Patents

Literature

78results about How to "Soft fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural dye mordanting dyeing or mordanting printing product and preparation method thereof

ActiveCN105113290AHigh color fastnessUniform base colorFibre treatmentDyeing processMordantNatural dye

The invention provides a method for preparing a natural dye mordanting dyeing or mordanting printing product. The preparation method comprises the steps of performing pretreatment on a fabric, using cation modified working solution to perform cation modification on the fabric, and obtaining cation-modified fabric; using natural dye to dye the cation-modified fabric and obtaining a natural dye dyeing fabric; using a mordant working solution or mordant working solution foam to perform mordanting dyeing or mordanting printing on the natural dye dyeing fabric at a predetermined area, performing steaming or baking at 80-180 DEG C for 10 s to 25 min, performing washing, softening and shaping, and obtaining the natural dye mordanting dyeing or mordanting printing product. The invention further provides the natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method. The natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method is good in color fastness and uniform in base color, the printing part is dark in color, the material loss is less, and a fabric is softer.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

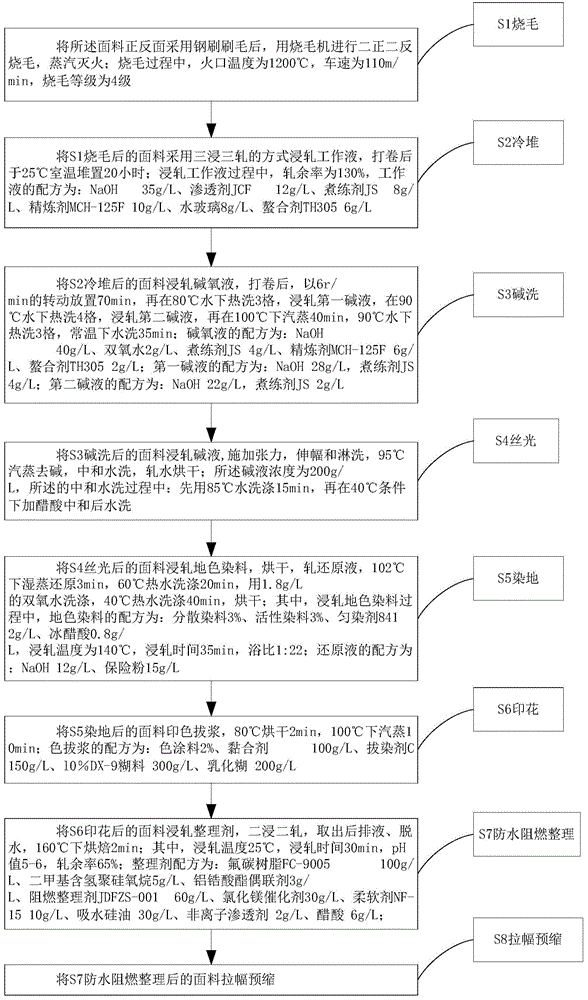

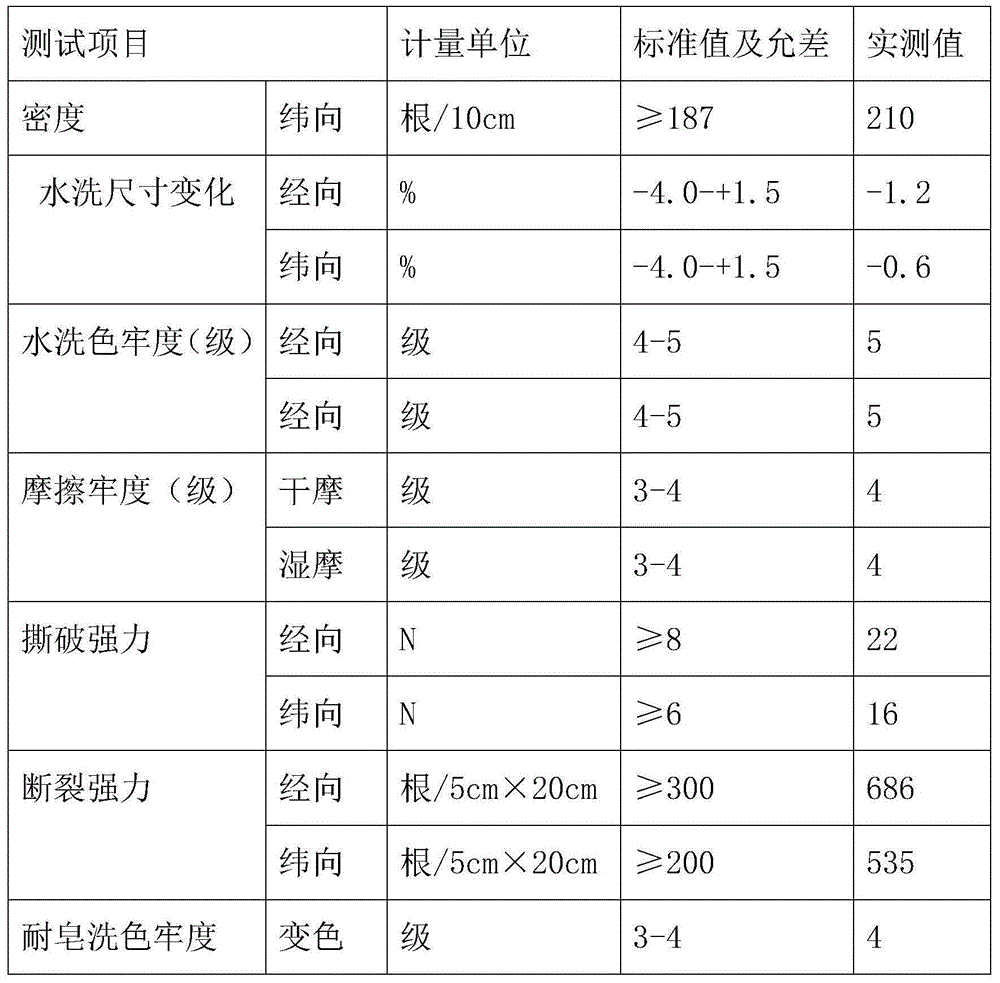

Dyeing and printing technology of camouflage fabric

InactiveCN105040490AImprove tensile propertiesImprove printing and dyeing adsorption functionDyeing processWoven fabricsCamouflagePolyester

The invention discloses a dyeing and printing technology of a camouflage fabric. The camouflage fabric is prepared by blending and interweaving the following raw materials in percentage by weight: 30%-50% of cotton fiber, 30%-50% of polyester fiber, 10%-30% of spandex fiber and 10%-20% of spun silk fiber. The dyeing and printing technology comprises the following steps: S1 singeing; S2 cold heaping; S3 alkaline washing; S4 mercerizing; S5 ground dyeing; S6 printing; S7 waterproof and flame-proof treatment; and S8 stentering pre-shrinking. According to the dyeing and printing technology of the camouflage fabric, the high color fastness of the dyed ground color and the front and rear stability of the color of the camouflage fabric can be ensured; the camouflage printing requirements can be met; the quality repeatability is good; and the quality index of the finished product can meet the customer requirements.

Owner:芜湖市瑞都服装贸易有限公司

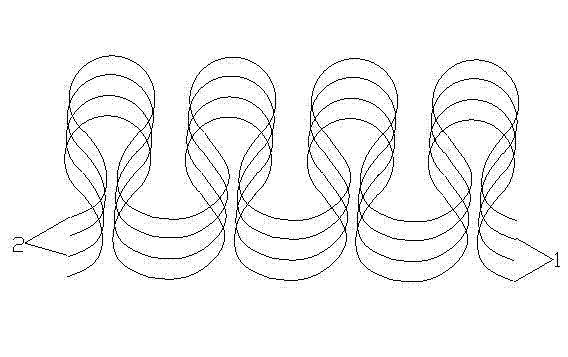

Production method of spun silk and cotton blended spunlace nonwoven fabric

The invention discloses a production method of spun silk and cotton blended spunlace nonwoven fabric, wherein a flat top card replaces the traditional carding machine used in a nonwoven production line, and can perform sufficient carding of fiber so that the silk cotton net has low trash content and is longitudinally and transversely uniform and the fiber is in regular arrangement. The method performs temperature / humidity control in a production area, control on the spinning adaptability, mixing uniformity and antistatic property of the raw material, and optimization of the cotton net production technology, spunlace forming technology and degreasing and bleaching technology, so that the produced nonwoven fabric product not only maintains the elasticity and moisture absorption of cotton fiber, but also has the additional advantages of softness, smoothness and good glossiness of the spun silk based on the pure cotton cloth. The spun silk and cotton blended spunlace nonwoven fabric produced by the method has good extensibility, soft cloth cover and good water absorption, sufficiently reflects the skin-friendly performance of the spun silk serving as protein fiber filament, and has wide application prospects in the female high-grade make-up mask material.

