Patents

Literature

60results about How to "Breathable with" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-permeable seepage-proof sand and sand-based planting tank using same

The invention discloses air-permeable seepage-proof sand and a sand-based planting tank using the same, belonging to the field of a crop planting tank. The air-permeable seepage-proof sand provided by the invention consists of a plurality of crude sand particles, seepage-proof resin and an adhesive, wherein the volume ratio of the crude sand particles to the seepage-proof resin to the adhesive is 200:(8-20):(5-15). The sand-based planting tank provided by the invention comprises a plurality of air-permeable seepage-proof sand plates which form a groove-like container in a surrounding manner, wherein each air-permeable seepage-proof sand plate comprises air-permeable seepage-proof sand, an adhesive and a solidifying agent, and the volume ratio of the air-permeable seepage-proof sand to the adhesive to the solidifying agent is (4-6):(3-4):(1-2). The air-permeable seepage-proof sand and the sand-based planting tank provided by the invention have the advantages of air permeability, seepage prevention, water and fertilizer retention, and long service life.

Owner:BEIJING RECHSAND SCI & TECH GRP

Air-permeable sound-permeable waterproof membrane

PendingCN109203623ASolve layeringPrevent impregnationSynthetic resin layered productsMetal layered productsEngineeringWater pressure

The invention provides an air-permeable sound-permeable waterproof membrane. The air-permeable sound-permeable waterproof membrane comprises a shell and further comprises a pressure plate and a waterproof air-permeable membrane assembly mounted in the shell, wherein the shell is provided with a first through hole; the pressure plate and the part, where the first through hole is arranged, of the shell form a closed area; the pressure plate is hermetically connected with the shell; the pressure plate is provided with a second through hole; the second through hole is arranged at a position corresponding to the position of the first through hole, and the two through holes communicate with each other; the waterproof air-permeable membrane assembly is installed in the closed area, and is closely attached to and fixedly connected with both the shell and the pressure plate; the waterproof air-permeable membrane assembly comprises a waterproof air-permeable membrane; and the waterproof air-permeable membrane is the only member that blocks the communication between the first through hole and the second through hole. The air-permeable sound-permeable waterproof membrane of the invention hasgood water resistance and can resist water pressure of 1 to 70 meters; and when the air-permeable sound-permeable waterproof membrane cooperates with an intelligent hardware shell structure, a part using the membrane has water resistance, air permeability and sound permeability.

Owner:崔福文

Method for producing waterproof moisture permeable fabric

The invention discloses a method for producing a waterproof moisture permeable fabric with functions of moisture permeating and water proofing, which comprises the following steps: firstly, soaking a fabric into a soaking groove filled with Teflon waterproof agent for 1 to 2 minutes, and then drying and baking the soaked fabric; next, calendering the fabric, and then coating bottom adhesive on the calendered fabric surface; and finally, coating surface adhesive on the surface of the surface of the fabric bottom adhesive, wherein the bottom adhesive consists of 100 portions of polyfluortetraethylene, 10 to 15 portions of toluene, 10 portions of polyacrylate, 3 to 5 portions of cross-linking agent, and 1 to 2 portions of accelerating agent in portion by weight; and the surface adhesive consists of 100 portions of polyfluortetraethylene, 10 to 15 portions of toluene, 10 portions of polyacrylate, and 2 portions of smooth anti-sticking agent in portion by weight.

Owner:石狮市亿祥染整有限公司

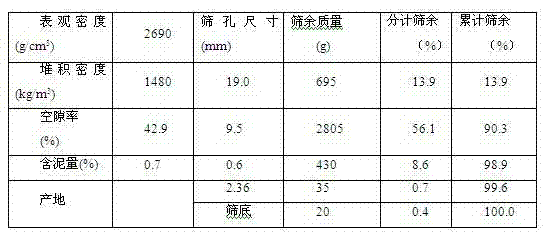

High water-storage concrete

InactiveCN103304250AImprove water storage performanceImprove breathabilityIn situ pavingsPaving detailsWater storageBrick

The invention discloses high water-storage concrete so as to solve the problem that the concrete does not has water-permeable and water-storage characteristics at the same time in the prior art. The high water-storage concrete comprises the following materials: cement and coarse aggregates, wherein the coarse aggregates comprise red brick particles. The high water-storage concrete is porous concrete formed by stirring the coarse aggregates, the cement, water and an admixture through a stirring process, does not contain fine aggregates, and is of a honeycomb structure with uniformly distributed holes which are formed by coating thin-layer cement slurries on the surface of the coarse aggregates and adhering the thin-layer cement slurries to each other; a large proportion of unclosed communication holes are contained inside the high water-storage concrete, so that the high water-storage concrete has the characteristics of water storage, water permeability, ventilation and light weight, and is an environmentally-friendly building material.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

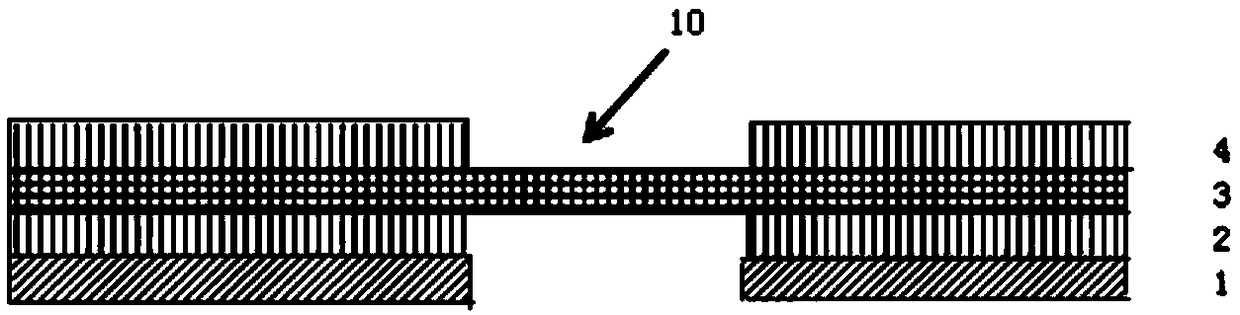

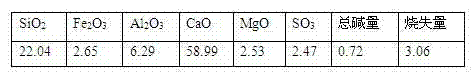

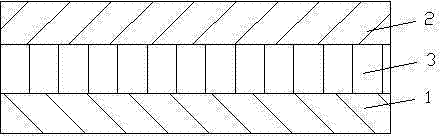

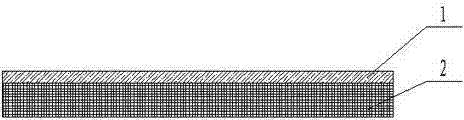

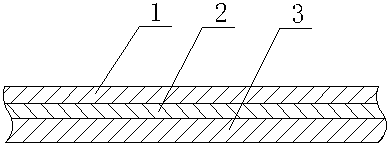

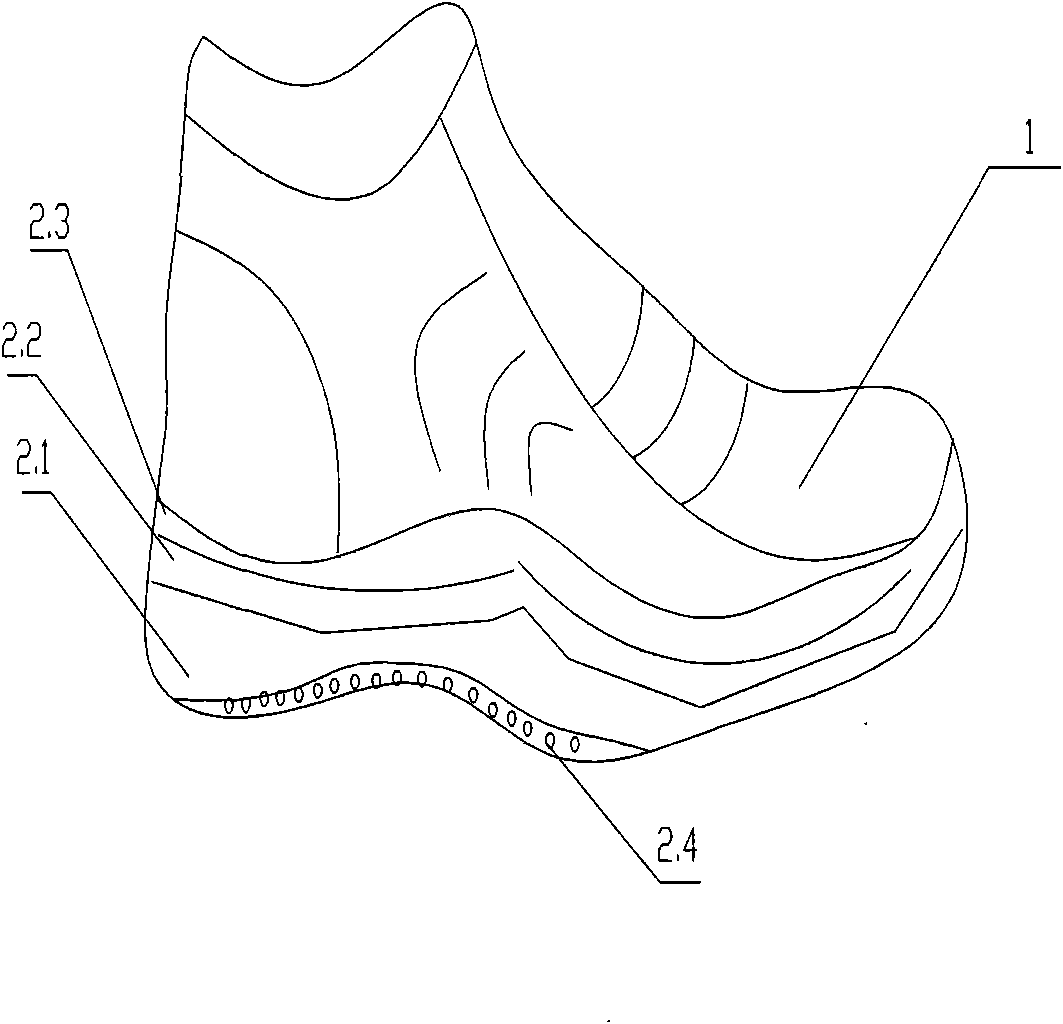

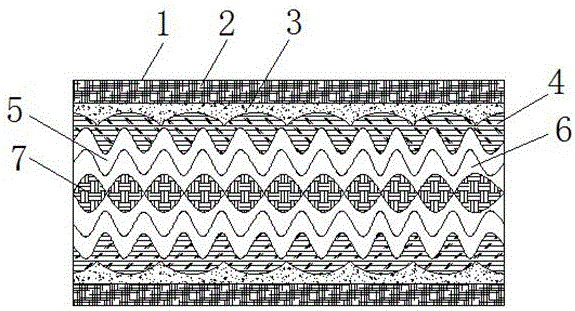

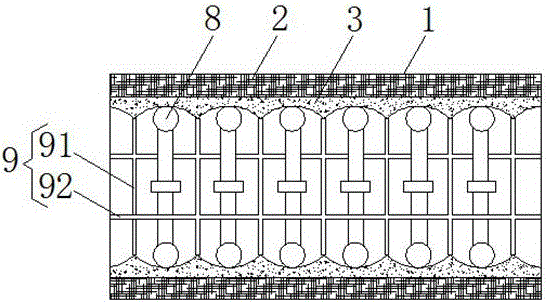

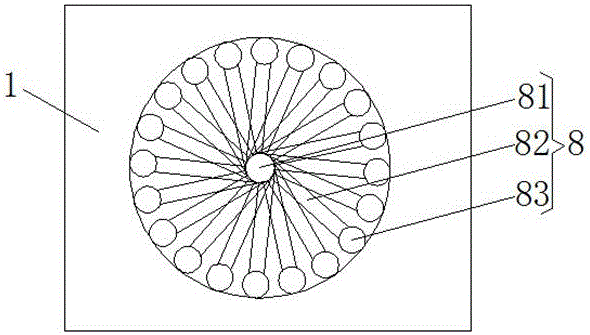

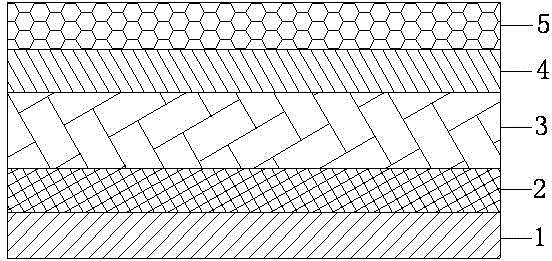

A waterproof and breathable fabric

InactiveCN102687920ABreathable withImprove insulation effectSynthetic resin layered productsProtective garmentCloakEngineering

The present invention relates to a waterproof and breathable fabric which is widely used in manufacturing raincoats, cloaks, top garments, etc. The said fabric belongs to the field of textile fabrics. The waterproof and breathable fabric comprises a fabric body (1). The fabic is characterized in that an external surface of the fabric body (1) is provided with a waterproof and breathable film layer (2) and a hot melt adhesive layer (3), the waterproof and breathable film layer (2) is a PU breathable and waterproof film layer, the hot melt adhesive layer (3) shows dotted distribution, and the waterproof and breathable film layer (2) is fixed on the external surface of the fabric body (1) through the hot melt adhesive layer (3). The waterproof and breathable fabric is waterproof and breathable, and preserves warmth. Clothes made of the fabric will not get wet even in a rainy day.

