Turbulent current type cheese dyeing method and apparatus thereof

A dyeing method and dyeing device technology, applied in liquid/gas/vapor yarn/filament processing, textile and papermaking, textile processing machine accessories, etc., can solve the problems of increased cotton yarn hairiness, different liquid flow, and damaged cotton yarn, etc. Achieve the effect of avoiding impervious dyeing and internal and external differences, reducing strength drop, and maintaining fabric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

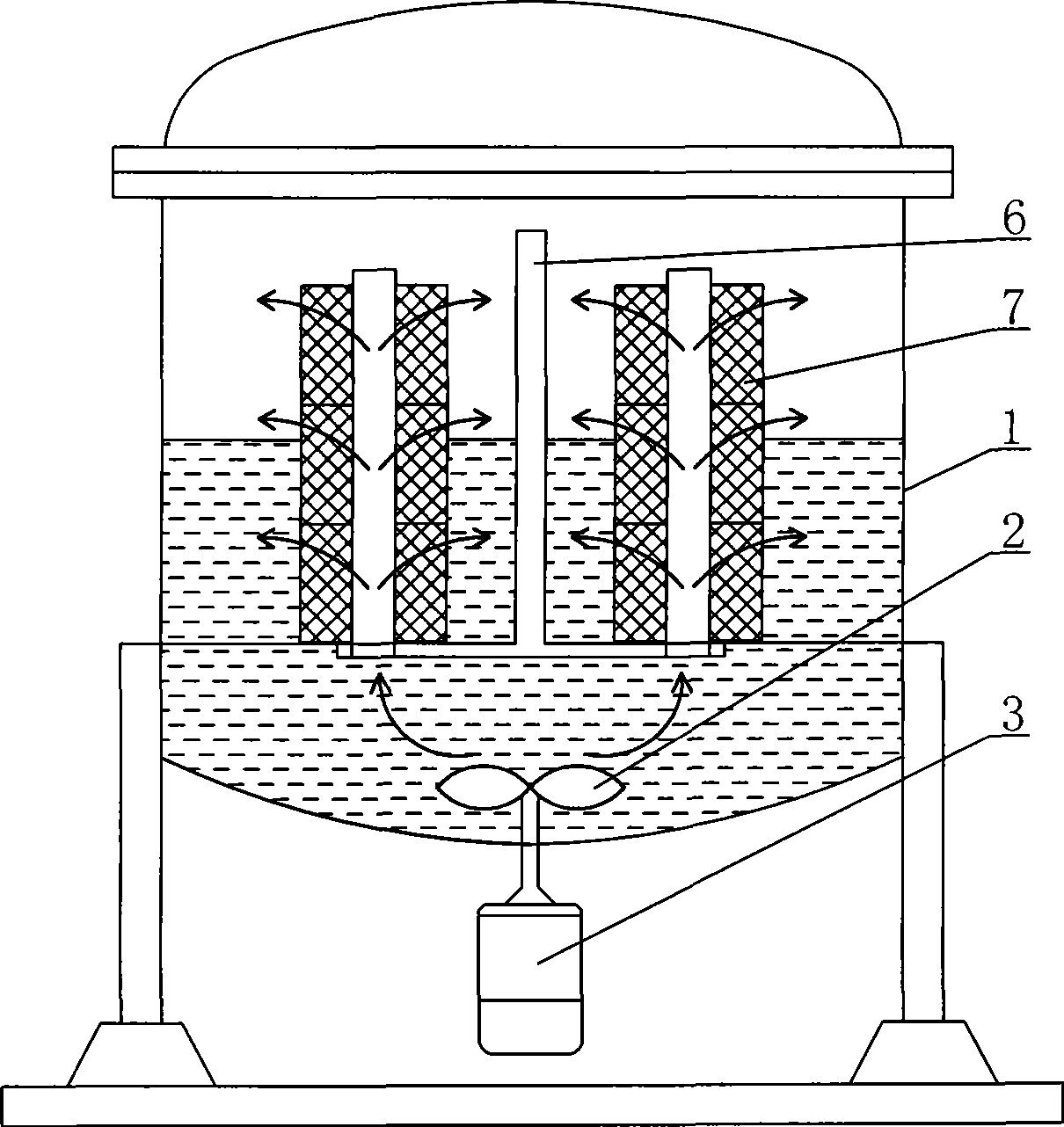

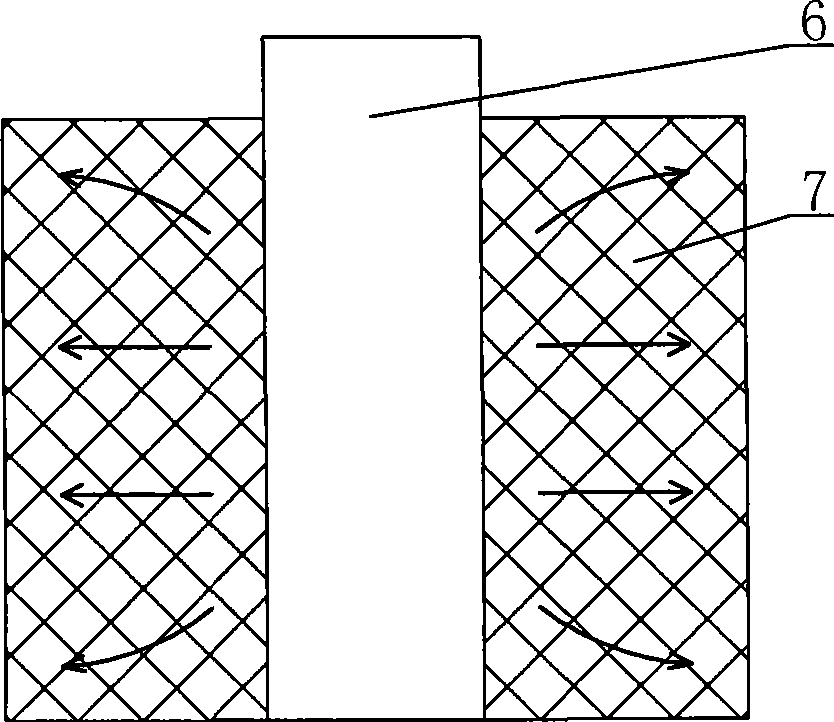

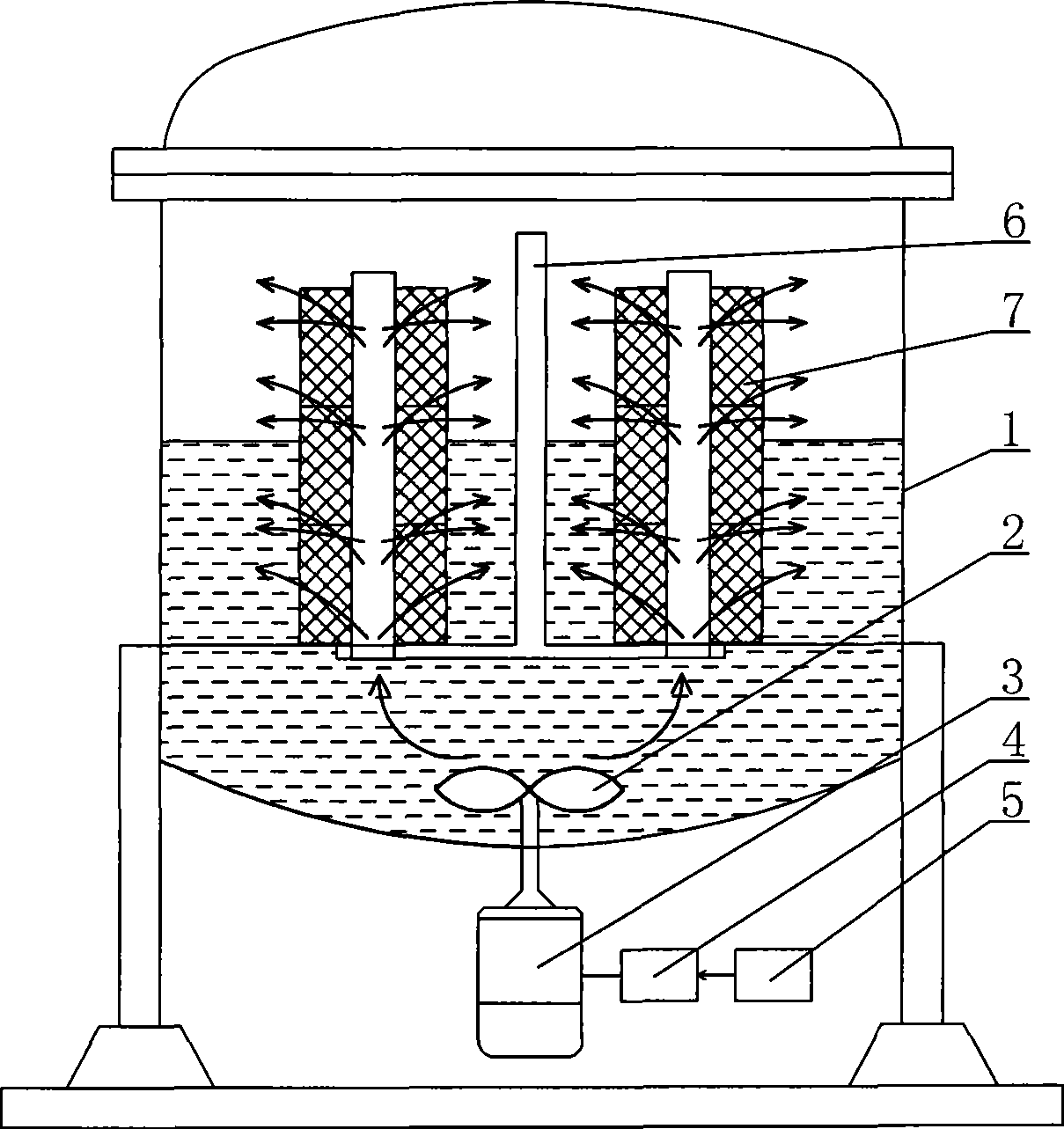

[0013] In the turbulent cheese dyeing method of the present invention, a plurality of cheeses are first mounted on the cheese bracket, and then the cheese bracket loaded with the cheese is lifted into the dyeing vat in an upright manner, so that the cheese Dipping into the dyeing liquid, the dyeing vat is sealed, and the main pump of the dyeing vat is driven to rotate, so that the dyeing liquid circulates in a turbulent flow in the dyeing vat under high temperature and high pressure conditions. The turbulent circulating flow of the dye liquor with varying amplitude can be formed by changing the rotating speed of the main pump of the dye vat. According to the Reynolds number Re≥4000, set the minimum pump speed. The calculation formula is:

[0014]

[0015] d: Dyeing liquid flow rate (converted according to the water pump speed) M / S

[0017] P: density of dye solution (kg / m3)

[0018] μ: dye solution viscosity (Pas)

[0019] After calculatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com