Owner:ANQING HUAWEI IND FABRICS HI TECH CO LTD

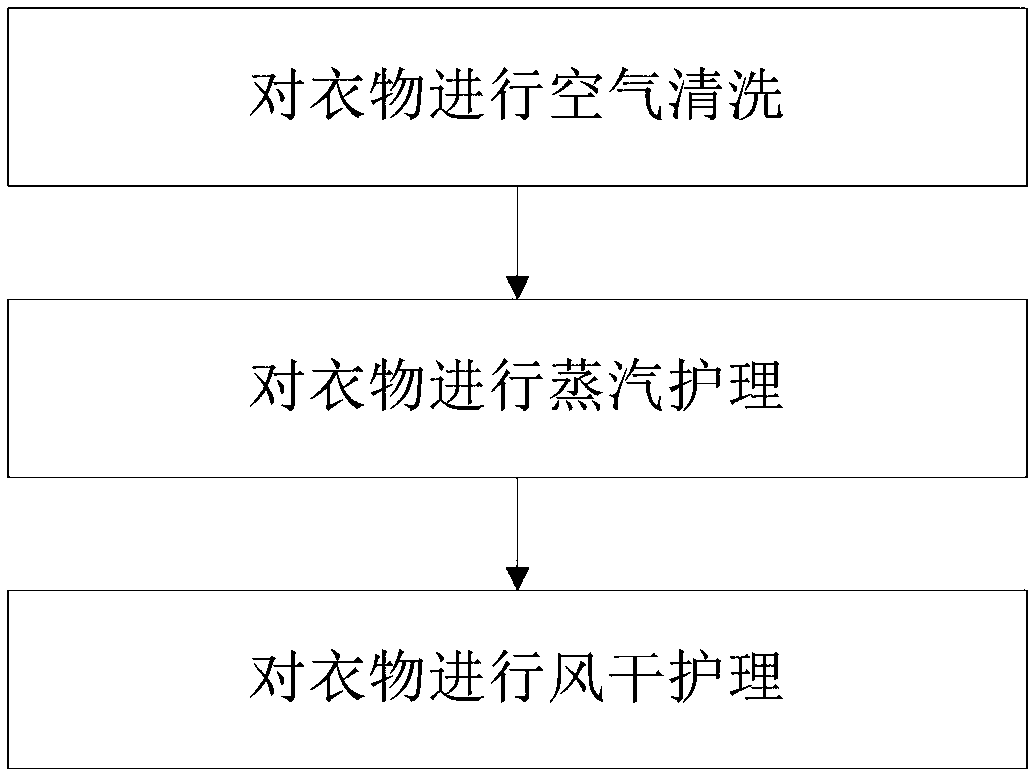

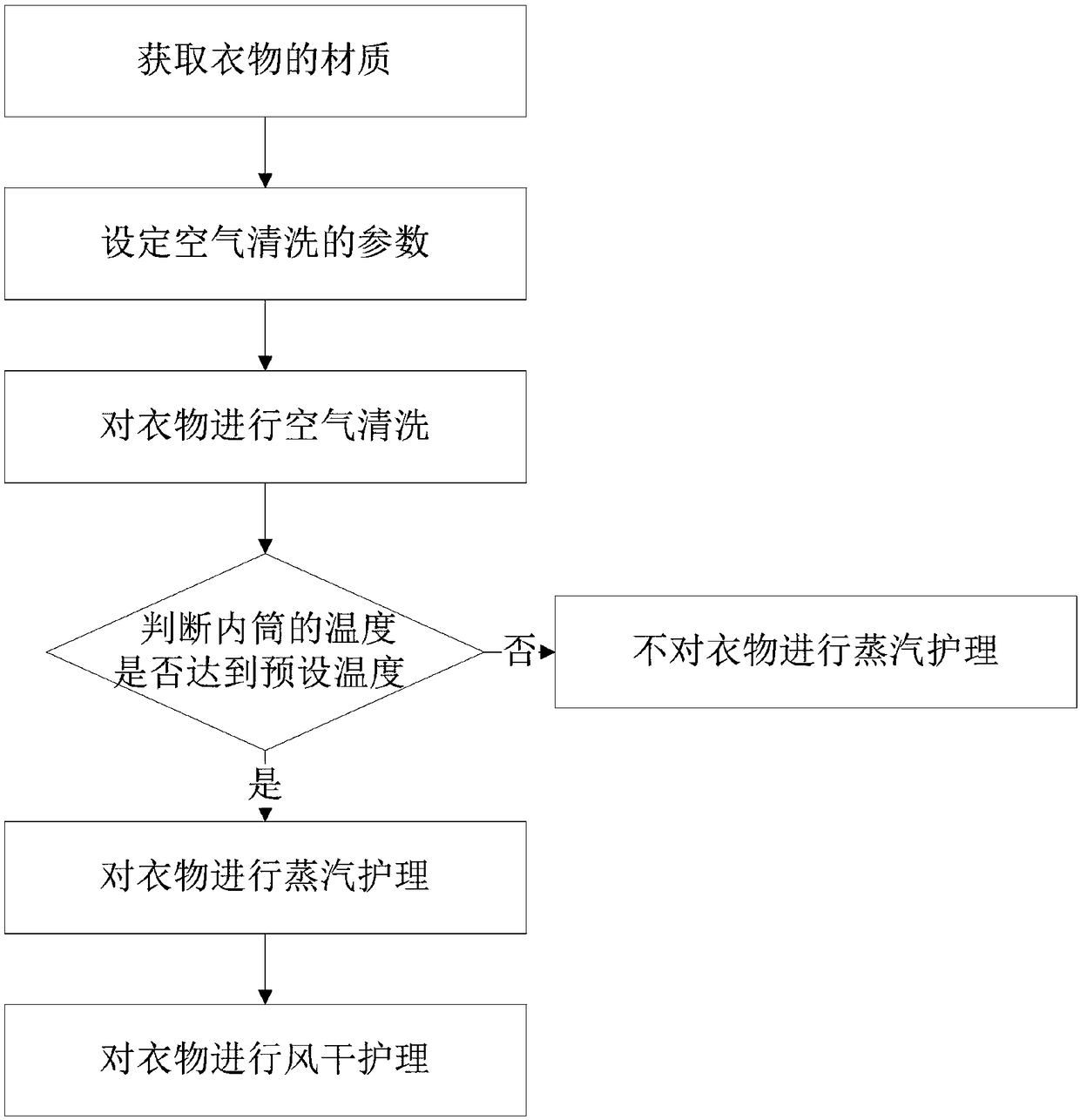

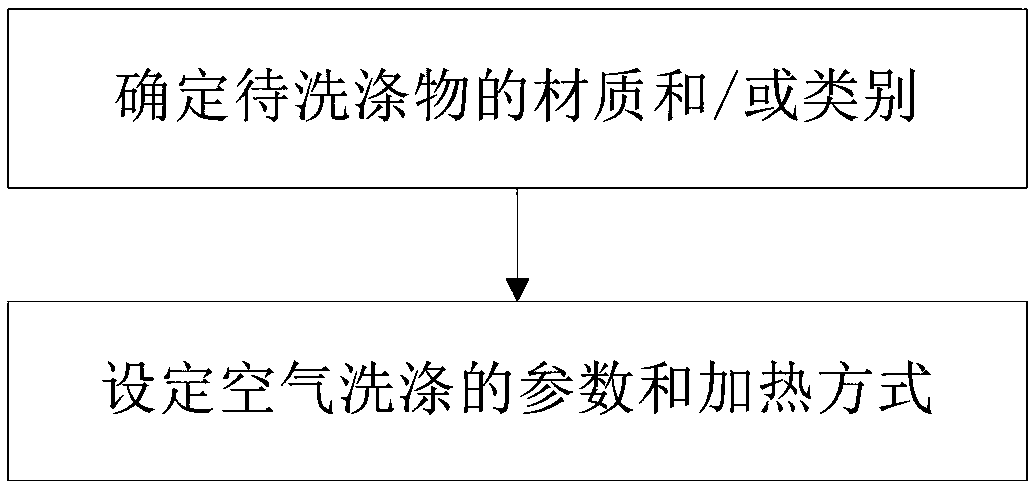

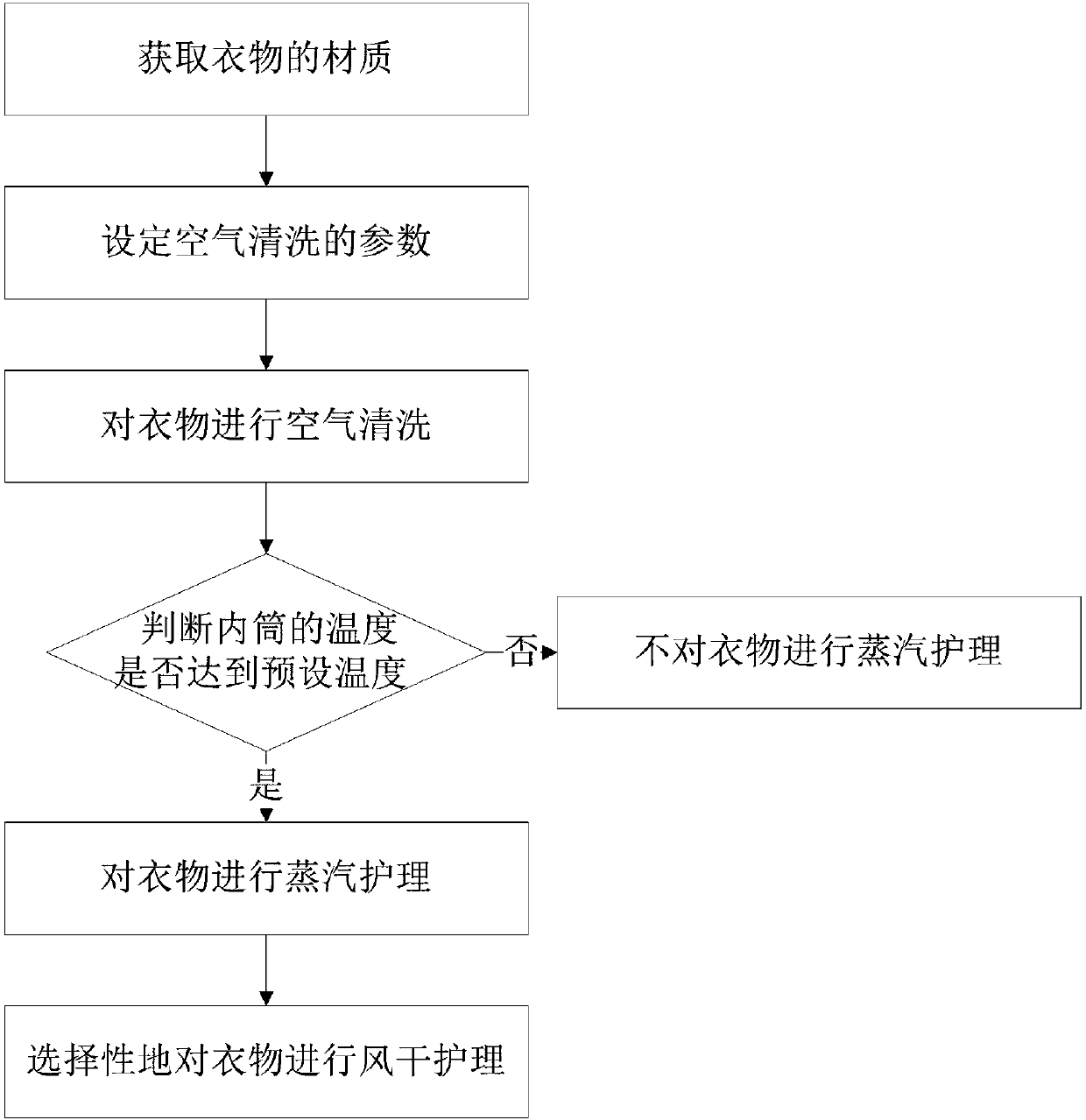

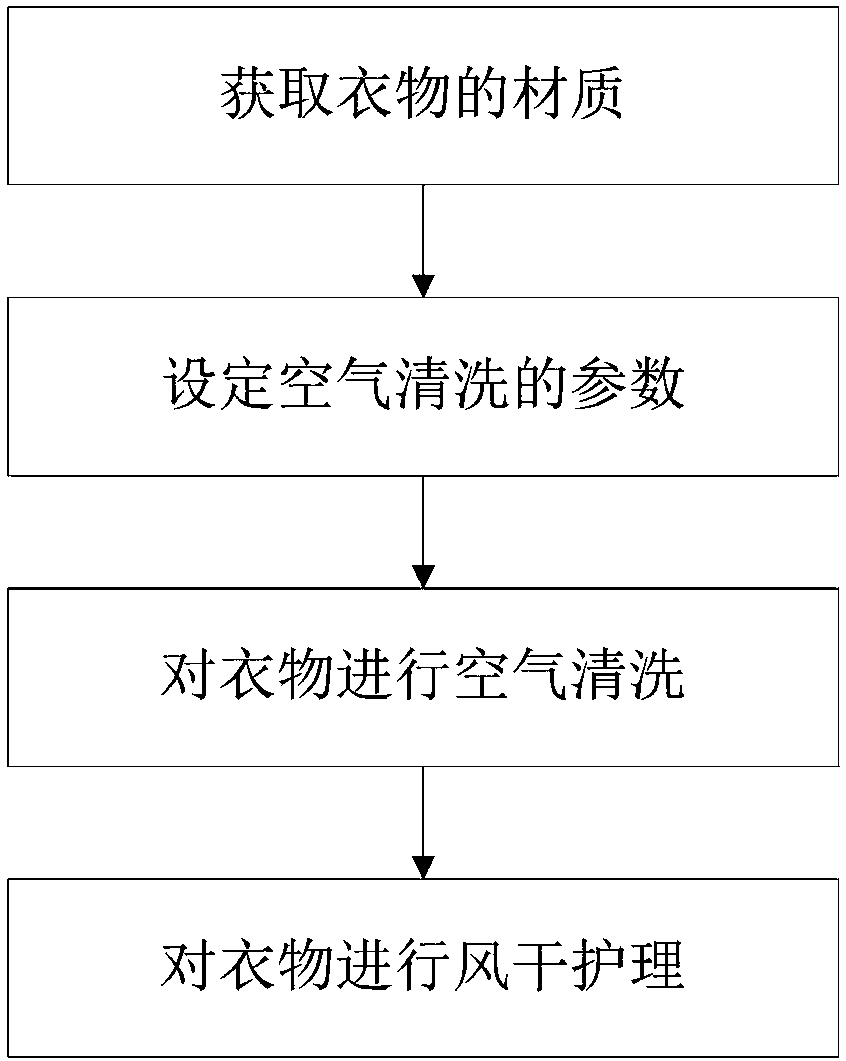

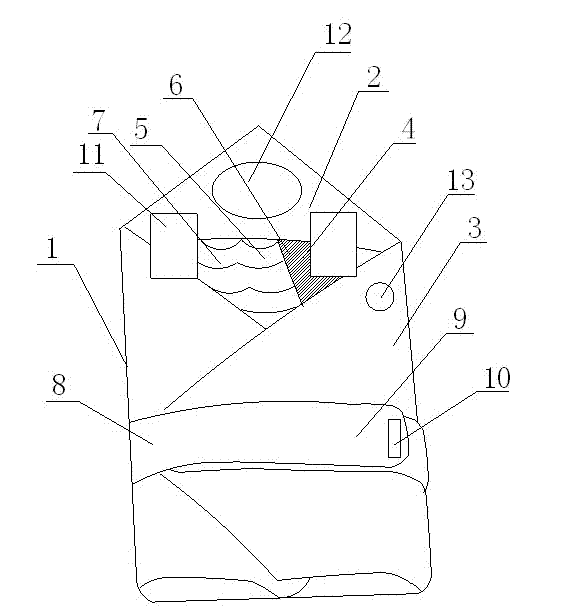

Clothes processing method for clothes processing device and clothes processing device

ActiveCN108315945AImprove wearing comfortFully stretchedOther washing machinesControl devices for washing apparatusAir cleaningEngineering

The invention belongs to the technical field of clothes processing, and aims at solving the problem that a traditional washing mode cannot meet cleaning requirements of users on clothes made of mediumand high-grade materials. For this purpose, the invention provides a clothes processing method for a clothes processing device and the clothes processing device. The clothes processing method includes the steps of conducting air cleaning on the clothes; conducting steam nursing on the clothes; conducting air drying nursing on the clothes. Through air cleaning, the fibers of the clothes are fullyextended, the elasticity of the clothes is increased, and the shell fabric of the clothes is softer; through steaming nursing, blots on the clothes are cleared away quickly, and steaming nursing has abactericidal effect; through air drying nursing, water vapor on the clothes is evaporated quickly, and the clothes is aired quickly. Through the combined processing mode, the shell fabric of the clothes is softer and more elastic, the wearable comfort level of the clothes is increased, the cleaning effect is good, the washing cleanliness is high, no damage is caused to the clothes, and thereforethe user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

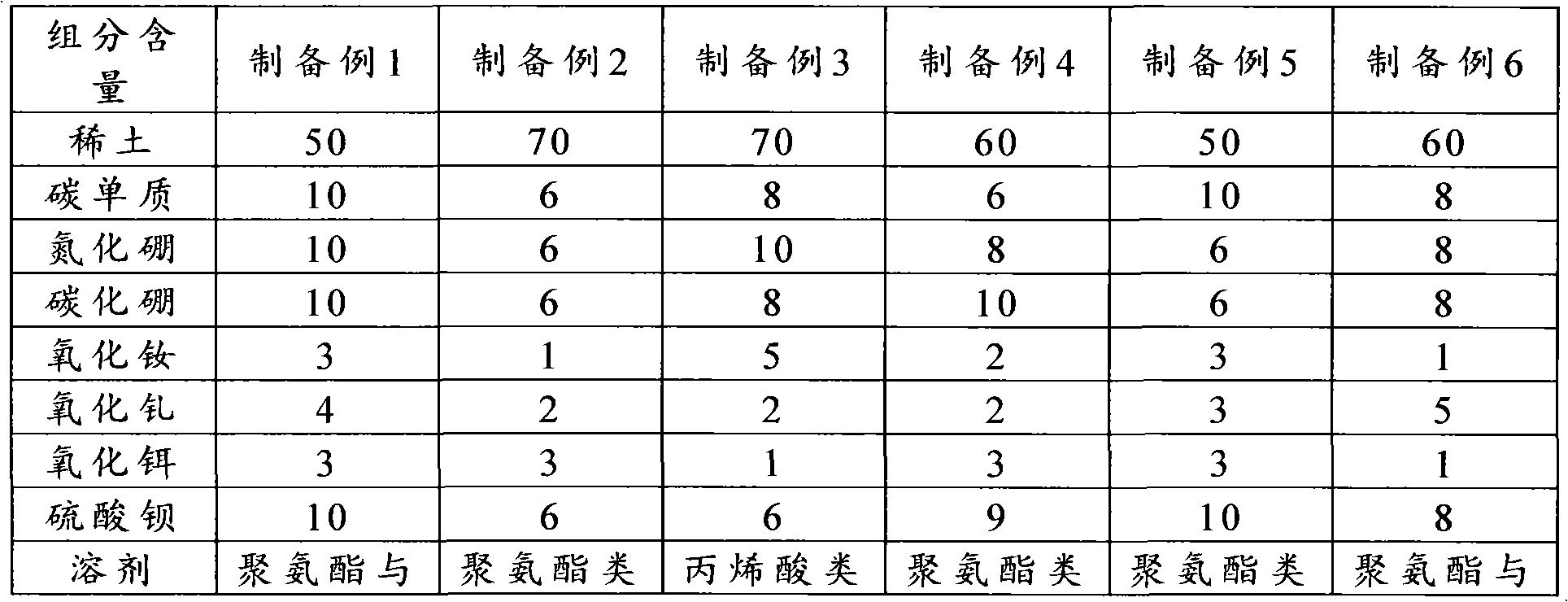

Silver-plated cloth with rare earth-shielding composite layer, preparation method thereof and clothes made of same

The invention relates to a piece of silver-plated cloth with a rare earth-shielding composite layer, comprising a piece of silver-plated cloth. The silver-plated cloth is characterized by comprising the rare earth-shielding composite layer, and the rare earth-shielding composite layer is formed by dissolving the following components in a solvent by mass percentage: 50-70 parts of rare earth and 30-50 parts of composite, wherein the composite comprises the following components by mass percentage: 6-10 parts of monoatomic carbon, 6-10 parts of boron nitride, 6-10 parts of boron carbide, 6-10 parts of neodymium oxide, gadolinium oxide and erbium oxide as well as 6-10 parts of barium sulfate. The silver-plated cloth with the rare earth-shielding composite layer can effectively shield various ionizing rays (x, alpha, beta or gamma) as well as electromagnetic radiation, and also has the function of shielding infrared rays; and the cloth achieves light weight and softness, and can be applied to the ray shielding of the fields of frocks, war industry, operations, electricians, and the like. The invention also relates to a method for preparing the silver-plated cloth with the rare earth-shielding composite layer and silver-plated clothes with the rare earth-shielding composite layer.

Owner:青岛天银纺织科技有限公司

Gas washing method for clothes treating equipment and clothes treating equipment

ActiveCN108374269AGas scrubbing facilitatesAvoid damageDry-cleaning apparatusOther washing machinesFiberProcess engineering

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Degreasing laundry detergent

InactiveCN105255602AWash thoroughlySoft fabricInorganic/elemental detergent compounding agentsAmpholytes/electroneutral surface-active compoundsChemistrySODIUM OLEFIN SULFONATE

The invention discloses degreasing laundry detergent. The specific combination of sodium sulfonate surfactant and inner sodium-olefin sulfonate is adopted for the degreasing laundry detergent. In the process of removing grease steeped in fabric, washing is thorough, and the fabric is soft and smooth.

Owner:华玉叶

High-light, elastic and easy-to-tear sport fabric and preparation method thereof

InactiveCN107119377AThe preparation method is simple and easy to operateSoft fabricFilament/thread formingHeating/cooling textile fabricsPolyesterWeft yarn

The invention discloses high-light, elastic and easy-to-tear sport fabric. The fabric comprises warp yarn and weft yarn, wherein the warp yarn adopts cation-modified polyester yarn or cation-modified polyester double-covered spandex yarn; the weft yarn adopts cation-modified polyester yarn or cation-modified polyester double-covered spandex yarn; the section of the cation-modified polyester yarn is flat or rhombic; the cation-modified polyester double-covered spandex yarn is formed by covering spandex with two pieces of cation modified polyester yarn. The preparation method of the high-light, elastic and easy-to-tear sport fabric comprises steps as follows: preparation of the cation-modified polyester yarn, preparation of the cation-modified polyester covered spandex yarn, preparation of high-light and elastic sport fabric and preparation of the high-light, elastic and easy-to-tear sport fabric. The high-light, elastic and easy-to-tear sport fabric and the preparation method thereof are simple and easy to operate; the prepared high-light, elastic and easy-to-tear sport fabric has the characteristics of being soft, good in elasticity, high in glossiness and convenient and easy to tear and is attractive and convenient to use.