Owner:JIANGYIN XINGWU WOOL FABRIC TECH

Moisture-absorbing and sweat-discharging fabric of double-layer structure and preparation process thereof

The invention discloses a moisture-absorbing and sweat-discharging fabric of a double-layer structure and a preparation process thereof and belongs to the field of textile fabrics. The process comprises the following preparation steps of weaving two groups of warp yarns and two groups of weft yarns through a loom to form a double-layer gray fabric; treating the woven double-layer gray fabric to obtain a pre-treated fabric; electrostatically spraying a hydrophobic coating to the surface layer of the pre-treated fabric, performing drying at the high temperature, and then performing cooling and coiling to obtain a moisture-absorbing and sweat-discharging fabric; using blended polyester cotton yarn or acetic acid yarn as a warp yarn, adopting the warp yarn for manufacturing a supporting surface serving as the inner surface of the fabric, using a moisture-absorbing and sweat-discharging fiber as a weft yarn, and adopting the weft yarn for manufacturing a supporting surface serving as the outer surface of the fabric. The process aims to alleviate the technical problems that single-layer moisture-absorbing and sweat-discharging fabrics in the prior art are low in strength and likely to bebroken, the moisture discharging effect of multi-layer fabrics is not ideal, and outer-layer fabrics cannot drain out accumulated water stains in time. The moisture-absorbing and sweat-discharging fabric is soft and fluffy on the inter side, can maintain the skin dry and comfortable and avoid generation of damp and cool feeling, and has the properties of light weight, moisture guidance, ventilation and the like.

Owner:ZHEJIANG HAIMING IND CO LTD

Environment-friendly thickened stitch-bonded nonwoven fabric, production technology and insole

The invention discloses an environment-friendly thickened stitch-bonded nonwoven fabric which can be used for making of products such as bags, insoles and floor mats. The environment-friendly thickened stitch-bonded nonwoven fabric is made of environment-friendly raw materials, the thickness of the fabric is larger than that of ordinary stitch-bonded nonwoven fabric, and the air permeability and hygroscopicity are good. The invention relates to an insole made of the environment-friendly thickened stitch-bonded nonwoven fabric, when a person wears the insole, the insole cannot collapse by being subjected to pressure of the foot for a long time, patterns on the surface have the massage effect, the set time is long, deformation is not prone to occur, and the insole has the effects of being air permeable, resistant to odor and capable of absorbing sweat, draining sweat and removing moisture. The insole is put into a shoe, foot pain caused by a long walk can be relieved, and the body health is significantly improved.

Owner:特斯(中国)有限公司

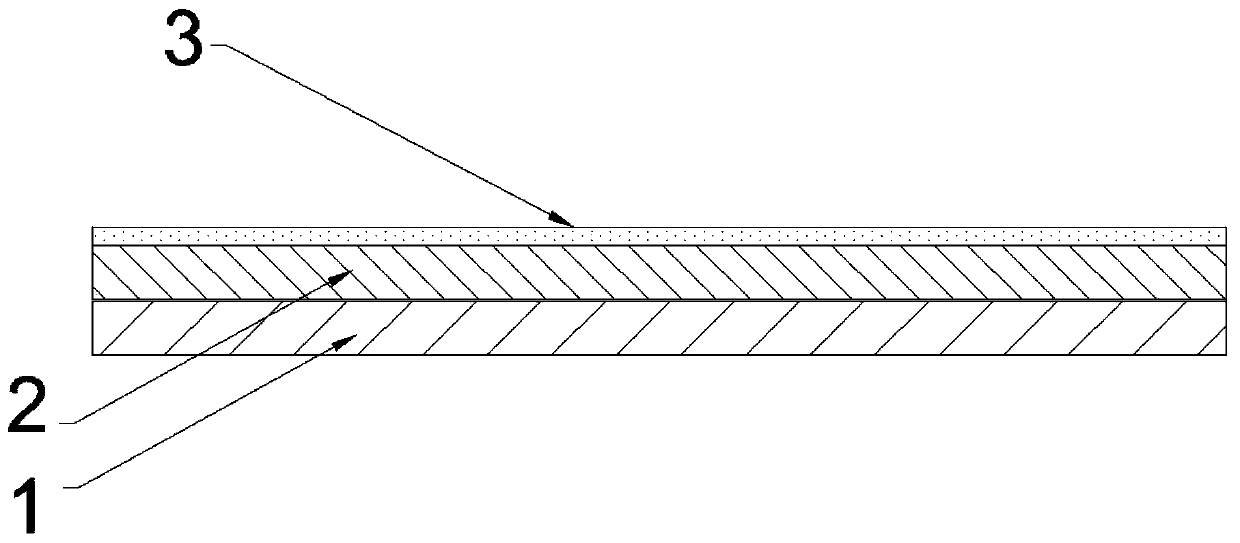

Waterproof warm-keeping fabric

InactiveCN103653464ABreathable withReliable warmthSynthetic resin layered productsProtective garmentCarbon fibersAdhesive

The invention discloses a waterproof warm-keeping fabric. The waterproof warm-keeping fabric comprises an outer waterproof layer and an inner warm-keeping fabric layer, wherein the outer waterproof layer adheres to the inner warm-keeping fabric layer through an environment-friendly adhesive. The outer waterproof layer is a waterproof breathable film. The inner warm-keeping fabric layer is formed by warp and weft in a blended mode. The warp is composed of 30%-60% of wool fibers and 5%-15% of bamboo charcoal fibers in a blended mode. The weft is composed of 10%-30% of rabbit hair fibers and 25%-30% of seaweed carbon fibers in a blended mode. In this way, the waterproof warm-keeping fabric is reliable in warm-keeping performance and waterproof performance, good in breathability, antimicrobial performance, deodorization preference and the like, non-toxic, harmless, safe, and reliable.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

