Wool fabric with milk fiber and processing technique thereof

A milk fiber and processing technology, applied in the direction of fabric, fiber type, fiber treatment, etc., can solve the problem of dyeing reproducibility, dyeing uniformity, dyeing fastness is not ideal, can not meet the needs of healthy, fashionable and comfortable life, Airtight and other problems, to achieve the effect of smooth feel, good shape retention and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

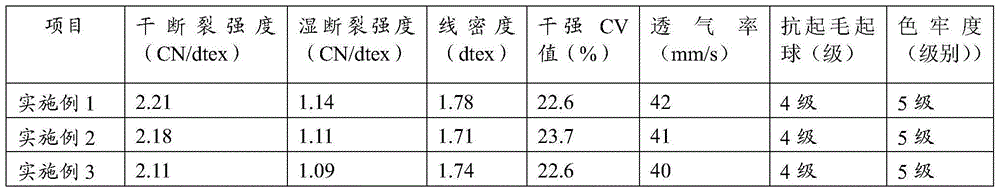

Embodiment 1

[0020] A woolen fabric containing milk fiber, the warp yarn is blended from silk fiber, polylactic acid fiber, and fine-denier chemical fiber filament, and the weft yarn is blended from milk fiber, corn fiber, and wool. The silk fiber, polylactic acid fiber, The fine-denier chemical fiber filaments are mixed in a weight ratio of 10:15:20, the milk fiber, corn fiber, and wool are mixed in a weight ratio of 10:20:15, and the warp and weft yarns are The twist of fine denier chemical fiber filament is 400 twists / meter, and the fineness of described warp yarn and weft yarn is respectively 15dtex, 20dtex.

[0021] The processing technology of above-mentioned woolen fabric containing milk fiber, comprises the following steps:

[0022] (1) Spinning: Blend silk fiber, polylactic acid fiber, and fine-denier chemical fiber filament according to the proportion, and blend milk fiber, corn fiber, and wool. In the entire design process, the milk protein fiber yarn or milk protein fiber The ...

Embodiment 2

[0030] A woolen fabric containing milk fiber, the warp yarn is blended from silk fiber, polylactic acid fiber, and fine-denier chemical fiber filament, and the weft yarn is blended from milk fiber, corn fiber, and wool. The silk fiber, polylactic acid fiber, Fine-denier chemical fiber filaments are mixed in a weight ratio of 15:20:35, the milk fiber, corn fiber, and wool are mixed in a weight ratio of 15:30:20, and the warp and weft yarns are The twist of the fine-denier chemical fiber filament is 600 twists / meter, and the fineness of the warp and weft are 30dtex and 30dtex respectively.

[0031] Processing steps are with embodiment 1.

Embodiment 3

[0033] A woolen fabric containing milk fiber, the warp yarn is blended from silk fiber, polylactic acid fiber, and fine-denier chemical fiber filament, and the weft yarn is blended from milk fiber, corn fiber, and wool. The silk fiber, polylactic acid fiber, The fine-denier chemical fiber filaments are mixed in a weight ratio of 13:18:30, the milk fiber, corn fiber, and wool are mixed in a weight ratio of 14:25:40, and the warp and weft yarns are The twist of the fine-denier chemical fiber filament is 800 twists / meter, and the fineness of the warp and weft are 20dtex and 40dtex respectively.

[0034] Processing steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com