Wet type low-VOC high-durability sofa furniture polyurethane synthetic leather and preparation method thereof

A durable, polyurethane technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of difficult to effectively control the VOC content of finished leather, affect the appearance and use, and be difficult to meet, and achieve good washing effect. The effect of reducing solvent output and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

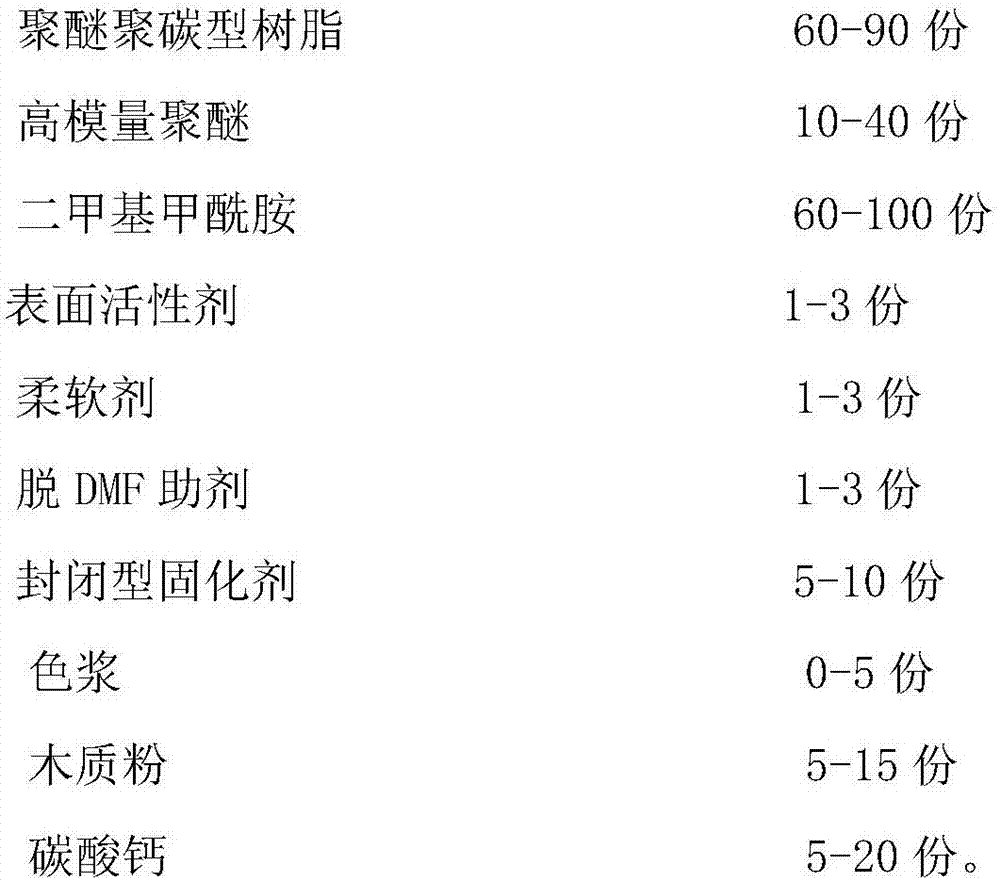

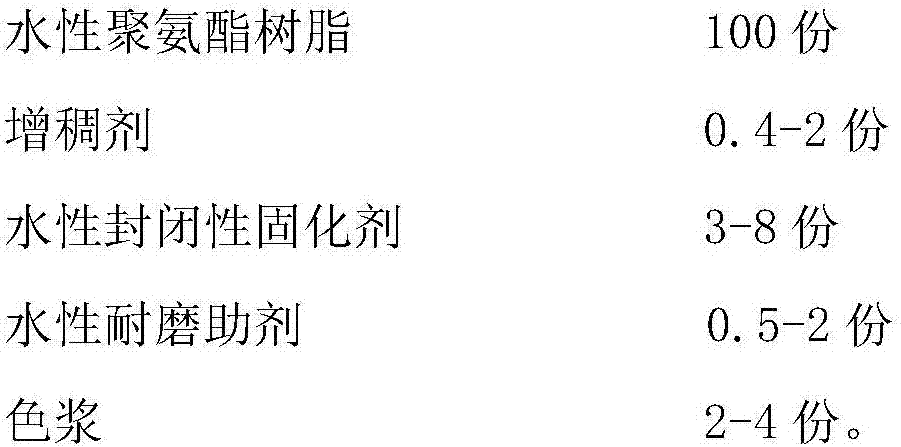

Method used

Image

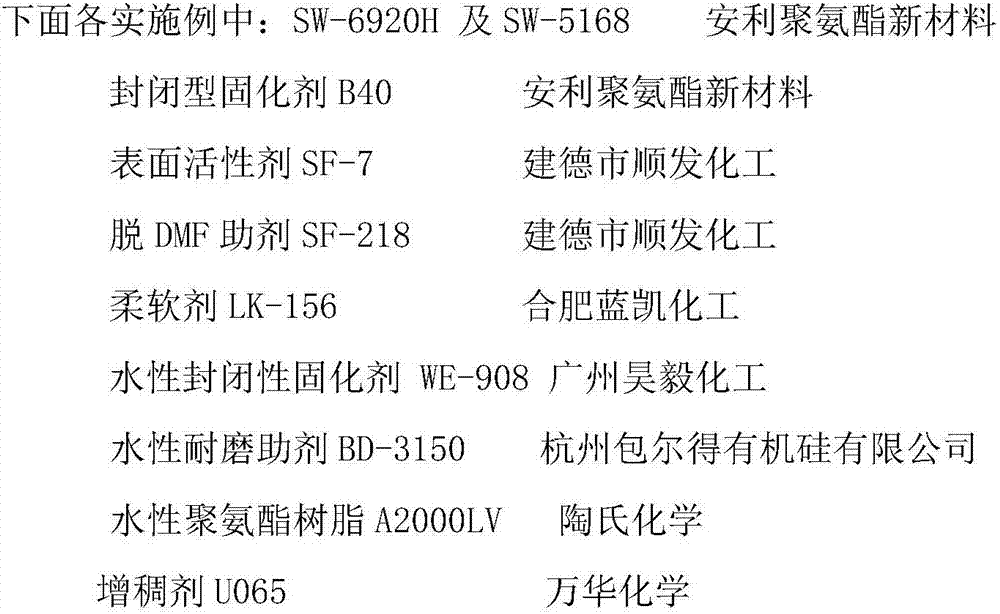

Examples

Embodiment 1

[0028] A method for preparing polyurethane synthetic leather for wet-process low-VOC high-durability sofa furniture, comprising the following steps:

[0029] (1) Select the thick 0.65mm polyester viscose double-sided raised cloth as the cloth base, first place the cloth base in a surfactant aqueous solution with a mass concentration of 1-3% for impregnation pretreatment, and then squeeze and iron to obtain pre-processing the cloth base;

[0030] (2) Coating wet-process polyurethane slurry on the surface of the pre-treated cloth base, and then condensing-washing-pre-drying-drying to obtain wet-fabric base; the thickness of wet-fabric base is 0.9mm; pre-drying adopts a length of 50m Vertical "double S" type pre-drying structure, the pre-drying temperature is 100°C; the drying is heated at 150°C by an oven with a length of 30m.

[0031] (3) Use two-component water-based polyurethane resin to carry out reverse roller coating treatment process on wet bass, and the glue amount is 1...

Embodiment 2

[0038] A method for preparing polyurethane synthetic leather for sofa furniture with low VOC and high durability by wet method, comprising the following steps:

