One-step polylactic acid spun-laid spunlace non-woven fabric and manufacturing method of non-woven fabric

A technology of non-woven fabrics and spun webs, which is applied in the field of non-woven fabrics to achieve the effects of short process flow, good moisture absorption and breathability, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

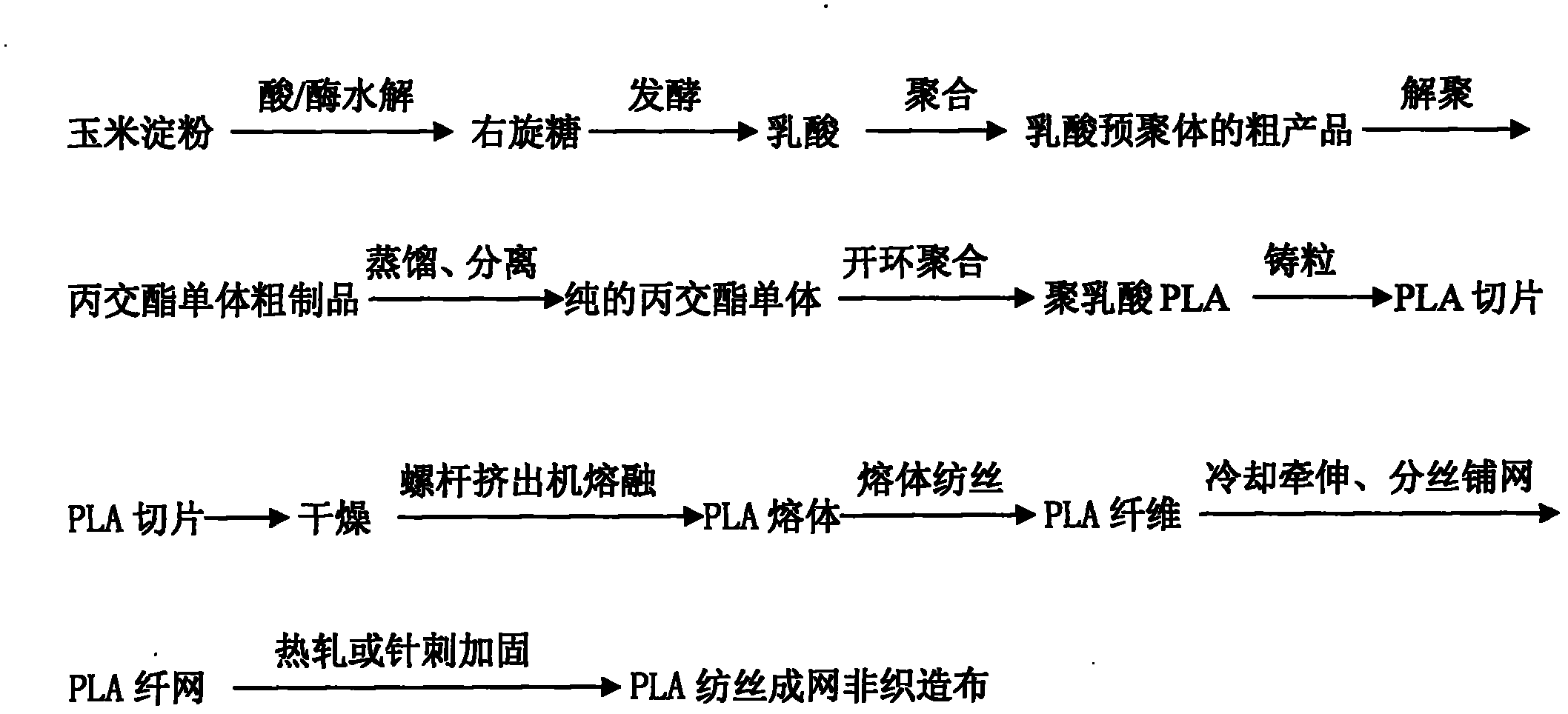

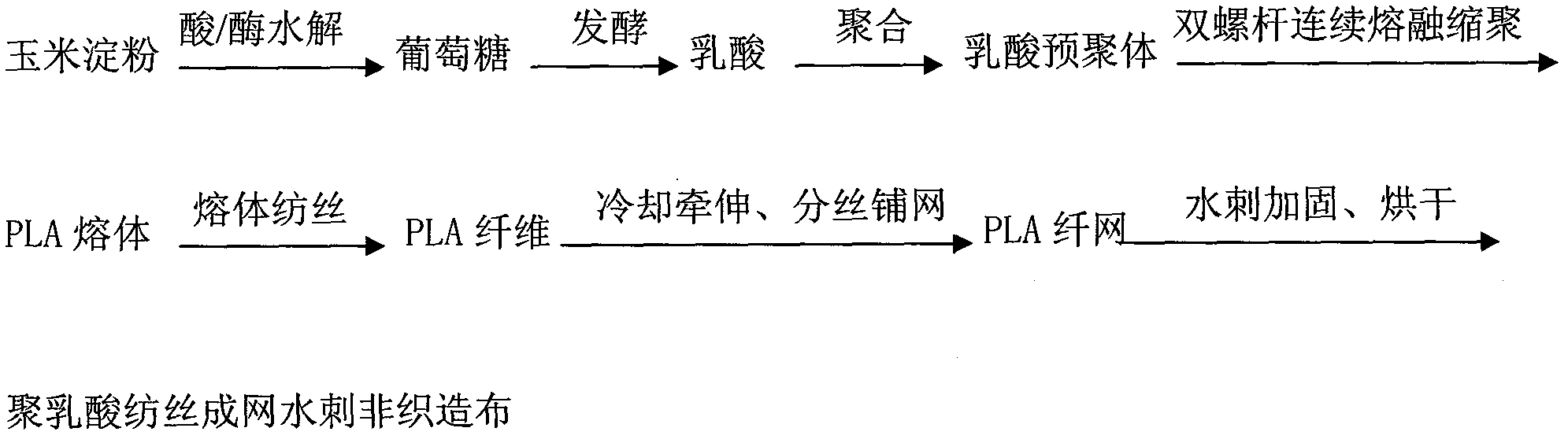

Method used

Image

Examples

Embodiment 1

[0031] Corn starch is hydrolyzed to make glucose, and then anaerobically fermented with Lactobacillus. During the fermentation process, lactic acid is neutralized with liquid caustic soda. After the fermentation liquid is purified, it is produced by electrodialysis process to produce L-lactic acid with a purity of 99.5%. The resulting L-lactic acid is dehydrated under reduced pressure to prepare lactic acid oligomers. When the reaction temperature is 150°C, the amount of stannous octoate catalyst is 0.3%, and the screw speed is 60r / min, the viscosity-average molecular weight is 158,000 through twin-screw reaction. Polylactic acid melt; the melt is filtered through a filter, metered by a metering pump, and then spun at 225°C. After cooling, it is drawn and laid in an airflow of 5000m / min. After spunlace, the above-mentioned nonwoven fabric was obtained by drying at 115°C.

[0032] The basis weight of the nonwoven product is 80g / m 2 , The average fineness of the fibers in the f...

Embodiment 2

[0034] Corn starch is hydrolyzed to make glucose, and then anaerobically fermented with Lactobacillus. During the fermentation process, lactic acid is neutralized with liquid caustic soda. After the fermentation liquid is purified, it is produced by electrodialysis process to produce