Owner:杭州巨胜实业有限公司

Fabric containing milk protein fiber, manufacturing technique and textile of fabric containing milk protein fiber

InactiveCN103255536ASoft fabricImprove permeabilityDyeing processWoven fabricsProcess engineeringWool fibre

The invention relates to fabric containing milk protein fiber and a manufacturing technique thereof. The manufacturing technique mainly comprises warp-wise weaving and broad-wise weaving with different raw materials. The fabric containing the milk protein fiber is manufactured through dyeing, sizing, gray fabric test, singeing, relaxation, refining, thermoforming, washing, drying, forming, relaxation, test and curling. The dyeing and sizing technology is adjusted through a dyeing technology which is pretreated and processed through hyperthermic treatment for two times, therefore, a good processing effect is obtained, and damage to the milk protein fiber and wool fiber under various processing technological conditions is reduced effectively. In addition, the fabric containing the milk protein fiber is suitable for being applied to top-grade home textile, top-grade clothing, sports goods and health care goods.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Naturally-degradable environmentally-friendly fiber fabric and processing technology thereof

The invention relates to a naturally-degradable environmentally-friendly fiber fabric which is characterized by comprising, by weight percent, 30-40 % of corn fiber, 20-30 % of bamboo charcoal fiber, 10-20 % of Lyocell fiber, and 10-15 % of polylactic acid fiber. The selected fiber materials are all easy to degrade, thereby being capable of reducing pollution to the environment. Furthermore, the fabric is relatively soft, relatively comfortable if wore, high in fabric strength, good in extensibility, soft in touch, good in drapability, and good in resilience, and can be applied in clothes, home textiles articles, sport articles, and healthcare fabric.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Top-grade Shengma fiber towel fabric and manufacturing method

InactiveCN102560822AGood moisture absorptionImprove breathabilityFibre treatmentWoven fabricsCotton fibreSizing

The invention discloses a top-grade Shengma fiber towel fabric, comprising a base part and a circle part, wherein the base part and the circle part are made from Shengma fibers, bamboo fibers and cotton fibers by mixed spinning. According to the invention, the top-grade Shengma fiber towel fabric prepared by the steps of mixed spinning, sizing and weaving has good hygroscopicity and air permeability and good bacteriostatic and mildew resistance, and the fabric is soft and has natural and soft luster.

Owner:李兆栋

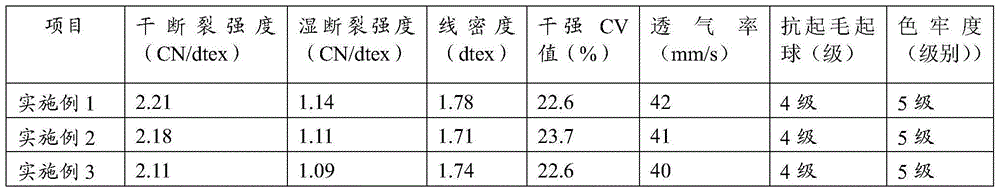

Polyester two-way-stretch fabric dyeing process

InactiveCN109403010AUniform dyeingDyeing firmDry-cleaning apparatus for textilesDyeing processDisperse dyeSewage

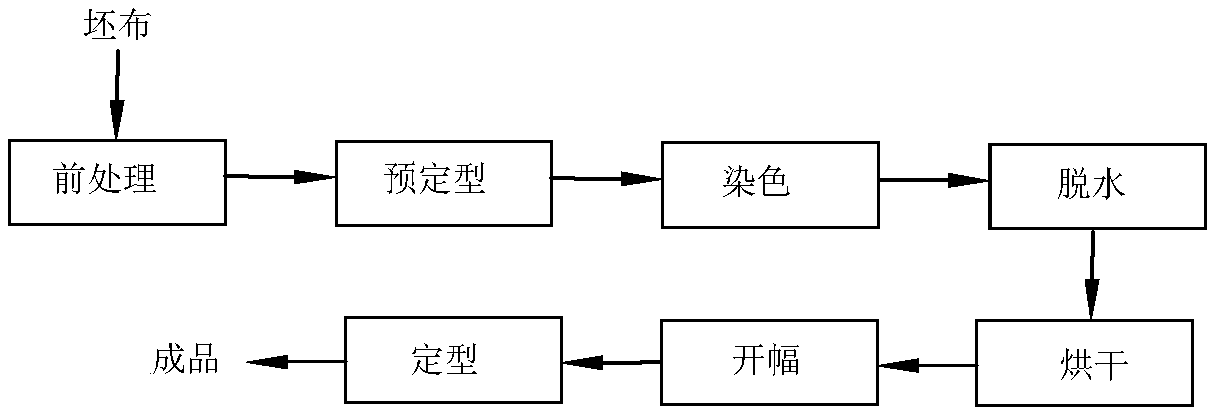

The invention discloses a polyester two-way-stretch fabric dyeing process including the steps of pretreatment, preshaping, dyeing, dehydration, drying, scotching and shaping to obtain a dyed polyestertwo-way-stretch fabric. In the method, under a low bath ratio condition, a dispersed dye is used for dyeing the fabric in two stages in a heat insulation manner, then the temperature is slowly decreased, sewage is discharged and the fabric is cleaned in clear water. The process is used for dyeing the polyester two-way-stretch fabric, is high in dyeing rate and good in color fastness, can reduce folds, shorten operation time and save energy, and can reduce cost.

Owner:SHAOXING COUNTY KWONG FUNG PRINTING & DYEING

Wool fabric with milk fiber and processing technique thereof

InactiveCN104480610AGood moisture absorption and air permeabilityFeel smoothSucessive textile treatmentsWoven fabricsFibrous cornMaterials science

The invention discloses wool fabric with milk fiber and a processing technique thereof. The wool fabric with the milk fiber includes warps prepared from silk fiber, polylactic acid fiber and fine denier chemical fiber filament in a blending mode according to the weight ratio of (10-15): (15-20): (20-35), weft yarns are prepared from milk fiber, corn fiber and wool in a blending mode according to the weight ratio of (10-15): (20-30): (15-40), wherein the twist of the fine denier chemical fiber filament is 400-800 twist / meter, the fineness of the warp is 15 dtex-30 dtex, and the fineness of the weft yarn is 15-60 dtex. The fiber fabric prepared by the processing technique is more comfortable, and moreover, the processing technique is easy and convenient to operate, and the dyeing effect is better.

Owner:关捷

Clothes processing device and clothes processing method for same

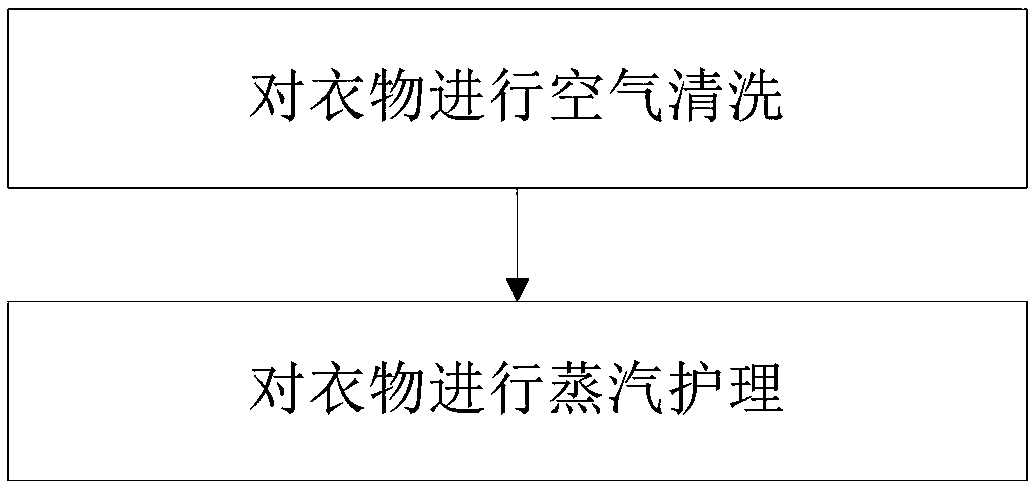

ActiveCN110042619AIncrease elasticitySoft fabricOther washing machinesTextiles and paperFiberAir cleaning

The invention belongs to the technical field of clothes processing, and aims at solving the problem that a traditional washing mode cannot meet the requirement of users for cleaning middle and top grade material clothes. In order to solve the problem, the clothes processing method comprises the steps of performing air cleaning on clothes, and performing steam nursing on the clothes. By performingair cleaning on the clothes, fiber of the clothes can be stretched sufficiently, elasticity of the clothes is improved, the fabric of the clothes is more flexible, by performing steam nursing on the clothes, stains on the clothes can be rapidly removed, and the clothes can be sterilized to a certain degree. Due to the clothes combined processing mode, the fabric of the clothes is more flexible andhas elasticity, the clothes wearing comfort is improved, the cleaning effect is good, the cleanness is high, no damage is caused to clothes, and therefore the user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Bian-stone ear-receivable pillow

InactiveCN105231738AUnique and reasonable structureNice appearancePillowsMedical devicesAdditive ingredientMedicine

The invention relates to a pillow, in particular to a Bian-stone ear-receivable pillow which is composed of a pillow capsule and a filler. Ear-receivable grooves are formed in the pillow capsule which is filled with the filler, shoulder placement grooves are formed in one side of the pillow capsule, and the filler is composed of buckwheat hull, tea stem, Bian stone and various traditional Chinese medical healthcare ingredients. The Bian-stone ear-receivable pillow is unique and reasonable in structure and attractive in appearance and is made of comfortable fabric; when the Bian-stone ear-receivable pillow is in use, ears can be arranged in the ear-receivable grooves when a person is in a lateral position, auricular blood is circulated smoothly, and eardrums are stressed normally, so that people can enjoy healthy sleep; due to the shoulder placement grooves which are unique, shoulders can be arranged inside the shoulder placement grooves when the person lies on the side, and sleeping posture is more comfortable; different healthcare effects of maintaining health and refreshing, dredging meridians and collaterals and nourishing brain to stabilize sleeping can be realized, and a user acquires certain healthcare effect while enjoying comfortability.

