Patents

Literature

122results about How to "Reduce creases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

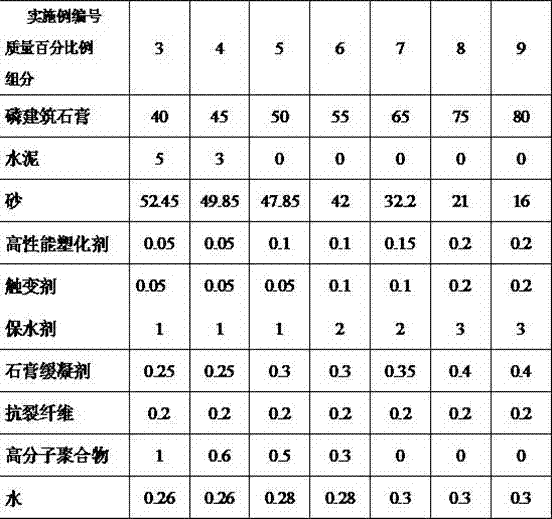

Preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of external wall

The invention discloses a preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of an external wall. The preparation method is characterized in that the anti-cracking mortar comprises the following components in percentage by mass: 40-80% of building phosphogypsum, 20-50% of dried sand, 0-20% of cement, 0-5% of fly ash, 0-0.2% of a high-performance plasticizer, 0-0.2% of a thixotropic agent, 0.1-0.3% of a water-retaining agent, 0.01-0.4% of a gypsum retarder, 0-3% of a micromolecular polymer and 0-0.25% of anti-cracking fiber. According to the preparation method, the building phosphogypsum prepared by washing and calcining industrial byproduct phosphogypsum is used as a cementing material, so that the problems that a cement-based material is easy to shrink, hollow and crack are solved; through full use of the characteristics of fast setting and hardening, good volume stability and low own ratio of compressive strength to flexural strength of a gypsum material, the anti-cracking mortar, of which the ratio of the compressive strength to the flexural strength is lower than 2.5, the operable time is 1-2h, the final setting time is shorter than 3h, the insulation board bonding strength is higher than 0.10MPa and breakage occurs inside an insulation board, is prepared. The anti-cracking mortar is applied to the interior insulation of the external wall and low in cost, reduces the environment pollution, and is simple in production process, low in energy consumption and good in product performance; compared with other insulation board crack resisting products, the anti-cracking mortar has higher market competitiveness and is strong in practicality.

Owner:四川华邦保和涂料有限公司

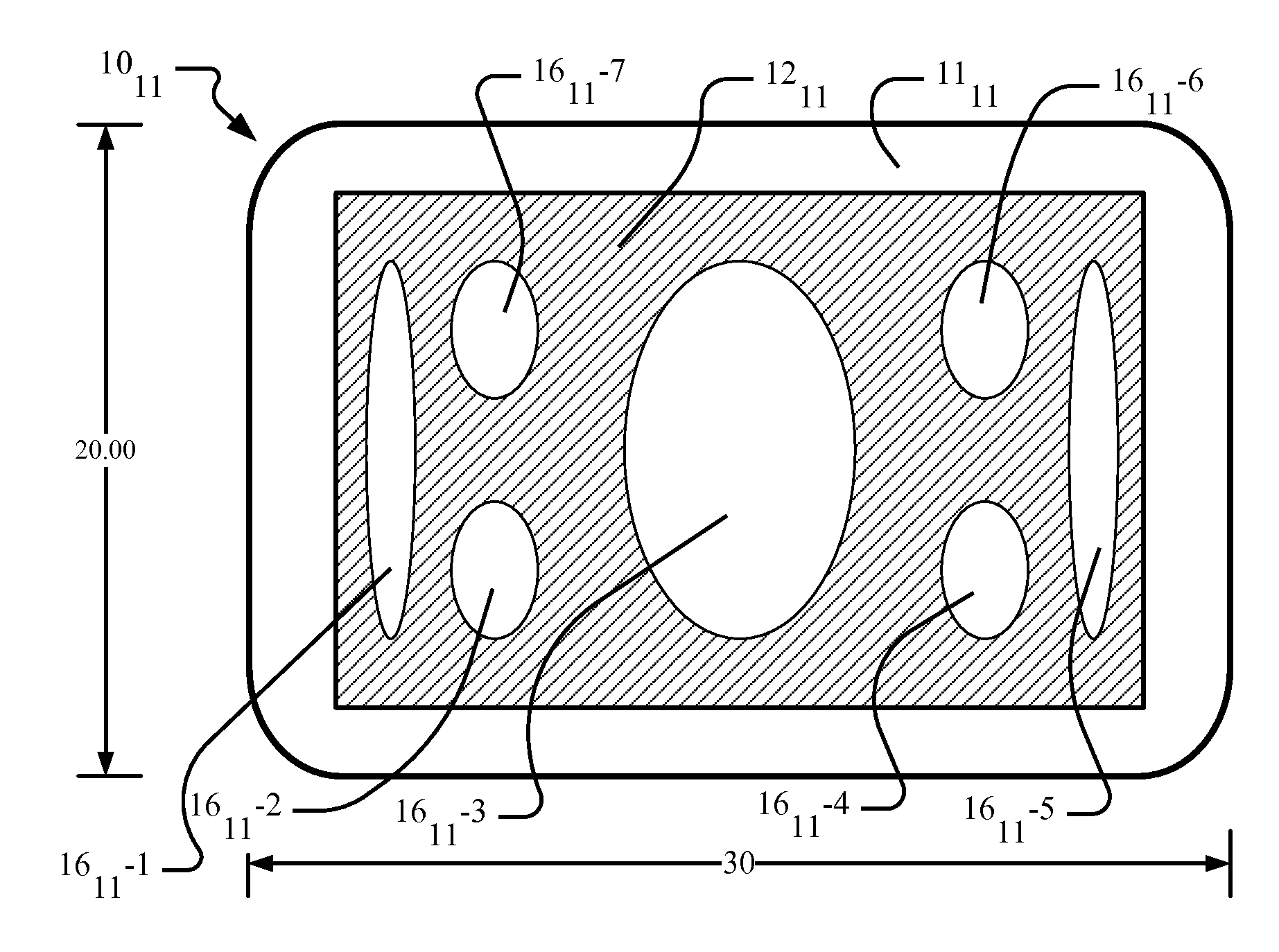

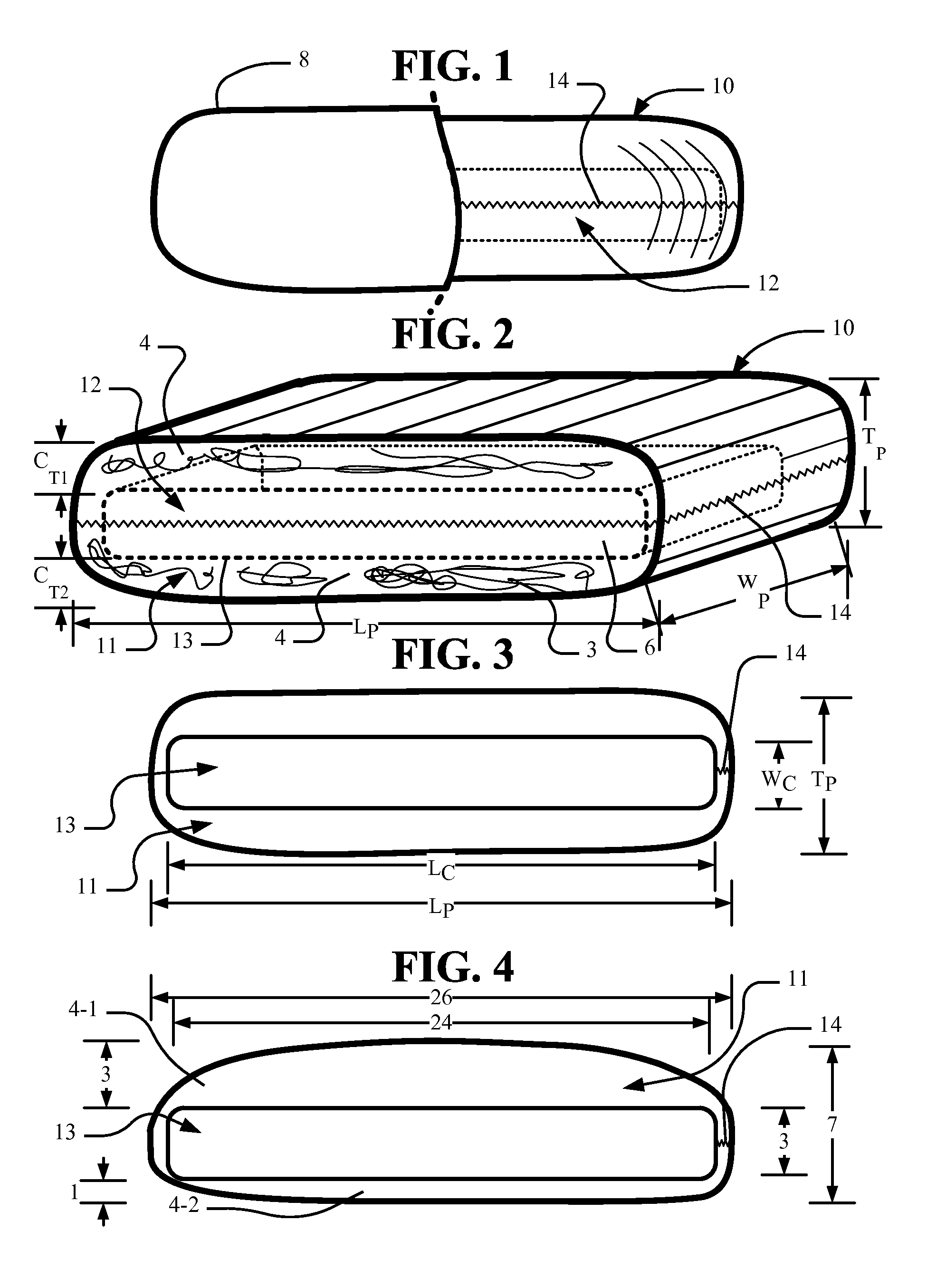

Pillow having structurally varying core and cover

A pillow for supporting the head of a reclining body. The pillow has a core formed with variable displacement parameters along the length and width and the pillow has a cover formed of a soft material for encasing the core. The cover imparts a soft feeling to the head on the pillow and distributes the weight of the head over the core. The core and the cover are displaced by the head as a function of the displacement parameters of the core so that the pillow functions to control the alignment of the head in a comfortable sleeping position while maintaining natural neck and head alignment.

