Graphene antibacterial fabric and preparation method thereof

A kind of antibacterial fabric and graphene technology, which is applied in the field of fabric processing, can solve the problems of fabric antibacterial performance limitation, fabric antibacterial finishing, etc., and achieve the effect of improving color fastness, high antifouling performance and good dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

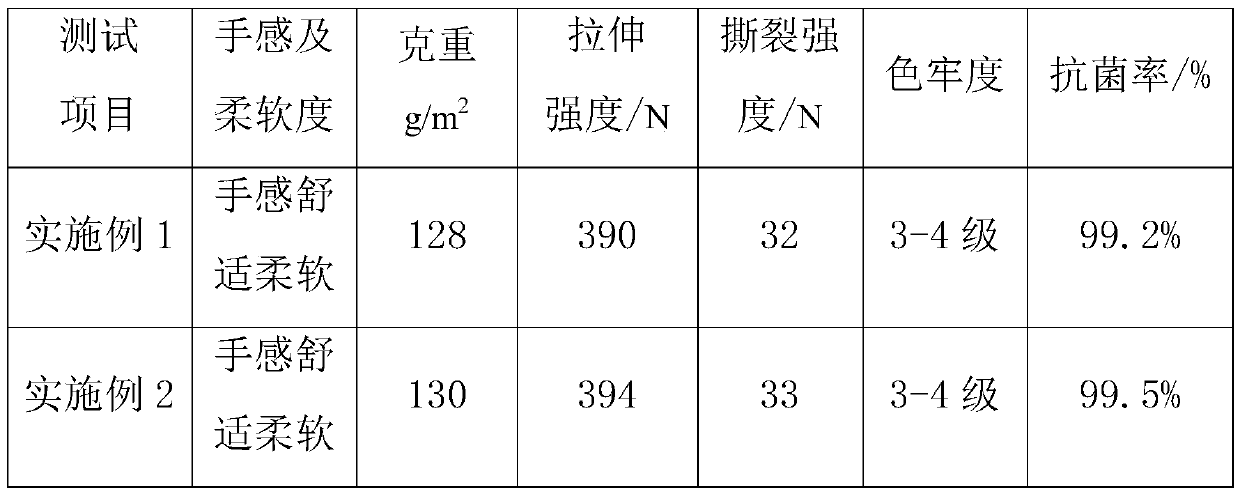

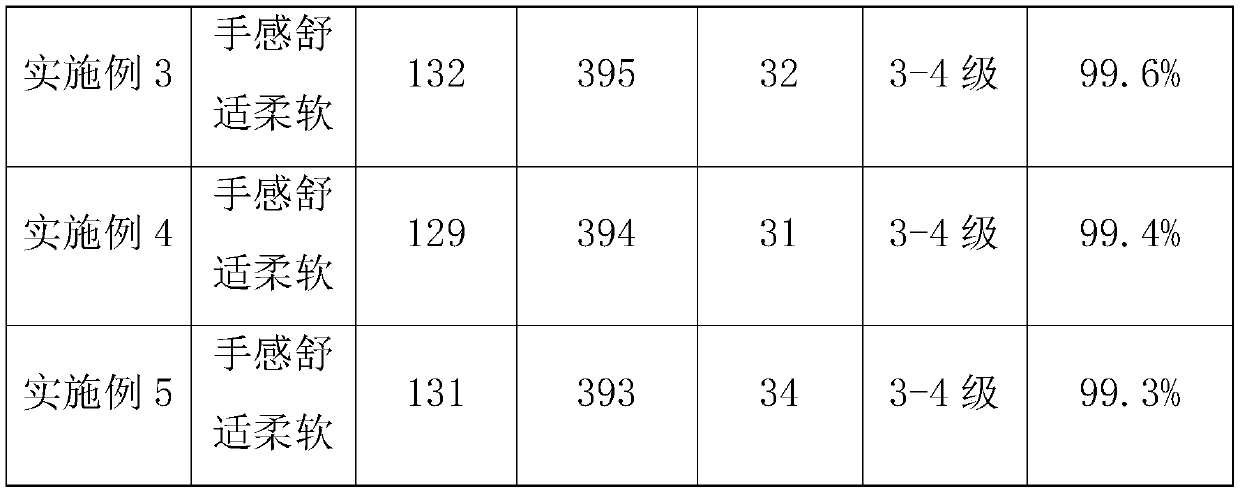

Examples

Embodiment 1

[0048] A graphene antibacterial fabric, comprising the following components by weight:

[0049] 80 parts of graphene composite fiber, 10 parts of bamboo charcoal fiber, 6 parts of PTT, 30 parts of cotton, and 8 parts of antibacterial agent; wherein, graphene composite fiber includes 0.6 part of graphene and 79.4 parts of fiber matrix.

[0050] The preparation steps of graphene composite fiber are as follows:

[0051] S1. Pretreatment: put the graphene and fiber matrix into a vacuum oven for drying, the drying temperature is 60°C, and the drying time is 8 hours;

[0052] S2, dry mixing: put graphene and fiber matrix into a high-speed mixer, adjust the rotating speed to 220rpm, mix for 1min, then adjust the rotating speed to 800rpm, and continue mixing for 1min to obtain the premix of graphene-fiber matrix;

[0053] S3. Blending and granulation: put the graphene-fiber matrix pre-mixture into a twin-screw blender for blending and granulation. The melt blending temperature is 180 °...

Embodiment 2

[0064] A graphene antibacterial fabric, comprising the following components by weight:

[0065] 92 parts of graphene composite fiber, 12 parts of bamboo charcoal fiber, 8 parts of PTT, 35 parts of cotton, and 9 parts of antibacterial agent; wherein, graphene composite fiber includes 0.8 part of graphene and 91.2 parts of fiber matrix.

[0066] The preparation steps of graphene composite fiber are as follows:

[0067] S1. Pretreatment: put the graphene and fiber matrix into a vacuum oven for drying, the drying temperature is 70°C, and the drying time is 10 hours;

[0068] S2, dry mixing: put graphene and fiber matrix into a high-speed mixer, adjust the rotating speed to 240rpm, mix for 2min, then adjust the rotating speed to 850rpm, and continue mixing for 1min to obtain the premix of graphene-fiber matrix;

[0069] S3. Blending and granulation: put the graphene-fiber matrix pre-mixture into a twin-screw blender for blending and granulation. The melt blending temperature is 19...

Embodiment 3

[0080] A graphene antibacterial fabric, comprising the following components by weight:

[0081] 104 parts of graphene composite fiber, 13 parts of bamboo charcoal fiber, 10 parts of PTT, 40 parts of cotton, and 10 parts of antibacterial agent; wherein, graphene composite fiber includes 1 part of graphene and 103 parts of fiber matrix.

[0082] The preparation steps of graphene composite fiber are as follows:

[0083] S1. Pretreatment: put the graphene and fiber matrix into a vacuum oven for drying, the drying temperature is 80°C, and the drying time is 12 hours;

[0084] S2, dry mixing: put graphene and fiber matrix into a high-speed mixer, adjust the rotating speed to 260rpm, mix for 3min, then adjust the rotating speed to 900rpm, and continue mixing for 1min to obtain the premix of graphene-fiber matrix;

[0085] S3. Blending and granulation: put the graphene-fiber matrix pre-mixture into a twin-screw blender for blending and granulation. The melt blending temperature is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com