Moisture-absorbing and sweat-discharging fabric of double-layer structure and preparation process thereof

A technology of moisture absorption and perspiration, double-layer structure, applied in textiles, fabrics, multi-strand fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

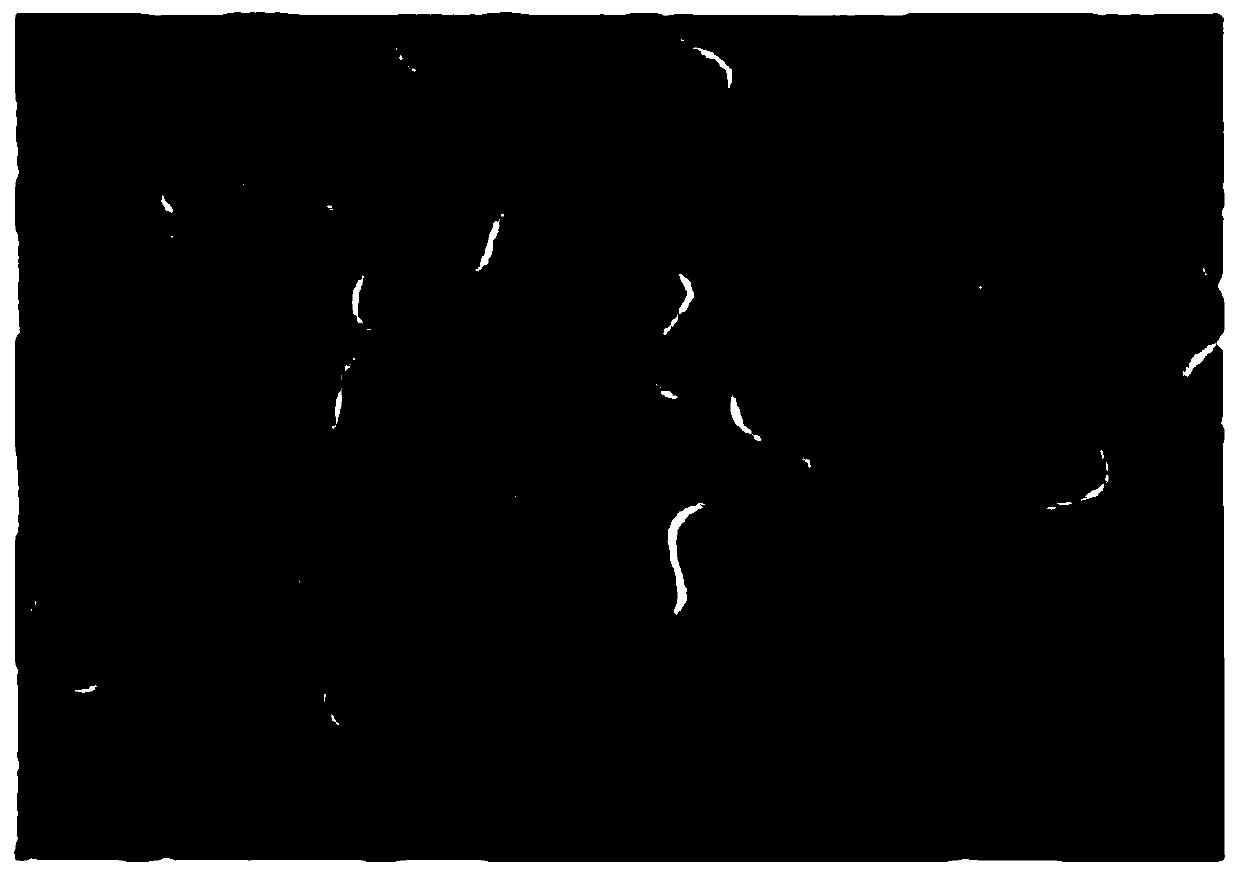

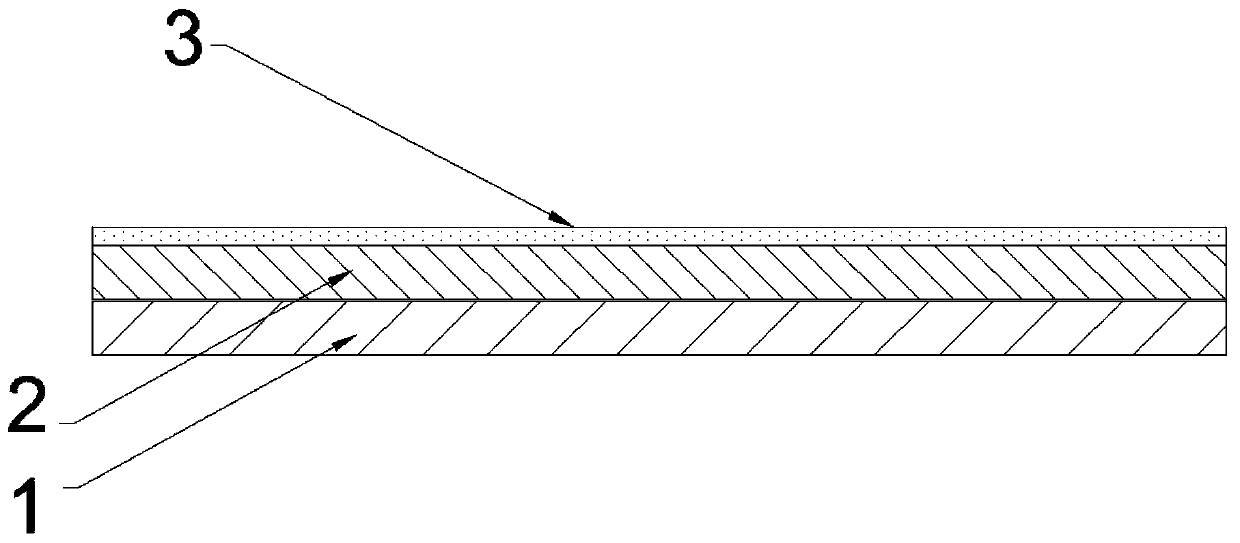

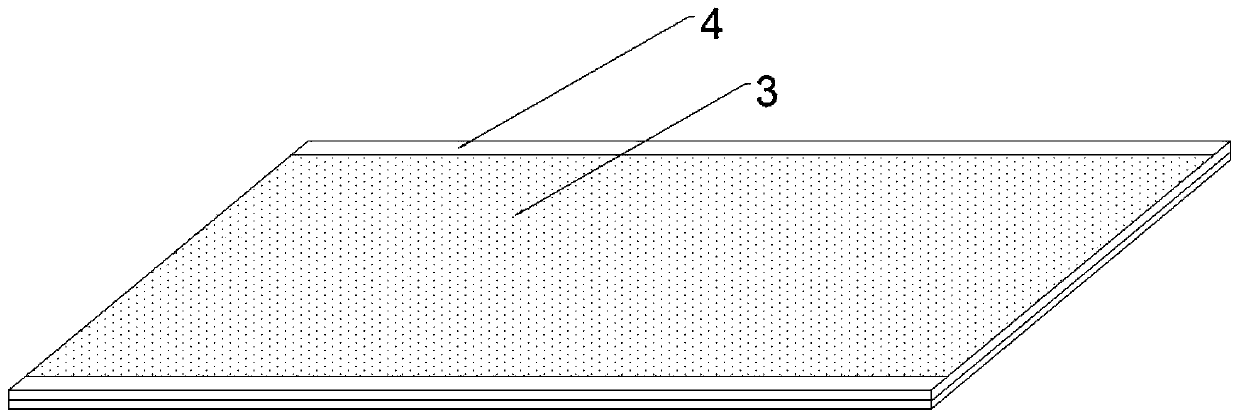

Image

Examples

Embodiment 1

[0025] Embodiment 1 discloses a preparation process for a moisture-absorbing and perspiration-wicking fabric with a double-layer structure, including the following preparation steps:

[0026] Step 1. Preparation of double-layer grey fabric

[0027] Two sets of warp yarns and two sets of weft yarns are weaved on a warp loom, and double-layer grey fabrics are formed after warping, sizing, reeding and weaving in turn; wherein, in the warping process in step 1, a mechanical tension controller is used to warp The vehicle speed is controlled at 150-180r / min to prevent uneven warping tension and mis-twisting. In the sizing process, the mass ratio of the size is polyvinyl alcohol: low-viscosity starch: modified starch: LMA-95 synthetic size: antistatic agent: sizing oil agent=5:4:2:1:1:0.5 The temperature of the slurry tank is 80°C, and the vehicle speed is controlled at 30-40m / min.

[0028] Step 2: Finishing the grey fabric

[0029] The woven double-layer grey fabric is sequential...

Embodiment 2

[0034] Embodiment 2 discloses a preparation process of a moisture-absorbing and perspiration-wicking fabric with a double-layer structure, including the following preparation steps:

[0035] Step 1. Preparation of double-layer grey fabric

[0036]Two sets of warp yarns and two sets of weft yarns are weaved on a warp loom, and double-layer grey fabrics are formed after warping, sizing, reeding and weaving in turn; wherein, in the warping process in step 1, a mechanical tension controller is used to warp The vehicle speed is controlled at 150-180r / min to prevent uneven warping tension and mis-twisting. In the sizing process, the mass ratio of the size is polyvinyl alcohol: low-viscosity starch: modified starch: LMA-95 synthetic size: antistatic agent: sizing oil agent=5:4:2:1:1:0.5 The temperature of the slurry tank is 80°C, and the vehicle speed is controlled at 30-40m / min.

[0037] Step 2: Finishing the grey fabric

[0038] The woven double-layer grey fabric is sequentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com