Owner:SRAMEK ROGER A

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

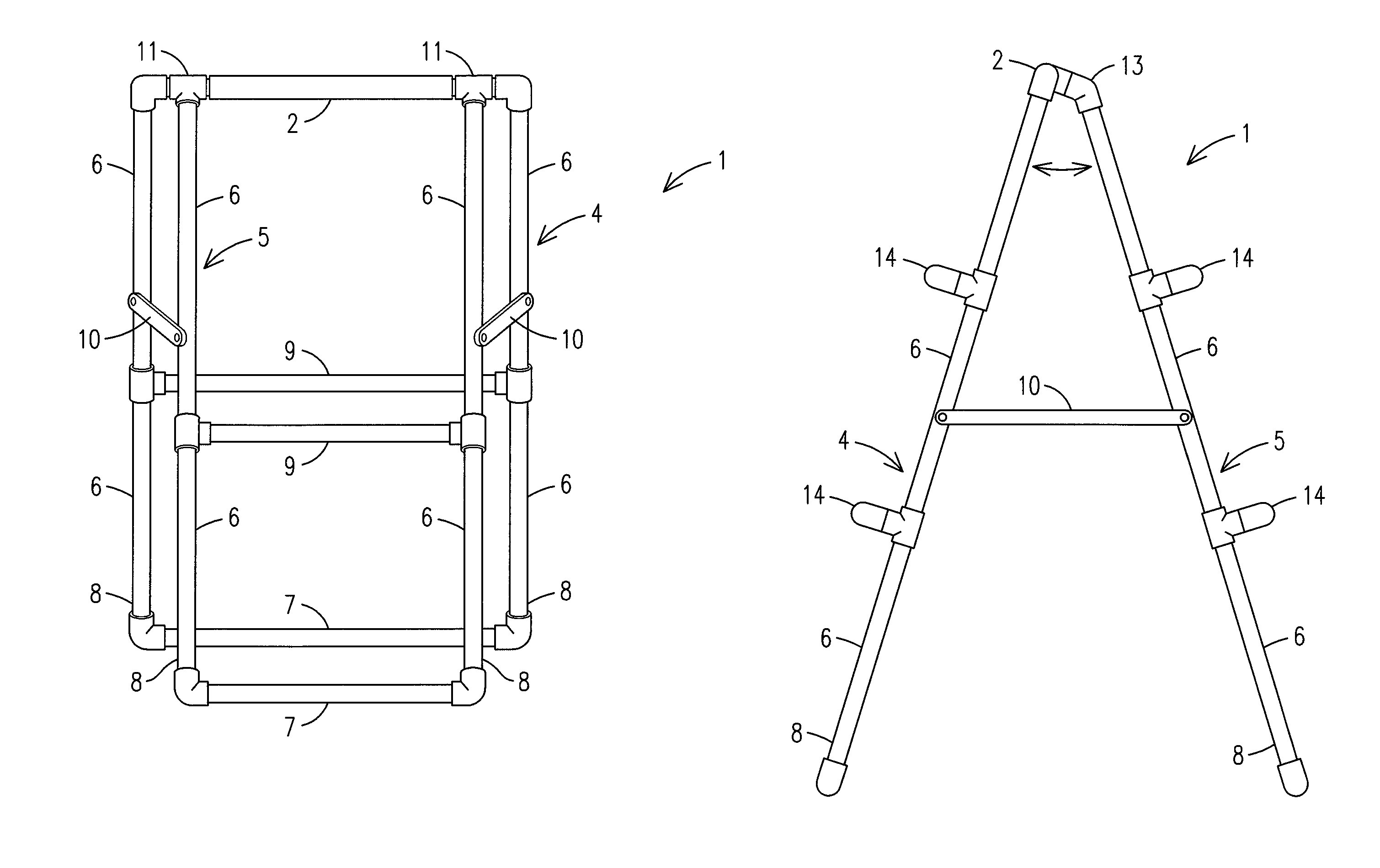

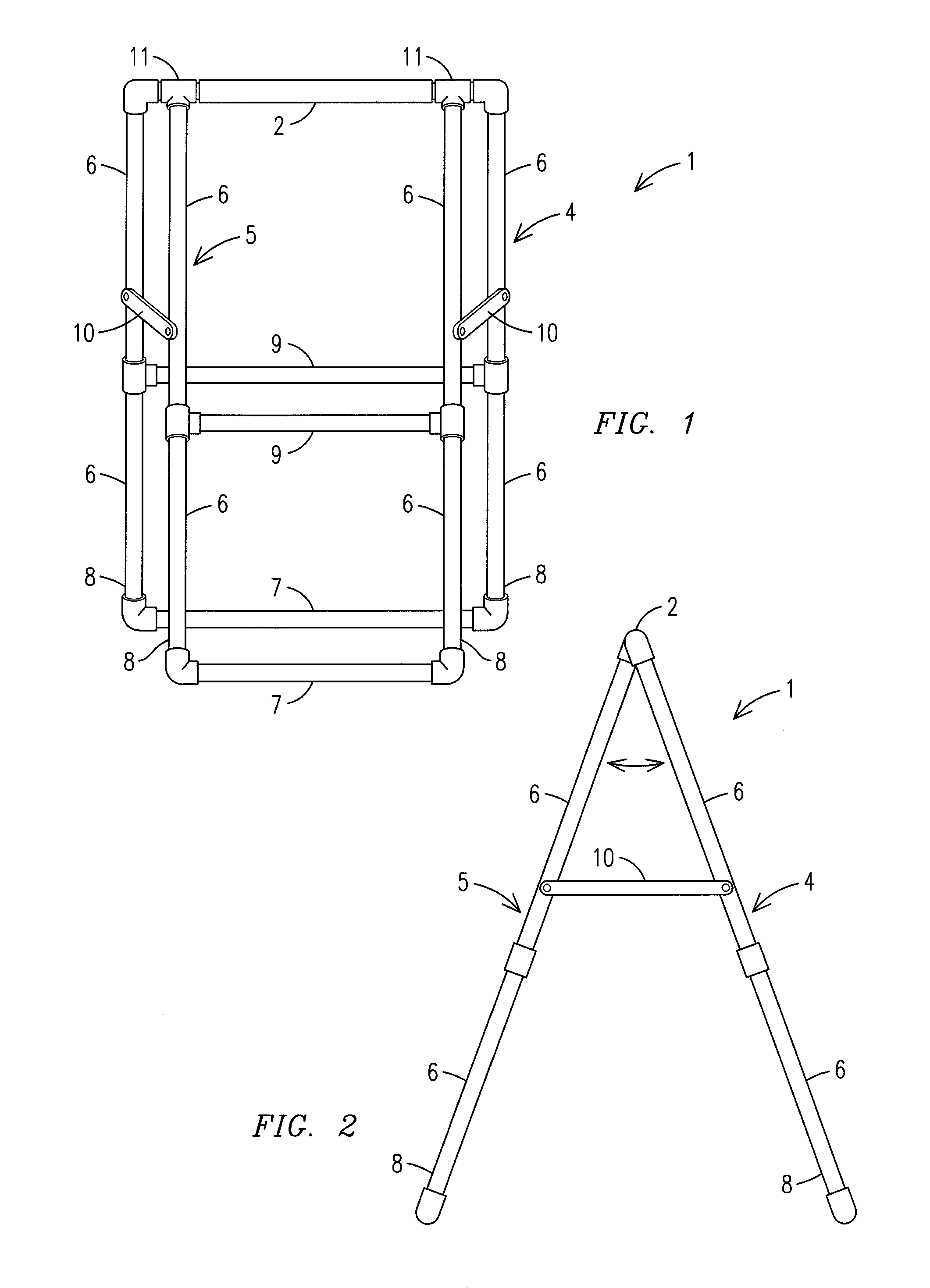

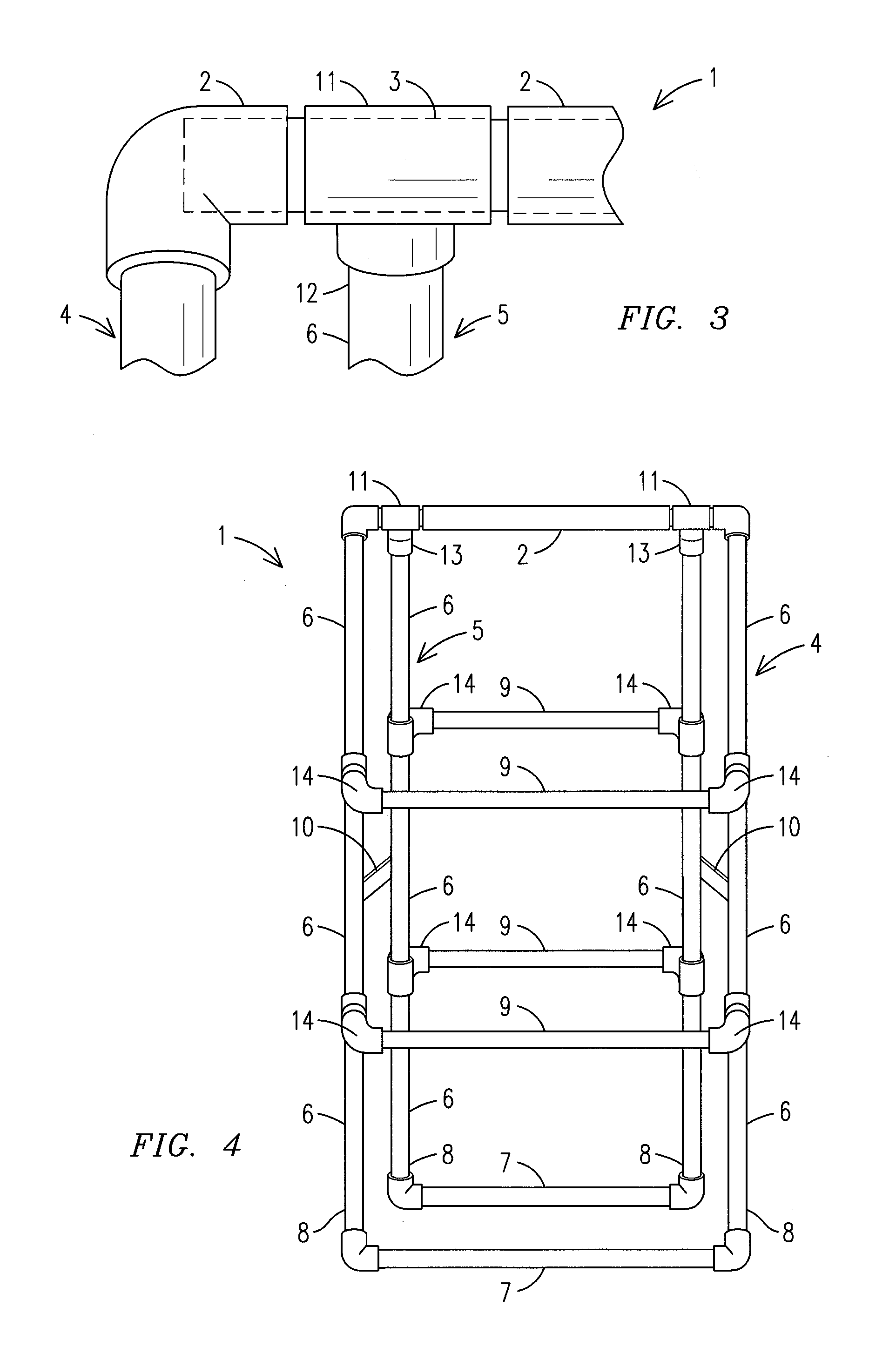

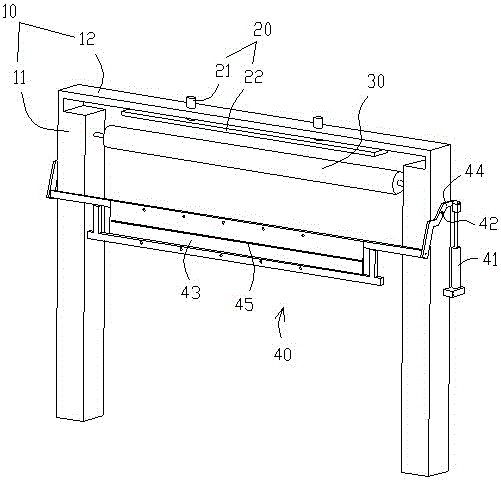

Folding clothes rack

InactiveUS8783473B1Sufficient air flowWithout taking up too much roomApparel holdersKitchen equipmentEngineeringAirflow

A triangular folding clothes rack (1) having a top tubular cross piece (2) with an inner axle (3) to allow a front frame (4) of the rack and a rear frame (5) of the rack to fold outward into an open position for drying articles of clothing and inward into a closed position for storing the rack. Clothes may be hung from the top tubular piece and / or hanging rods (9) either directly and / or by using conventional hangers. Offsets (13) located on the rear frame and extensions (14) located on hanging rods allow clothes to be hung without the clothes lying on top of each other, thereby providing maximum airflow between the clothes to allow for expedited drying.