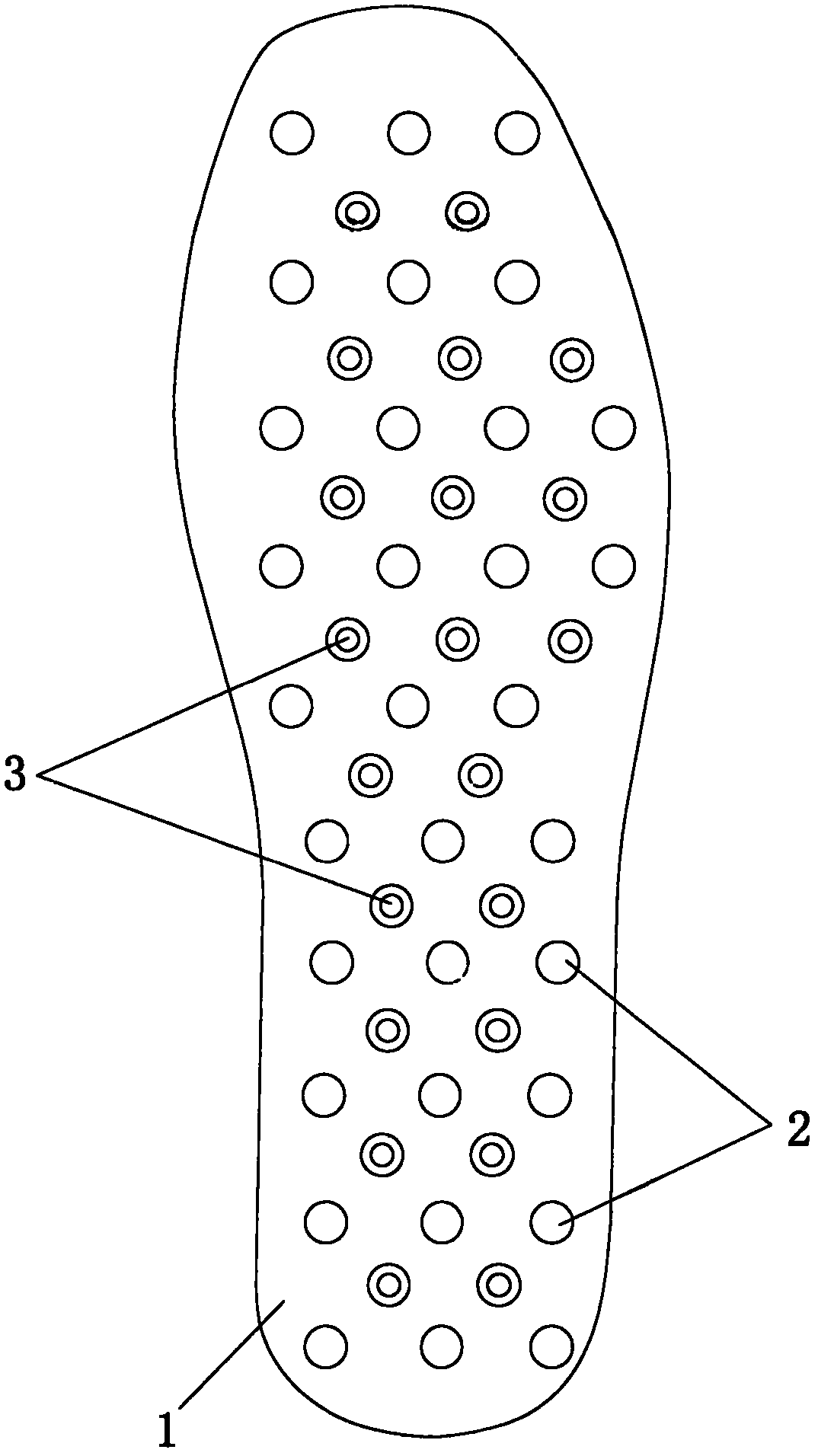

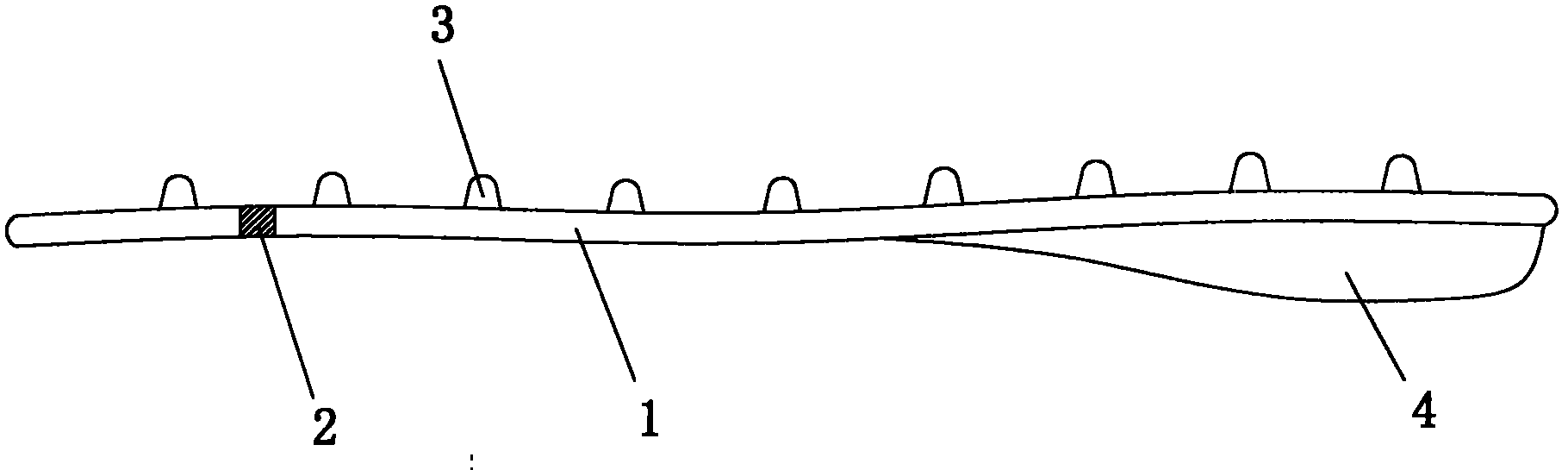

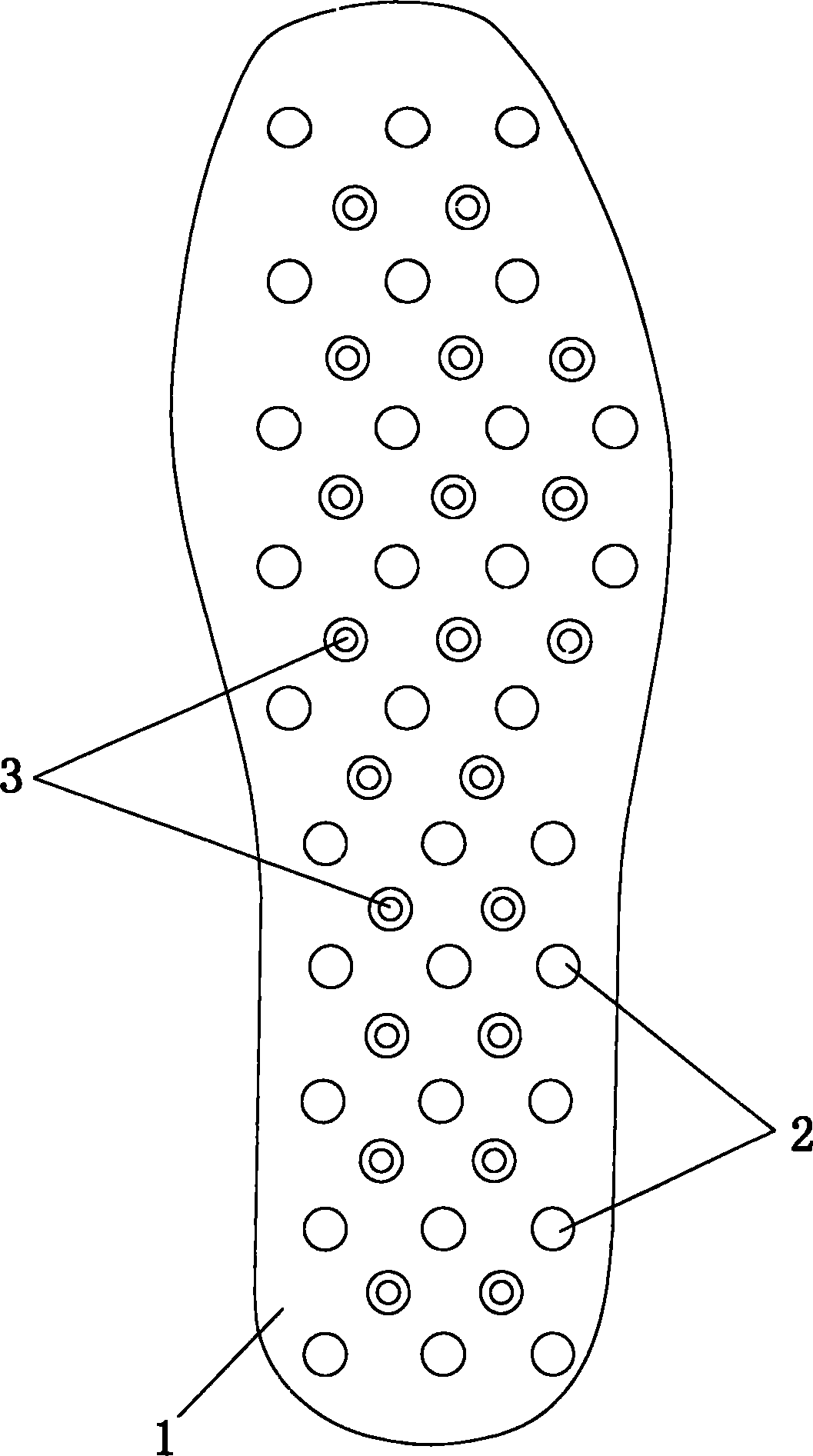

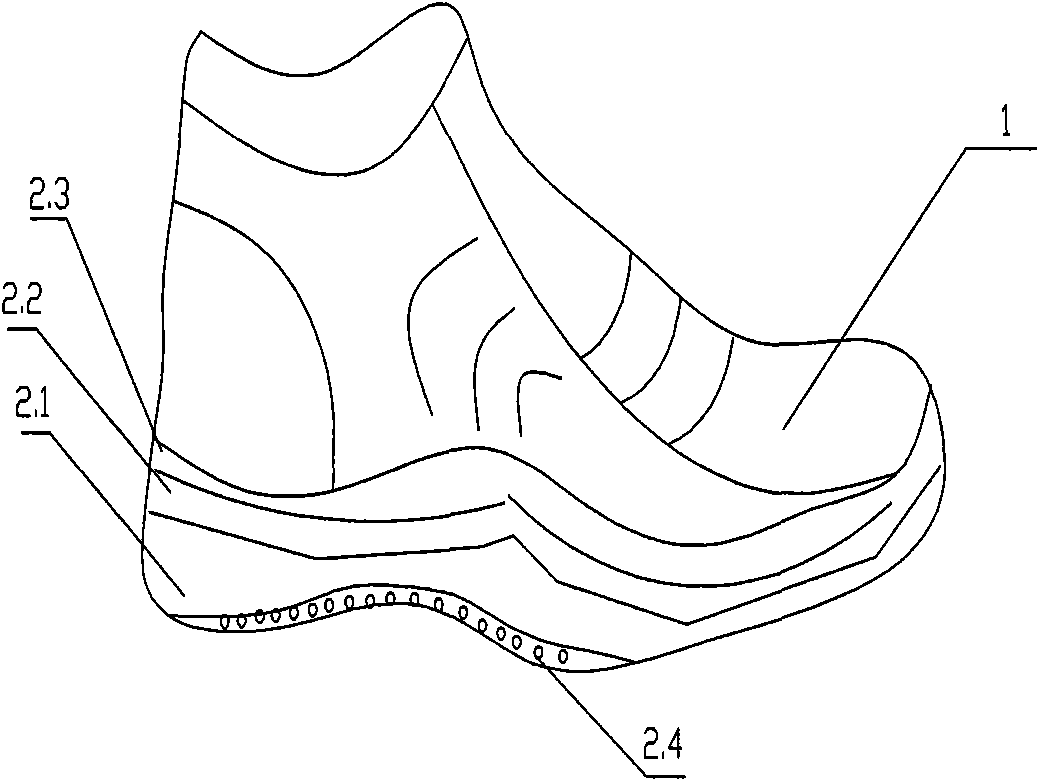

Massage ventilated height-increasing insole

InactiveCN102038330AGood for healthBreathable withInsolesDevices for pressing relfex pointsMassagePediatrics

The invention discloses a massage ventilated height-increasing insole. The massage ventilated height-increasing insole comprises an insole body, wherein a plurality of air holes are formed on the insole body and run through the upper surface and the lower surface of the insole body; massage beads are arranged in the gaps among the air holes; the surface of each massage bead has an arc-shaped structure; the air holes and the massage beads are distributed all over the whole insole body; a heel pad with height-increasing effect is arranged on position of the heel of the insole body; and the heel pad is made of an elastic material and is arranged on the bottom surface of the insole body. The air holes, the massage beads and the height-increasing heel pad are formed on the insole, so the massage ventilated height-increasing insole has ventilating, massage and height-increasing functions on the basis of the functions of the traditional insole and is good for the health of each human organ after long-term foot massage; and the height-increasing heel pad is arranged on the insole, so the height-increasing effect can be achieved, the height-increasing heel pad is difficult to find, and self-confidence and physical and psychological health of people are improved.