L-lactic acid with a purity of 99.5%. The resulting L-lactic acid is dehydrated under reduced pressure to prepare lactic acid oligomers. When the reaction temperature is 150°C, the amount of stannous octoate catalyst is 0.4%, and the screw speed is 75r / min, the viscosity-average molecular weight is 182,000 through twin-screw reaction. Polylactic acid melt; the melt is filtered through a filter, metered by a metering pump, and then spun at 230°C. After cooling, it is drawn and laid in an airflow of 5500m / min. After spunlace, the above-mentioned nonwoven fabric was obtained by drying at 115°C.

[0035] The basis weight of the nonwoven product is 80g / m 2 , The average fineness of the fibers in the f...

Embodiment 3

[0037] Corn starch is hydrolyzed to make glucose, and then anaerobically fermented with Lactobacillus. During the fermentation process, lactic acid is neutralized with liquid caustic soda. After the fermentation liquid is purified, it is produced by electrodialysis process to produce L-lactic acid with a purity of 99.5%. The resulting L-lactic acid is dehydrated under reduced pressure to prepare lactic acid oligomers. When the reaction temperature is 150°C, the amount of stannous octoate catalyst is 0.5%, and the screw speed is 75r / min, the viscosity-average molecular weight is 198,000 through twin-screw reaction. Polylactic acid melt; the melt is filtered through a filter, metered by a metering pump, and then spun at 230°C. After cooling, it is drawn and laid in an airflow of 6000m / min. After spunlace, the above-mentioned nonwoven fabric was obtained by drying at 115°C.

[0038] The basis weight of the nonwoven product is 80g / m 2 , The average fineness of the fibers in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com