Owner:SCHOSEK WILLIAM O

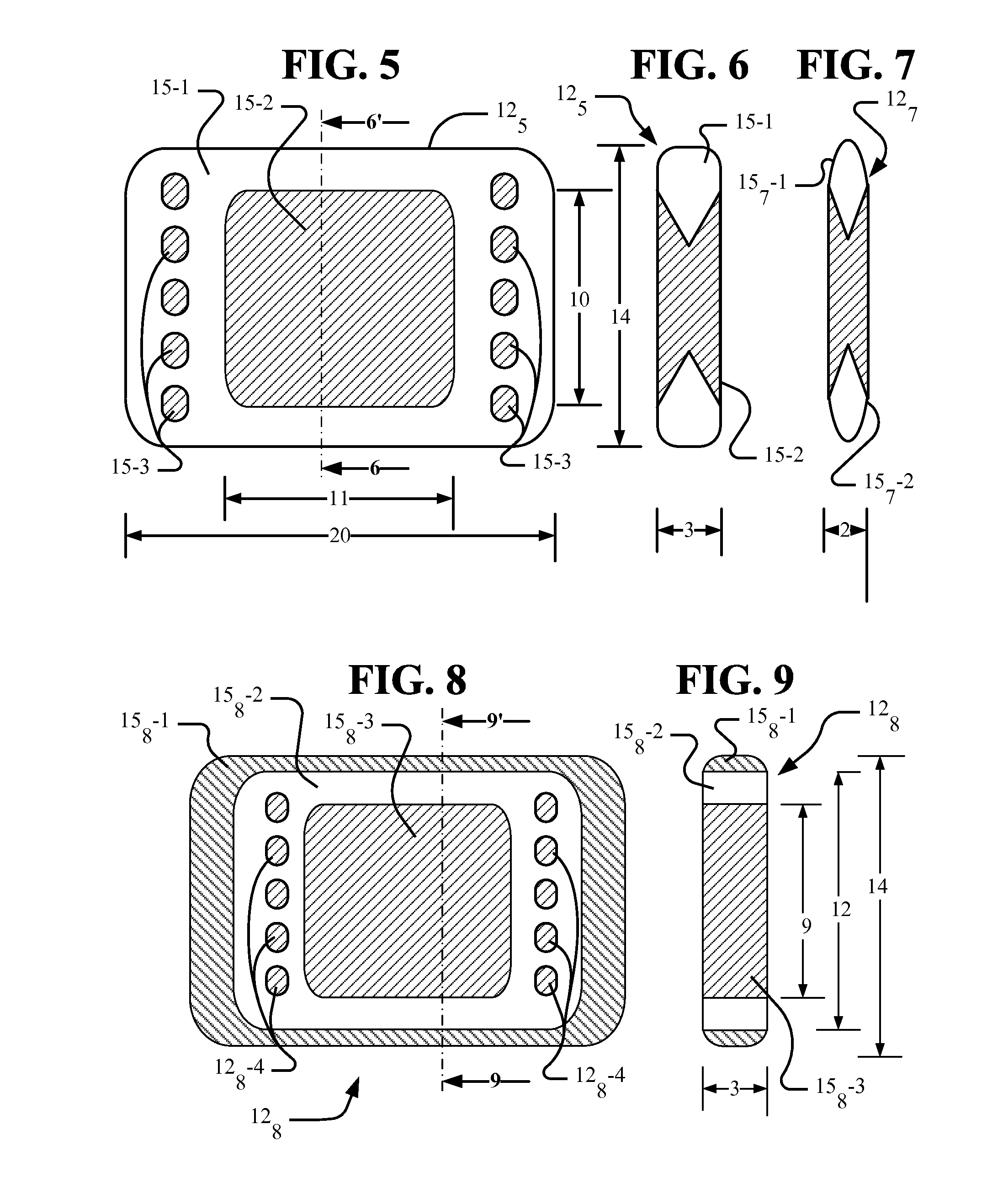

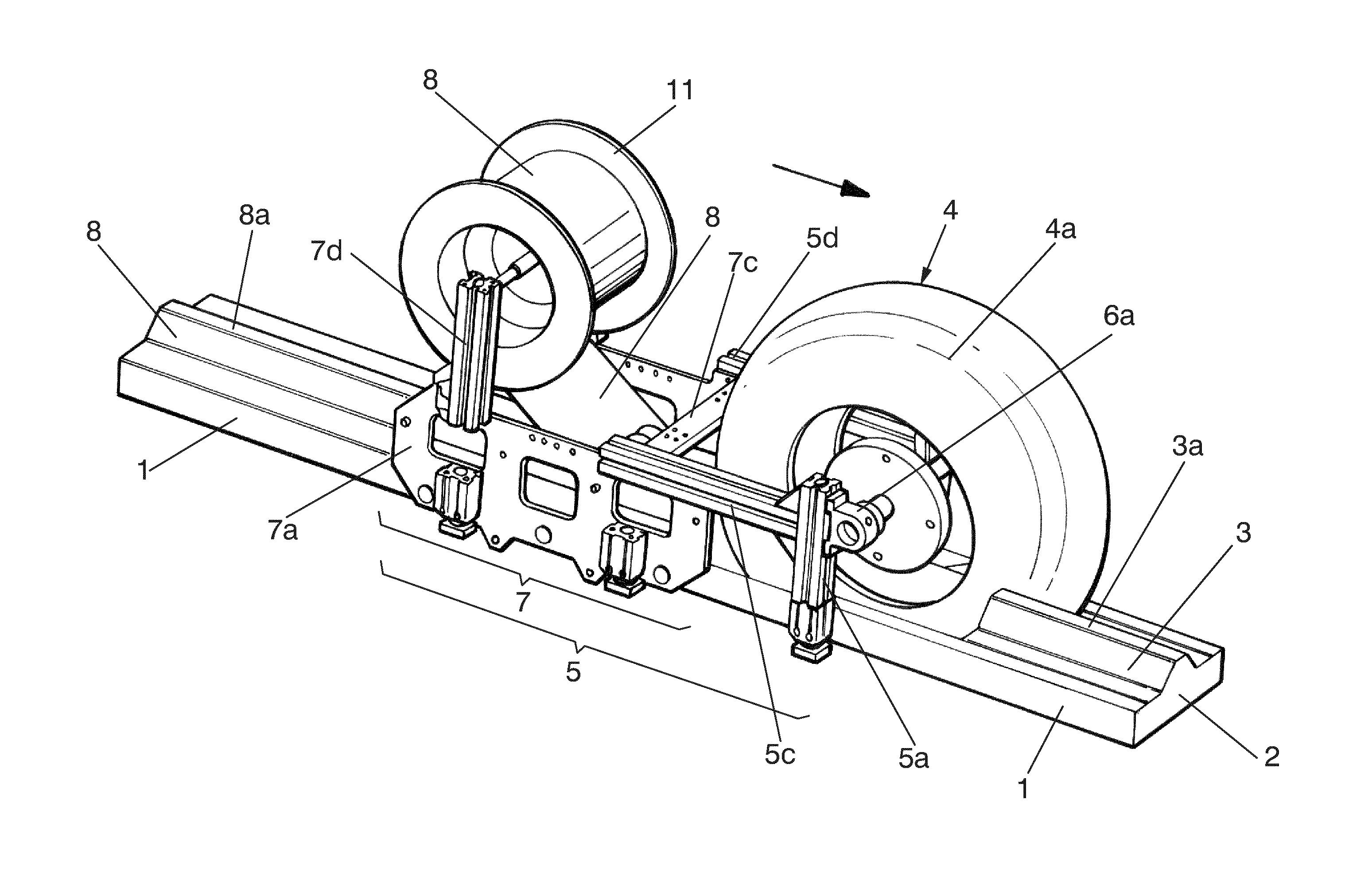

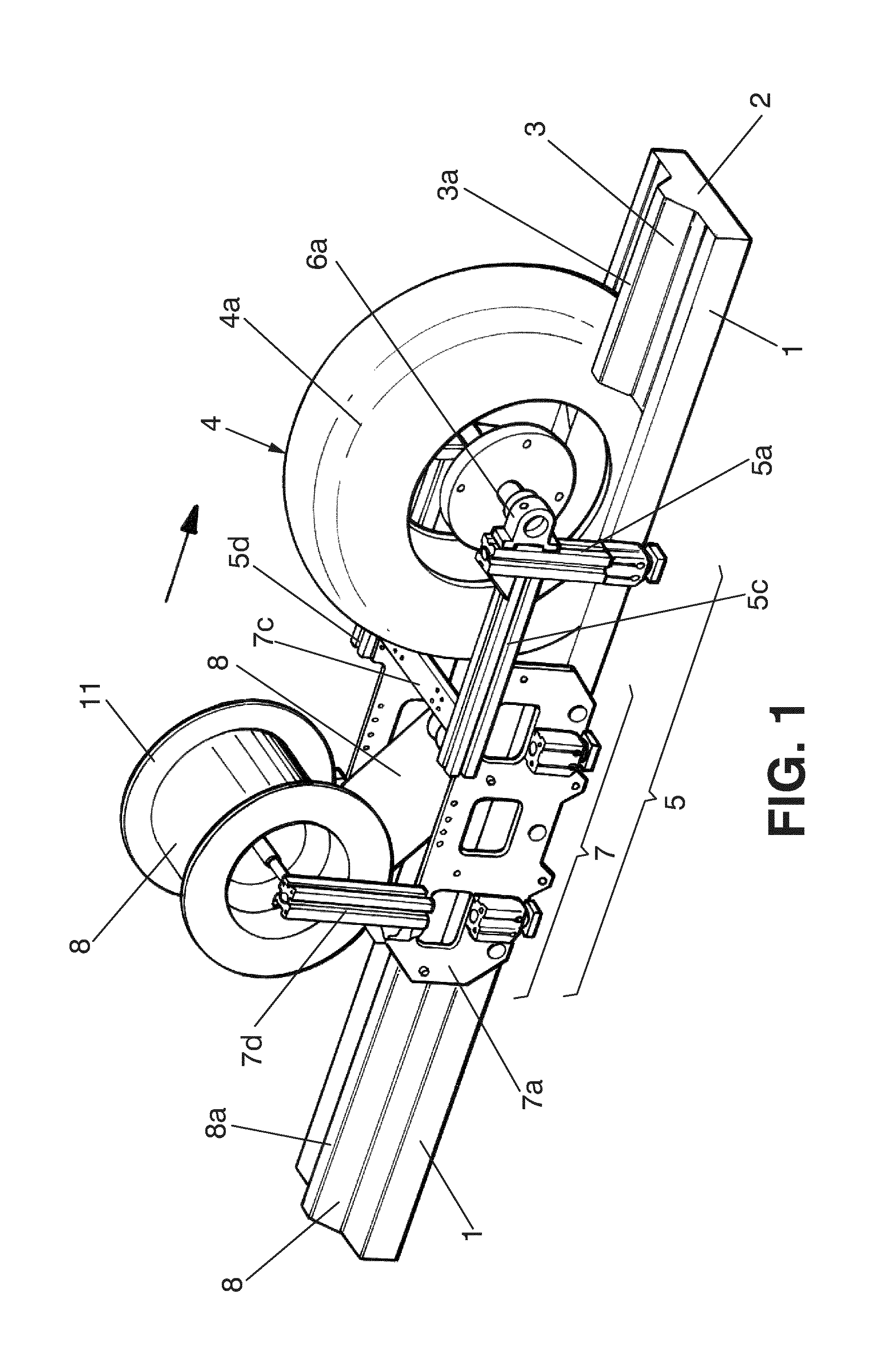

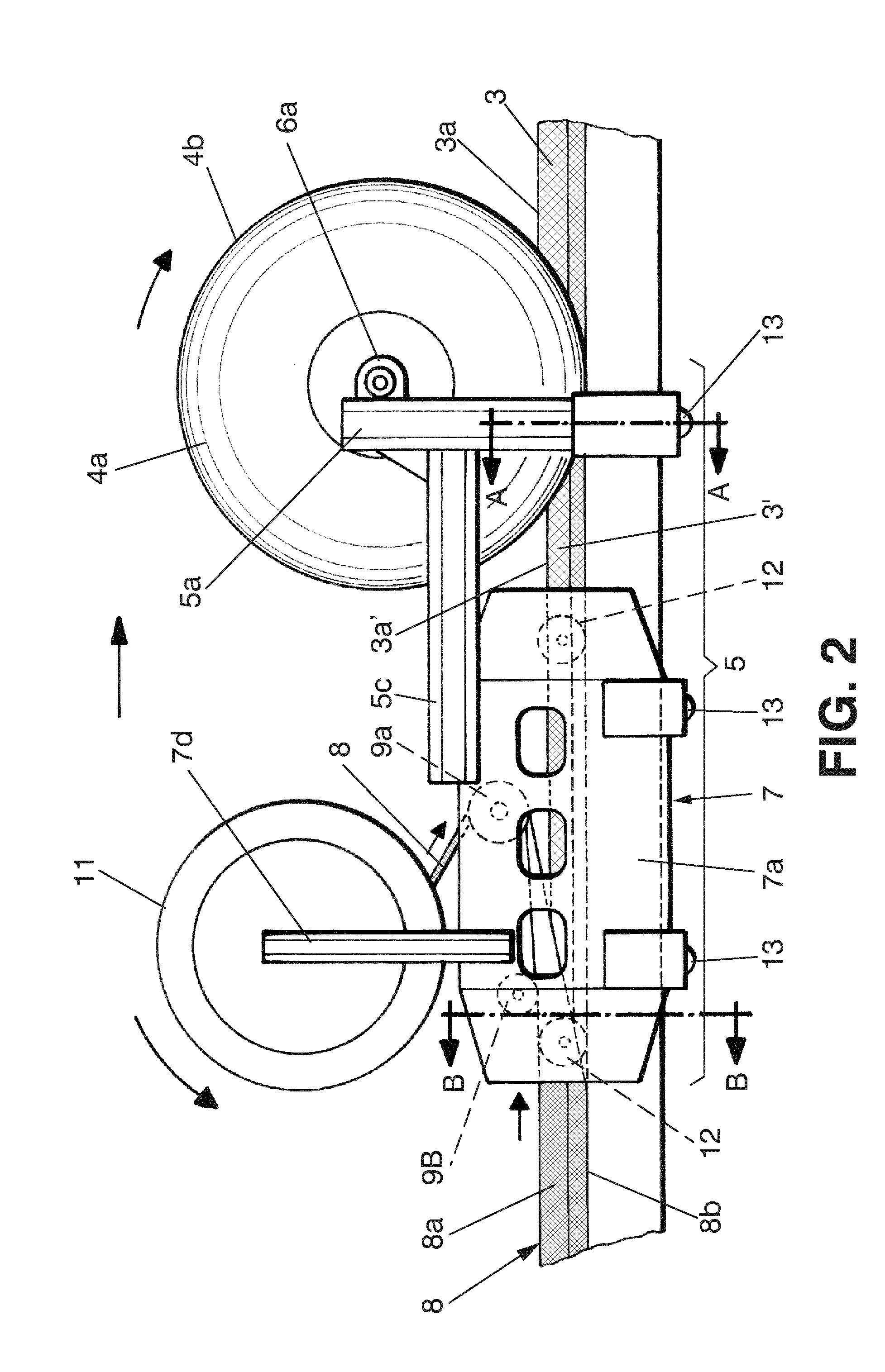

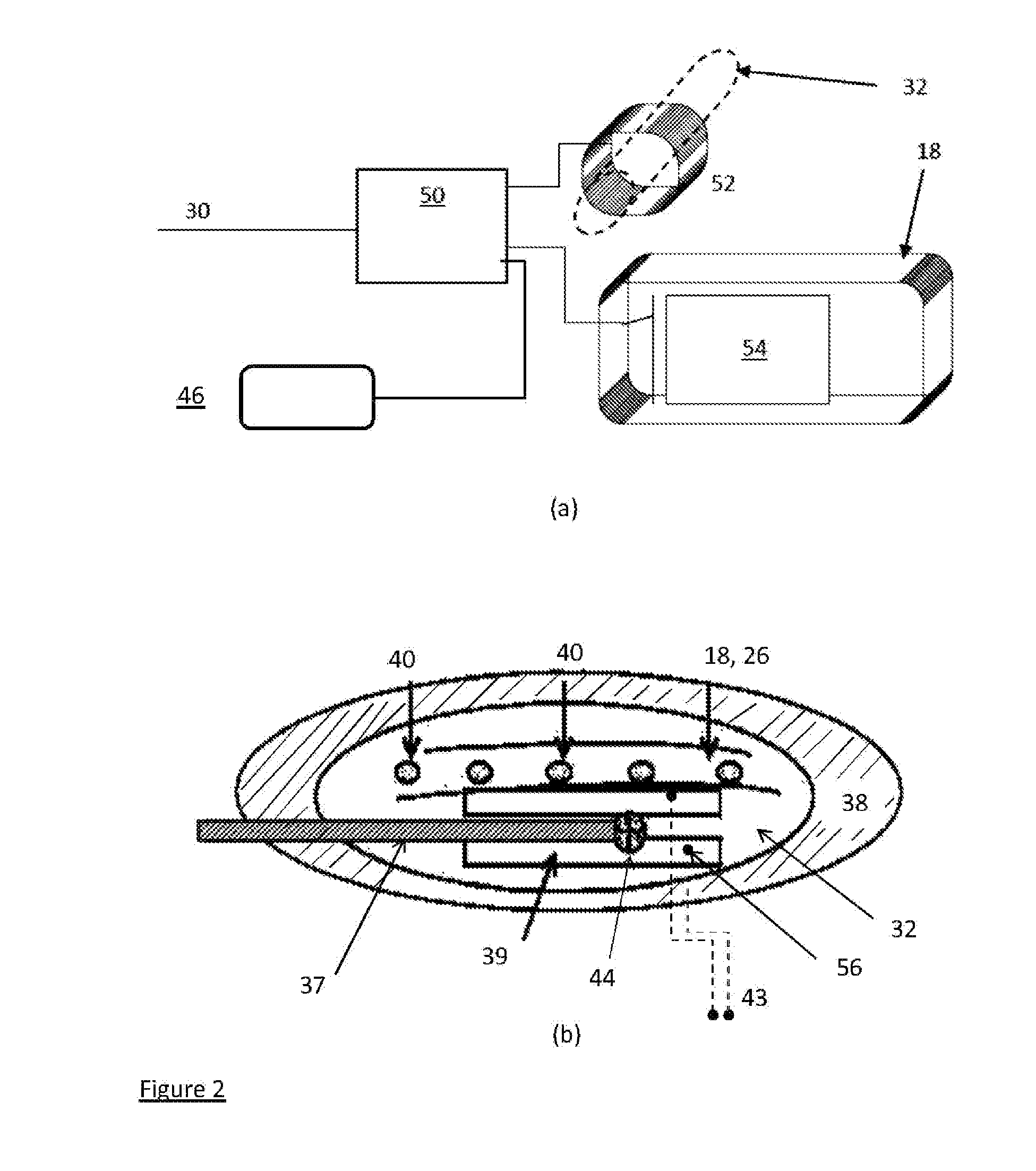

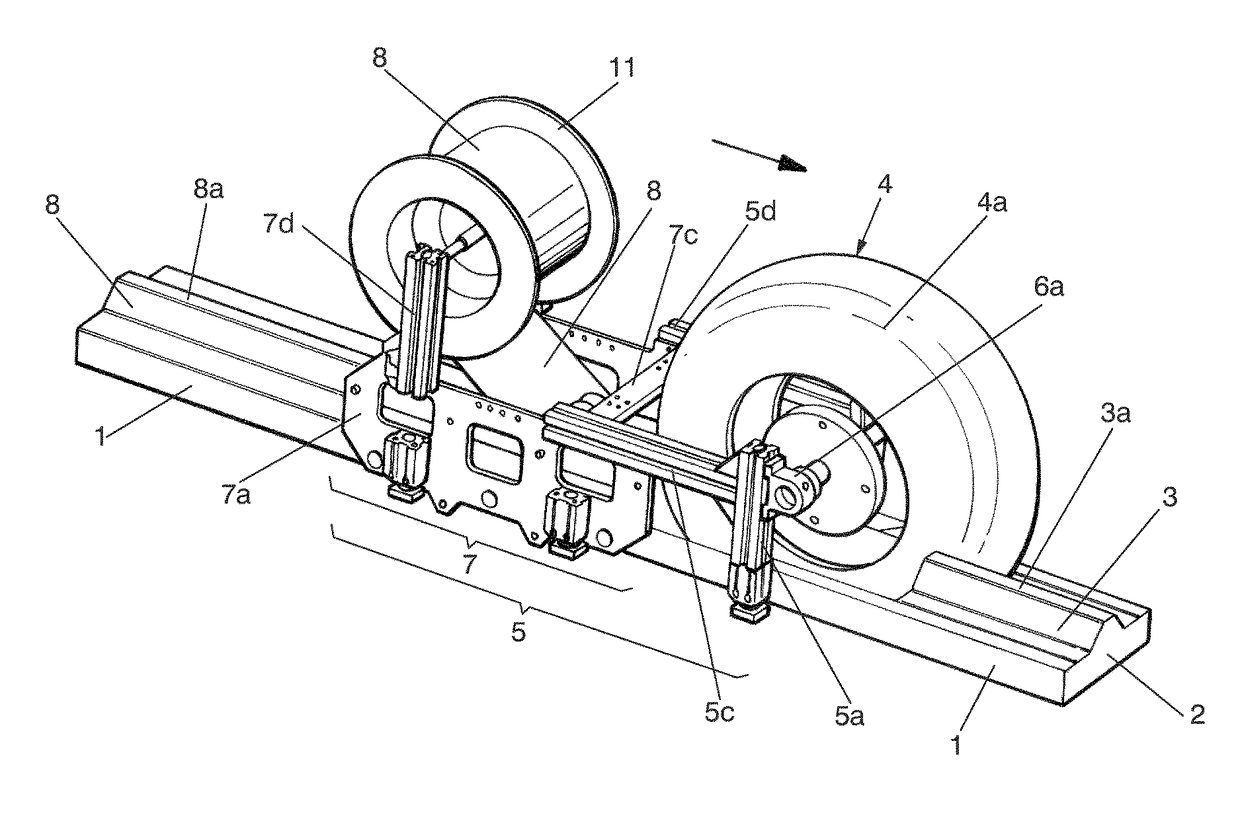

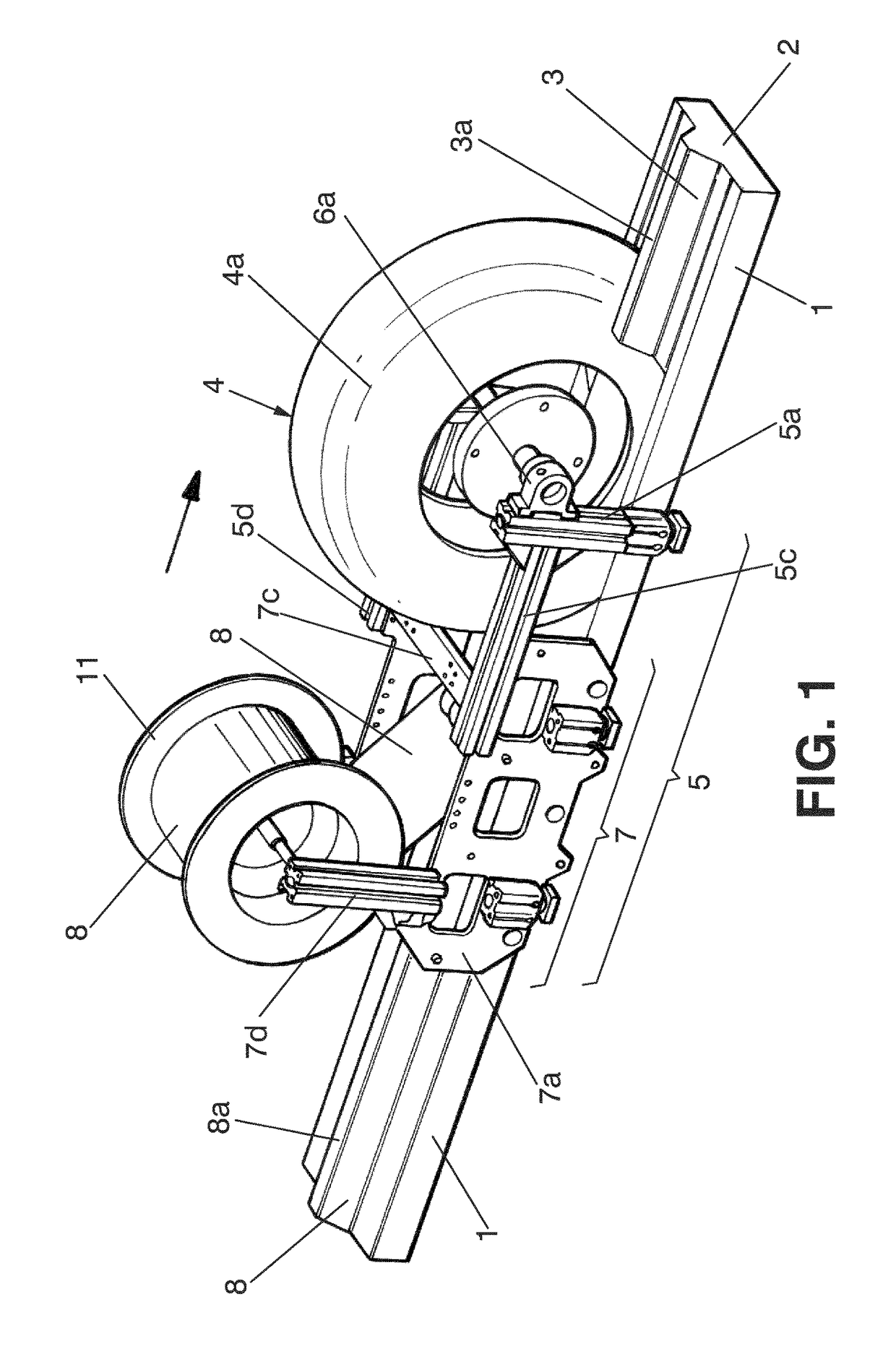

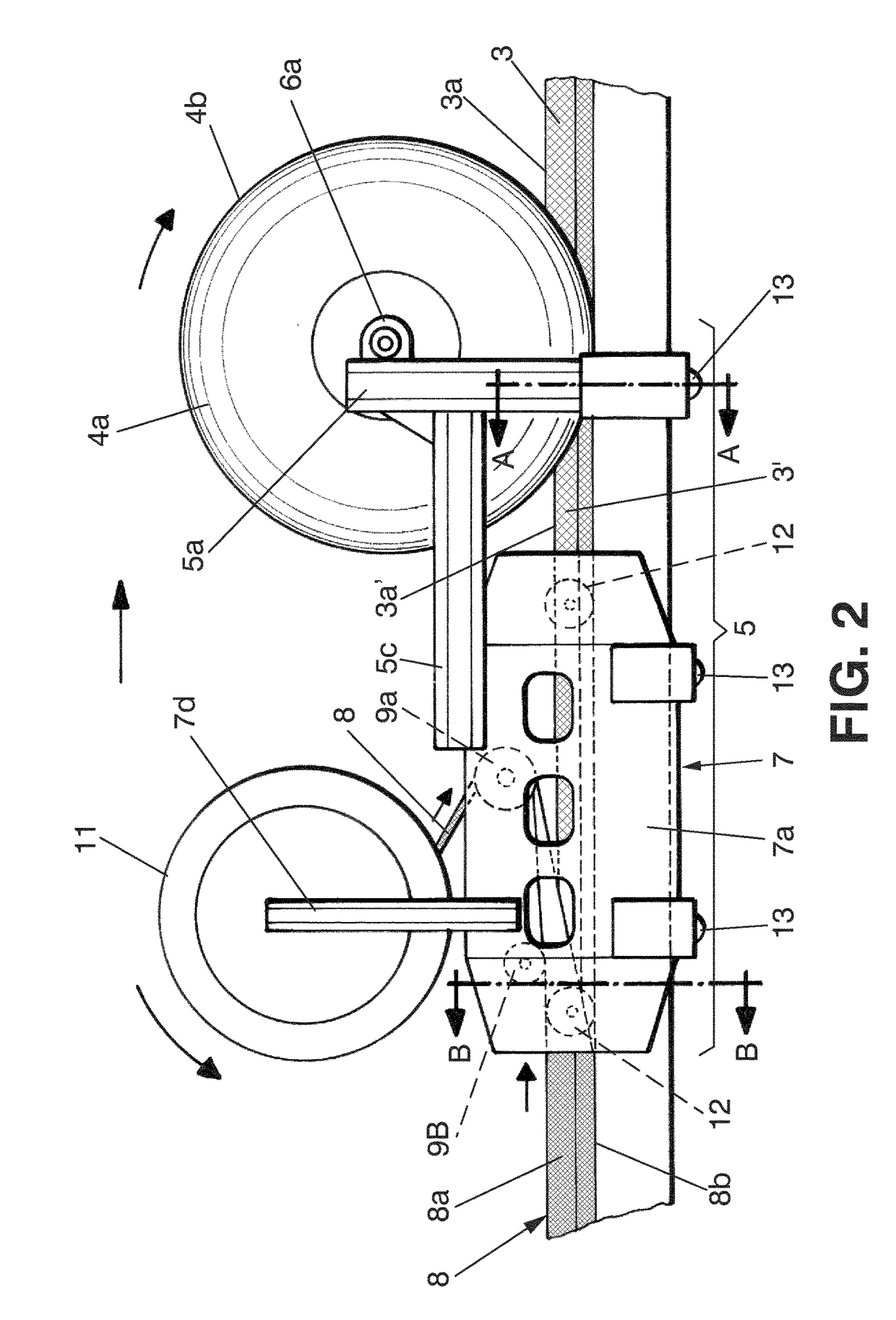

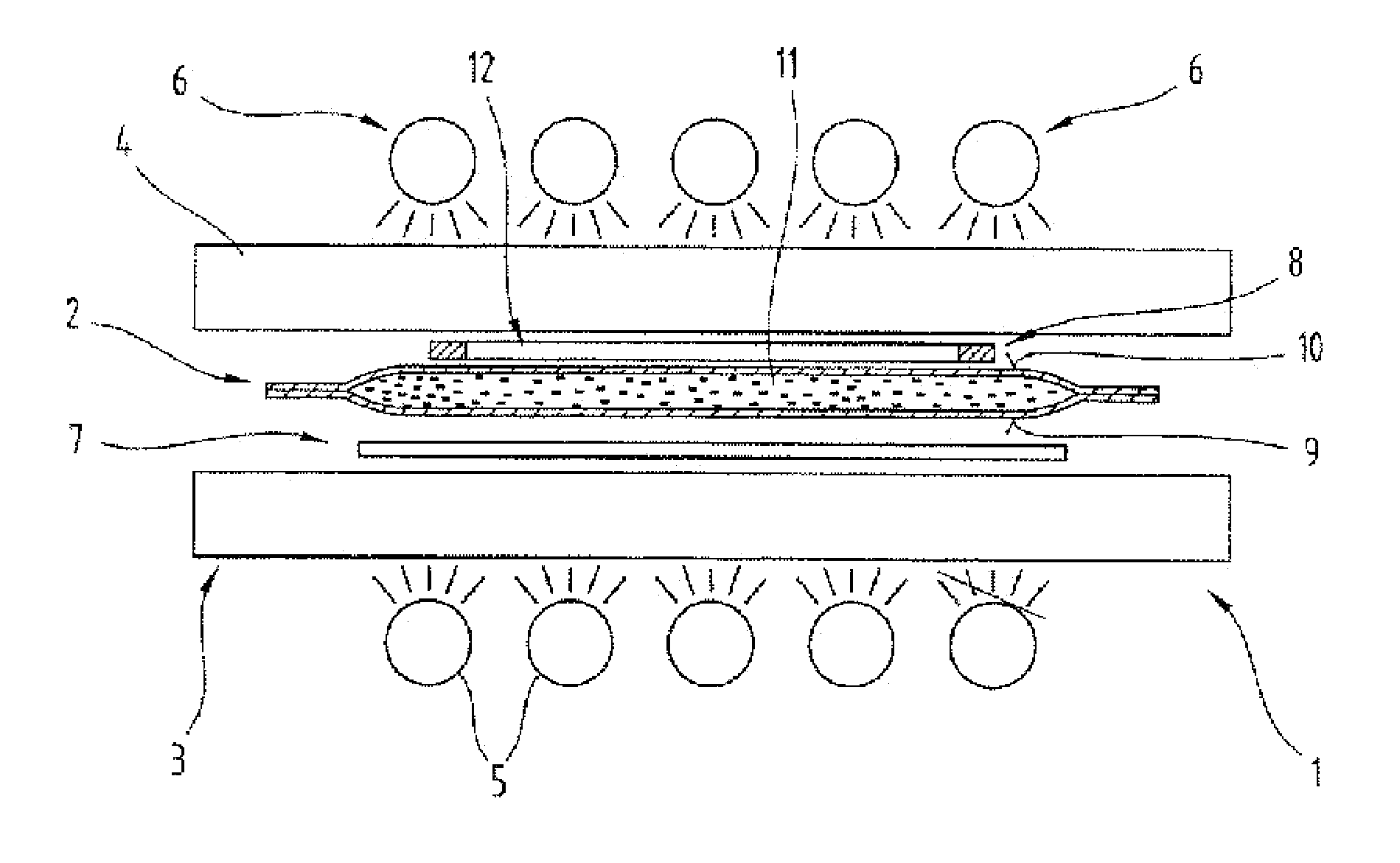

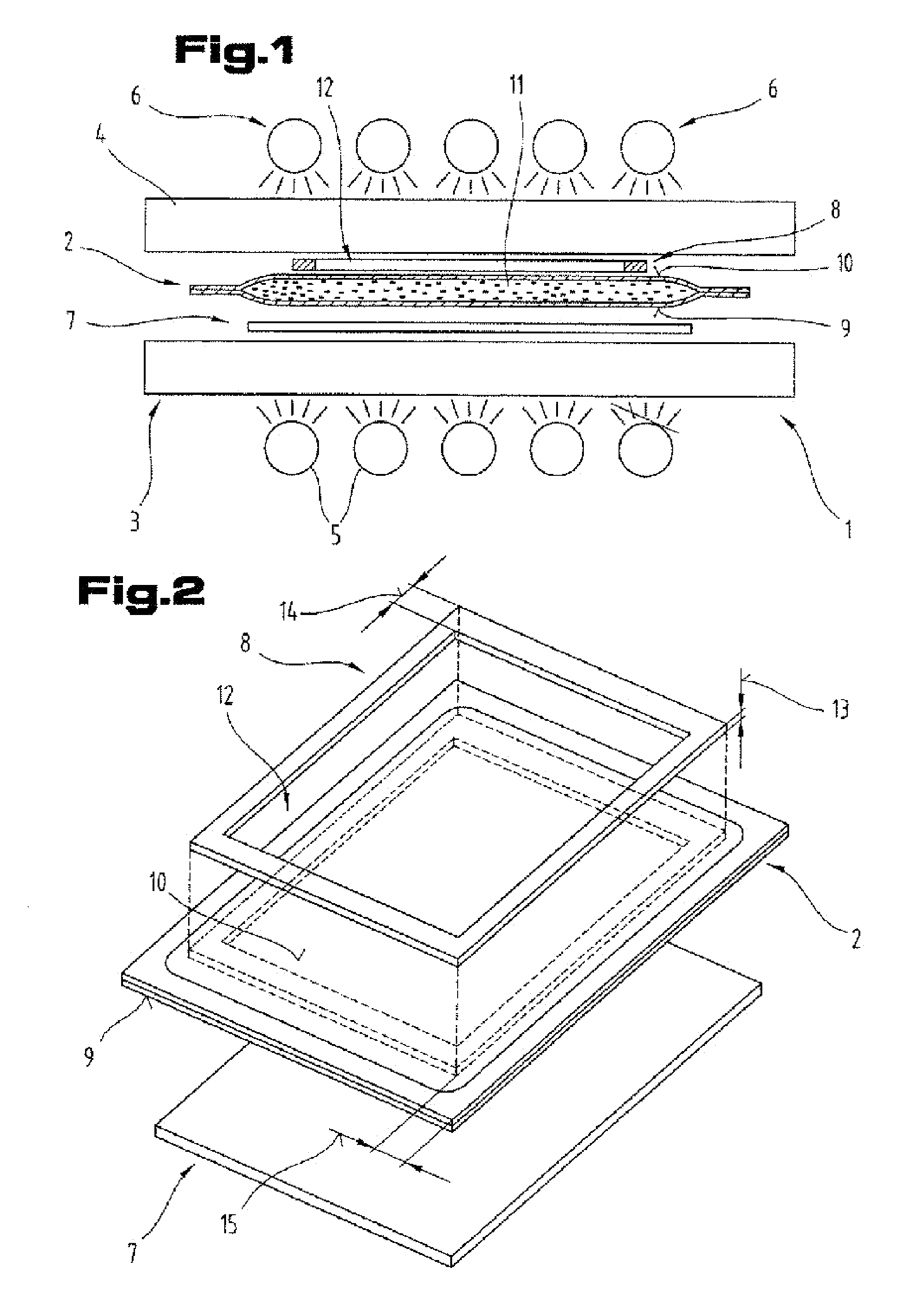

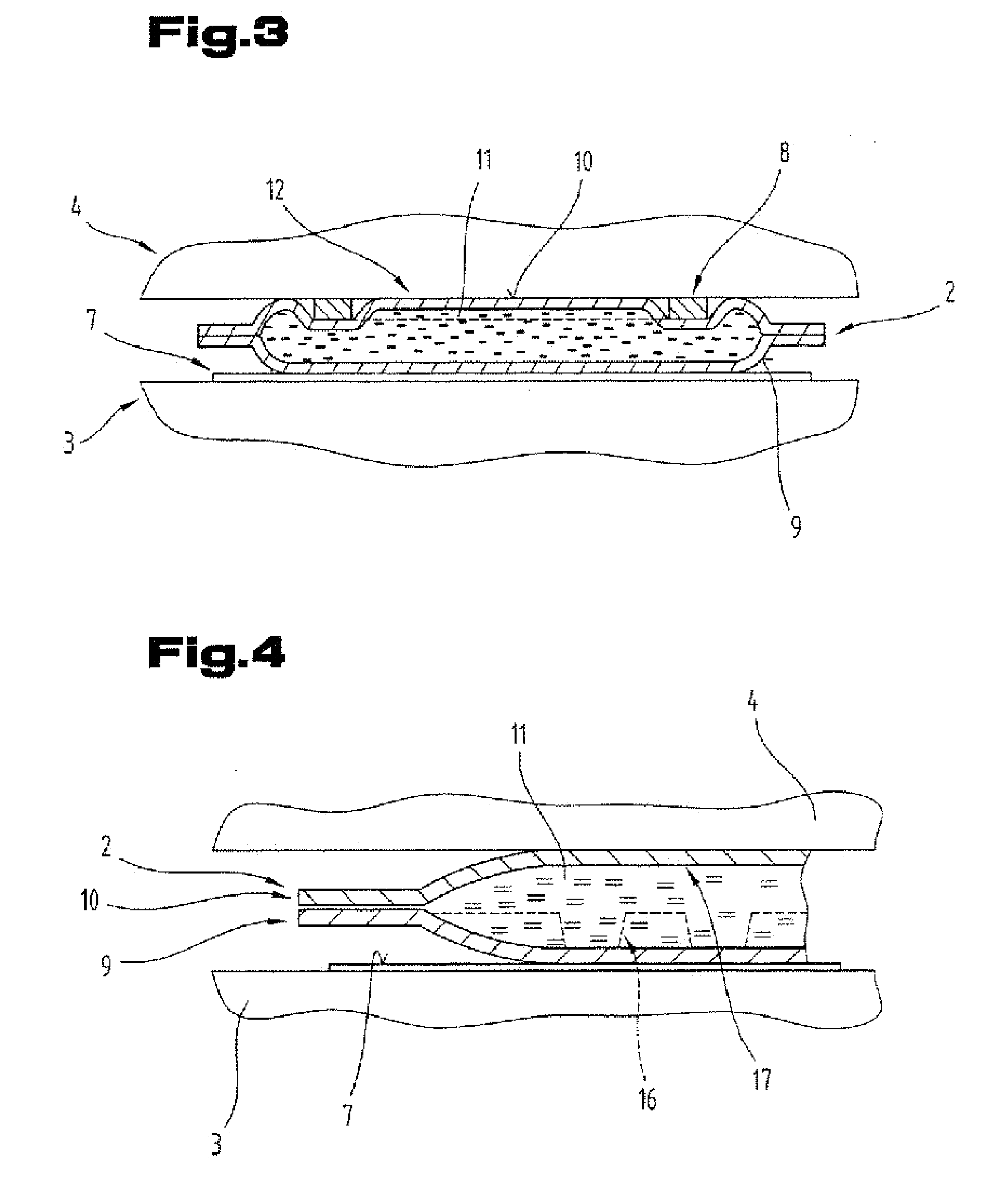

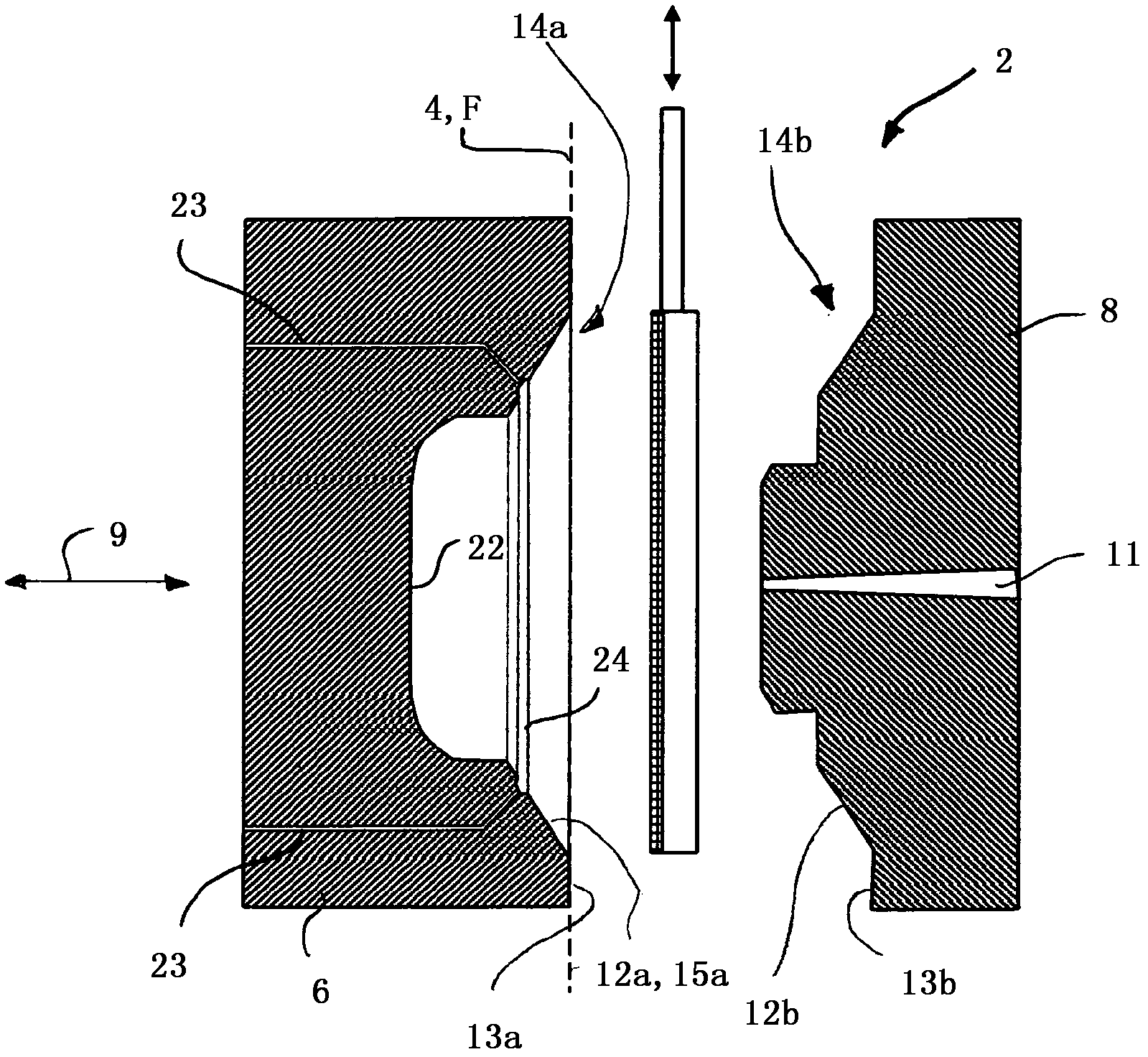

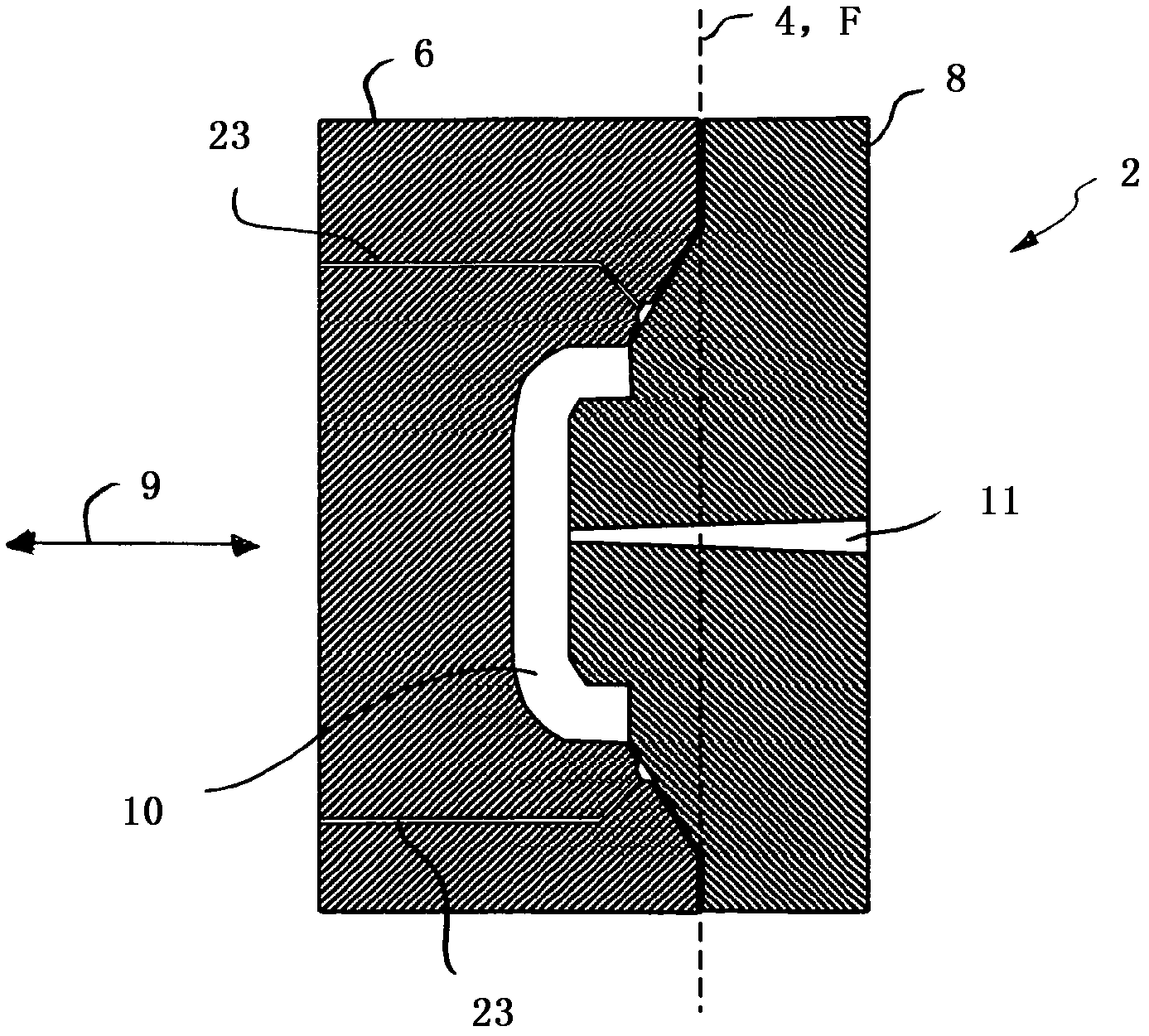

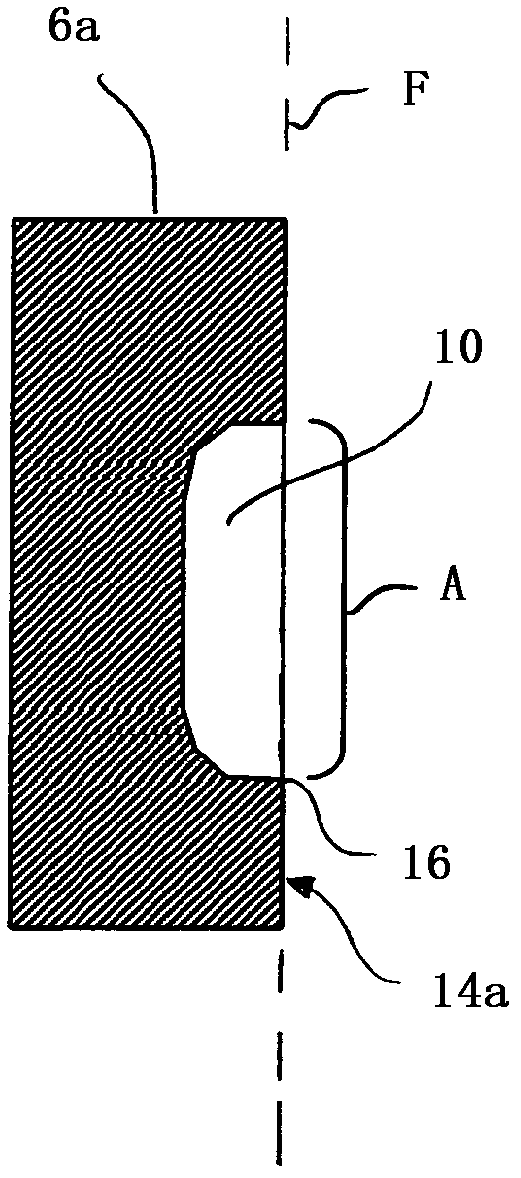

System for forming stacks of composite materials

InactiveUS20140290866A1AdaptablePrevent movementLamination ancillary operationsLaminationMechanical engineeringMoulding device

The invention relates to a system for shaping laminar composite materials, comprising a base (1) with at least one longitudinal mandrel element (2) comprising a shape to be given to a stack of composite material (3) arranged on the mandrel element (2) for obtaining a formed stack (3′) of composite material, and at least one pressure rolling forming device (4) assembled in a support carriage (5) such that it is capable of placing the pressure rolling forming device (4) in at least one position in which it rolls over the stack of composite material (3) pressing it against the mandrel element (2) for forming it and obtaining the formed stack (3′), the pressure rolling forming device (4) comprising a rolling hollow cover (4a) made of elastically flexible material with a tread (4b), and the rolling hollow cover (4a) being susceptible to containing: a fill fluid at a fill pressure and / or a plurality of particles (27) which allow the tread (4b) to elastically adapt to the shape of the mandrel element (2) and exert a chosen pressure on the stack of composite material (3).

