High-temperature high-pressure air flow dyeing machine

An airflow dyeing machine, high temperature and high pressure technology, applied in textile processing machine accessories, liquid/gas/vapor jet propulsion fabrics, textiles and papermaking, etc., can solve the problem of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

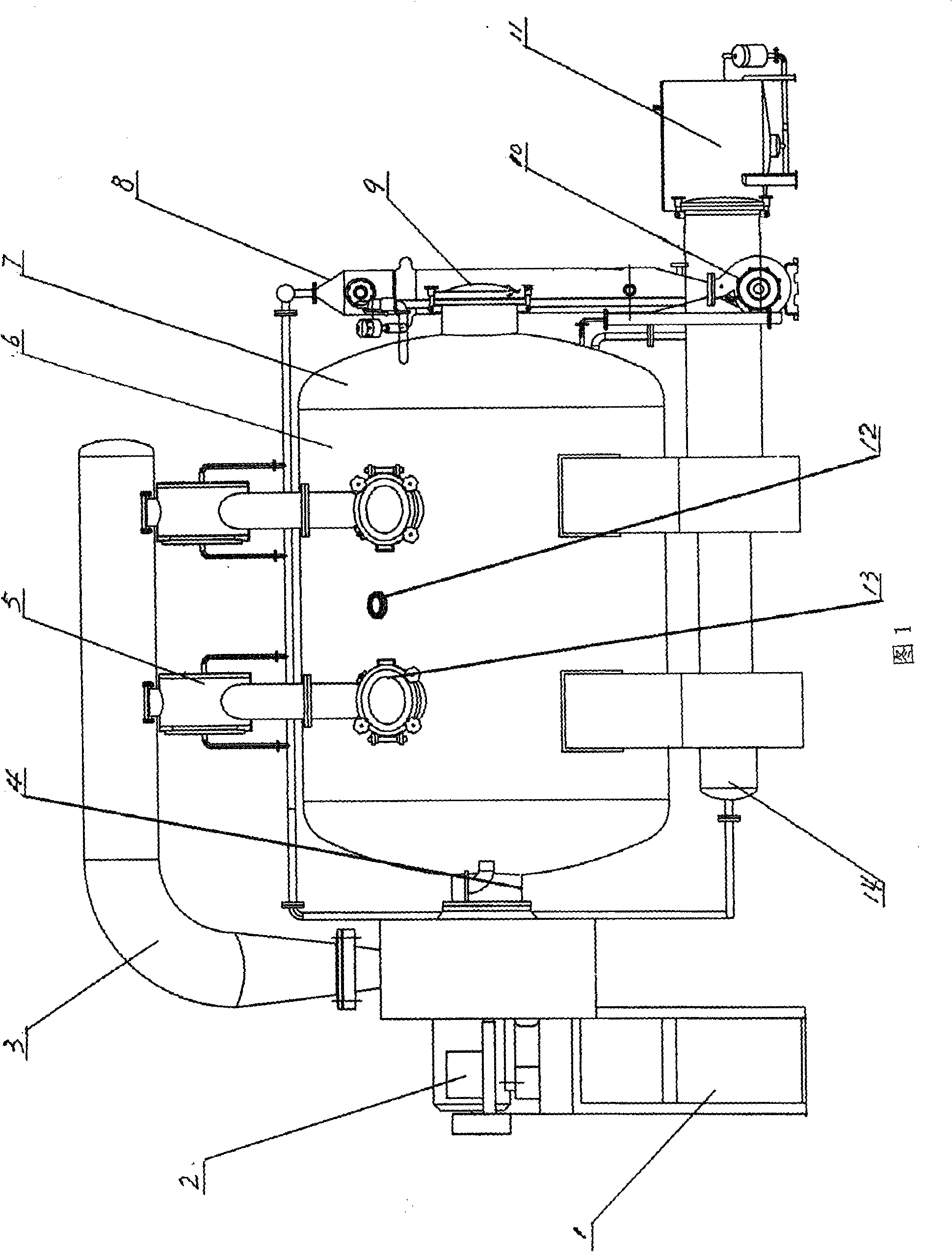

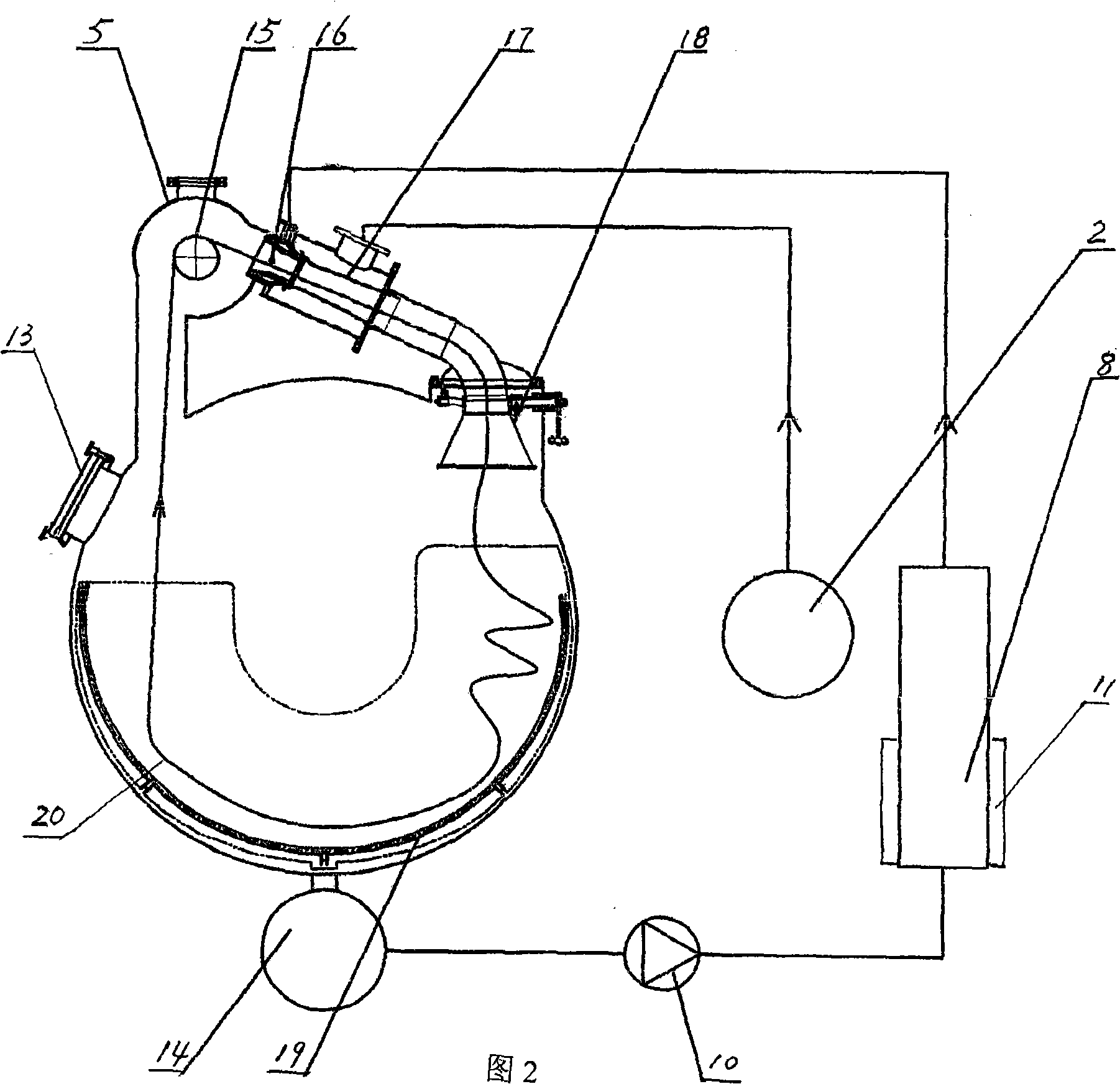

[0010] As shown in FIGS. 1 and 2 , the high-temperature and high-pressure airflow dyeing machine of the present invention includes a cylinder body 6 , a heat exchanger 8 , a fan 2 and a barrel 11 . Wherein, the cylinder body 6 is a closed cylinder, which is arranged horizontally, and an operation hole 13 is processed on the upper wall of the cylinder, and a dyeing tank 19 is processed inside it. The dye tank 19 is circumferentially arranged along the lower half of the inner wall of the cylinder body 6, and two openings are processed on the upper wall of the cylinder body 6 corresponding to the two ends of the dye tank 19, and a swing mechanism 18 is fixed in one of the openings. The effect of swing mechanism 18 is to prevent that dyed fabric 20 knots. A wheel housing 5 is arranged above the opening without the swing mechanism 18, and two ports are processed on the wheel shell 5, one of which communicates with the opening below it through a pipeline, and the other port is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com