Full-automatic washing machine for removing fluff and suspended matters and washing method thereof

A fully automatic washing machine and suspended matter technology, which is applied to washing machines with containers, other washing machines, washing machine appliances, etc., can solve the problems of unclean rinsing and adhesion on the clothes, so as to reduce the washing time, reduce the wear and tear of clothes, and reduce the wear and tear of clothes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

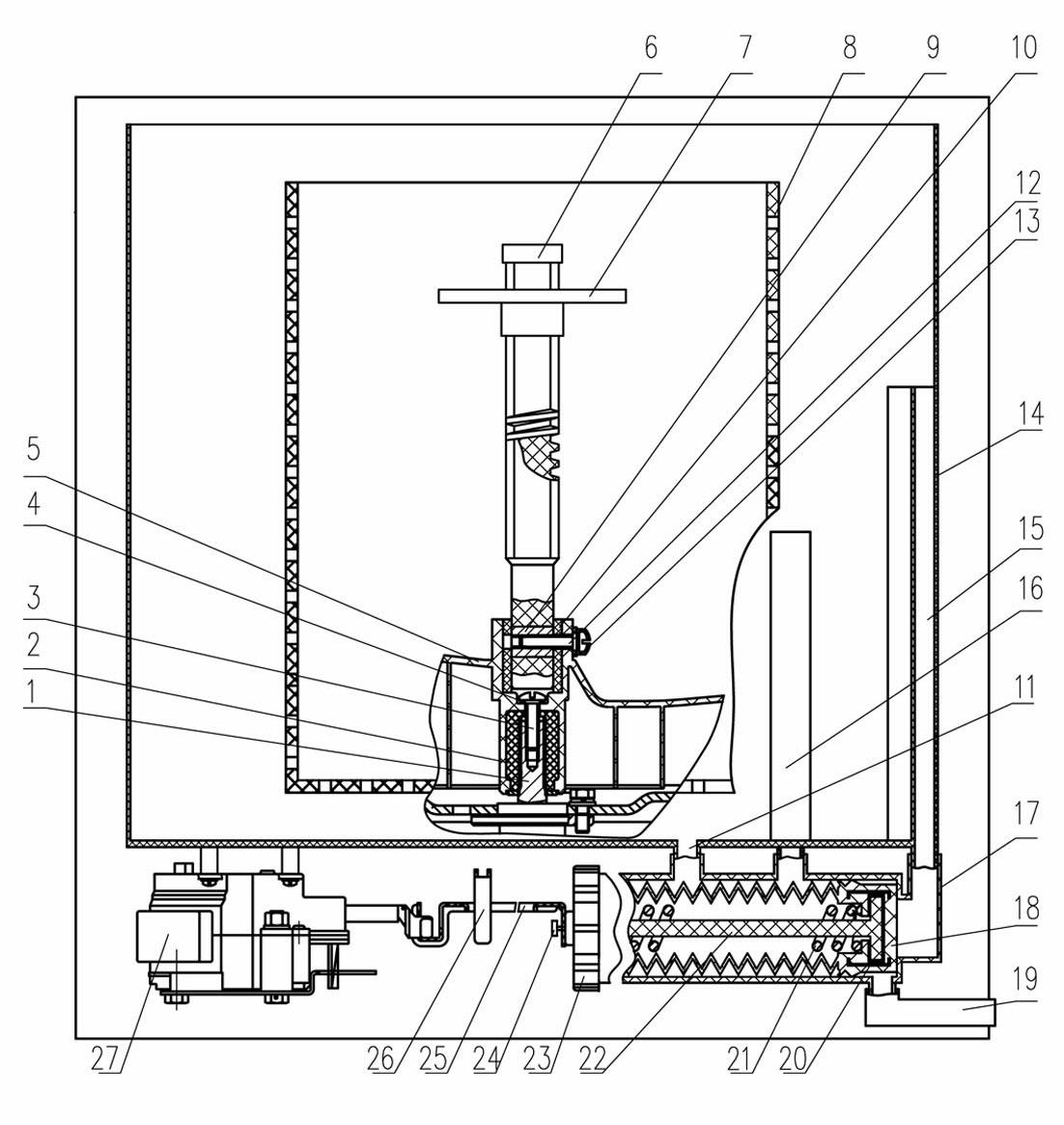