Owner:曾祥军

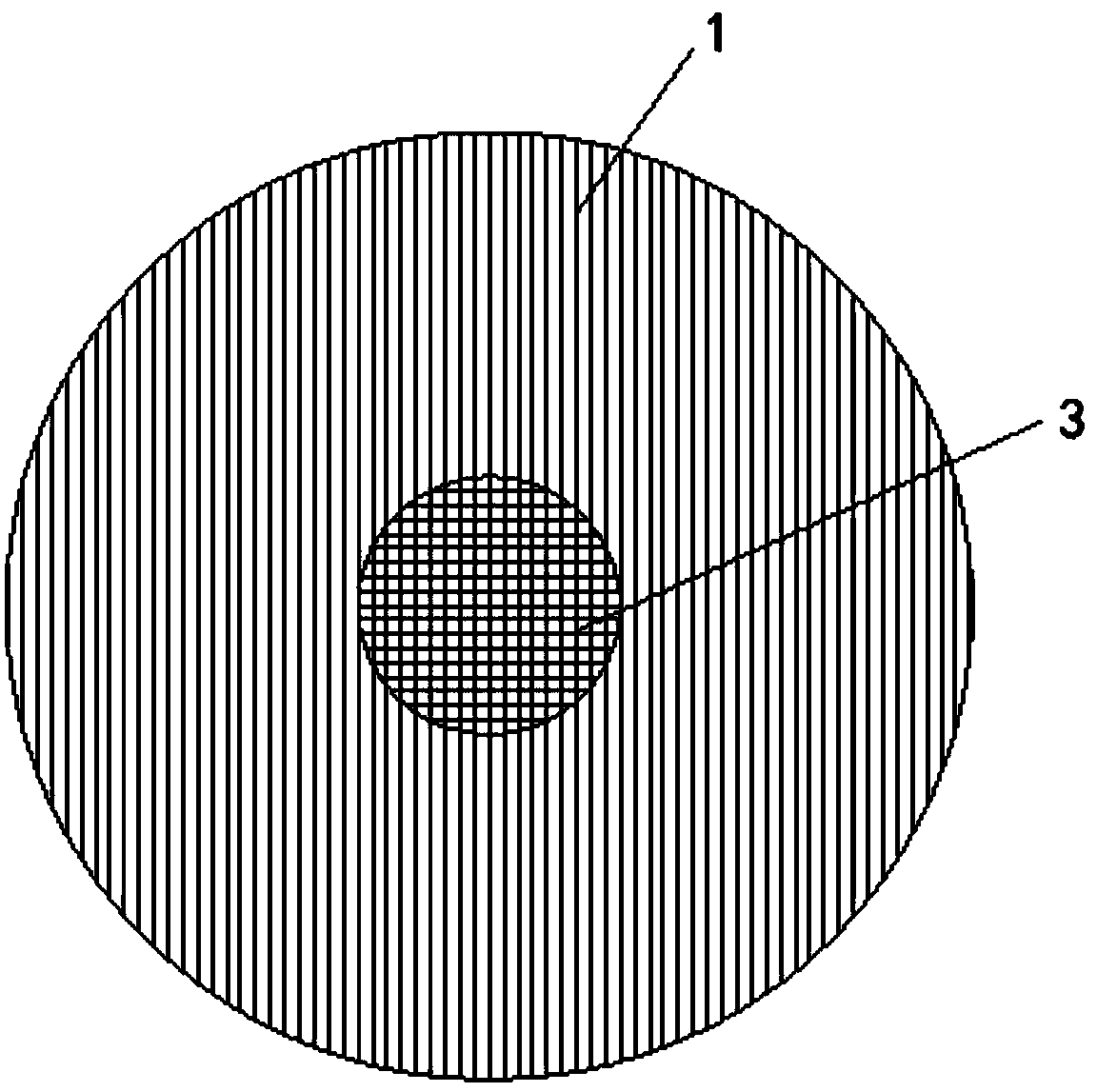

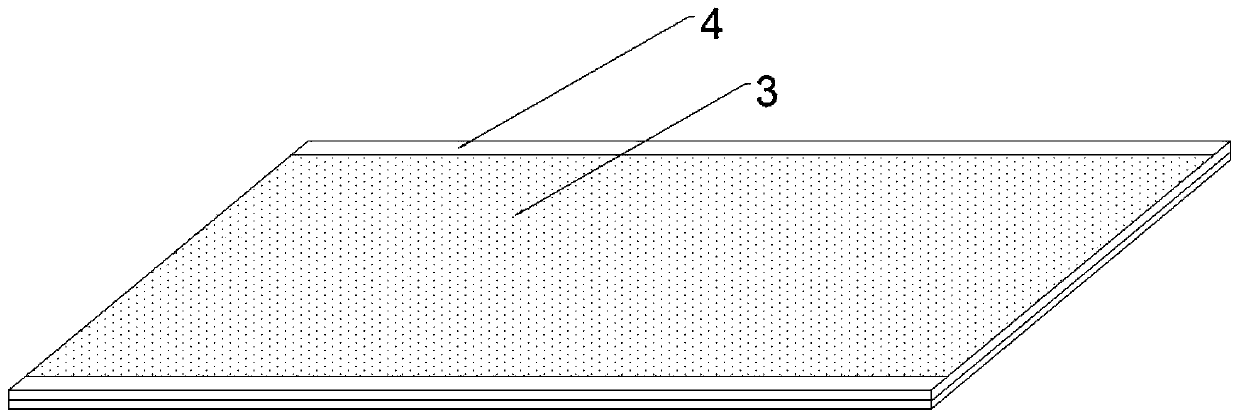

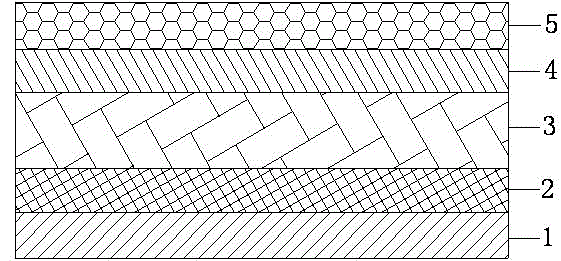

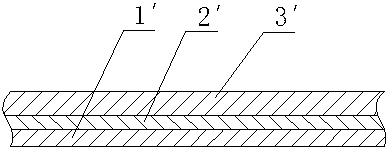

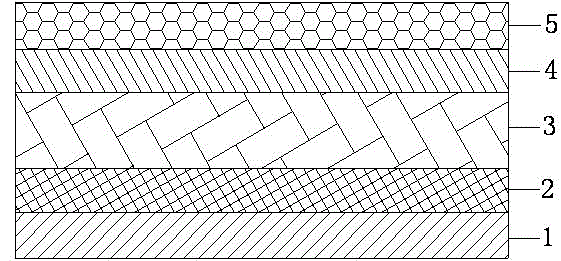

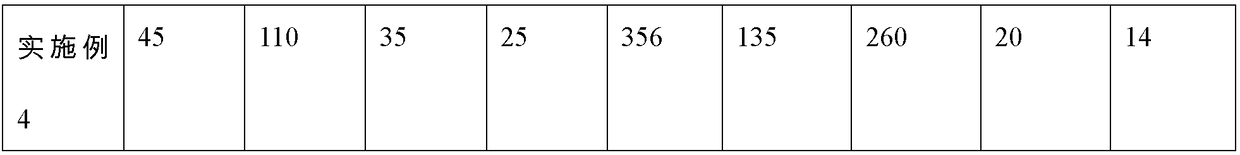

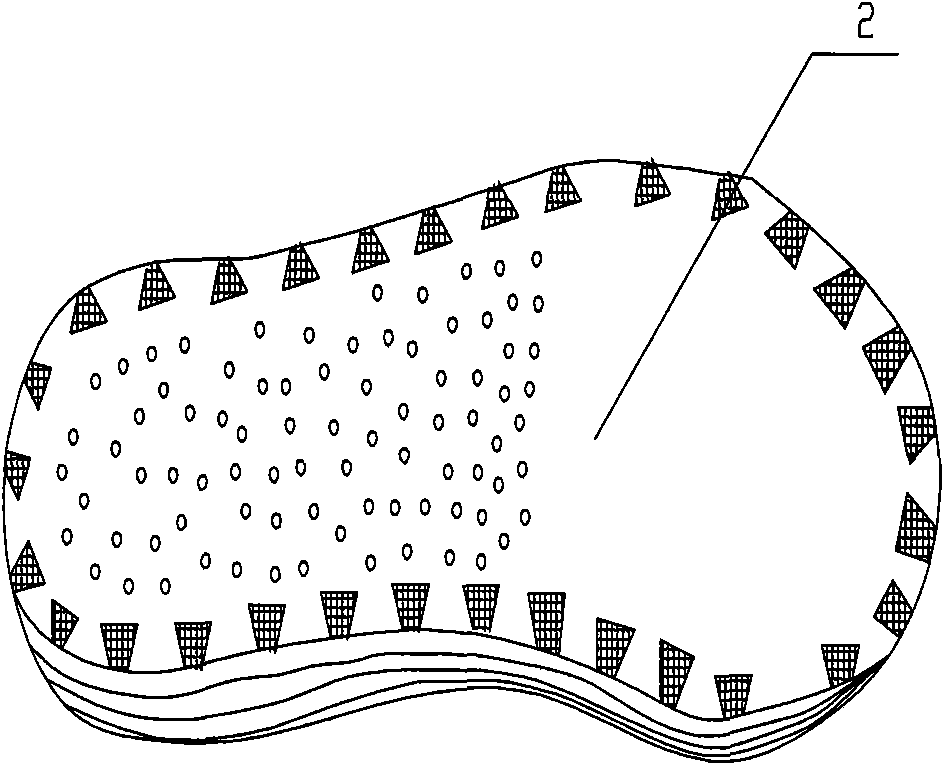

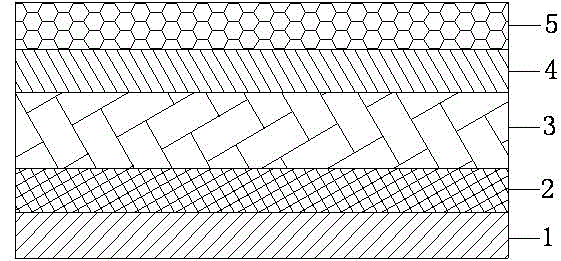

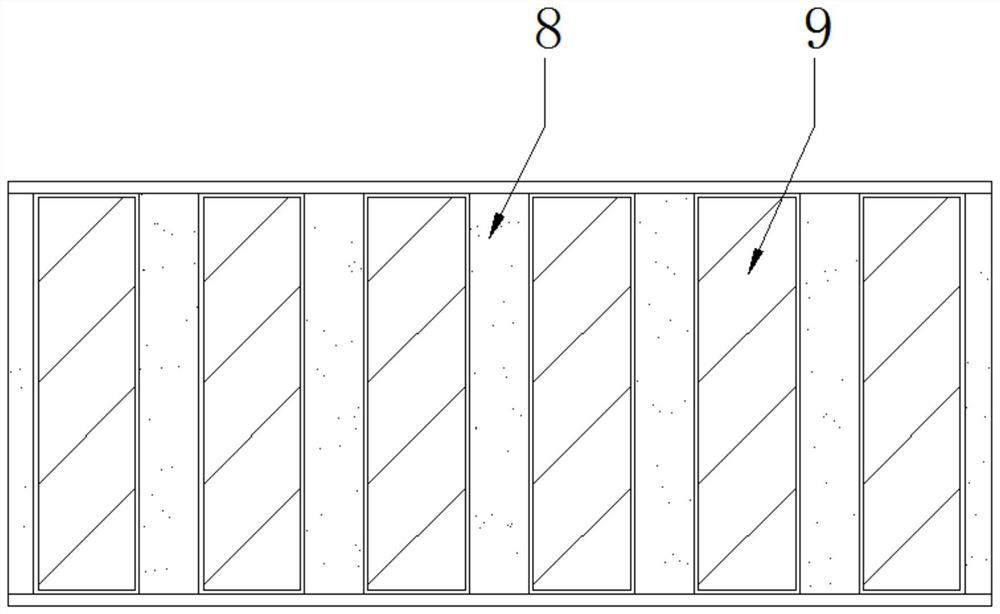

Waterproof, conductive and antibacterial fabric with high safety

InactiveCN104856314APrevent penetrationImprove smoothnessSynthetic resin layered productsClothingsFiberMoisture absorption

The invention relates to a waterproof, conductive and antibacterial fabric with the high safety. The waterproof, conductive and antibacterial fabric with the high safety comprises a fabric body (1), the surface of the fabric body is covered by a polyurethane film (2), the surface of the polyurethane film is covered by moisture absorption and sweat discharge fibers (3), the surfaces of the moisture absorption and sweat discharge fibers are provided with air holes and covered by a waterproof layer (4), and the surface of the waterproof layer (4) is covered by a polyurethane coating layer (5). The fabric body is made of textile fabric which comprises warp yarn and weft yarn, the warp yarn and the weft yarn are mutually interwoven, and the outer sides of fibers in the warp yarn and the weft yarn are covered by silver plating layers. According to the waterproof, conductive and antibacterial fabric with the high safety, the smoothness of the fabric can be improved, the fabric is not prone to being contaminated, the waterproof and breathable effects are achieved, and the conductive and antibacterial effects are achieved.

Owner:JIANGYIN KEHAO GARMENT & YARN DYE WEAVING

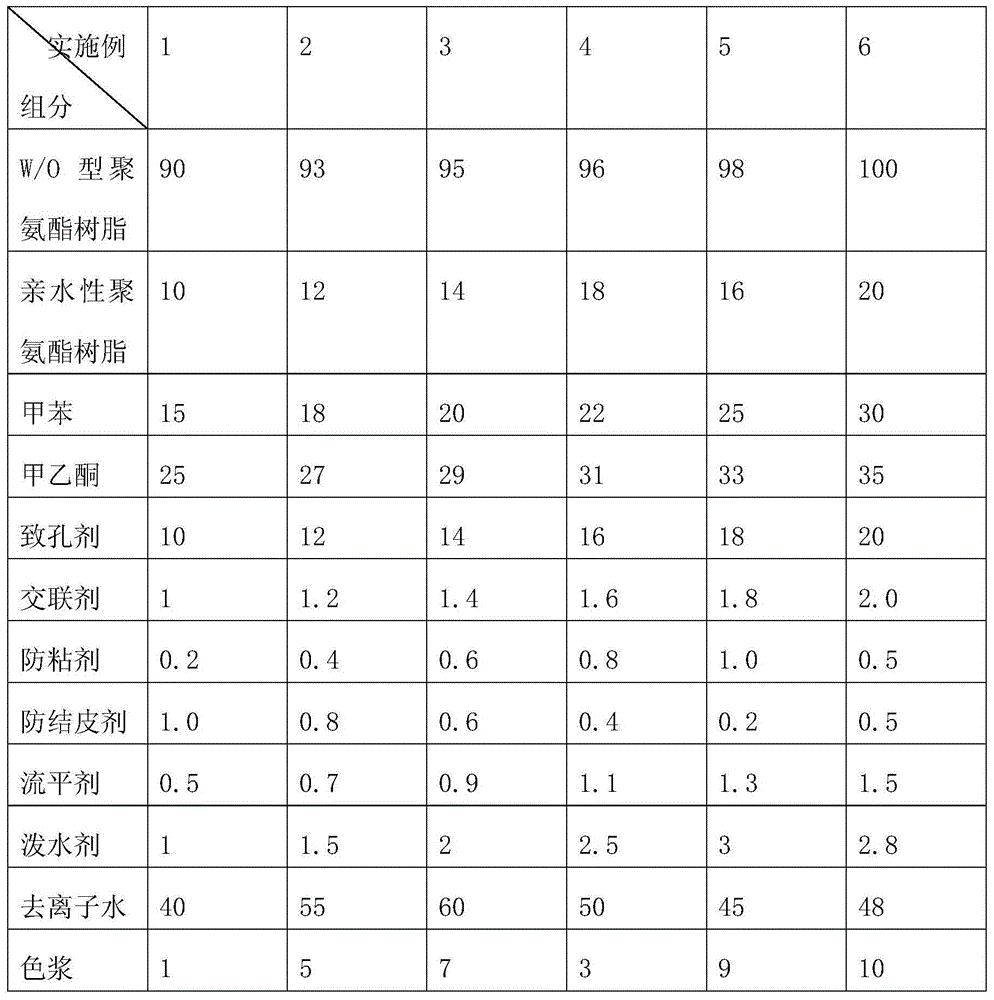

Preparation method of polyurethane microporous membrane

InactiveCN104448380ANo pollution in the processNo pollutionProtective garmentSpecial outerwear garmentsEmulsionToluene

The invention discloses a preparation method of a polyurethane microporous membrane, which comprises the following steps: (1) uniformly stirring the following components in parts by mass to form a coating emulsion: 90-100 parts of W / O polyurethane resin, 10-20 parts of hydrophilic polyurethane resin, 15-30 parts of toluene, 25-35 parts of methylethylketone, 10-20 parts of pore-forming agent, 1-2 parts of crosslinking agent, 0.2-1.0 part of releasing agent, 0.2-1.0 part of anti-skinning agent, 0.5-1.5 parts of leveling agent, 1-3 parts of water-sprinkling agent, 40-60 parts of deionized water and 1-10 parts of color paste; and (2) coating the coating emulsion to a transfer carrier, drying, and peeling to obtain the polyurethane microporous membrane. The polyurethane microporous membrane prepared by the preparation method has the functions of windproofness and ventilation and the function of actively absorbing moisture and discharging sweat, and is applicable to different clothing facing materials.