Owner:陈英华

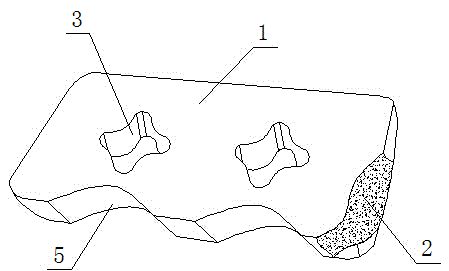

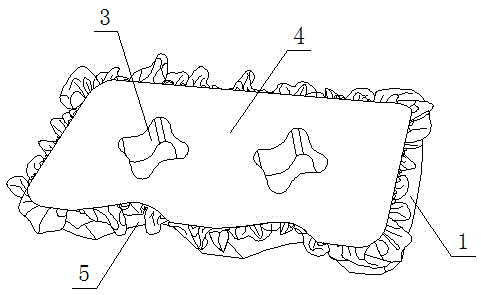

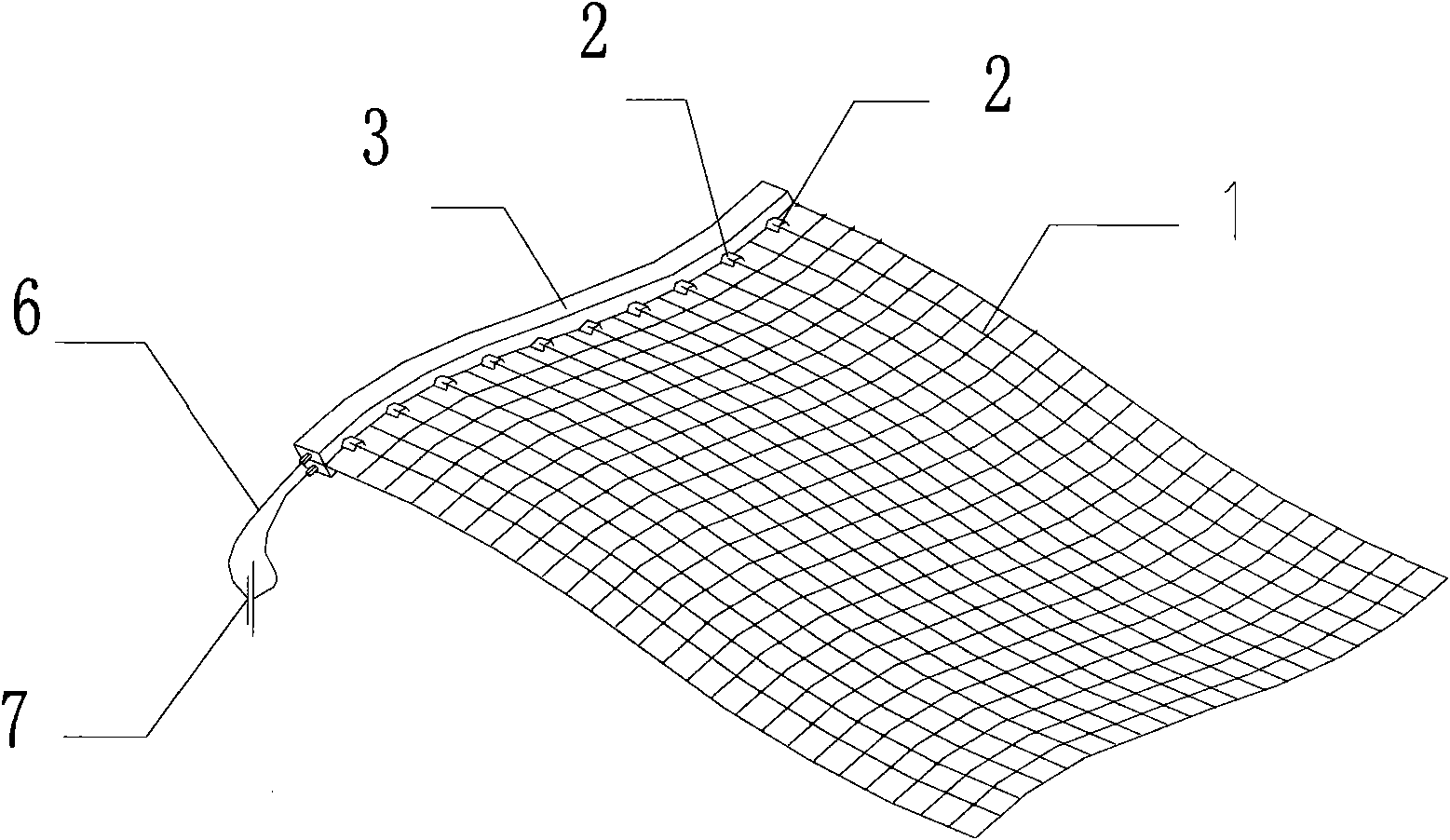

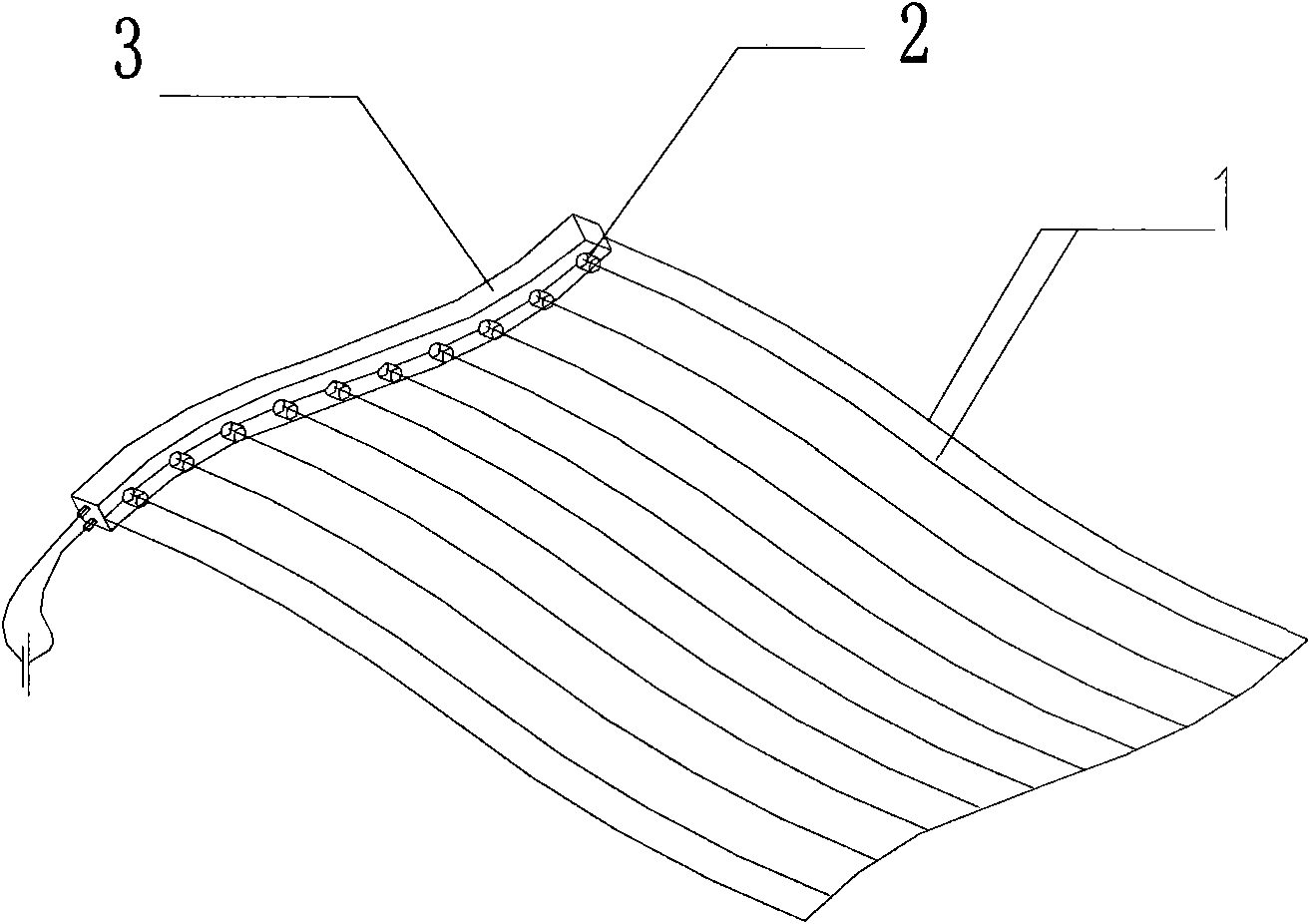

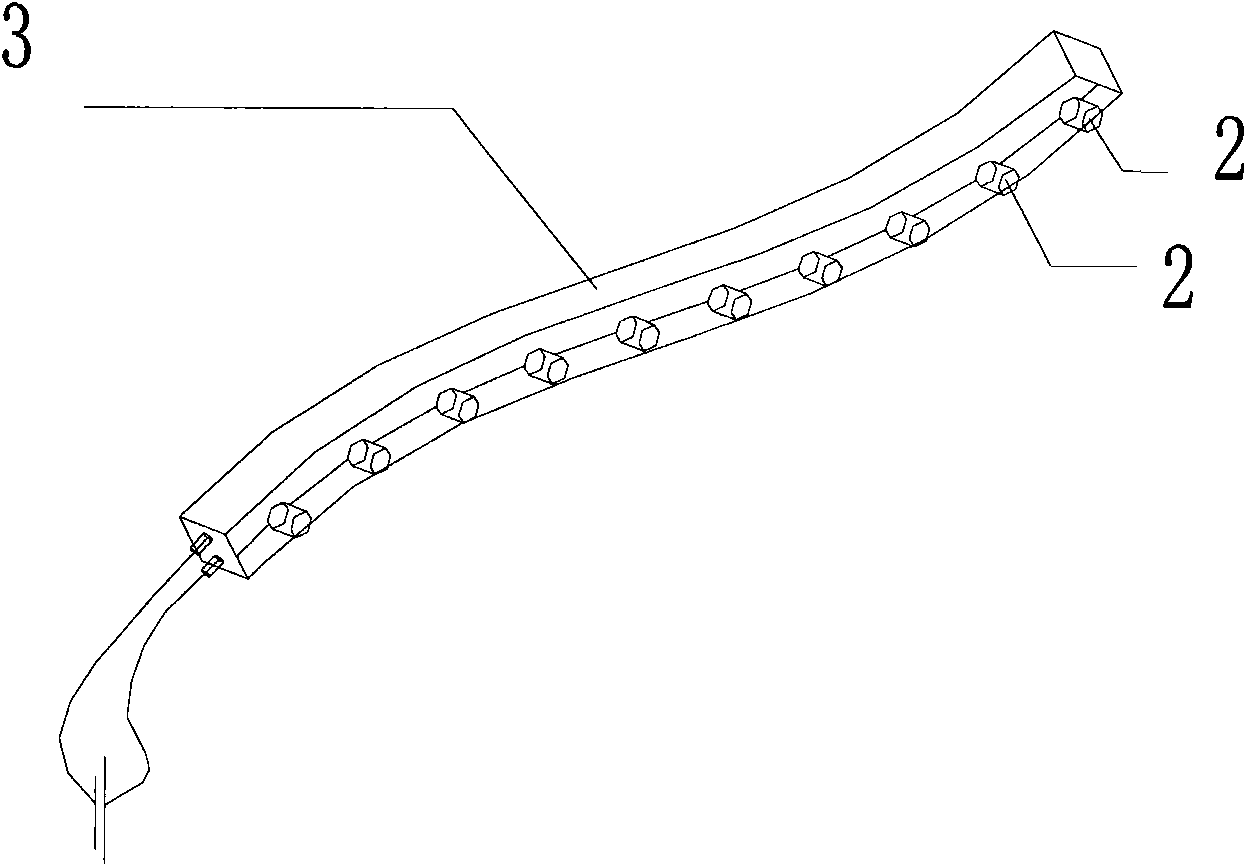

Luminous textile fabric

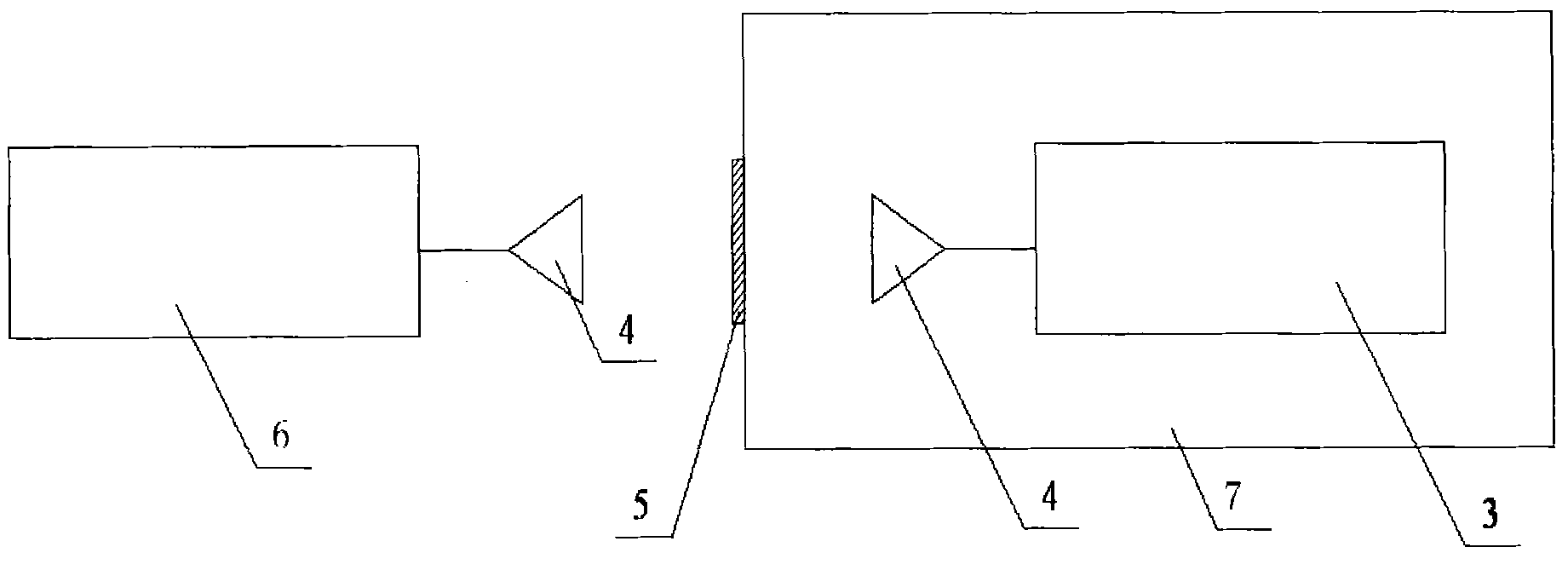

InactiveCN102154859ASimple structureQuality improvementPoint-like light sourceLighting elementsFiberLight guide

The invention discloses a luminous textile fabric which is provided with a light guide fiber (1), a light source is arranged at one end of the light guide fiber (1), the light guide fiber (1) is clamped in the textile fabric, the light guide fiber (1) and a light-emitting diode (2) are inlaid in a gib (3) at one end of the textile fabric, the gib (3) is connected with a power supply (7) through a lead (6). The luminous textile fabric has a simple structure, reliable quality, soft hand feel and a good luminous effect, and is suitable for being used on clothes.

Owner:WUJIANG HEXIN TRANSFER PRINTING

Anti-bacterial fabric with fireproof and flame-retardant functions and preparation method thereof

InactiveCN108866743AHigh specific surface areaIncrease the area of actionWoven fabricsYarnAnti bacterialMaterials science

The invention discloses an anti-bacterial fabric with fireproof and flame-retardant functions. The anti-bacterial fabric is prepared from, by weight, 24-30 parts of pearl fiber, 12-16 parts of modified silk fiber, 8-16 parts of polyimide fiber, 14-18 parts of charcoal fiber, 6-10 parts of anti-bacterial modifying agent, 4-8 parts of talcum powder, 3-5 parts of tourmaline powder and 16-22 parts ofdeionized water. The purpose of the invention is to provide the anti-bacterial fabric with the fireproof and flame-retardant functions. The fabric not only has a good anti-bacterial property, but alsohas an excellent flame-retardant property, and has higher use value and a good application prospect.

Owner:合肥昂诺新材料有限公司

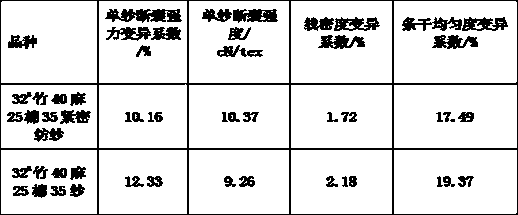

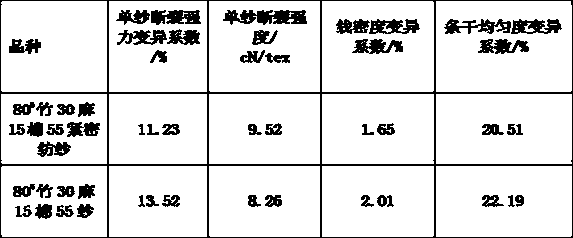

Bamboo hemp cotton blended compact spinning yarn and producing method thereof

The invention discloses a bamboo hemp cotton blended compact spinning yarn and a producing method thereof. The bamboo hemp cotton blended compact spinning yarn is formed by blending 20-50% of bamboo fiber, 10-30% of hemp fiber and 20-50% of cotton fiber. The invention further discloses the producing method of the bamboo hemp cotton blended compact spinning yarn. The produced blended yarn reaches the national standards, clothes woven from the blended yarn are smooth and soft in fabric surface, have the functions of cooling, bacterial resisting and restraining, blood circulation improving, metabolism promoting, disease preventing and fatigue eliminating, have excellent breathability and quite high micro-elasticity, have the good function of preventing fluffing and pilling, and are easy to wash and rapid in dirt removal.

Owner:湖南瑞亚高科集团有限公司

Flax bright canvas

InactiveCN105350327AImprove clarityStrong sense of three-dimensional paintingVegetal fibresEmulsionPattern perception

A flax bright canvas is disclosed. A preparation method for the flax bright canvas comprises (1) preparing a bottom glue, concretely uniformly dispersing 20-25 parts of pure acrylic emulsion, 10-15 parts of deionized water, and 20-25 parts of a clear slurry; (2) preparing a surface glue, concretely, uniformly dispersing 30-33 parts of deionized water, 25-30 parts of pure acrylic high-glossiness emulsion, 12-15 parts of titanium dioxide, 10-12 parts of talcum powder, 8-13 parts of lithopone, 8-13 parts of heavy calcium carbonate, 0.3-0.4 part of a dispersant, 0.2-0.3 part of an antifoaming agent, 1-2 parts of a multifunctional