater treatmentWater treatment systemEngineering

The invention relates to a washing machine and a water treatment system using the washing machine. The washing machine comprises an external drum, an internal drum arranged in the external drum, and a thumb wheel arranged in the internal drum, wherein the thumb wheel is driven by a main motor, and an output shaft of the main motor is connected with the external drum and the internal drum through an electronic clutch; the internal drum comprises at least two pairs of elastic valve bodies and non-elastic valve bodies which are connected together in turn to form a drum body, and through holes which are only opened when the washing machine performs a dewatering process are distributed on wall bodies of the non-elastic valve bodies; each non-elastic valve body is distributed along the outer edge of the thumb wheel and is connected with a connecting rod which is used for controlling the radial displacement of the non-elastic body, and the connecting rod is connected with a driving mechanism; when the washing machine performs a washing process and a rinsing process, along with the rotation of the thumb wheel, the driving mechanism controls each non-elastic valve body to perform quick radial reciprocating displacement through the connecting rod; and when the washing machine performs the dewatering process, along with the rotations of the external drum and the internal drum, the driving mechanism controls each non-elastic valve body to extrude towards the center of the thumb wheel through the connecting rod and releases each non-elastic valve body until the dewatering process is finished. The washing machine can knead and rub clothes in the washing and rinsing processes and can perform dewatering with extruding force in the high-speed rotary dewatering process.

Owner:南通贺禧机械设备贸易有限公司

A kind of washing machine and washing method

ActiveCN110670294BReduce weightAvoid noiseOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention relates to the technical field of household appliances, in particular to a washing machine and a clothes washing method. The washing machine comprises a clothes container for containingclothes, a spraying device for washing clothes by spraying, and a control device; the control device controls the spraying device to drive a pressure jetting device to jet a high-pressure water flow to to-be-washed clothes placed in the clothes container, and thus, the clothes can be cleaned effectively through the high-pressure water flow, time for washing is shortened, noise generated by a motored drum can be avoided, and dirt hiding between the outer tub and the inner tub in use of the conventional drum washing machines can be prevented effectively; further, the clothes in the clothes container can be washed in a targeted manner, bacterial cross-infection between different clothes caused in mixing of washing of the conventional washing machine and staining of other clothes due to easy-to-fade clothes are both avoided effectively; arrangement of weights is omitted, so that the washing machine is light, and is convenient to move and transport, and the like.

Owner:GREE ELECTRIC APPLIANCES INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com