Owner:APPLUS SERVICIOS TECHCOS

Dyeing process of polyester cotton fiber fabric

ActiveCN103993487AAvoid wrinklesAvoid severe shrinkageHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention provides a dyeing process of a polyester cotton fiber fabric. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, washing, soaping, color fixing, drying, forming and winding. According to the dyeing process, a high-temperature leveling agent is added during dyeing, so that the problem that level dyeing effect and penetration dyeing effect are affected and even generate color dots and color patches occur caused by gathering of dyes because the heat stability resistance of fuel is reduced due to temperature increase is avoided, and the dyeing effect is good; the temperature is increased in a stepped progressive mode in the dyeing procedure, and the temperature increase and decrease velocity and the dyeing time are strictly controlled, so that high dyeing fastness, dyeing uniformity and good dyeing stability of the polyester cotton fiber fabric are achieved; the dyes with single property are not used and dispersed dyes and neutral dyes are compounded in the dyeing procedure, and the dispersed dyes and the neutral dyes supplement each other, so that good dyeing fastness is achieved; the traditional two-bath two-step method dyeing is abandoned, and the one-bath one-step method dyeing is adopted, so that the energy is saved, and the emission amount is reduced.

Owner:广东欣薇尔服装有限公司

Method for dyeing mercerizing wool or mercerizing wool fabric by yellow chrysanthemum flower dye

