Preparation method of polyurethane microporous membrane

A microporous film, polyurethane technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of poor wind resistance, bad hand feel, hard and brittle, etc., and achieves strong cold resistance, wide application prospects, and soft feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preparation method of polyurethane microporous film, comprising the following steps:

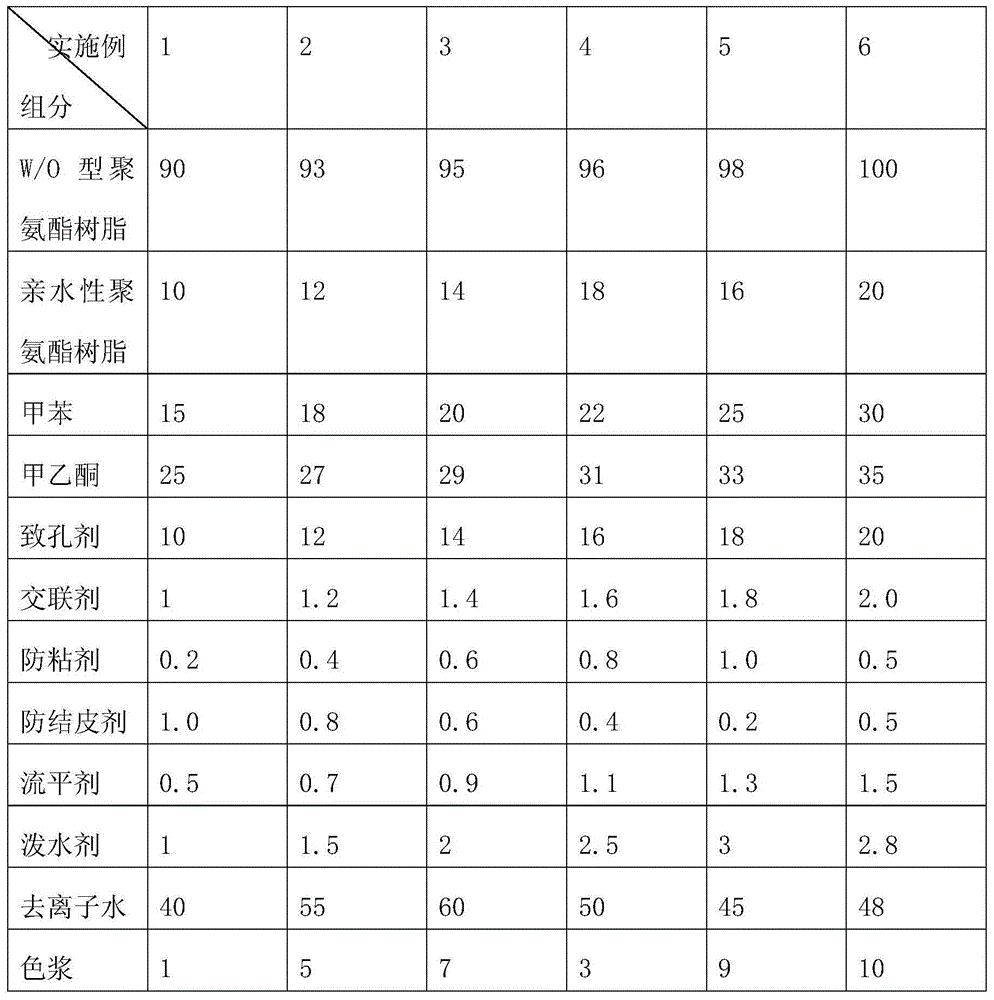

[0038] 1. Take the composition of the mass parts of each embodiment listed in Table 1 respectively, stir to form the emulsion to be coated, wherein, W / O type polyurethane resin and hydrophilic polyurethane resin that can be miscible with it form polyurethane Blend the resin, and then form a coating solution with various additives such as toluene, methyl ethyl ketone, water, and porogen;

[0039] ② Coating the above-mentioned coating emulsion on the transfer carrier, peeling off after drying to obtain the polyurethane microporous film. When coating, the principle of dry phase transition is mainly used to form a polyurethane microporous film. The pore-forming mechanism is as follows: from the components of the solution to be coated, the solvent used is a mixture of four courtyards, and toluene is a diluent. , methyl ethyl ketone is a solvent, water is a non-solvent, and porogen is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com