One-way moisture-conducting tooling fabric and preparation method thereof

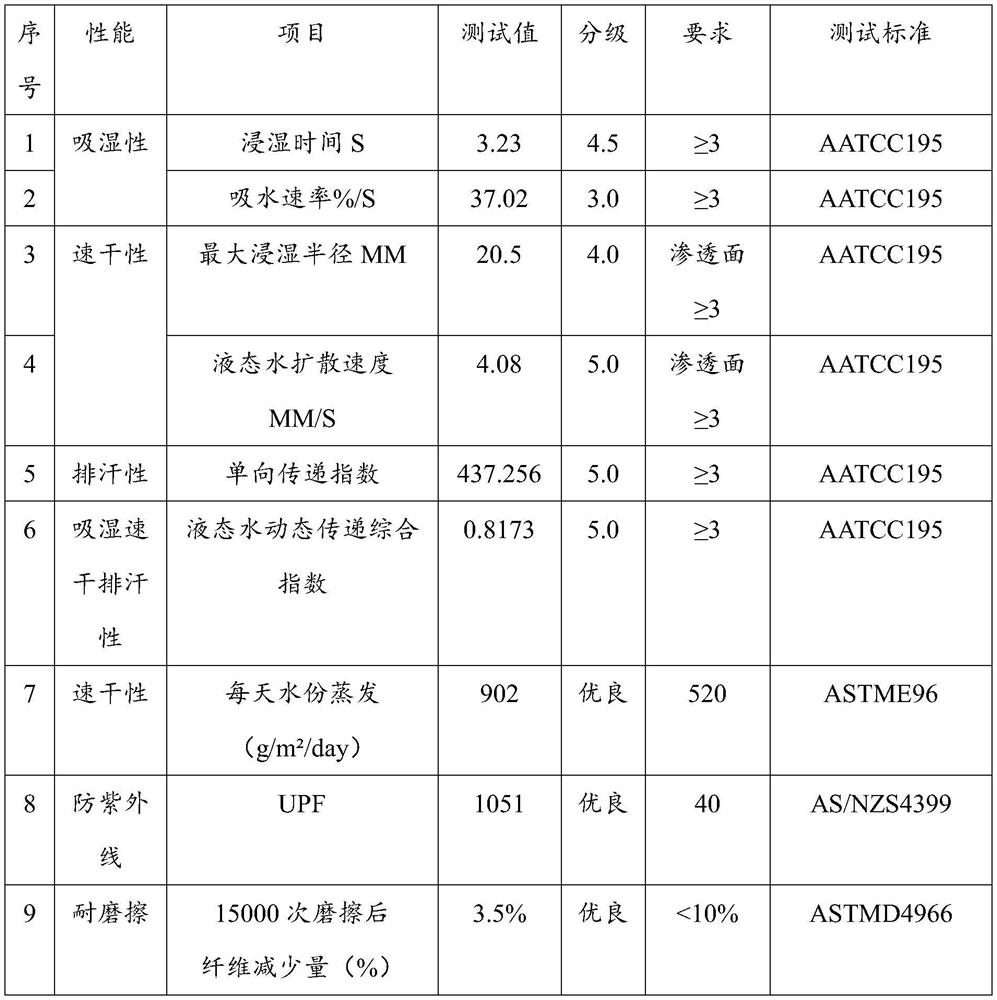

A one-way moisture guide and tooling technology, which is applied in textile, plant fiber, fiber treatment, etc., can solve the problems of high cost of fiber physical or chemical modification, thick multi-layer structure cloth, complex process, etc., to achieve good one-way moisture guide Excellent performance, good moisture-conducting effect, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a unidirectional wet-conducting tooling fabric, comprising the following steps:

[0024] 1) using a finishing agent to carry out moisture absorption and quick-drying finishing to the blended fabric to obtain a modified blended fabric;

[0025] 2) Coating the coating slurry on the surface of the modified blended fabric, and then performing single-sided printing to obtain a single-sided wet-conducting tooling fabric.

[0026] In the present invention, the blended fabric is made by blending cotton and polyester, wherein the blending ratio of cotton and polyester is 52-58:42-48, preferably 53-56:44-47, more preferably 55:45 .

[0027] In the present invention, the blended fabric is made of 3 / 2 twill weave, and the warp and weft density of the blended fabric is 143×112 pieces / inch.

[0028] In the present invention, during the moisture-absorbing and quick-drying finishing process, the rolling ratio is 70-80%, preferably 72-78%, and more preferably 75...

Embodiment 1

[0036] The cotton and polyester blended yarns with a ratio of 55:45 were woven with a 3 / 2 twill weave, and the warp and weft density was designed to be 143×112 threads / inch to obtain a blended fabric. The blended fabric with HMW8871 finishing agent is used for moisture absorption and quick-drying finishing to obtain a modified blended fabric (the rolling ratio is 75%, and the shape is set at 180°C after the impregnation is completed);

[0037] The waterproof coating prepared by using C6 water repellent 50g / L, anti-ultraviolet agent HTUV100 6g / L, thickener N254 with a total mass of 3% and the balance of water was used as the coating slurry. The surface of the blended fabric, and then single-sided printing (the single-sided printing process is: use a 125-mesh rotary screen for single-sided printing, the diameter of the squeegee bar is 8mm, the pressure is 70N, the sizing ratio is 68%, and the printing speed is 50m / min) to obtain a unidirectional wet guide tooling fabric.

[003...

Embodiment 2

[0043] The cotton and polyester blended yarns with a ratio of 52:48 were woven with a 3 / 2 twill weave, and the warp and weft density was designed to be 143×112 threads / inch to obtain a blended fabric. Use HMW8871 finishing agent blended fabric to carry out moisture-absorbing and quick-drying finishing to obtain modified blended fabric (rolling ratio is 70%, after dipping is completed, it is set at 190 ° C);

[0044] The waterproof coating prepared by C8 water repellent 45g / L, anti-ultraviolet agent HTUV100 8g / L, thickener N254 with a total mass of 2% and the balance of water was used as the coating slurry. The surface of the blended fabric, and then single-sided printing (the single-sided printing process is: use a 125-mesh rotary screen for single-sided printing, the diameter of the squeegee bar is 8mm, the pressure is 70N, the dipping ratio is 65%, and the printing speed is 45m / min) to obtain one-way guide wet tooling fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com