Method for dying cotton fiber by utilizing tea vegetable dye

A plant dye and cotton fiber technology, applied in plant fiber, dyeing method, fiber treatment, etc., can solve the problems of affecting the coloring effect and doubling the production cost, and achieve the effect of simple and elegant color, good color fastness and uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

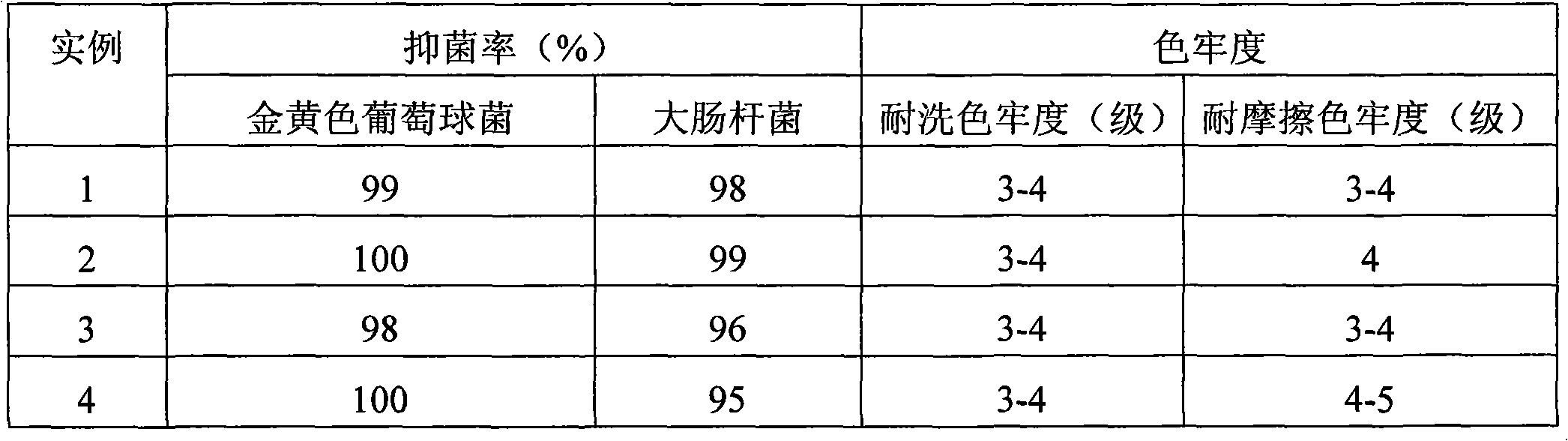

Examples

Embodiment 1

[0014] Embodiment 1: The fresh tea leaves are crushed, and clear water is added to extract the tea plant dye. When extracting, the ratio of material to liquid is weight ratio, and the extraction temperature and extraction time are respectively controlled at 1:10-50, 10-30°C and 0.5-1h. After the extraction is completed, the filtrate is concentrated and dried to obtain tea plant dyes. Plant dyes contain more than 30% tea polyphenols as pigment components; take cotton fibers and rinse with water, add water at a bath ratio of 1:50, add 3.0% (o.w.f) copper salt mordant, the temperature is 60 ° C, mordant for 1 hour, and then drain. Add water to the tea plant dye powder with a tea polyphenol content of more than 30% to prepare a dye solution, the dye concentration is 3.0%, the pH value of the dye solution is 4.1, and the bath ratio is 1:50. Dye at 60°C for 1.5 hours, then add water to wash. The cotton fabric obtained after dehydration is yellow-brown.

Embodiment 2

[0015] Embodiment 2: The fresh tea leaves are crushed, and clear water is added to extract the tea plant dye. When extracting, the ratio of material to liquid is weight ratio, and the extraction temperature and extraction time are respectively controlled at 1:10-50, 10-30°C and 0.5-1h. After the extraction is completed, the filtrate is concentrated and dried to obtain tea plant dyes. Plant dyes contain more than 30% tea polyphenols as pigment components; take cotton fibers and rinse with water, add water at a bath ratio of 1:20, add 2.5% (o.w.f) aluminum salt mordant, temperature is 50°C, and drain after 1 hour of mordant dyeing. Add water to the tea plant dye powder with a tea polyphenol content of more than 30% to prepare a dye solution, the dye concentration is 2.5%, the pH value of the dye solution is 4.1, and the bath ratio is 1:20. Dye at 50°C for 1.5 hours, then add water to wash. The cotton fabric obtained after dehydration is orange-yellow.

Embodiment 3

[0016] Embodiment 3: The fresh tea leaves are crushed, and clear water is added to extract the tea plant dye. When extracting, the ratio of material to liquid is weight ratio, and the extraction temperature and extraction time are respectively controlled at 1:10-50, 10-30°C and 0.5-1h. After extraction, the filtrate is concentrated and dried to obtain tea plant dyes, tea leaves Plant dyes contain more than 30% tea polyphenols as pigment components; cotton fibers are rinsed with water, then added with tea plant dyeing solution, and drained after 1.5 hours of dyeing. Wherein, the concentration of the dye solution is 1.0% (o.w.f), the pH value of the dye solution is 4.2, the bath ratio is 1:20, and the temperature of the dye bath is 60°C. After the tea is dyed, it is put into 1.0% (o.w.f) copper salt mordant dye solution, and its bath ratio, dye bath temperature and mordant dyeing time are the same as above. After the dyeing is finished, rinse with clear water, and the cotton fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com