Owner:昆山贝环电子技术服务有限公司

Ultra-soft, waterproof, breathable fabric for infants

InactiveCN102963095AWaterproofBreathable withSynthetic resin layered productsEngineeringFabric structure

An ultra-soft, waterproof, breathable fabric for infants relates to the fabric structure field, and comprises a single-side French terry bottom layer; a waterproof PU resin surface layer is disposed on the single-side French terry bottom layer through a backing material PU resin middle layer. According to the invention, through thermalization of the backing material PU resin middle layer, the waterproof PU resin surface layer is combined with the single-side French terry bottom layer; the waterproof PU resin surface layer is smooth and waterproof, and the single-side French terry bottom layer is soft and breathable. The fabric of the invention is environment-friendly and hygienic, can resist water washing for more than 10 times, can be manufactured into bibs, mattresses, enclosures, diapers and the like for infants, can also be manufactured into appliances for hospitals and travel, and is also suitable for people needing medical care and old people.

Owner:仪征新天地织物面料实业有限公司

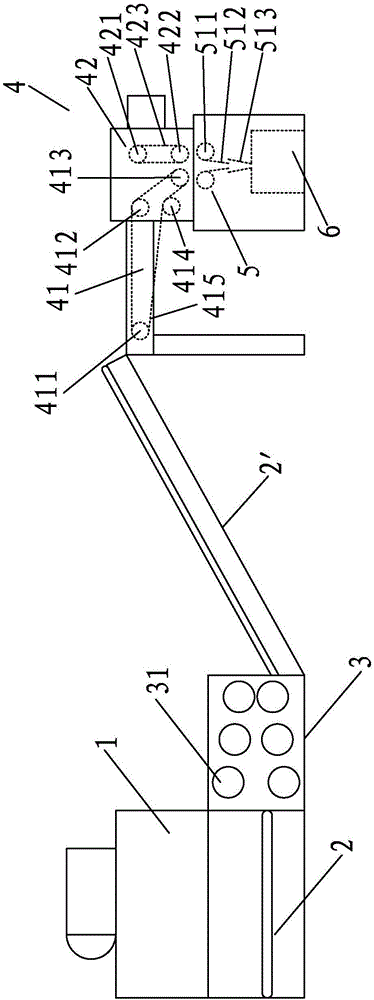

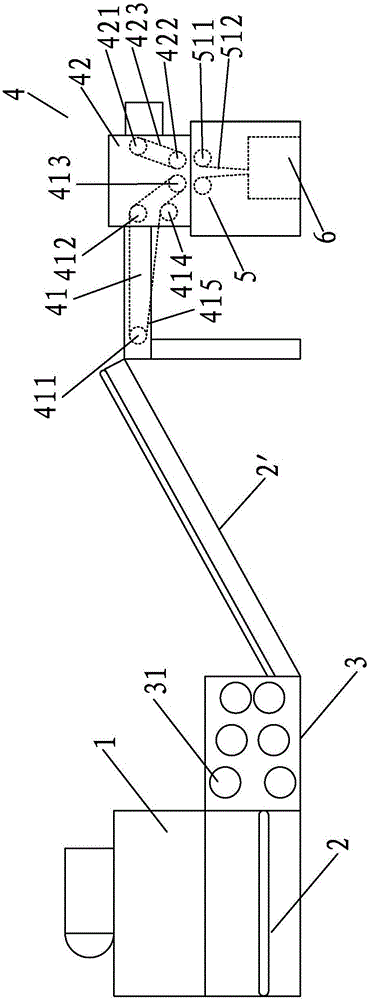

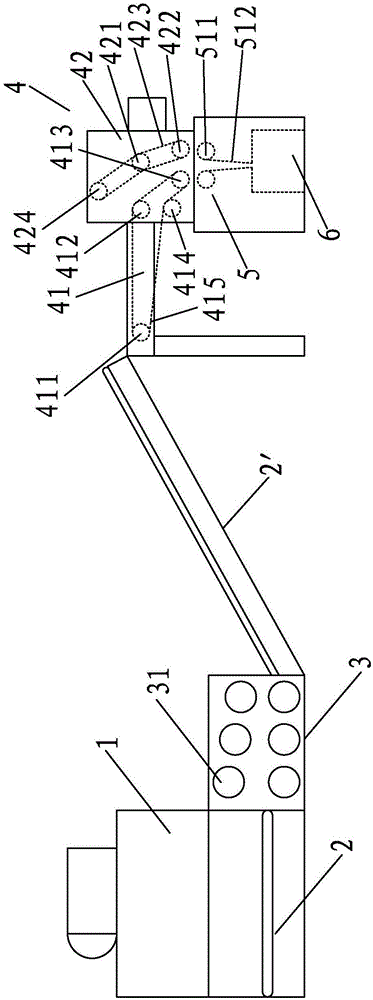

Production technology of thin film for thermal and breathable fabric

The invention discloses a production technology of thin film for thermal and breathable fabric. The production technology comprises the following steps of: firstly, mixing polyurethane resin, thickening agent, PH regulator and solvent together, stirring into colloidal liquid, coating a substrate with the colloidal liquid by blade coating, and carrying out sectional drying to obtain the finished product. By addition of aluminum powder and silver powder, human body temperature is reflected to the clothes, a thermal insulation circulating system is formed inside the clothes, temperature is increased by more than 6 DEG C, functions, such as breathing, warm keeping and protection against wind and rain, are realized, and thus, the thin film produced by the production technology has stronger thermal insulation performance; by three-section type drying, micropores without preservative water solution are formed, meanwhile, polyurethane micropores are formed, and pore diameter of such kind of micropores is greater than that of water vapor molecule and less than that of water molecule, so that the water vapor molecules in vapor state can pass through, and the breathable property is realized. Compared with the prior art, the thin film has the advantages of being breathable, light and thin, windproof and rainproof, and the like, is especially suitable for being used on garment materials, and is particularly suitable for being used on products, such as garment, home textiles and shoes.

Owner:平湖市新保纺织科技有限公司

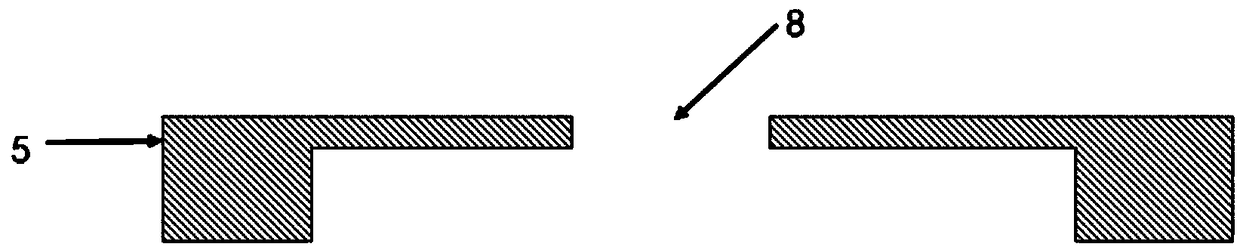

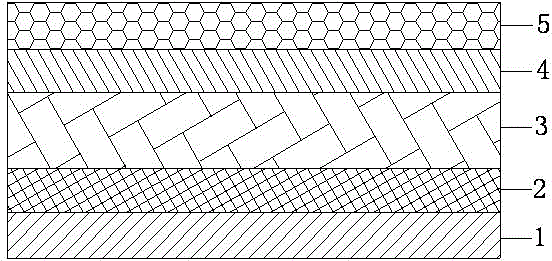

High-safety water-proof three-phase braided fabric

InactiveCN104872884AImprove compactnessImprove smoothnessSynthetic resin layered productsProtective garmentFiberThree dimensionality

The invention relates to a high-safety water-proof three-phase braided fabric. The fabric comprises a fabric body (1), wherein the surface of the fabric body is covered by a polyurethane film (2); the surface of the polyurethane film is covered by moisture absorption and sweat releasing fibers (3); the surfaces of the moisture absorption and sweat releasing fibers are provided with breathable holes; the surfaces of the moisture absorption and sweat releasing fibers (3) are covered by a water-proof layer (4); the surface of the water-proof layer (4) is covered by a polyurethane coating layer (5). The fabric body is made of a fabric; the fabric is interwoven by yarns; the yarns comprise weft yarns, left-leaning warp yarns and right-leaning warp yarns; the interweaving rule is shown in the specification in the left-leaning warp yarns and the right-leaning warp yarns. According to the fabric, the smoothness of the fabric can be improved, so the fabric is difficult to contaminate; the fabric has water-proof and breathable effects. The grain of the fabric is changed, the compactness and the firmness are increased, and layering, three-dimensionality and rich color can be produced.

Owner:JIANGYIN YASHUN GARMENT

Waterproof elastic plus material with high safety

InactiveCN104875459AElastic easyElastic and comfortableSynthetic resin layered productsClothingsMoisture absorptionPolyurethane coating

The invention relates to a waterproof elastic plus material with high safety. The waterproof electric plus material comprises a plus material body (1), wherein the surface of the plus material body is coated with a polyurethane film (2), the surface of the polyurethane film is coated with moisture absorption and sweat removing fibers (3), air vents are formed in the surface of the moisture absorption and sweat removing fiber, a waterproof layer (4) covers the surface of the moisture absorption and sweat removing fiber (3), and the surface of the waterproof layer (4) is coated with a polyurethane paint layer (5). The plus material body is made of a fabric, the fabric is a warp-knitted fabric, a yarn lining rule is 1-0 / 2-3, a 75D / 36 T400 polyester fiber fully-drawn yarn filament yarn is adopted for the surface yarn, a FDY 84D / 36F polyester filament yarn is adopted for the bottom yarn, the T400 polyester fiber fully-drawn yarn filament yarn is hollow, and the cross section of the T400 polyester fiber fully-drawn yarn filament yarn is in cross shape. By adopting the waterproof elastic plus material, the smoothness of the plus material can be improved, the plus material is unlikely to contaminate, and the waterproof and ventilation effect can be realized. The fabric made of the waterproof elastic plus material is high in elasticity, comfortable and durable. The fabric is soft, stiff and smooth and good in drapability.

Owner:JIANGYIN CHUNLAN TEXTILE

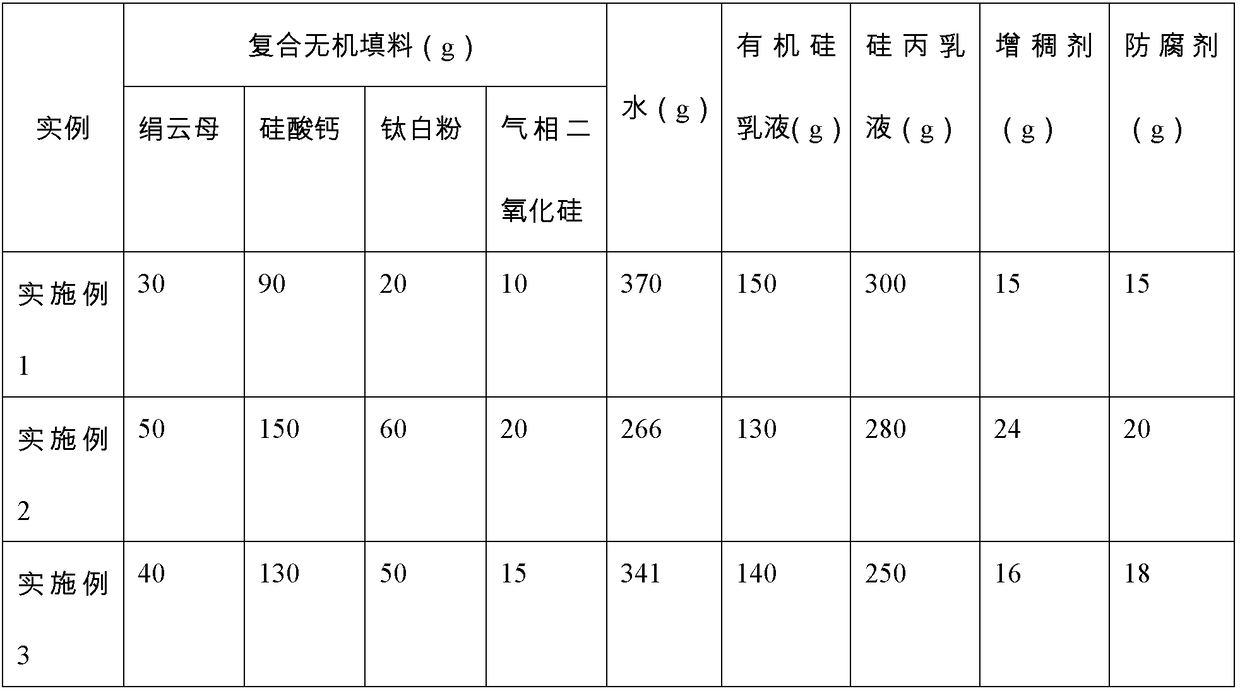

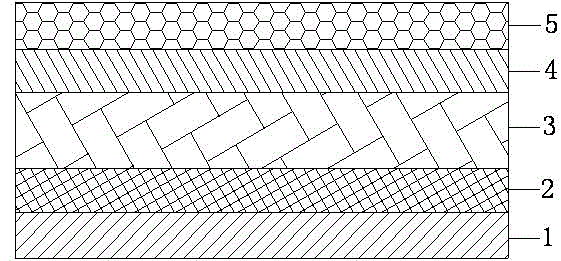

Concrete low-water-absorption protecting agent, preparation method and application method thereof

