A kind of hydrogel printing fabric and preparation method thereof

A hydrogel printing and hydrogel technology, which is applied in the field of clothing fabrics, can solve the problems of weakened cooling effect and long-lasting cooling effect, and achieve the effects of lasting cooling effect, promoting the generation of cool feeling, and reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Correspondingly, the invention provides a kind of preparation method of hydrogel printing fabric, comprises the following steps:

[0047] Mixing hydrogel powder, printing paste, cooling material, thickener and oily solvent to obtain slurry; the hydrophilic group content in the hydrogel powder is 20-30wt%;

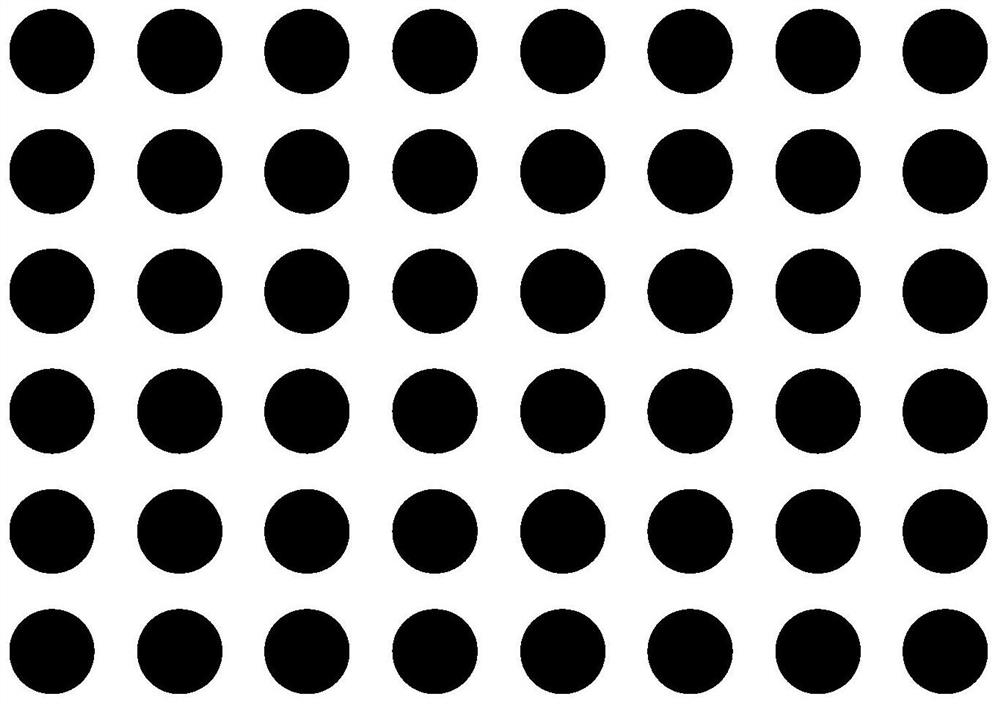

[0048] The slurry is printed on the fabric, dried and baked to obtain a hydrogel printed fabric with discontinuous printing patterns.

[0049] The invention prepares a hydrogel printed fabric with a cool feeling function through a printing process, and the fabric has a long-lasting cool feeling, and at the same time can maintain a stable temperature of the human body without sweating a lot, so that the human body can maintain a good and comfortable clothing environment for as long as possible. Conducive to the protection of human health.

[0050] In the embodiment of the present invention, 10-20 parts of hydrogel powder, 10-20 parts of printing glue, 2-3 parts of co...

Embodiment 1

[0059] 1. Hydrogel synthesis:

[0060] In parts by mass, dissolve 4 parts of N-isopropylacrylamide, 6 parts of methyl methacrylate, 15 parts of hydrophilic monomer acrylic acid, 15 parts of methyl acrylate, and 15 parts of butyl acrylate in 25 parts of ethanol , then add 15 parts of water, and at the same time add 1 part of cross-linking monomer diacetone acrylamide to the reaction system, dissolve it with constant temperature magnetic stirring and seal it in the reaction kettle.

[0061] Add 0.01-0.02 parts of reducing agent sodium bisulfite to the reaction kettle, pass nitrogen to remove oxygen, remove the oxygen in the reaction kettle that has the effect of inhibiting polymerization for 10-20min, slowly drop into the aqueous solution of 0.03-0.04 parts of potassium persulfate, Stir and polymerize at 50-60°C for 4h. After the reaction, the resulting gel was soaked in distilled water for 6 h at room temperature to remove residual monomers and uncrosslinked macromolecules. F...

Embodiment 2

[0070] 1, hydrogel synthesis (same as embodiment one):

[0071] In parts by mass, dissolve 4 parts of N-isopropylacrylamide, 6 parts of methyl methacrylate, 15 parts of hydrophilic monomer acrylic acid, 15 parts of methyl acrylate, and 15 parts of butyl acrylate in 25 parts of ethanol , then add 15 parts of water, and at the same time add 1 part of cross-linking monomer diacetone acrylamide to the reaction system, dissolve it with constant temperature magnetic stirring and seal it in the reaction kettle.

[0072]Add 0.01-0.02 parts of reducing agent sodium bisulfite to the reaction kettle, pass nitrogen to remove oxygen, remove the oxygen in the reaction kettle that has the effect of inhibiting polymerization for 10-20min, slowly drop into the aqueous solution of 0.03-0.04 parts of potassium persulfate, Stir and polymerize at 50-60°C for 4h. After the reaction, the resulting gel was soaked in distilled water for 6 h at room temperature to remove residual monomers and uncrossl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com