InactiveCN101117775AReduce the chance of occurrenceImprove uniformityDyeing processSodium bicarbonatePhosphate

The present invention relates to a method of dyeing mercerized wool or mercerized wool fabrics with yellow chrysanthemum paint, which is taken as the paint, and the dyeing method is divided into two steps including ecological pretreatment and subsequent innocuous mordant dyeing: the first step, treatment conditions: baking soda of 1-3 percent of cloth weight, 1-5 percent coconut oil diethanol amide as detergent of 1-5 percent of cloth weight, 0.2-1.0g / L neutral phosphate, temperature 20-60 DEG C, duration 10-60min, bathing ratio 1 to 20-50; the second step, mordant dyeing: the mercerized wool or mercerized wool fabrics with ecological pretreatment is treated with mordant front dyeing, single bathing or post dyeing. The yellow chrysanthemum resources are rich, easy for expanding plantation, with sound dyeing and less damage to mercerized wool during dyeing.

Owner:HAILAN GRP +1

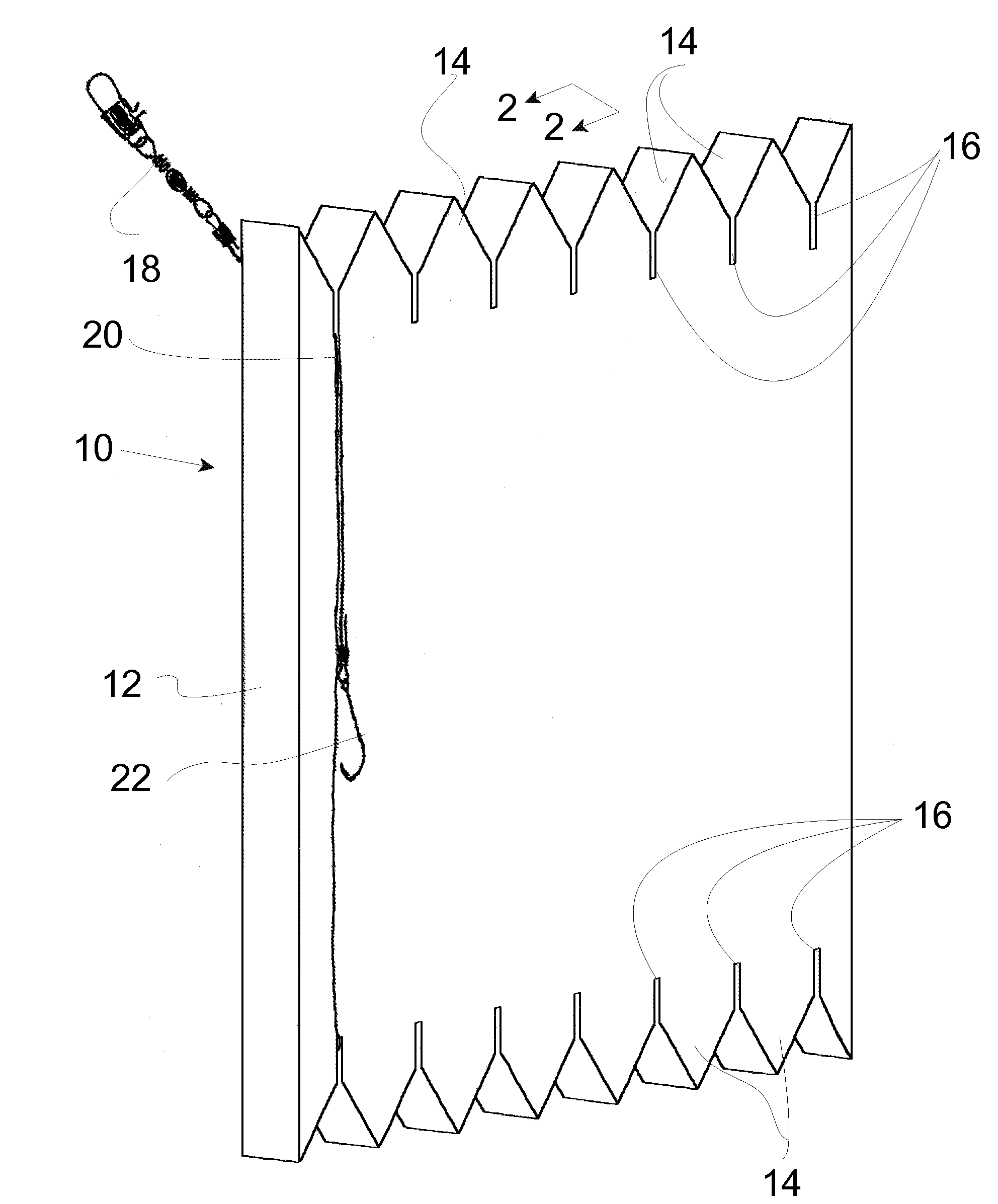

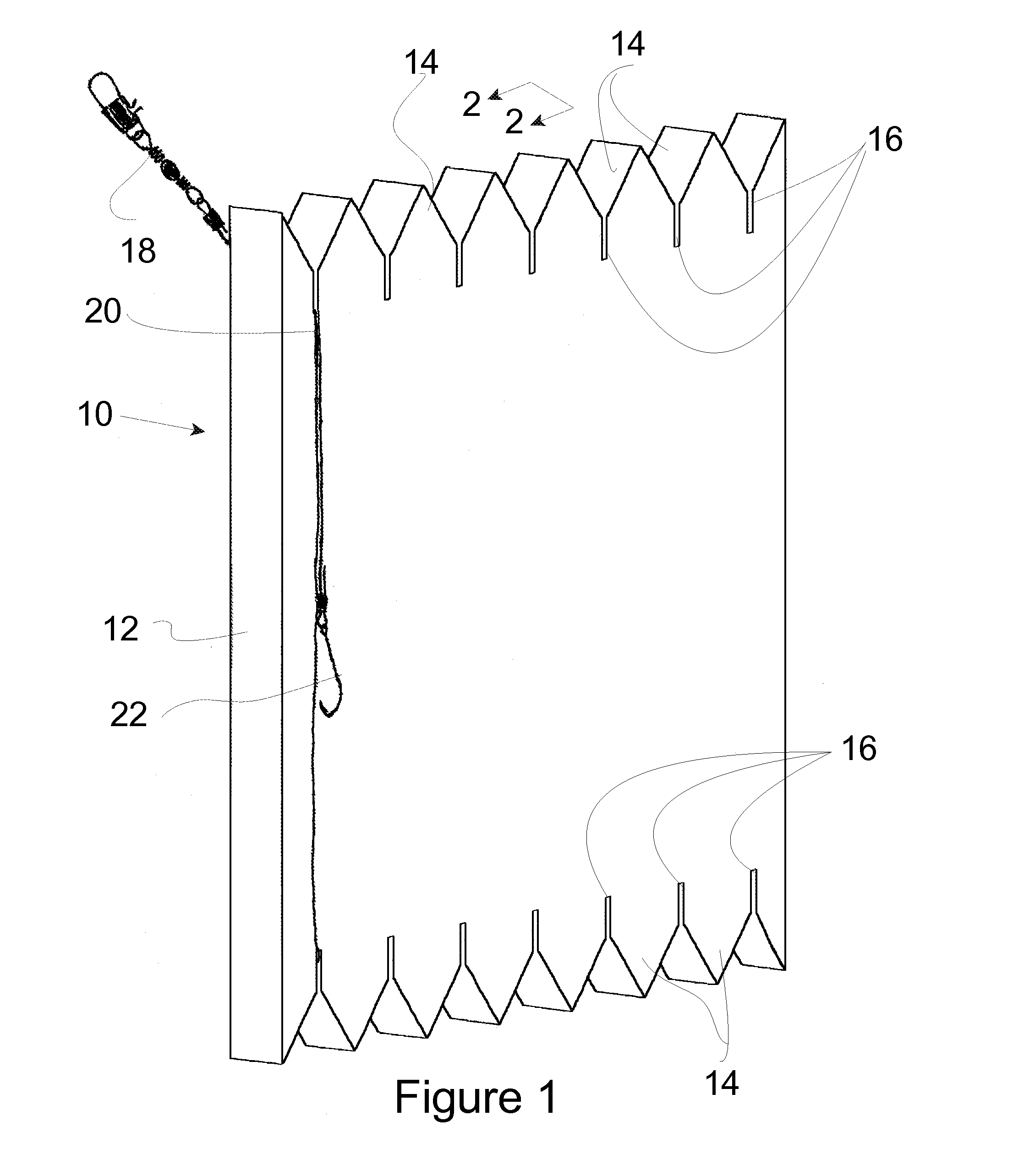

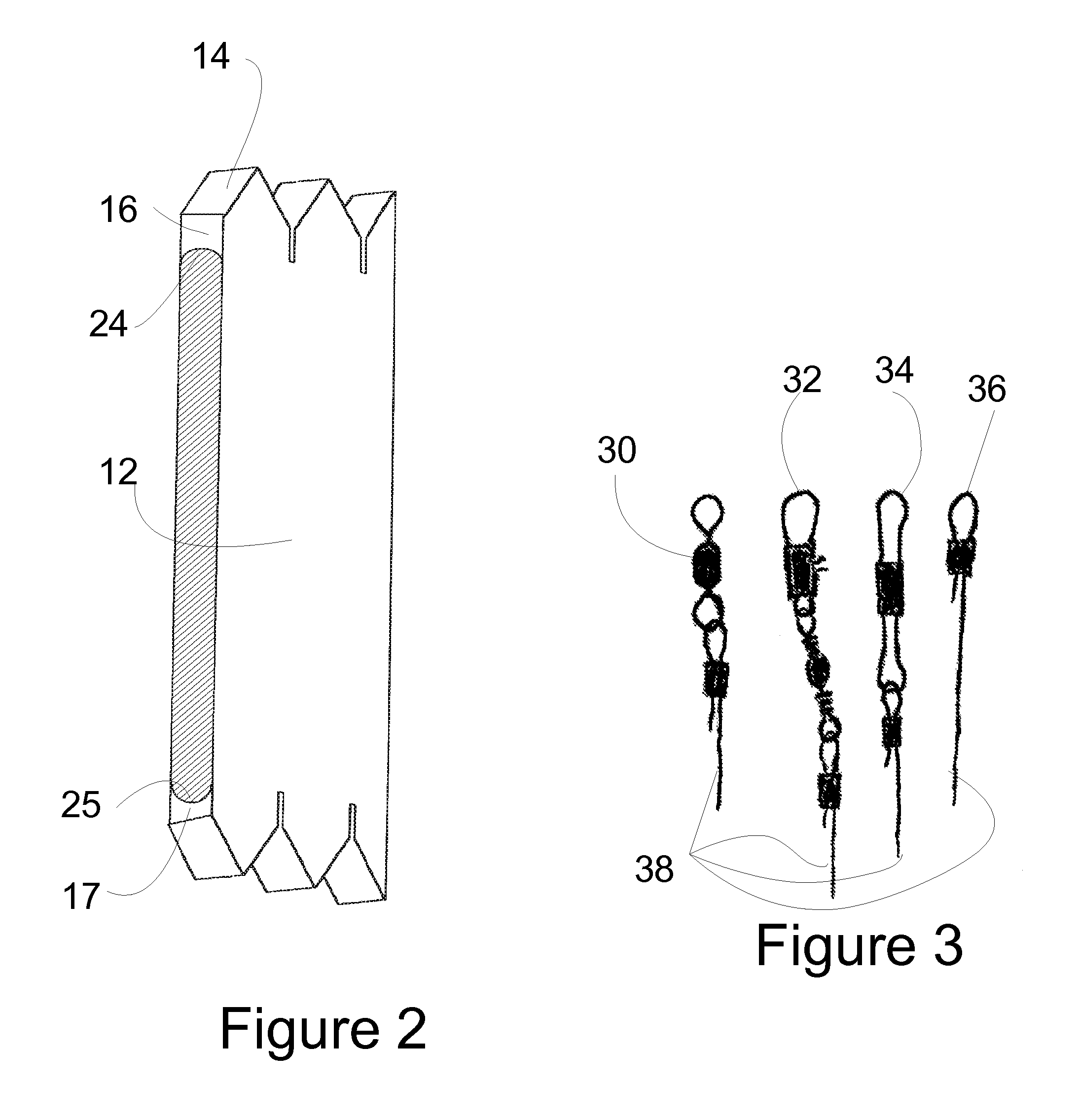

Fishing Line Holder

InactiveUS20090119974A1Reduce bend and kink and creaseReduce creasesOther angling devicesMulti materialEngineering

The disclosed device is an improved fishing line organizer that, among other features, provides a frame to wrap multiple and varying fishing lines and terminal tackle around for storage reducing tangling, preventing line kinks and maintaining each fishing line available for use. An embodiment of the device provides for construction of the device from a material (or materials) sufficiently buoyant to float when holding multiple fishing lines and terminal tackle.