InactiveCN108250881ARequirements for durable long-term protectionMeet the requirements of durable long-term protectionAnti-corrosive paintsEmulsionLow speed

The invention discloses a concrete low-water-absorption protecting agent, a preparation method and an application method thereof. The preparation method comprises the following steps: uniformly premixing composite inorganic filler; adding water; dispersing at high speed for 60-80min; then sequentially adding organosilicone emulsion, modified pure acrylic emulsion, a thickening agent and a preservative; stirring to uniform mix; and dispersing and stirring for 40-60min at low speed to obtain ultra-low water-absorption bare concrete protecting agent, wherein the composite inorganic filter is a mixture of sericite, calcium carbonate, titanium dioxide and fumed silica; the composite inorganic filler accounts for 15-30% of the total mass; the organosilicone emulsion accounts for 10-15% of the total mass; the modified pure acrylic emulsion accounts for 20-30% of the total mass. The prepared ultra-low water-absorption bare concrete protecting agent overcomes the shortages of existing bare concrete which is easy to suck water and easily discolored due to microorganism attaching, has the characteristics of being waterproofing, breathing, and resistant to environment change, and is capable ofobviously improving the durability of the bare concrete.

Owner:CCCC FOURTH HARBOR ENG INST +2

Waterproof elastic shell fabric with high safety

InactiveCN104856317AGood drapabilityElastic footWarp knittingSynthetic resin layered productsEngineeringMoisture absorption

The invention relates to a waterproof elastic shell fabric with the high safety. The waterproof elastic shell fabric with the high safety comprises a fabric body (1), the surface of the fabric body is covered with a polyurethane film (2), the surface of the polyurethane film is covered with moisture absorption and sweat discharge fibers (3), the surfaces of the moisture absorption and sweat discharge fibers are provided with air holes and covered with a waterproof layer (4), and the surface of the waterproof layer (4) is covered with a polyurethane coating layer (5). The fabric body is made of a textile fabric which is a double-faced warp knitting fabric made by the 1-0 / 5-6 weaving rule, bottom yarn adopts FDY84D / 36F polyester filament yarn and spandex yarn, and surface yarn adopts 75D / 144F polyester drawn textured yarn and spandex yarn. According to the waterproof elastic shell fabric with the high safety, the smoothness of the fabric can be improved, the fabric is not prone to being contaminated, and the waterproof and breathable effects are achieved; the waterproof elastic shell fabric with the high safety has the advantages of being sufficient in elasticity, good in flexible strength, full in surface velvet sense, good in feeding in wealth and the like.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Preserve and antibacterial treatment process for silk cotton fabric

InactiveCN107100005AImprove breathabilityBreathable withBiochemical fibre treatmentLiquid/gas/vapor removalPolypropyleneSilicon dioxide

The invention discloses a preserve and antibacterial treatment process for a silk cotton fabric. The preserve and antibacterial treatment process comprises: preparing raw materials such as 0.5-4 parts of nanometer silica, 0.5-4 parts of nanometer silver, 25-55 parts of polypropylene, 1-4 parts of folium artemisiae argyi charcoal, 35-55 parts of bamboo fiber, 65-85 parts of cotton fiber, 10-35 parts of aramid fiber, 2-6 parts of nanometer chitin, 1-5 parts of polycaprolactone, 1-5 parts of lavender, 8-16 parts of silk fiber, and 22-30 parts of banana fiber; carrying out normal pressure boiling on the bamboo fiber, the cotton fiber, the aramid fiber, the silk fiber and the banana fiber, cyclically washing with hot water and cold water, impregnating with a weak acid, and washing; treating in a solution containing polypropylene and nanometer chitin, and treating in a mixed solution, wherein the mixed solution contains nanometer silica, nanometer silver, folium artemisiae argyi charcoal and lavender; and drying to obtain the fabric. According to the present invention, the obtained fabric has advantages of good softness, close fitting, good gas permeation, cooling property, preserve, antibacterial property, bactericidal property, bacterial inhibition, wear resistance, and a certain tensile strength.