auxiliary agent, and 1-2 parts of a brightener; (3) uniformly coating flax basal cloth with the bottom glue in a shower way, and putting in a baking oven with the temperature of 100-120 DEG C for drying; and (4) coating the base material obtained in the step (3) with the surface glue in a shower way, and putting in a baking oven with the temperature of 70-80 DEG C for drying. The canvas possesses brightness, is strong in painting stereo perception, good in handfeel and soft in cloth surface, possesses relatively good affinity with pigments, is relatively high in pattern sharpness, and can be stored for a long time.

Owner:WUXI PHOENIX ARTIST MATERIALS

High-elasticity underwear fabric

The invention discloses a high-elasticity underwear fabric. The high-elasticity underwear fabric comprises surface yarns and bottom yarns, wherein the surface yarns are blue spar modal fibers; the bottom yarns are lycra polyurethane fibers; the blue spar modal fibers and the lycra polyurethane fibers are woven by a siro compact spinning process; and the high-elasticity underwear fabric is woven by performing double-yarn weft knitting, and interweaving the blue spar modal fibers and the lycra polyurethane fibers front and back at intervals. The high-elasticity underwear fabric made of green fibers is green and environment-friendly and has the characteristics of high elasticity, strong water absorption, softness and the like; through the siro compact spinning process, the high-elasticity underwear fabric is resistant to pilling and fluffing; and through antibacterial treatment, the high-elasticity underwear fabric is antibacterial and sanitary.

Owner:JIANGSU JINCHENZHEN TEXTILE

Thin stretch fabric

InactiveCN105747290AIncrease elasticityStrong water absorptionUndergarmentsProtective garmentPolyesterCarbon fibers

Components of a thin stretch fabric includes kapok fibers, blue modal fibers, viscose fiber, lycra spandex fibers, polyester bi-component fibers, bamboo carbon fibers, polyester fibers, elastic complex fibers, and soybean fiber. The obtained fabric by the formula is excellent in elasticity and water absorbing performance, and is soft in surface of the fabric. Through reasonable selection of fibers, the fabric has thin and flat characters and excellent wearability, has health functions of anion, far infrared ray, bacteria resistance, and deodorization, and is environment-friendly, safe and comfortable.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

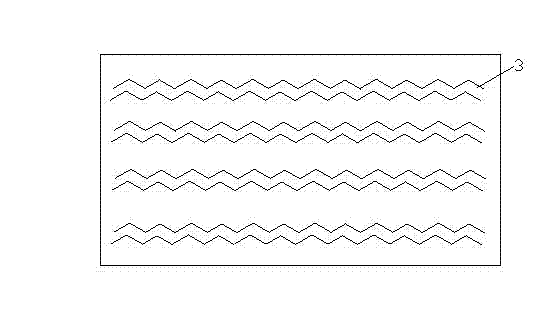

Static-eliminating cleaning agent for textile materials and preparation method thereof

InactiveCN105113243AStrong stabilityMild formulaOrganic detergent compounding agentsNon-ionic surface-active compoundsAmmonium sulfateIon

The invention discloses a static-eliminating cleaning agent for textile materials and a preparation method thereof. The static-eliminating cleaning agent is prepared from, by weight, 10-20 parts of sodium alginate, 6-10 parts of titanate, 5-10 parts of polydimethylsiloxane bis-quaternary ammonium salt, 3-7 parts of polyvinyl alcohol, 1.5-3 parts of ethoxylated alkyl ammonium sulfate, 0.8-1.4 parts of octamethyl cyclotetrasiloxane, 0.5-2 parts of acetic acid aqueous solution, 3-7 parts of solvent, 60-100 parts of deionized water, 3-7 parts of sodium lauroyl sarcosine, 2-6 parts of polymethyl methacrylate, 7-12 parts of fatty alcohol-polyoxyethylene ether and 80-120 parts of alpha-olefin sulfonate solution. All the raw materials of the static-eliminating cleaning agent are environmentally friendly and degradable. The static-eliminating cleaning agent has good antistatic performance and also has good softening, maintaining and cleaning effects on clothes.