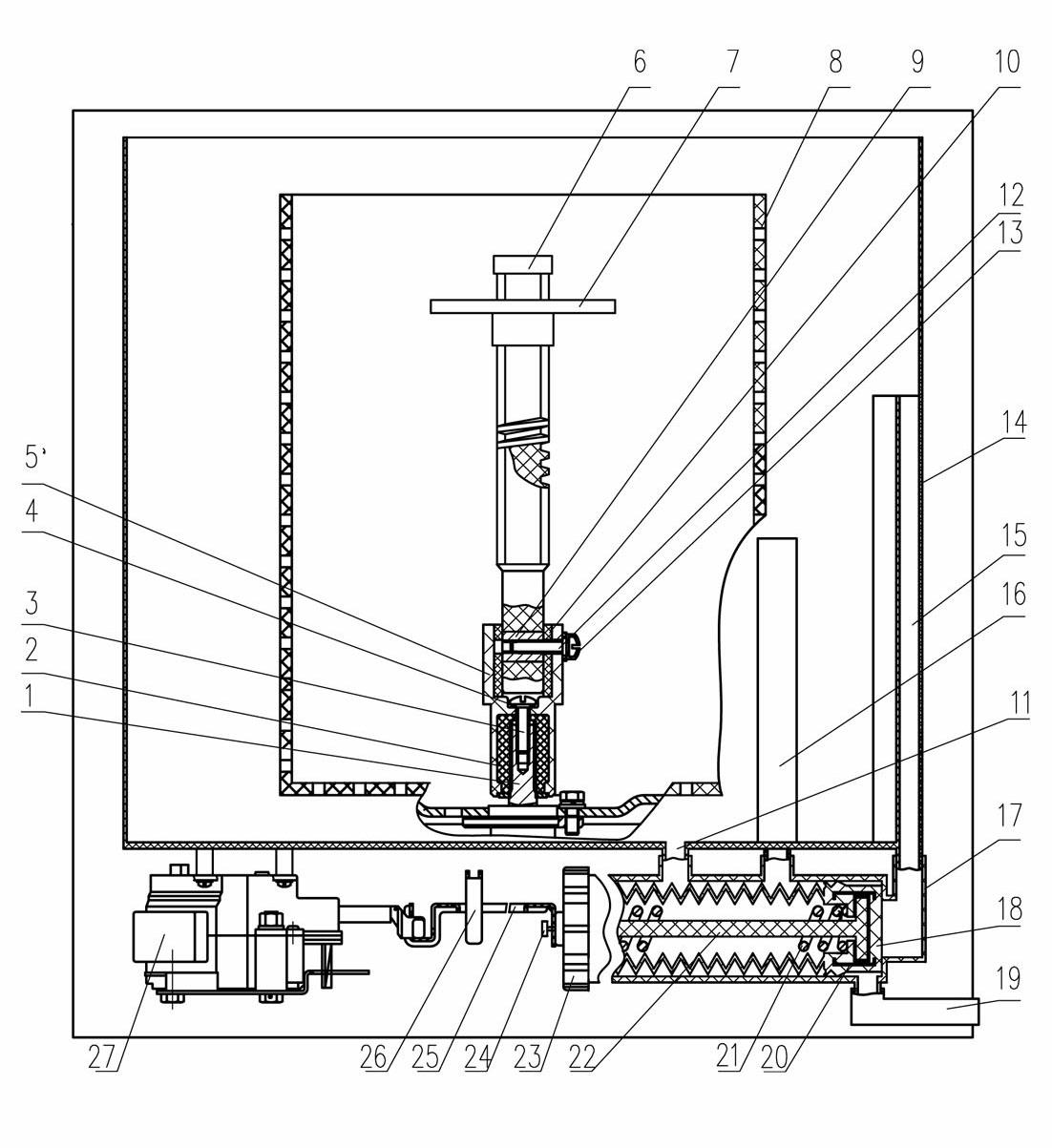

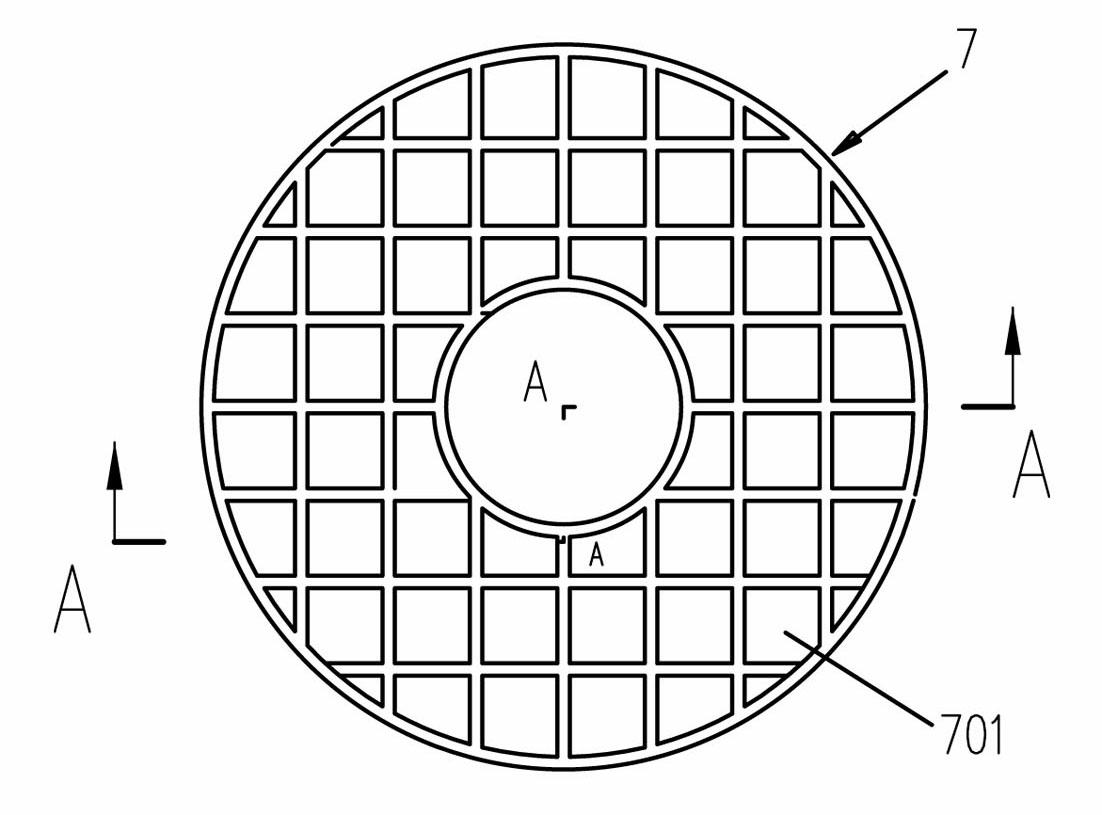

[0031] The fully automatic washing machine for removing fluff and suspended matter of the present invention is innovatively manufactured based on the basic structure of a pulsator-type fully automatic washing machine, and includes a body of a pulsator-type fully automatic washing machine with an inner dehydration drum 8 and an outer tub 14 with inner dehydration At the center of the cylinder 8 there is a pulsator 5 fixed on the clutch pulsator shaft 1 and rotating with it (see figure 1 ), or there is a clutch pulsator shaft 1 directly at the center of the inner dewatering drum 8 without a pulsator (see figure 2 ), the bottom of the outer bucket is provided with a drainage port 11; the inventive point of the present invention is to provide an squeezing unit device, the squeezing unit device includes a fixed connection with the clutch pulsator shaft 1 through the pulsator 5 or the connecting sleeve 5' And the synchronously rotating central screw 6, a screw nut disk 7 is sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com