Owner:FUYANG AOHONG FIBER PROD CO LTD

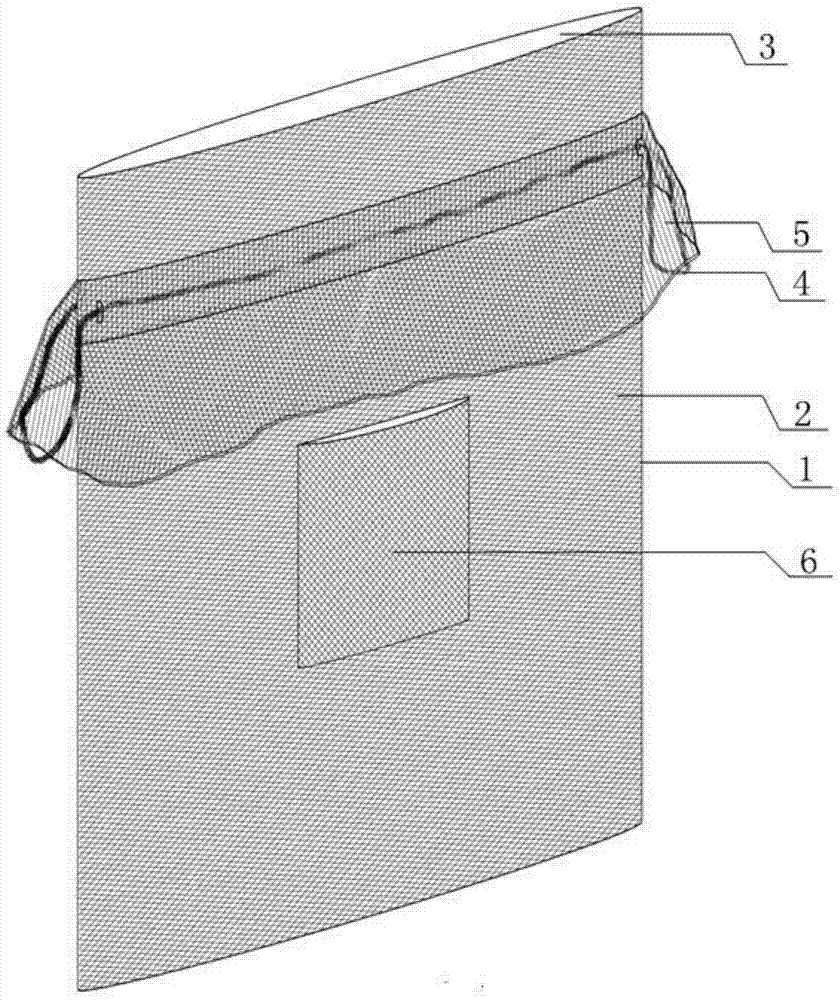

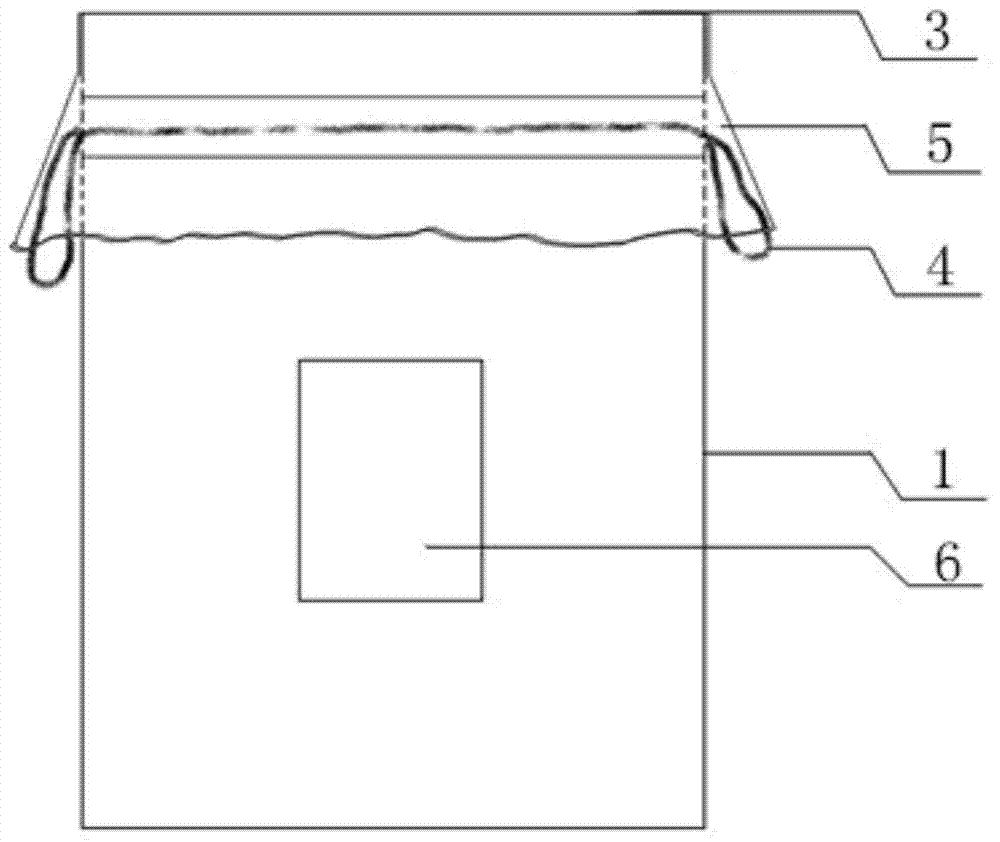

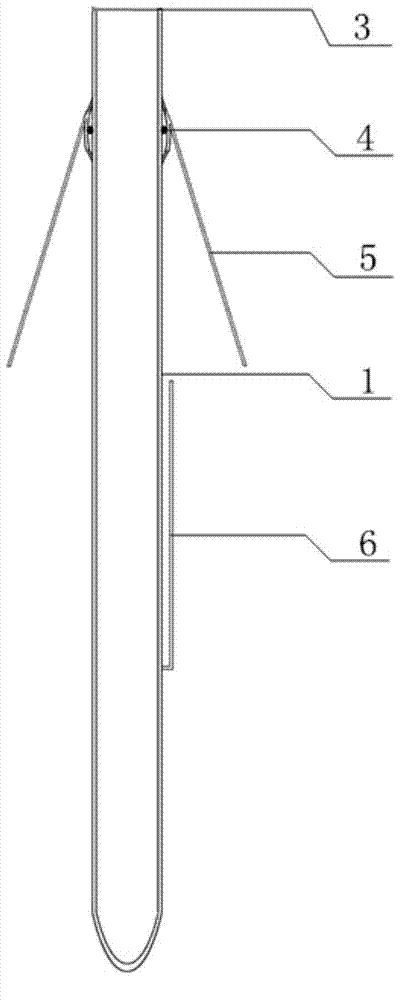

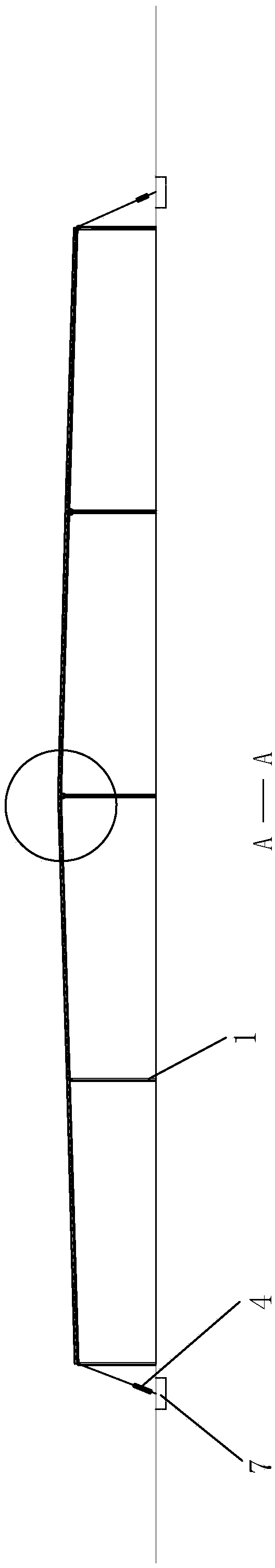

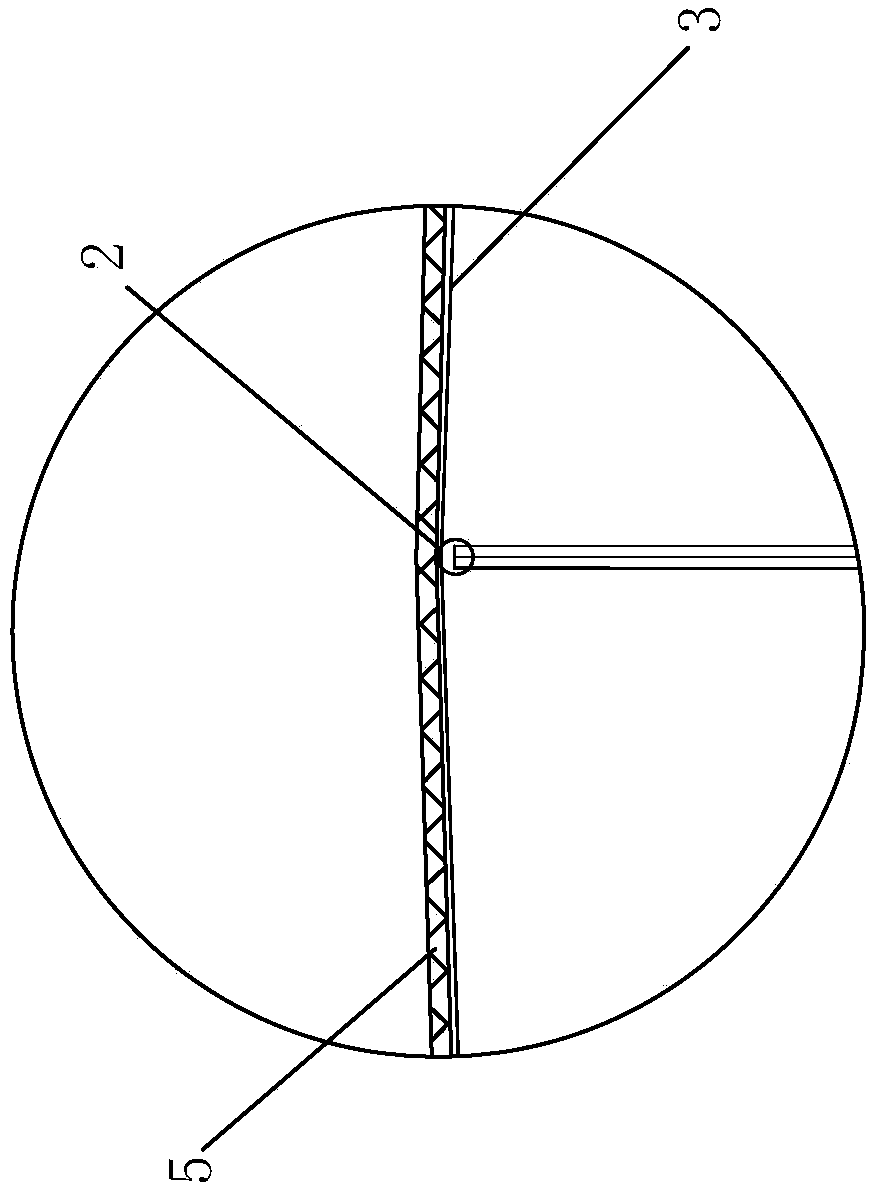

Pollination preventing and capsule protecting mesh bag for cassava artificial hybridization

InactiveCN104705135AEasy to observe developmentSimple structurePlant protective coveringsBiotechnologyPollination

The invention discloses a pollination preventing and capsule protecting mesh bag for cassava artificial hybridization. The mesh bag comprises a mesh bag body (1), a drawing rope (4), a transparent plastic film (5) and a hang tag bag (6). The mesh bag body (1) comprises a front layer and a rear layer, a cavity is formed in the middle, the two sides and the bottom end are closed, a mesh bag opening (3) is formed in the upper end, and air holes (2) are densely distributed in the mesh bag body (1). The drawing rope (4) is arranged on the upper portion of the mesh bag body (1). The transparent plastic film (5) is arranged between the mesh bag opening (3) and the drawing rope (4) in the mode of surrounding by one circle, and one part of the transparent plastic film (5) extends out. The hang tag bag (6) is arranged at the lower middle end of the bag face of the mesh bag body (1). The mesh bag can prevent pollination of media such as wind and insects after artificial hybridization is finished, prevent capsules naturally maturing from cracking and losing seeds, and protect the capsules against frost injuries and cold injuries of fog; bagging is carried out once till the capsules are harvested, and a great deal of time and labor can be saved.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Ventilated fiber cloth

The invention discloses a ventilated fiber cloth, and belongs to the field of fiber cloths. The ventilated fiber cloth is formed by compositing bamboo fibers, cotton fibers, aramid fibers and ramie fibers. According to the prepared ventilated fiber cloth, shell fabric is soft and close fitted, air permeability is good, and wet absorption air permeability of the ramie fibers in the ventilated fiber cloth is 3-5 times of that of the cotton fibers. Simultaneously, the ventilated fiber cloth contains beneficial elements of cerumen, pyrimidine, purine and the like, has bacterium inhibition, ventilation, cooling and corrosion prevention functions, and furthermore can effectively achieve ventilation and flame resisting effects due to the fact that the aramid fibers have flame resisting effects.

Owner:ANHUI CHUANGRONG CLOTHING ACCESSORIES

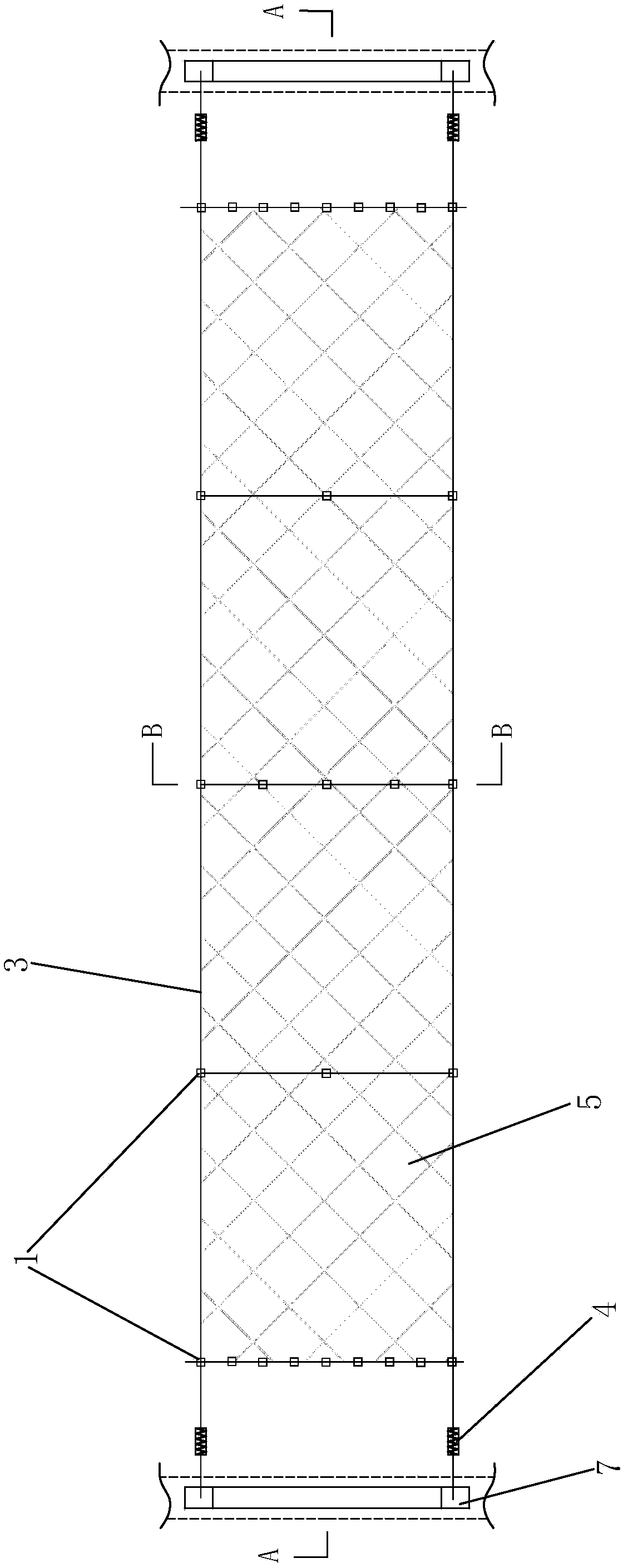

Light dustproof and ventilating bulk cargo warehouse

PendingCN109441189ASimple structureLight textureProtective buildings/sheltersBulk storage containerSteel columnsLower face

The invention discloses a bulk cargo warehouse of a light structure. The bulk cargo warehouse includes a plurality of steel columns, pulleys, steel wire ropes, tension regulators and dustproof ventilating nets, the steel columns are erected on the ground, the steel columns are arranged in transverse and longitudinal rows, the tops of the steel columns are provided with the pulleys, and one same steel wire rope is wound on the pulleys at the tops of the steel columns in the same transverse row, wherein both ends of the steel wire rope are fixed to the ground; and the tension regulators are installed on the steel wire ropes, the corresponding dustproof ventilating net is installed between the two steel wire ropes on the adjacent two transverse steel columns, each dustproof ventilating net isprovided with two layers of metal nets and an intermediate layer dustproof material, wherein the two layers of metal nets are supported on the upper and lower faces of the intermediate layer dustproof material correspondingly, the dustproof ventilating nets are fixed to the steel wire ropes through buckle pieces, thus the intermediate layer dustproof material is clamped in the two layers of metalnets for fixing, and the side faces of the steel columns in the foremost and backmost transverse rows are closed. According to the bulk cargo warehouse of the light structure, external discharging ofdust can be controlled organically, installation is convenient, site limitation is avoided, wind resistance and shock resistance are achieved, the construction speed is high, construction investmentis 1 / 10 of original investment, and application and promotion are facilitated.

Owner:XIAMEN QINGSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for making perspiration eliminating and ventilating shoes

The invention relates to a method for making a pair of perspiration eliminating and ventilating shoes, which comprises the steps of: making soles and vamps, and connecting the soles with the vamps together to make the perspiration eliminating and ventilating shoes, wherein the step of making the soles comprises the three procedures of making strong cloth soles, then designing non-woven fabrics deodorizing insoles, and finally, casting chemical layers on the bottom surfaces of the strong cloth soles by using an injection process, wherein the chemical layers are provided with ventilating holes, and the step of making the vamps comprises the procedure of designing various vamp types of casual shoes, leather shoes, ventilated shoes and sport shoes according to the need. The invention has the advantages of solving the problem of perspiration elimination and ventilation of the soles, keeping attractive appearances of the shoes and obtaining the effects of ventilation, perspiration elimination and deodorization of the shoes.

Owner:王廷申

High-strength glass panel protective film

InactiveCN106626541AHigh strengthExtended service lifeSynthetic resin layered productsRubber layered productsTectorial membraneHeat resistance

The invention relates to the technical field of glass panels and discloses a high-strength glass panel protective film. The high-strength glass panel protective film comprises a film body; a waterproof air-permeable film, a PE reinforcing layer, a PVC reinforcing layer, a heat-resistant layer and a corrosion-resistant layer are paved on each of the upper side and the lower side of the internal part of the film body sequentially from outside to inside; a PET reinforcing layer is paved between the heat-resistant layer and the corrosion-resistant layer; and a reinforcing layer and a supporting layer penetrate through the two PE reinforcing layers. The high-strength glass panel protective film has the advantages that the stress of the film can be effectively dispersed to each part, the strength is enhanced, the supporting layer is used for supporting the radian connecting part of the PE reinforcing layers, the load bearing capability is improved, high strength of the film body is guaranteed, the strength during actual use is guaranteed, the film body is prevented from being damaged too early, the service life of the glass panel is prolonged, resources are saved, the fact that the film body has the characteristics of water resistance, air permeability, heat resistance, corrosion resistance and the like is guaranteed, and the service life of the film body is prolonged, so that the service life of the glass panel is indirectly prolonged.

