Drum washing machine

The technology of a drum washing machine and an inner drum is applied to other washing machines, washing devices, textiles and paper making, etc., which can solve the problems of poor washing effect and long time for washing, and achieve the effect of good washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

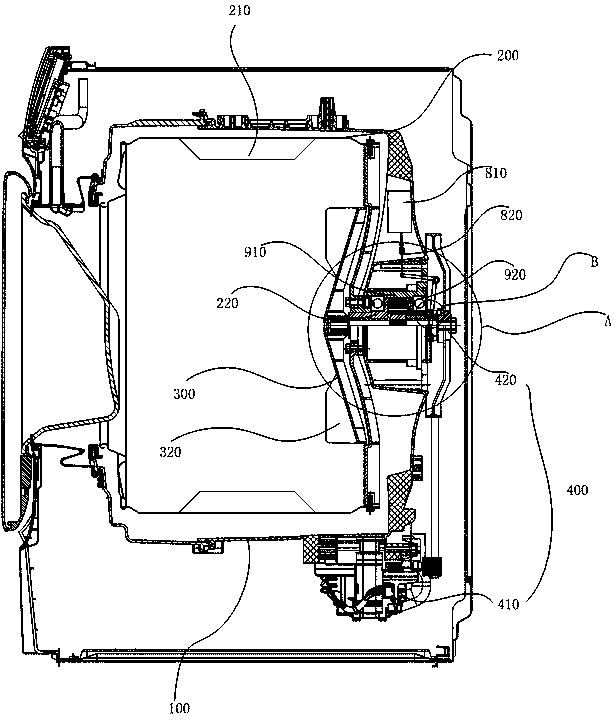

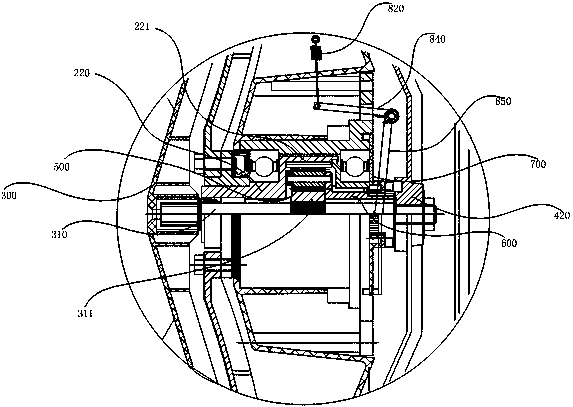

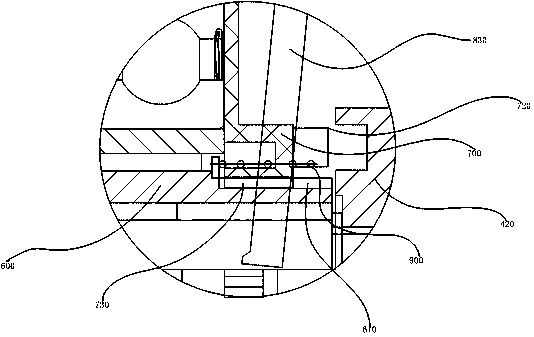

[0051] The present invention provides an embodiment of a drum washing machine, referring to Figure 1-Figure 5 As shown, it includes:

[0052] The outer cylinder 100 is fixedly connected with the machine body and is used to store washing water. A water inlet is provided on the wall of the outer cylinder 100. When washing, water enters the outer cylinder 100 through the water inlet on the wall of the outer cylinder 100;

[0053]The inner cylinder 200 has a storage space for storing clothes formed inside it, and a lifting rib 210 is provided on the inner wall of the inner cylinder 200, and the inner cylinder 200 can be aligned through the lifting rib 210 on the wall of the inner cylinder 200 when the inner cylinder 200 rotates. The washing function of the clothes inside the cylinder 200 is arranged inside the outer cylinder 100, a space for placing washing water is formed between the outer cylinder 100 and the inner cylinder 200, and a water inlet hole is provided on the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com