[0039] (1) Select the thick 0.65mm polyester viscose double-sided raised cloth as the cloth base, first place the cloth base in a surfactant aqueous solution with a mass concentration of 1-3% for impregnation pretreatment, and then squeeze and iron to obtain pre-processing the cloth base;

[0040] (2) Coating wet-process polyurethane slurry on the surface of the pre-treated cloth base, and then condensing-washing-pre-drying-drying to obtain wet-fabric base; the thickness of wet-fabric base is 0.93mm; pre-drying adopts a length of 50m Vertical "double S" type pre-drying structure, the pre-drying temperature is 110°C; the drying is heated at 140°C by an oven with a length of 30m.

[0041] (3) Use two-component water-based polyurethane resin to carry out reverse roller coating treatment process on wet bass, and the glue...

Embodiment 3

[0048] A method for preparing polyurethane synthetic leather for sofa furniture with low VOC and high durability by wet method, comprising the following steps:

[0049] (1) Select the thick 0.65mm polyester viscose double-sided raised cloth as the cloth base, first place the cloth base in a surfactant aqueous solution with a mass concentration of 1-3% for impregnation pretreatment, and then squeeze and iron to obtain pre-processing the cloth base;

[0050] (2) Coating wet-process polyurethane slurry on the surface of the pre-treated cloth base, and then condensing-washing-pre-drying-drying to obtain wet-fabric base; the thickness of wet-fabric base is 0.87mm; pre-drying adopts a 50m length Vertical "double S" type pre-drying structure, the pre-drying temperature is 105°C; the drying is heated at 145°C by an oven with a length of 30m.

[0051] (3) Use two-component water-based polyurethane resin to carry out reverse roller coating treatment process on wet bass, and the glue am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com