Owner:无锡祁龙胶粘制品有限公司

Air-permeable anti-seepage sand and sand-based planting tank using the air-permeable and anti-seepage sand

ActiveCN103755303BBoth have a breathable effectBreathableReceptacle cultivationAdhesiveMaterials science

The invention discloses air-permeable seepage-proof sand and a sand-based planting tank using the same, belonging to the field of a crop planting tank. The air-permeable seepage-proof sand provided by the invention consists of a plurality of crude sand particles, seepage-proof resin and an adhesive, wherein the volume ratio of the crude sand particles to the seepage-proof resin to the adhesive is 200:(8-20):(5-15). The sand-based planting tank provided by the invention comprises a plurality of air-permeable seepage-proof sand plates which form a groove-like container in a surrounding manner, wherein each air-permeable seepage-proof sand plate comprises air-permeable seepage-proof sand, an adhesive and a solidifying agent, and the volume ratio of the air-permeable seepage-proof sand to the adhesive to the solidifying agent is (4-6):(3-4):(1-2). The air-permeable seepage-proof sand and the sand-based planting tank provided by the invention have the advantages of air permeability, seepage prevention, water and fertilizer retention, and long service life.

Owner:BEIJING RECHSAND SCI & TECH GRP

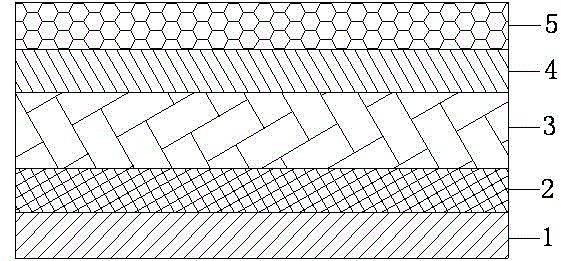

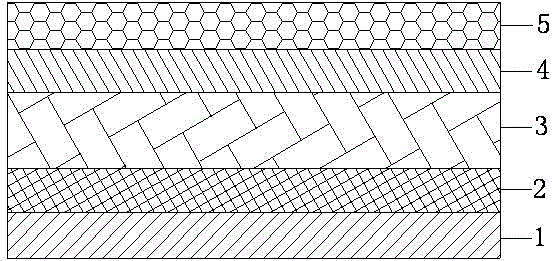

High-safety, water-proof, anti-ultraviolet and cold-resistant fabric

InactiveCN104872893AAntifoulingWaterproofSynthetic resin layered productsProtective garmentFiberUltraviolet

The invention relates to a high-safety, water-proof, anti-ultraviolet and cold-resistant fabric. The fabric comprises a fabric body (1), wherein the surface of the fabric body is covered by a polyurethane film (2); the surface of the polyurethane film is covered by moisture absorption and sweat releasing fibers (3); the surfaces of the moisture absorption and sweat releasing fibers are provided with breathable holes; the surfaces of the moisture absorption and sweat releasing fibers (3) are covered by a water-proof layer (4); the surface of the water-proof layer (4) is covered by a polyurethane coating layer (5). The fabric body is made of a fabric; the periphery of the fabric is covered by an elastic coating made of PU (polyurethane) material. According to the fabric, the smoothness of the fabric can be improved, so the fabric is difficult to contaminate; the fabric has water-proof and breathable effects. The fabric has anti-fouling property, water-proof property, anti-ultraviolet property and cold resistance performance.

Owner:JIANGYIN HARVEST KNITTING & GARMENTS

Waterproof light-emitting fabric with high safety

InactiveCN104875458APrevent penetrationImprove smoothnessSynthetic resin layered productsWire rodFiber

The invention relates to a waterproof light-emitting fabric with high safety. The fabric comprises a fabric body (1), wherein the surface of the fabric body is covered by a polyurethane film (2); the surface of the polyurethane film is covered by moisture adsorption and sweat removing fibers (3); the surfaces of the moisture adsorption and sweat removing fibers are provided with air holes; the surfaces of the moisture adsorption and sweat removing fibers (3) are covered by a waterproof layer (4); the surface of the waterproof layer (4) is covered by a polyurethane coating layer (5); the fabric body is made from a fabric; the fabric comprises a fabric body and light-emitting threads; the light-emitting threads are fixedly arranged on the fabric body by knitting or embroidery and form a modelling body on the fabric body. The fabric has the beneficial effects that the smoothness of the fabric can be improved, so that the fabric is not easy to stain; the fabric has waterproof and breathable effects; the fabric emits light.

Owner:JIANGYIN TIANCHENG TEXTILE

Waterproof, washable and quick-drying fabric with high safety

InactiveCN104875456APrevent penetrationImprove smoothnessSynthetic resin layered productsPolyurethane coatingMoisture

The invention relates to a waterproof, washable and quick-drying fabric with high safety. The fabric comprises a fabric body (1), wherein the surface of the fabric body is covered by a polyurethane film (2); the surface of the polyurethane film is covered by moisture adsorption and sweat removing fibers (3); the surfaces of the moisture adsorption and sweat removing fibers are provided with air holes; the surfaces of the moisture adsorption and sweat removing fibers (3) are covered by a waterproof layer (4); the surface of the waterproof layer (4) is covered by a polyurethane coating layer (5); the fabric body is made from a fabric; the fabric is formed by interweaving warps and wefts; both the warps and the wefts adopt core-spun yarns of cotton-covered polyester filament yarns; the cross sections of the polyester filament yarns are shaped like a pentagram. The fabric has the beneficial effects that the smoothness of the fabric can be improved, so that the fabric is not easy to stain; the fabric has waterproof and breathable effects; the fabric is washable and quick-drying.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Shuixiu stone matrix for health-preserving flower potting

InactiveCN105777311AFull of nutritionSufficient nutritionFertilizer mixturesThermal insulationManganese

The invention discloses a Shuixiu stone matrix for health-preserving flower potting. Raw materials of the matrix comprise, by weight, 50-65 parts of Shuixiu stone powder, 3-5 parts of black soil, 5-8 parts of sandy loam, 10-18 parts of humic acid, 0.03-0.05 part of trace element magnesium, 0.1-0.3 part of iron, 0.03-0.05 part of copper, 0.02-0.03 part of zinc, 0.03-0.05 part of manganese and 0.15-0.2 part of boric acid. The Shuixiu stone powder is particles which are obtained after smashing and grinding of Shuixiu stone and have particle size of 2-5 mm. the black soil is high-nutrient high-quality black soil with content of organic matter being 8-10% after screening grinding. After mixed, the above raw materials are stirred while sprayed with water until uniform; and then the mixture undergoes airing and bagging. In comparison with existing health-preserving flower potting matrixes, the matrix of the invention has advantages of good air permeability and water permeability and adequate and comprehensive nutrient and also has advantages of thermal insulation and fertilizer conservation.

Owner:马映成

Waterproof and good-sewing fabric with high safety

InactiveCN104859255AImprove insulation effectWith insulationLayered product treatmentSynthetic resin layered productsFiberCompound a

The invention relates to a waterproof and good-sewing fabric with high safety. The waterproof and good-sewing fabric comprises a fabric body (1), wherein a polyurethane membrane (2) covers the surface of the fabric body (1); moisture-absorption and perspiration fibers (3) cover the surface of the polyurethane membrane; air vents are formed in the surfaces of the moisture-absorption and perspiration fibers; a waterproof layer (4) covers the surfaces of the moisture-absorption and perspiration fibers (3); a polyurethane coating layer (5) covers the surface of the waterproof layer (4). The fabric body is made of a textile; the textile is formed by compounding a metal textile layer and a heat-insulation layer; the metal textile layer is formed by directly plating and covering a metal film layer and the textile; a single-layer composite structure is formed between the two layers or a multilayered composite structure is formed between the two layers. By virtue of the waterproof and good-sewing fabric with the high safety, the smoothness of the fabric can be improved, and the fabric is not easy to pollute, and has waterproof and ventilation effects. The waterproof and good-sewing fabric has a good sewing performance.

Owner:JIANGSU HEJIA TEXTILE

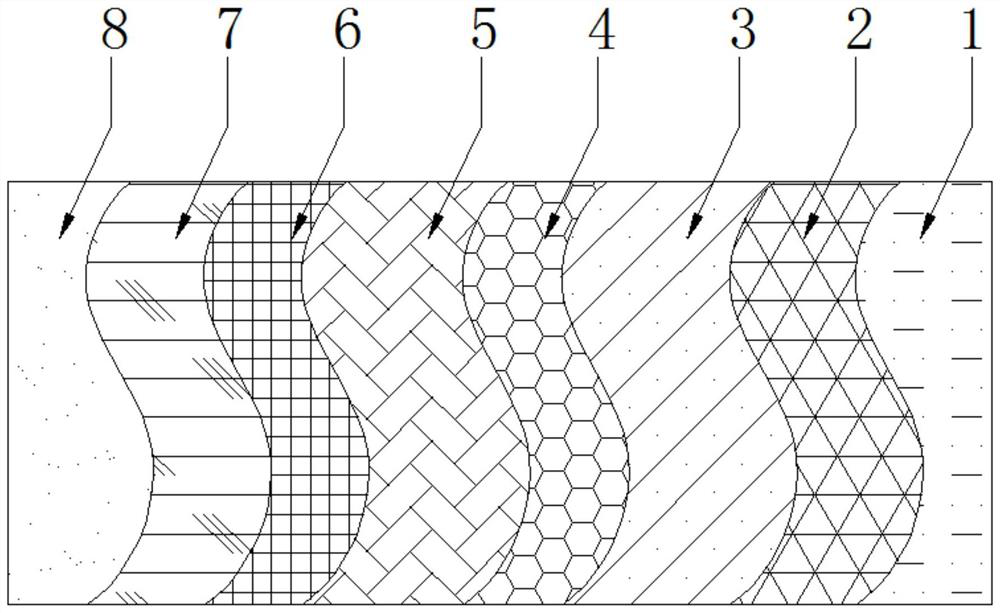

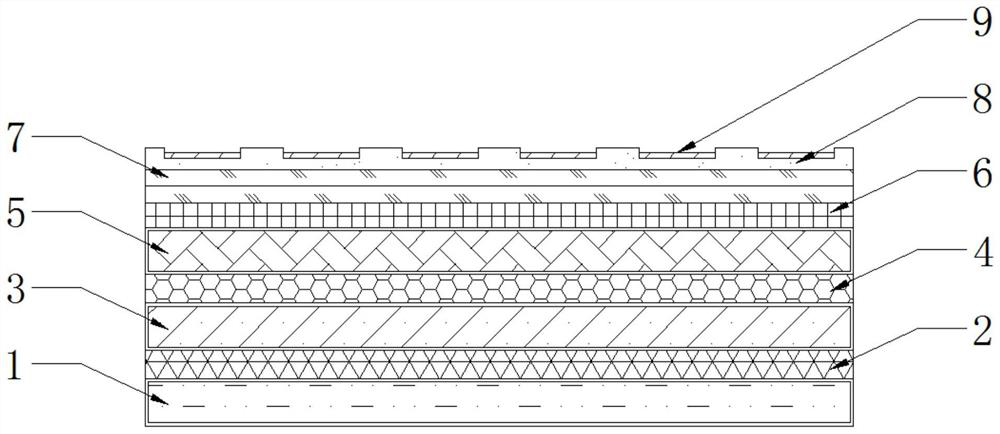

Fabric with heat-resistant and flame-retardant functions

InactiveCN114506138AIncreasing the thicknessAntibacterialSynthetic resin layered productsMetal layered productsPolyesterActivated carbon

The invention discloses a fabric with heat-resistant and flame-retardant functions, and relates to the technical field of fabrics, the fabric comprises an inner surface fabric layer, a middle fabric layer and an outer surface fabric layer, an anti-radiation fabric layer is fixed above the inner surface fabric layer, the middle fabric layer is fixed above the anti-radiation fabric layer, an anti-static layer is arranged on the upper side of the middle fabric layer, and the outer surface fabric layer is fixed above the anti-static layer. The outer surface fabric layer is fixed to the upper side of the anti-static layer, the breathable mesh cloth is arranged on the upper side of the outer surface fabric layer, the waterproof fabric layer is fixed to the upper side of the breathable mesh cloth, the jacquard layer is arranged on the upper side of the waterproof fabric layer, and the outer protective coatings are arranged on the surface of the jacquard layer at equal intervals. The fabric with the heat-resistant and flame-retardant functions is provided with a multi-layer composite structure, the fabric thickness and the cloth strength of the fabric are good, the fabric has the multiple functions of resisting bacteria, preventing ultraviolet rays, preventing static electricity and the like, and in addition, due to the arrangement of the composite chemical fiber layer, the flame-retardant polyester fiber layer, the activated carbon cloth and the like, the fabric with the heat-resistant and flame-retardant functions is good in heat-resistant and flame-retardant effect and wide in applicability.

Owner:牟向晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com