Polyester two-way-stretch fabric dyeing process

A technology of four-sided elastic and elastic cloth, which is applied in the field of fabric finishing, can solve the problems of lower dyeing rate of disperse dyes, lower utilization rate of disperse dyes, limited dispersion and solubility, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

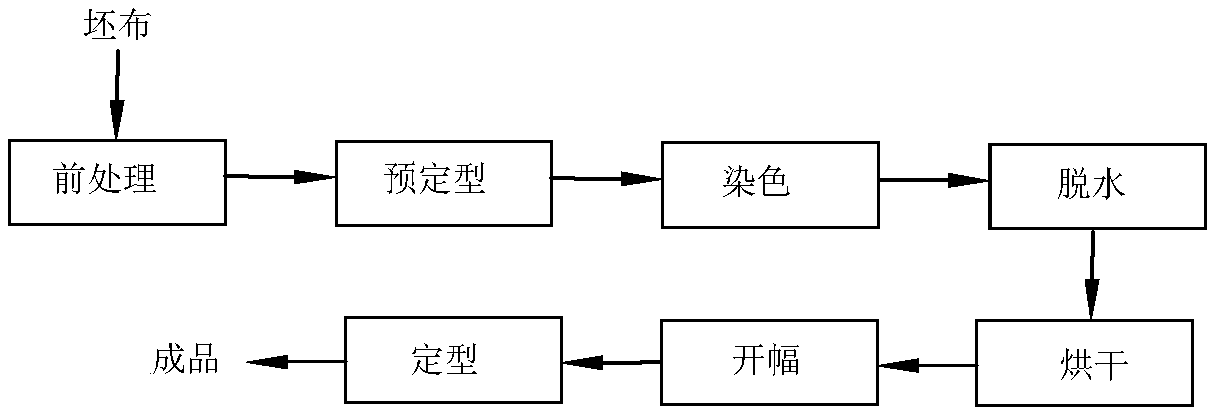

[0022] Dyeing process of polyester four-way elastic cloth, comprises the following steps:

[0023] a) Pre-treatment, put the polyester four-way elastic fabric into the clear water of the desizing washing machine, add 7g / L of soda ash, 4g / L of hydrogen peroxide, and 1.4g / L of desizing agent in the water bath, and the bath ratio is 1:15. Treat in a water bath at 45°C for 10 minutes, discharge the waste water, inject clean water and rinse at room temperature for 10 minutes;

[0024] b) Pre-setting, arrange the polyester four-sided elastic on the pre-setting machine, the pre-setting temperature is 180°C, and the speed is 17m / min;

[0025] c) Dyeing, at room temperature, put the pre-shaped polyester four-way stretch cloth into the clear water of the high-temperature and high-pressure overflow dyeing machine, and add high-temperature leveling agent styrene phenol polyoxyethylene ether ammonium sulfate 1g / L in the water bath, Penetrant JFC1.5g / L, when adding glacial acetic acid to a...

Embodiment 2

[0031] Dyeing process of polyester four-way elastic cloth, comprises the following steps:

[0032] a) Pre-treatment, put the polyester four-way elastic fabric into the clear water of the desizing washing machine, add 10g / L of soda ash, 6g / L of hydrogen peroxide, and 1.7g / L of desizing agent in the water bath, and the bath ratio is 1:15. Treat in a water bath at 45°C for 10 minutes, discharge the waste water, inject clean water and rinse at room temperature for 10 minutes;

[0033] b) Pre-setting, the polyester four-way stretch is arranged on the pre-setting machine, the pre-setting temperature is 200°C, and the speed is 21m / min;

[0034] c) Dyeing, at room temperature, put the pre-shaped polyester four-way stretch cloth into the clear water of the high-temperature and high-pressure overflow dyeing machine, and add high-temperature leveling agent styrene phenol polyoxyethylene ether ammonium sulfate 1.3g / L in the water bath , penetrating agent JFC2g / L, when adding glacial acet...

Embodiment 3

[0040] Dyeing process of polyester four-way elastic cloth, comprises the following steps:

[0041] a) Pre-treatment, put the polyester four-sided elastic fabric into the clean water of the desizing washing machine, add 12g / L of soda ash, 8g / L of hydrogen peroxide, and 2g / L of desizing agent in the water bath, and the bath ratio is 1:15. Treat in a water bath for 15 minutes at ℃, discharge the waste water, inject clean water and rinse at room temperature for 10 minutes;

[0042] b) Pre-setting, the polyester four-sided elastic is arranged on the pre-setting machine, the pre-setting temperature is 210°C, and the speed is 25m / min;

[0043] c) Dyeing, at room temperature, put the pre-shaped polyester four-way elastic cloth into the clear water of the high-temperature and high-pressure overflow dyeing machine, and add high-temperature leveling agent styrene phenol polyoxyethylene ether ammonium sulfate 1.5g / L in the water bath , penetrating agent JFC2.5g / L, when adding glacial ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com