Owner:杨洋

Light and thin heating wool spinning fabric manufacture method

The invention discloses a light and thin heating wool spinning fabric manufacture method comprising the following steps: raw material fiber configuration, mixing wools, dyeing, silver mixing, combing, roving, spinning, spooling, steaming yarn, weaving, dissolving vinylon, and after treatment; the raw material fiber comprises 30-40% of mercerized wool fibers, 3-15% of heating fibers, and balance water-soluble PVA fibers, wherein the heating fiber refers to eks fiber and / or softwarm fiber. The method blend and weave the heating fiber with the mercerized wool so as to manufacture the light and thin heating wool spinning fabric; the water-soluble PVA fiber is blended into the grey cloth, and the dissolving vinylon step can remove the water-soluble fibers in the grey cloth; the obtained fabric is relatively soft, and the cloth cover style is unique; the fabric can be worn to fit human body so as to absorb moisture heating radiated on the body surface; the mercerized wool is less in scales, so skin-friendly property of the fabric is excellent, and the fabric is suitable for sewing underclothes.

Owner:JIANGSU SUNSHINE GRP CO LTD

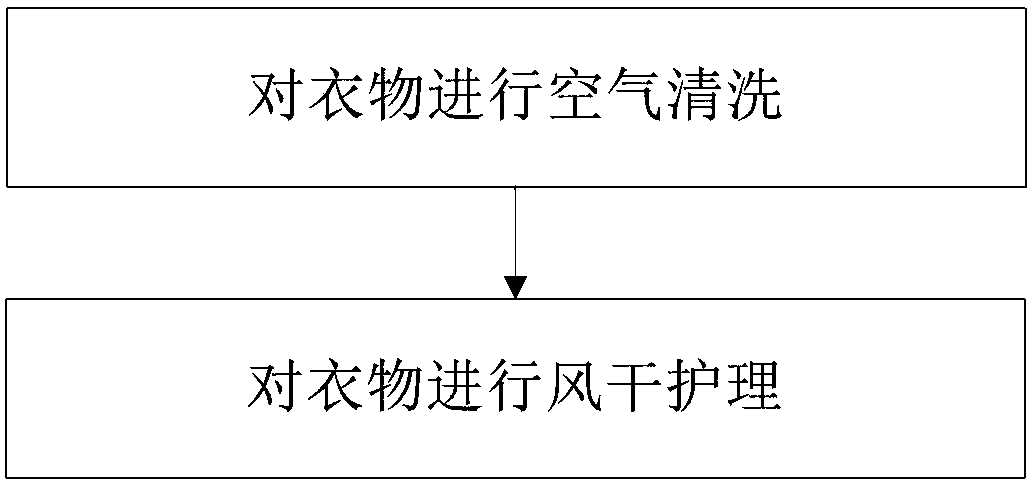

Clothes treating method for clothes treating equipment and clothes treating equipment

ActiveCN108103742AIncrease elasticitySoft fabricDry-cleaning apparatusTextiles and paperFiberBiochemical engineering

The invention belongs to the technical field of clothes treatment, and provides a clothes treating method for clothes treating equipment and the clothes treating equipment. The clothes treating methodand the clothes treating equipment aims at solving the problem that a traditional washing mode cannot meet cleaning requirements of clothes made of middle and high-quality materials. The clothes treating method comprises the steps of conducting air cleaning on the clothes; conducting airing nursing on the clothes. By conducting air cleaning on the clothes, fiber of the clothes is fully stretched,the elasticity of the clothes is improved, so that the materials of the clothes are softer, and if the clothes themselves are damp, by conducting airing nursing on the clothes, the clothes can be quickly aired; if the clothes are not damp, the clothes can continued to be cleaned through airing nursing. Through the combined treating mode, the materials of the clothes can be softer and elastic, thewearing comfort of the clothes is increased, the cleaning effect is good, the clothes cannot be damaged, and thus the user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Production technology of clinquant velvet soft fabric

InactiveCN107558057AMeet needsSoft fabricBiochemical fibre treatmentHeating/cooling textile fabricsAcetic acidSilicone oil

The invention discloses a production technology of clinquant velvet soft fabric. The technology comprises the following steps of dyeing, aftertreatment, dehydration, padder and squeezing, galling, preforming, softening and forming. 0.5% glacial acetic acid, 1% biological soaping enzyme, 2% dye bath softening agent, 0.5% sodium alginate and 0.1% nano-titanium dioxide are added in the aftertreatmentprocess, kept at the temperature of 80-85 DEG C for 10 minutes and then washed; in the padder and squeezing process, firstly deionized water and 0.5% softening agent are added into a rolling groove,and then the moisture content of the cloth cover is made even after padder and squeezing; in galling, the fabric width is large as far as possible, and cross air blowing treatment is conducted after galling so that wool can be tall and straight; in softening, the fabric is immersed into 60 g / L softening agent at the temperature of 120 DEG C and then immersed in 150 g / L after-finishing silicone oil, and the wet fixed fabric width is enlarged as far as possible; finally wet fixing is conducted. The fabric prepared by adopting the production technology of the clinquant velvet soft fabric is complete in fabric variety and has obvious cost advantage, the hand feeling and elasticity are improved, and the fabric is softer.

Owner:ZHEJIANG HONGSHENG DYEING & PRINTING

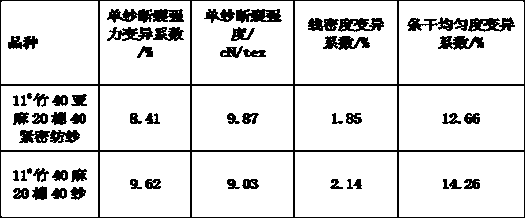

Bamboo fiber, bast fiber and wool blended yarn and production method thereof

The invention provides bamboo fiber, bast fiber and wool blended yarn and a production method thereof. The blended yarn is formed by blending, by mass, 20-50% of bamboo fibers, 15-30% of bast fibers and 20-65% of wool. The invention further discloses the production method of the bamboo fiber, bast fiber and wool blended yarn. The yarn woven through the method is up to the national standard, and clothes woven from the yarn is flat and soft in surface, has the antibacterial and bacteriostatic effects, can improve blood circulation, promote metabolism, prevent diseases and eliminate fatigue, is excellent in moisture absorption and air permeability and good in micro-elasticity, and can well relieve fuzzing and pilling.

Owner:湖南瑞亚高科集团有限公司

Liquid laundry detergent capable of removing grease dirt

InactiveCN105273858AWash thoroughlySoft fabricInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLiquid laundry detergentSODIUM OLEFIN SULFONATE

The invention discloses liquid laundry detergent capable of removing grease dirt. According to the liquid laundry detergent, a specific combination of sodium sulfonate surfactants and internal olefin sulphonates is adopted, and in the process of removing the grease dirt immersed in a fabric, washing is thorough and the fabric is soft and smooth.

Owner:华玉叶

Neonate quilt

The invention discloses a neonate quilt. The neonate quilt comprises a quilt body which is connected with a hat. The quilt body comprises shell fabric, an interlayer and lining, wherein the interlayer is arranged between the shell fabric and the lining. The lining sewed with patterns in quilting mode, a bandage is arranged outside the quilt body, cotton fibers are filled in the bandage, and magic tapes are arranged on two ends of the bandage for bonding. The quilt body, close to shoulders of a neonate, is provided with shoulder protection covers. The hat is provided with a pillow supporting part used for rest of a head portion of the neonate. The neonate quilt has the advantages that the shell fabric is soft, the bandage is arranged outside the quilt body and can wrap the neonate quilt tightly, and the shoulder protection covers are arranged on the neonate quilt and can prevent the shoulders from catching cold. Meanwhile, the neonate quilt is simple and practical.

Owner:张汉平

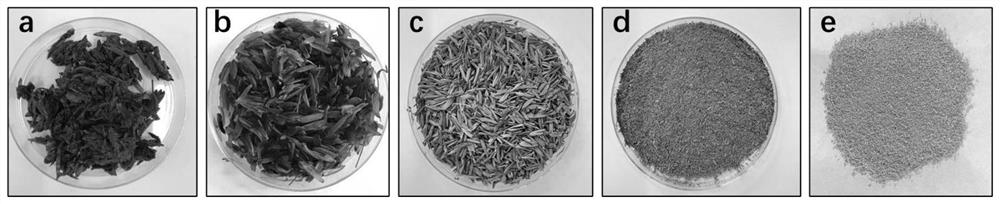

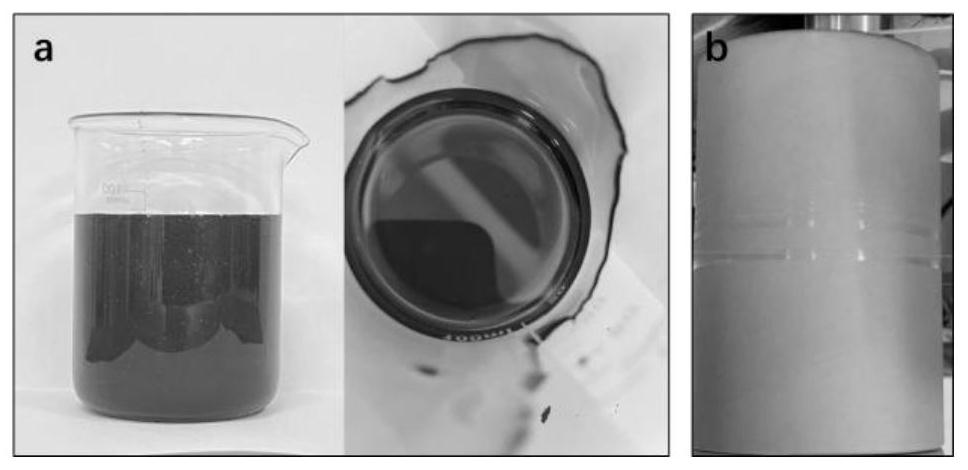

Method for preparing green regenerated cellulose fiber by taking vinasse as raw material

PendingCN114808173AReduce manufacturing costGood mechanical propertiesMonocomponent cellulose artificial filamentPaper material treatmentSpinningPulp and paper industry

The invention relates to a method for preparing green regenerated cellulose fibers by taking vinasse as a raw material. The method comprises the following steps: soaking vinasse after wine brewing in dilute alkali liquor, filtering, washing with water, drying, separating, crushing obtained vinasse lignocellulose, alkalizing by using alkali liquor, carrying out a lignin removal process, drying, dissolving the obtained vinasse cellulose in a solvent, and spinning. According to the method, starting from the idea of environmental protection and low-carbon cyclic regeneration, the green regenerated cellulose fiber is prepared by taking the vinasse as a raw material, and the fiber is applied to the field of textiles, so that a high-valued application technical path for turning waste into wealth is developed, and technical guidance and theoretical support are provided for application of the vinasse in the field of regenerated cellulose fiber.