Owner:NAVY UNLIMITED

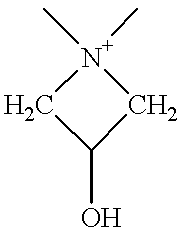

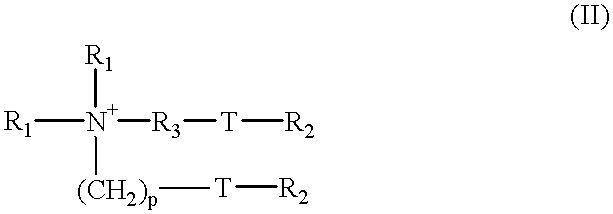

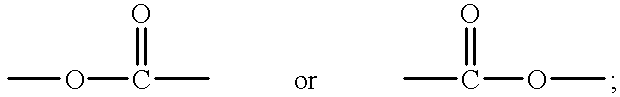

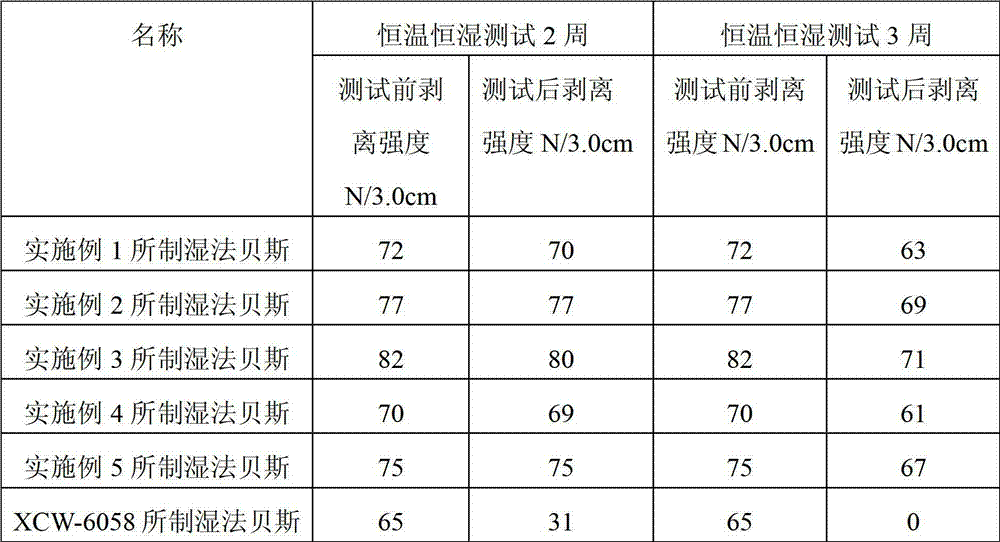

Anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and preparation method thereof

ActiveCN105002748AReduce creasesIncrease softnessLamination ancillary operationsSynthetic resin layered productsFiberWrinkle skin

The invention discloses anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and a preparation method thereof. The preparation method comprises the steps that fiber screen laying and needling are carried out on a spunlaced non-woven fabric surface, and a anti-wrinkle non-woven base is formed; after dipping carried out in a polyurethane dipping sizing agent is finished, condensing and ironing are carried out in a DMF aqueous solution; after coating is carried out by a polyurethane coating, the condensing, washing and drying are sequentially carried out; a post-processing grinding machine is used for carrying out orientated grinding on the surface of a semi-finished product; one layer of a thermoplastic polyurethane resin dry coating sizing agent is coated on release paper, after drying is conducted, one layer of a thermoplastic polyurethane dry bonding layer sizing agent is coated on the release paper, then drying is carried out in a drying oven until the release paper is half-dried, and a dry synthetic leather semi-finished product is obtained; the dry synthetic leather semi-finished product is attached to the wet synthetic leather semi-finished product, and after drying and ripening are conducted, the non-woven fabric polyurethane synthetic leather is obtained. The non-woven fabric polyurethane synthetic leather has the advantages that wrinkles cannot be generated, the physical mechanical strength is high, meanwhile sizing of shoemaking is good, and the durability is good; processing and performance requirements for children shoes, sport leisure shoes and the like are completely met.

Owner:ANHUI ANLI MATERIAL TECH

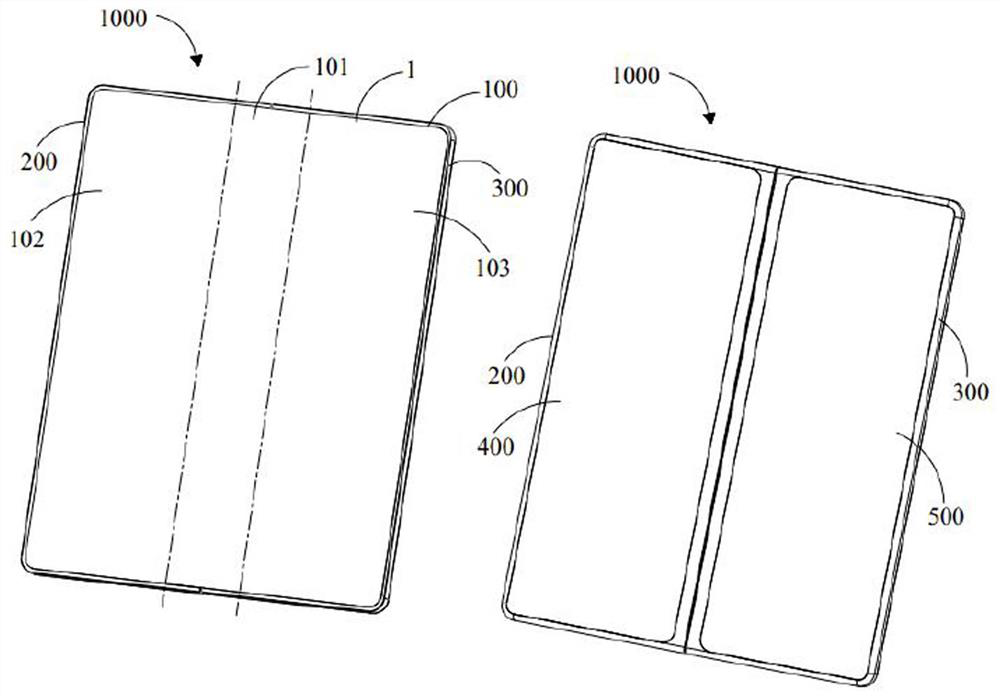

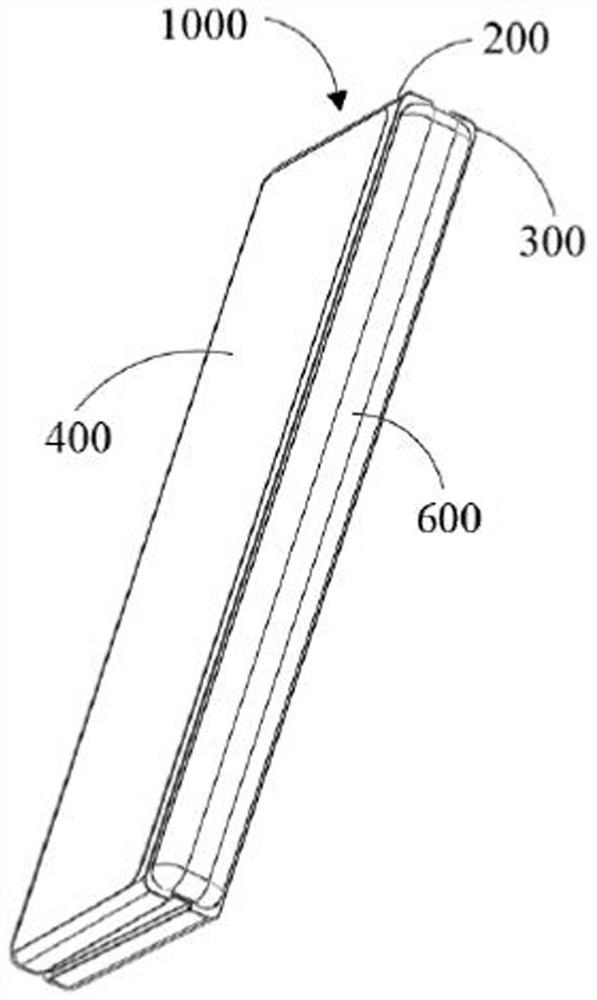

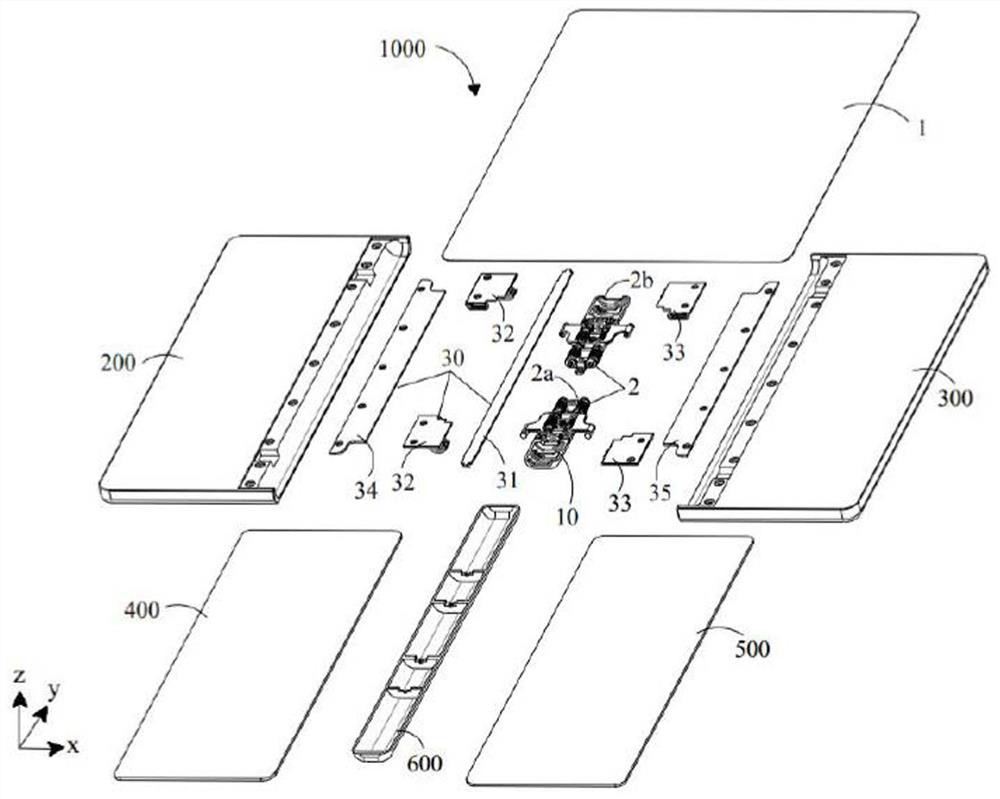

Hinge, flexible display panel and electronic device

ActiveCN113202857AImprove flatnessAvoid squeezingShaftsCasings/cabinets/drawers detailsStructural engineeringFlexible display

The embodiment of the invention provides a hinge, a flexible display panel and an electronic device. The electronic device comprises the flexible display panel. The flexible display panel comprises a flexible display panel main body and the hinge. The flexible display panel main body comprises a flexible part. The hinge comprises a fixed support, a rotating mechanism and a supporting piece, wherein a moving mechanism is movably connected to the fixed support. When the flexible part is in a flat state, the first supporting plate is far away from the fixing support and supports the flexible part, so that the segment difference between the flexible part and other parts of the flexible display panel body is reduced, the flatness of the flexible display panel is improved, creases of the flexible part are reduced, and when the flexible part is in a bent state, the first supporting plate is far away from the flexible part, in this way, the space for containing the flexible display panel is reserved, and the flexible display panel is prevented from being extruded in the bending process.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

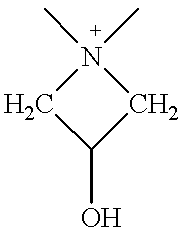

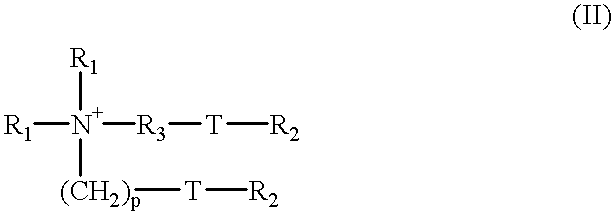

Fabric care composition

InactiveUS6255271B1Reduce creasesGood dimensional stabilityOrganic detergent compounding agentsSoap detergents with inorganic compounding agentsEpichlorohydrinSilicone

A fabric care composition comprises an amine or amide-epichlorohydrin resin or derivative thereof, a silicone component and, optionally, a textile compatible carrier. The textile compatible carrier facilitates contact between the resin and a fabric. The composition is adapted for use in the rinse cycle of a laundering process and may be used, as part of such a process, in the treatment of fabric to reduce creasing of the fabric.