Owner:上海飒卓新材料科技有限公司

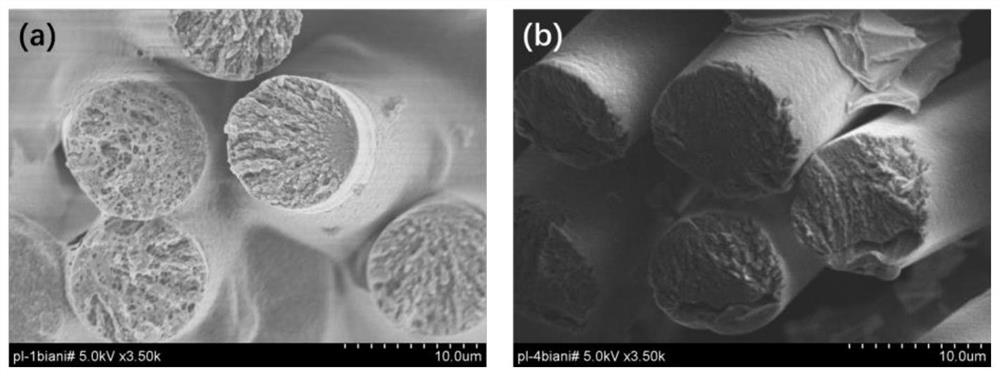

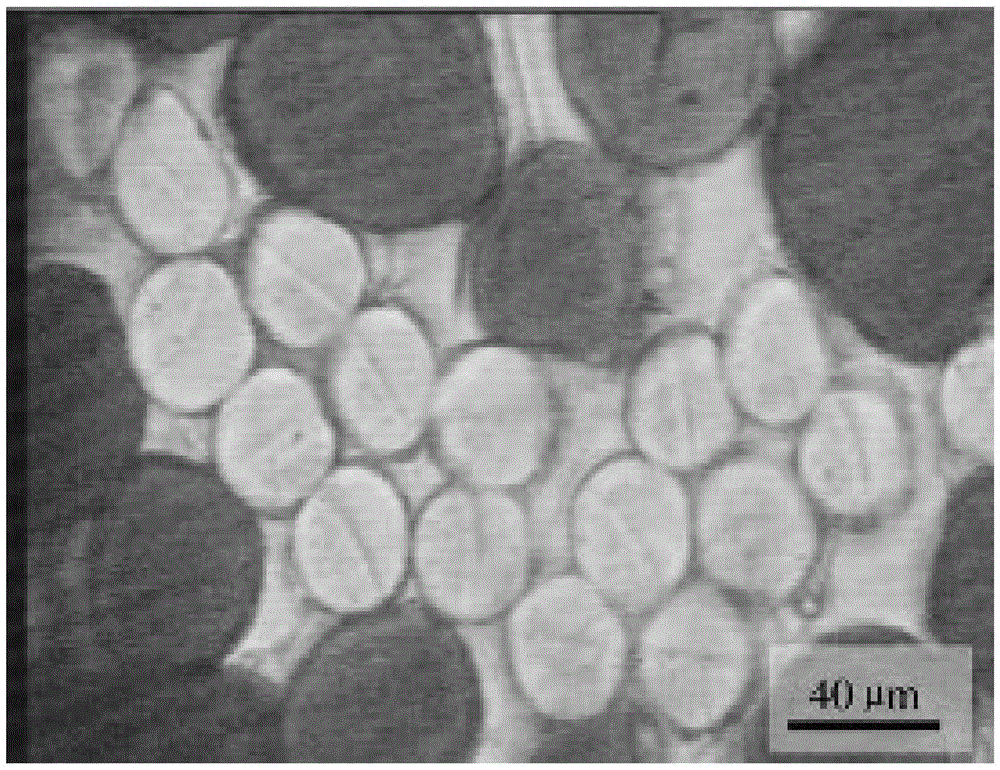

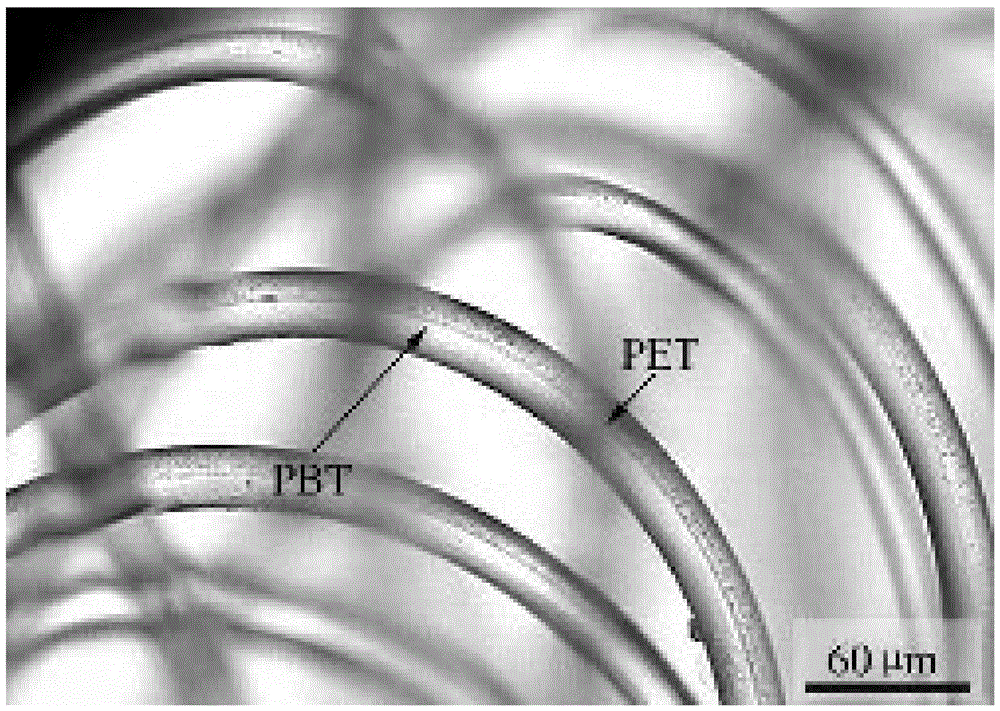

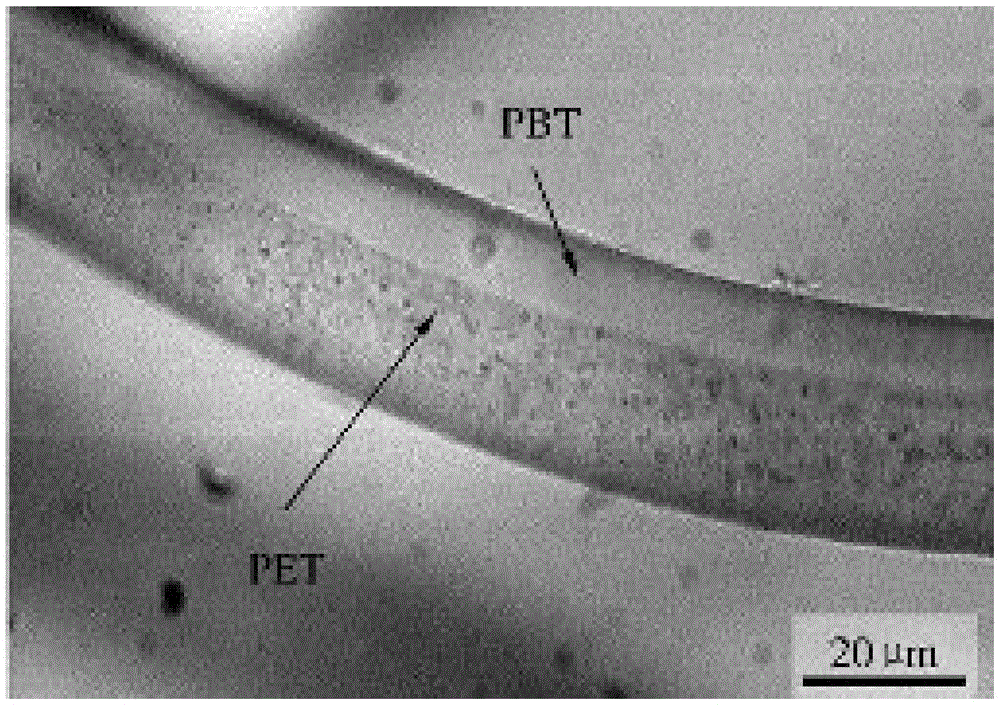

PBT-PET (Polybutylece Terephthalate-Polyethylene Terephthalate) composite elastic fibers and preparation method of PBT-PET composite elastic fibers

InactiveCN105603574APermanent three-dimensional curlIncrease elasticityArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention discloses PBT-PET (Polybutylece Terephthalate-Polyethylene Terephthalate) composite elastic fibers and a preparation method of the PBT-PET composite elastic fibers. A polybutylene terephthalate and polyethylene terephthalate composite material is fused and then is compounded and spun into a spring shape, and a cross section thereof is in a round structure, wherein a PET component is distributed at the outer side of a spiral and a PBT component is distributed at the inner side of the spiral; the content ratio of the PET to the PBT is (3 to 7):(7 to 3). The PBT-PET composite elastic fibers have the following beneficial effects that (1) the PBT is used for replacing original PTT (Polytrimethylene Terephthalate) and PET composite spinning and a monofilament breaking problem of T-400 fibers in a warp-wise spinning process is solved; (2) the fibers have the advantages of high rebound resilience, good stability, soft fabric, good drapability, flat cloth surface, strong crease resistance, moisture adsorption and quick drying, smooth hand feeling, stable size, no need of ironing and easiness of being cared; (3) the PBT-PET composite elastic fibers can be used for independently and purely weaving and also can be interwoven with cotton, sticky fibers, dacron, chinlon and the like. Textiles of the PBT-PET composite elastic fibers can be widely applied to fabrics of trousers and skirts, sports wear, stockings, jean fabrics, underwear, top-grade woman dresses and the like.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com