Owner:HENKEL IP & HOLDING GMBH

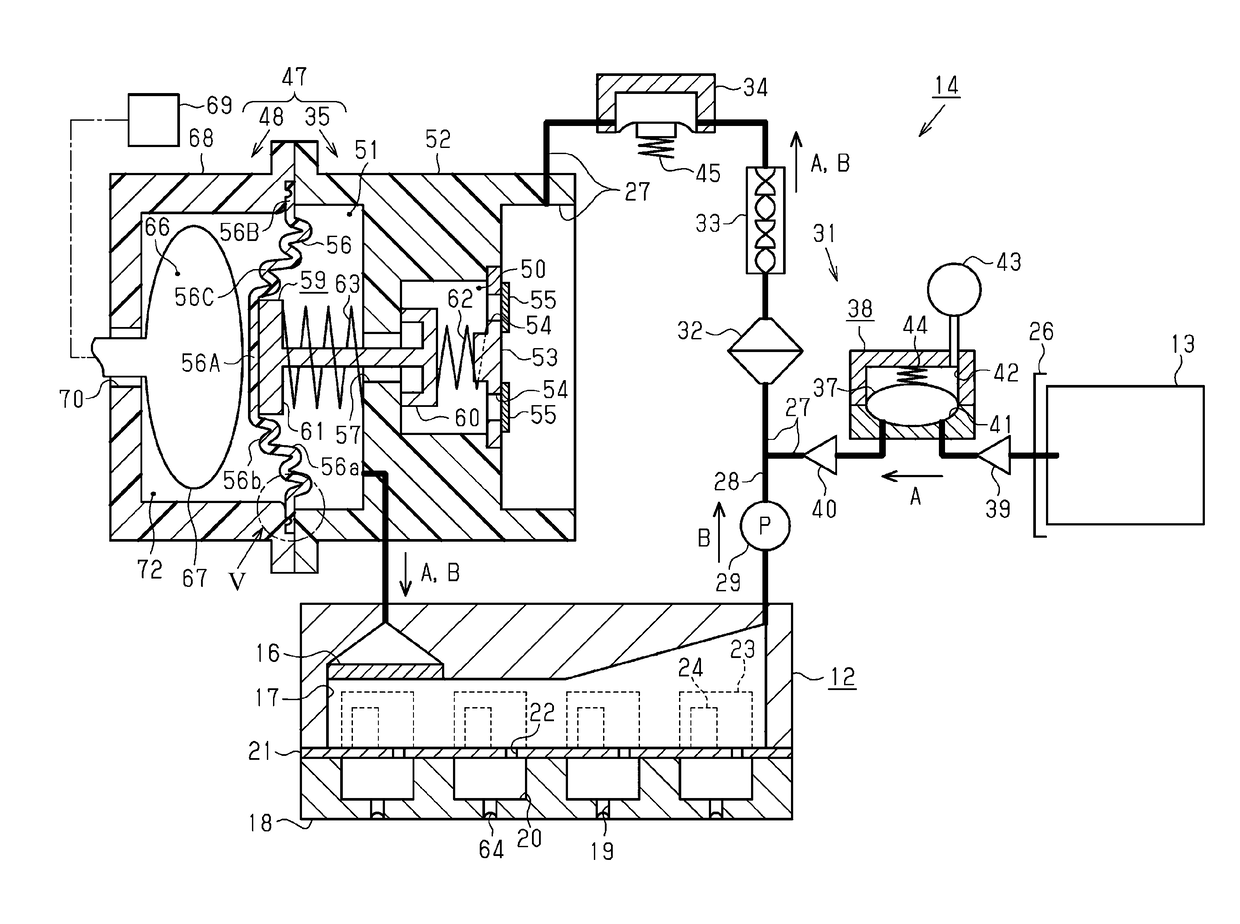

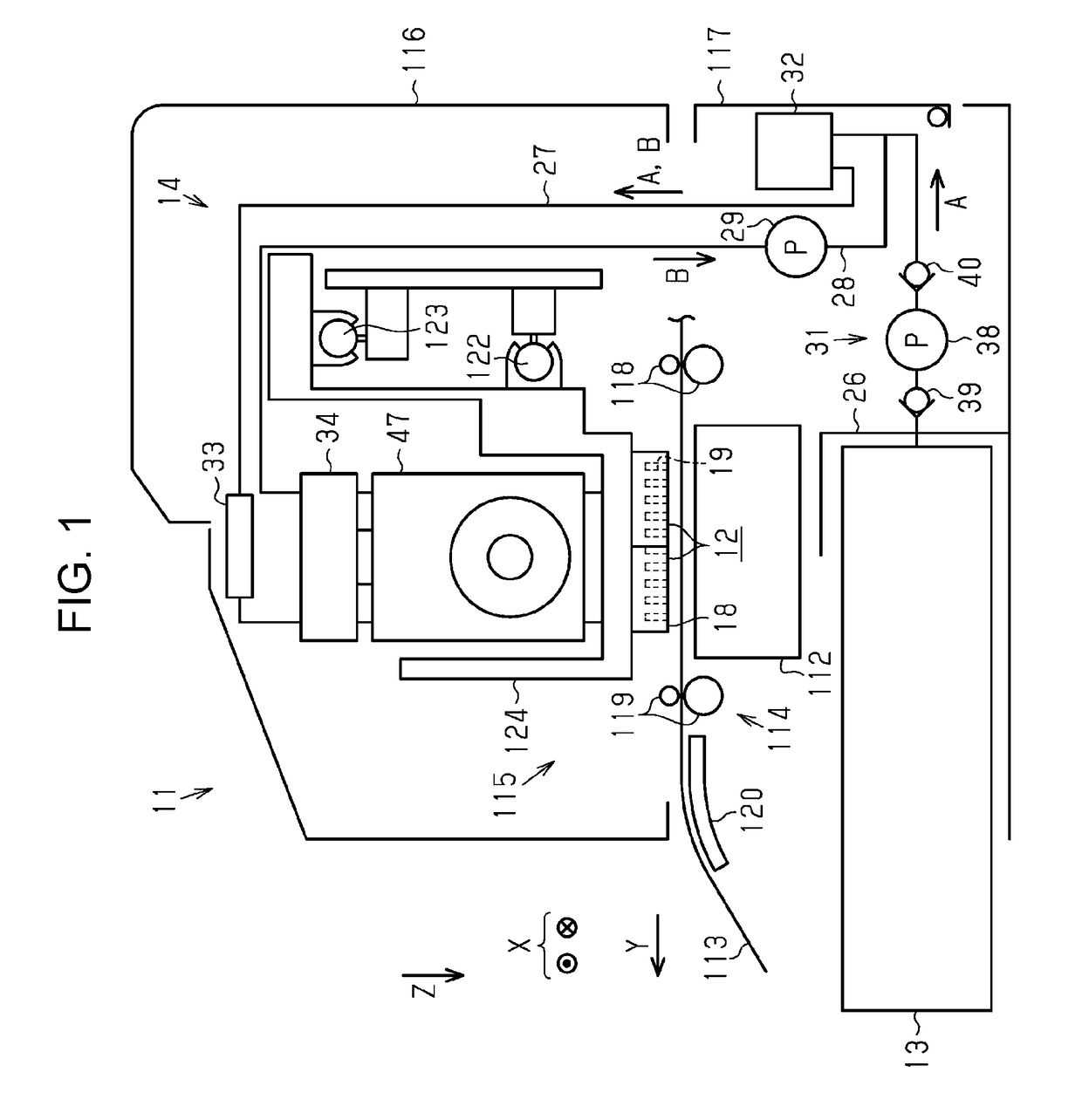

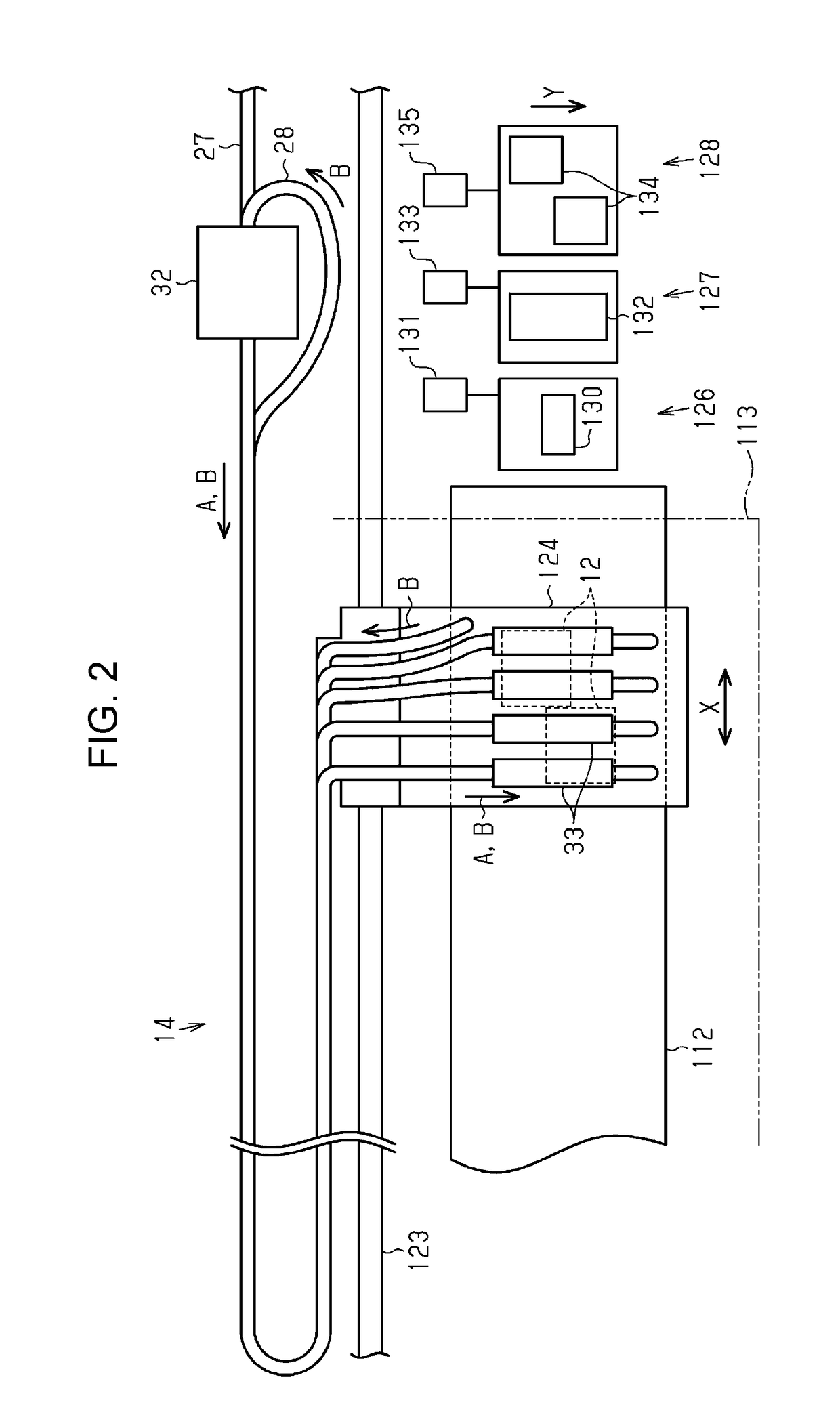

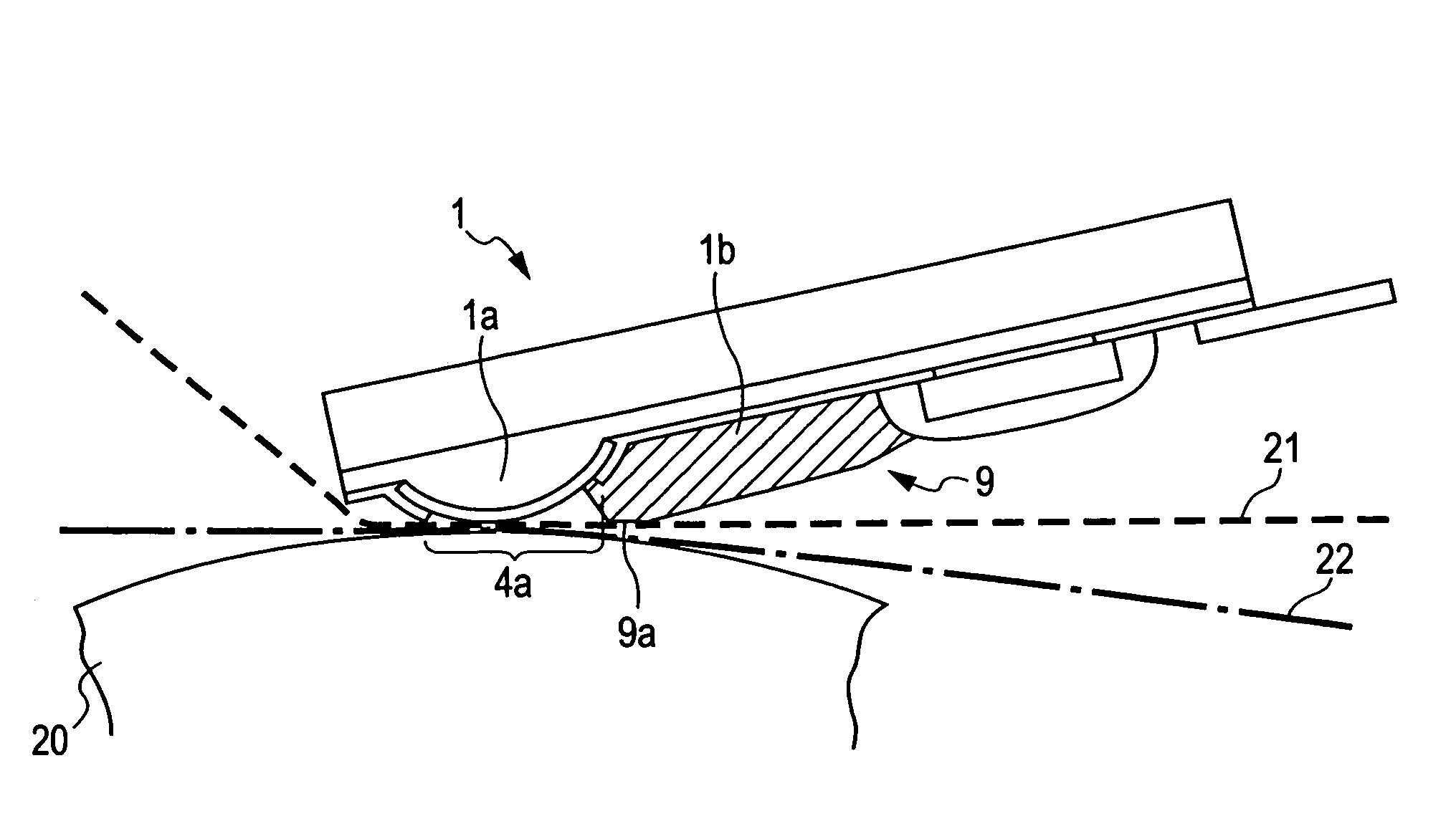

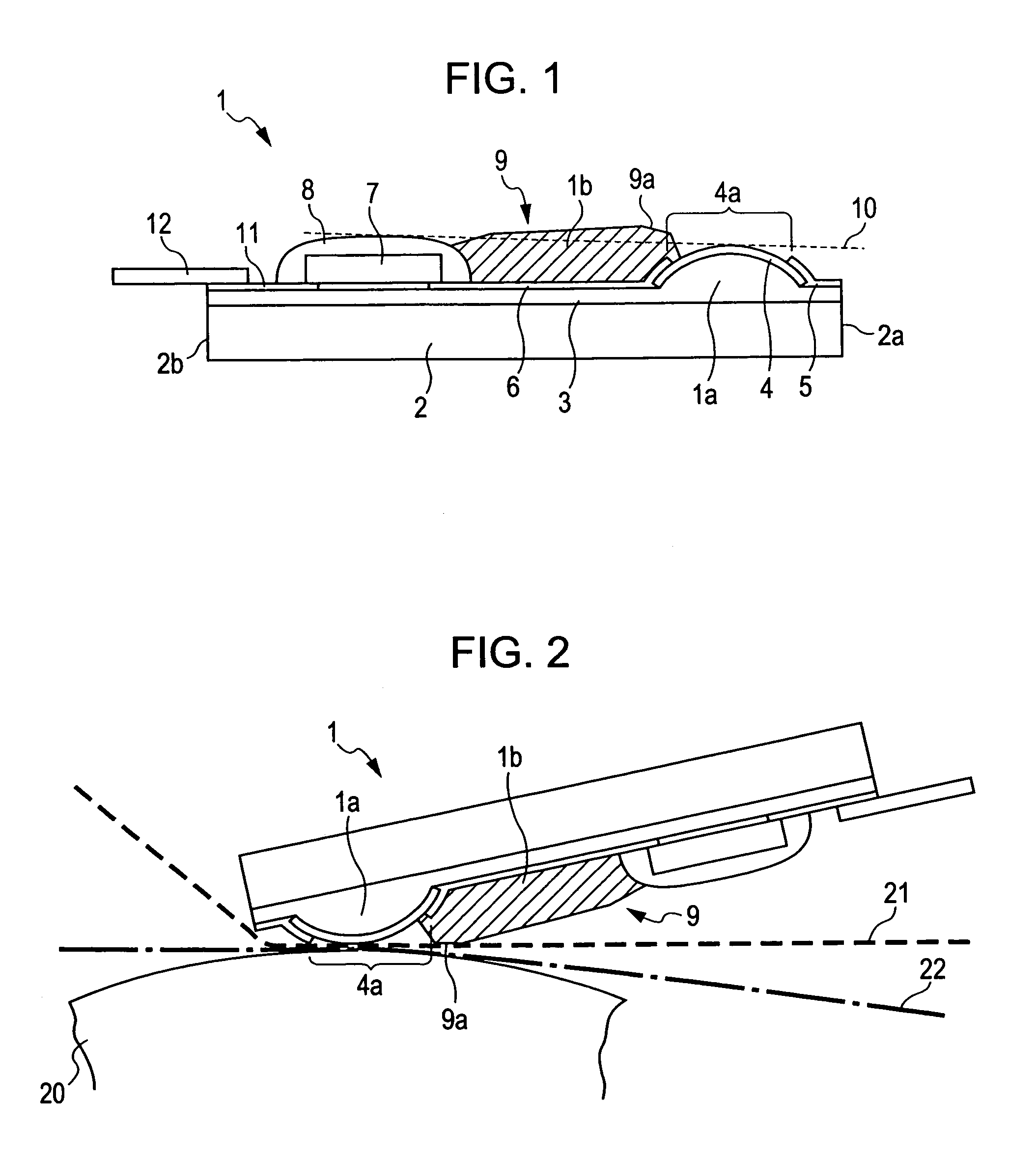

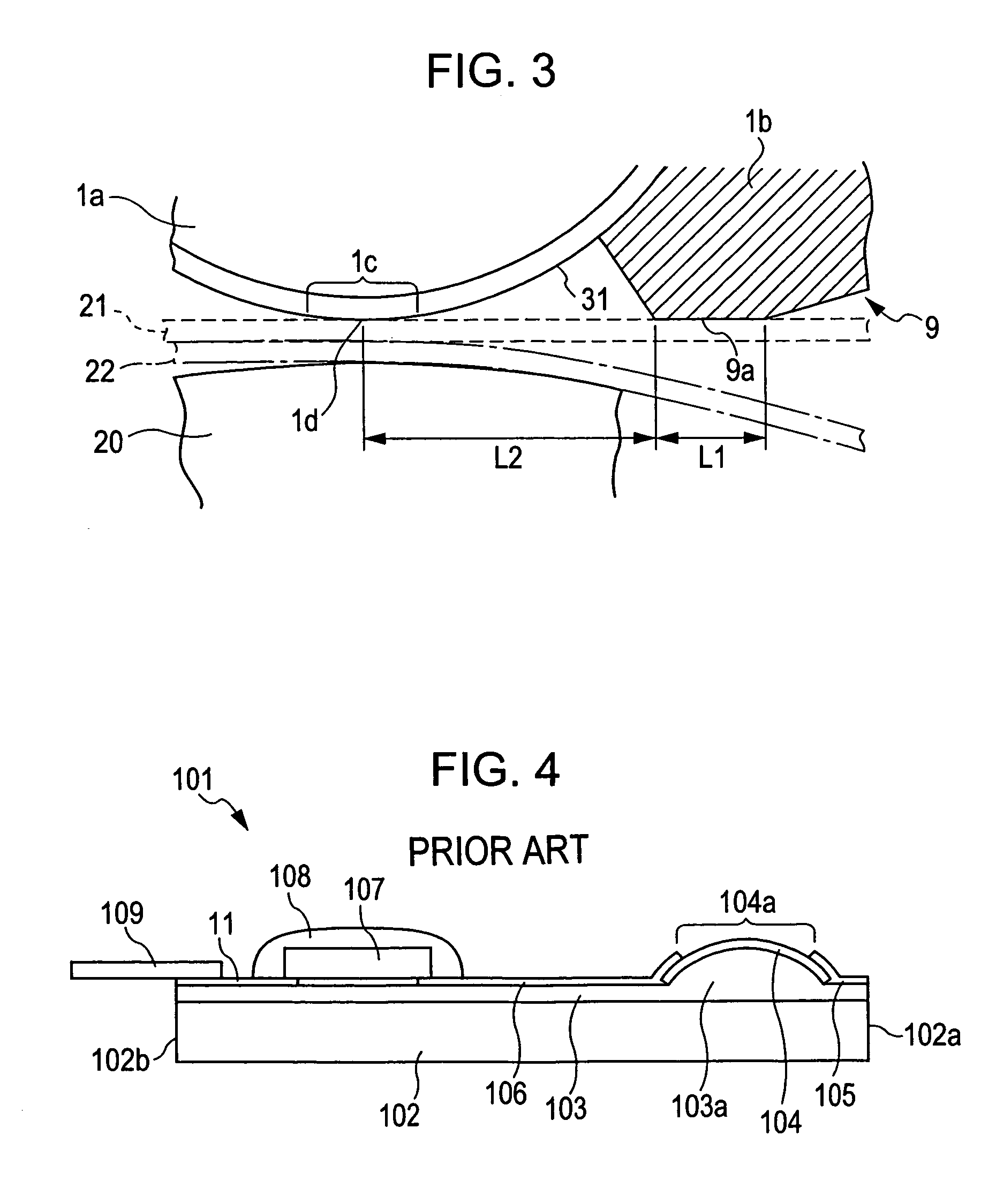

Liquid ejecting apparatus and pressure-regulating device

A liquid ejecting apparatus includes a pressure-regulating mechanism which is provided in a liquid supply path in which it is possible to supply liquid to a liquid ejecting unit, and includes a liquid accommodation part which can accommodate the liquid internally, and in which a volume of the liquid accommodation part is changed depending on displacing of a diaphragm section, in which the diaphragm section includes an annular corrugated portion formed in a sectional waveform shape which is deformed when the diaphragm section receives pressure.

Owner:SEIKO EPSON CORP

Fabric Ironing Apparatus

InactiveUS20140007470A1Stay in shapeReduce creasesApparel holdersTents/canopiesEngineeringMechanical engineering

Owner:MOHAMAD WAIEL

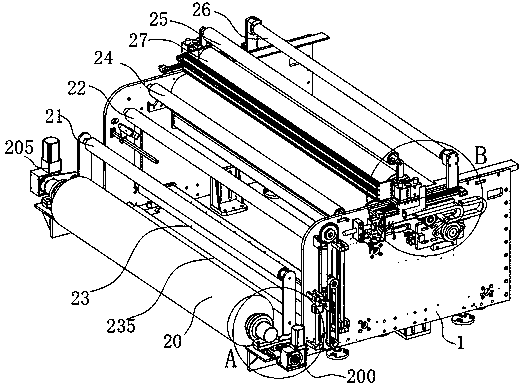

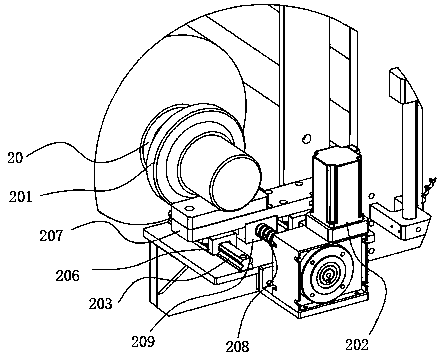

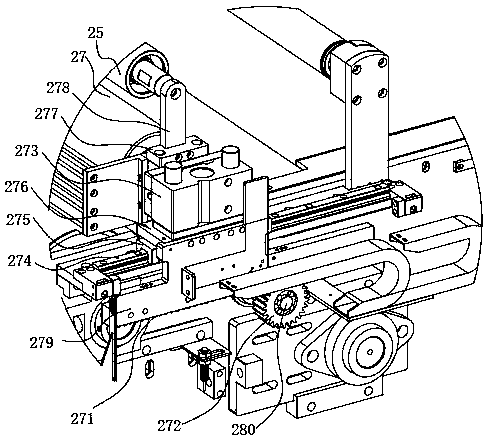

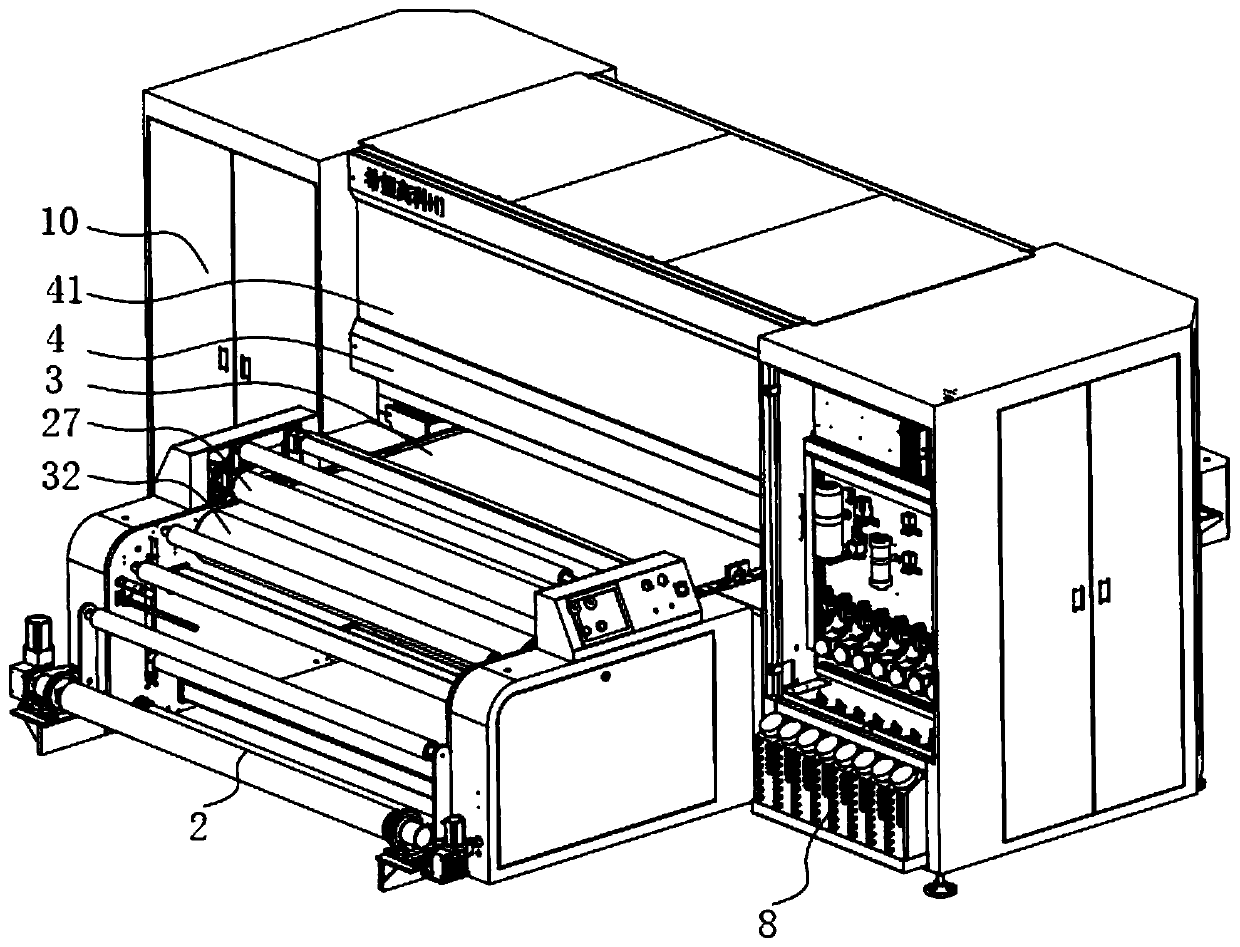

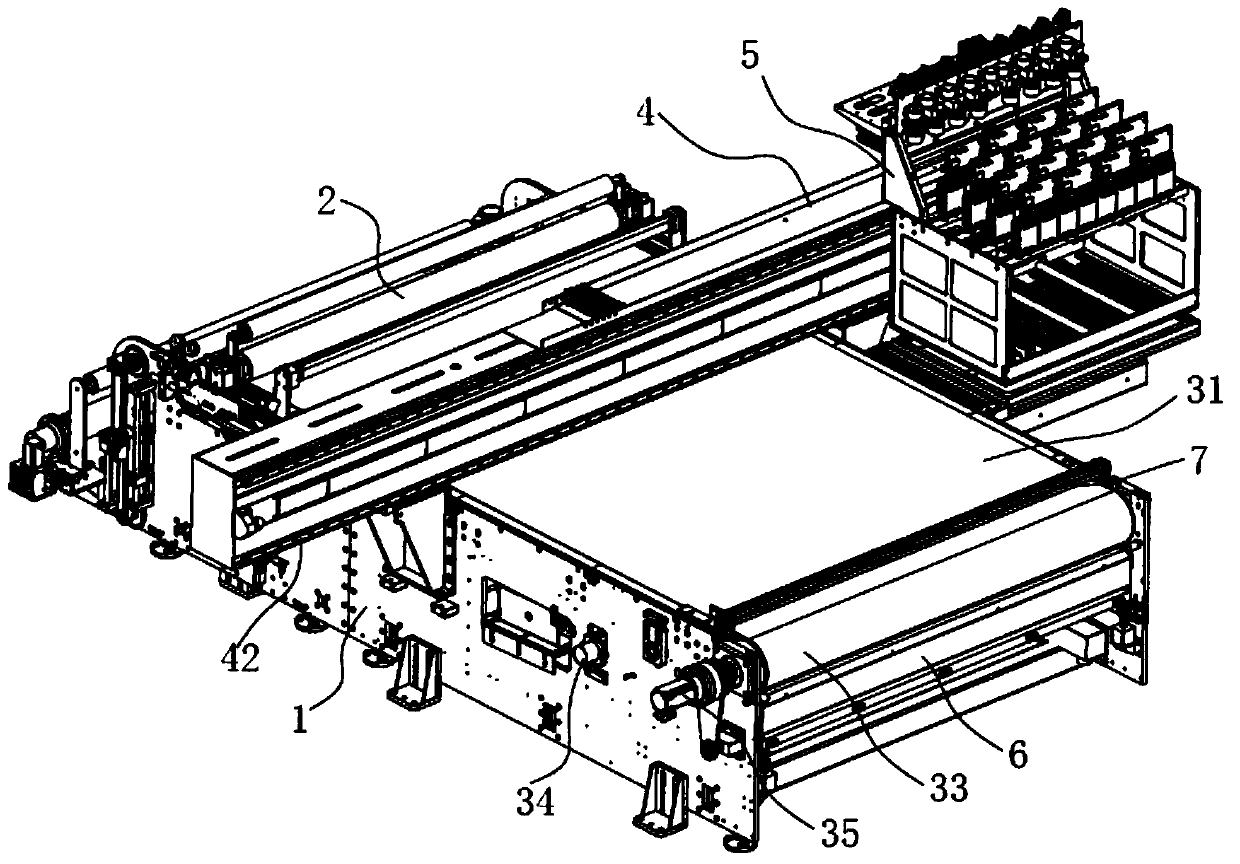

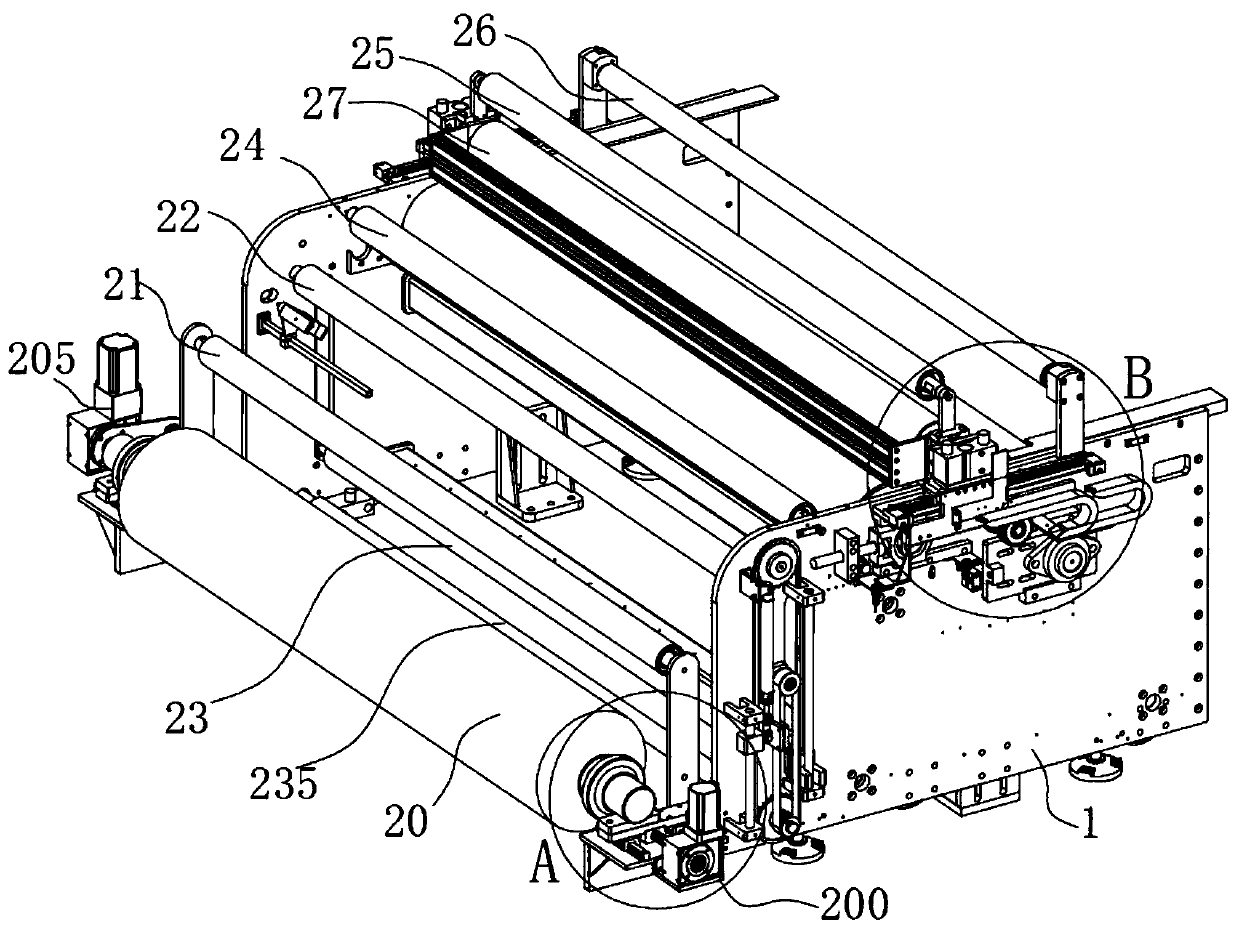

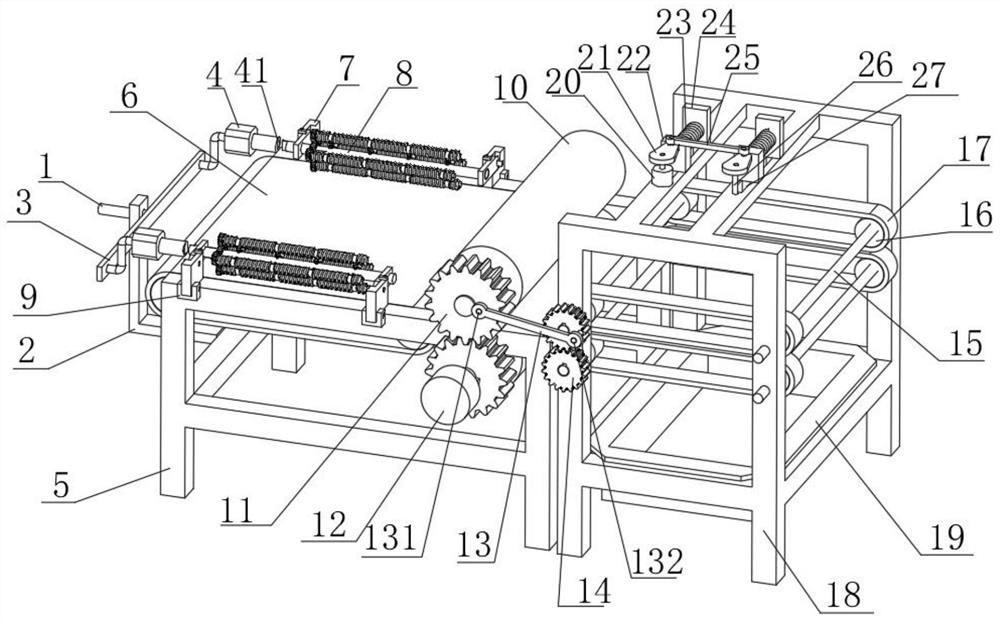

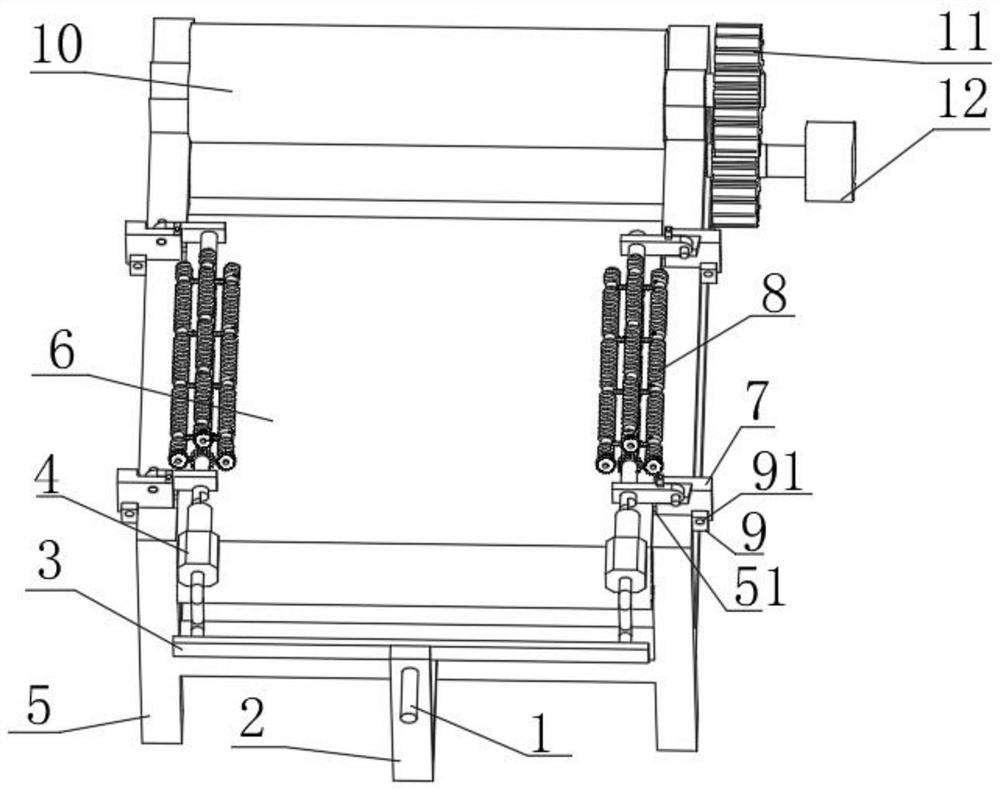

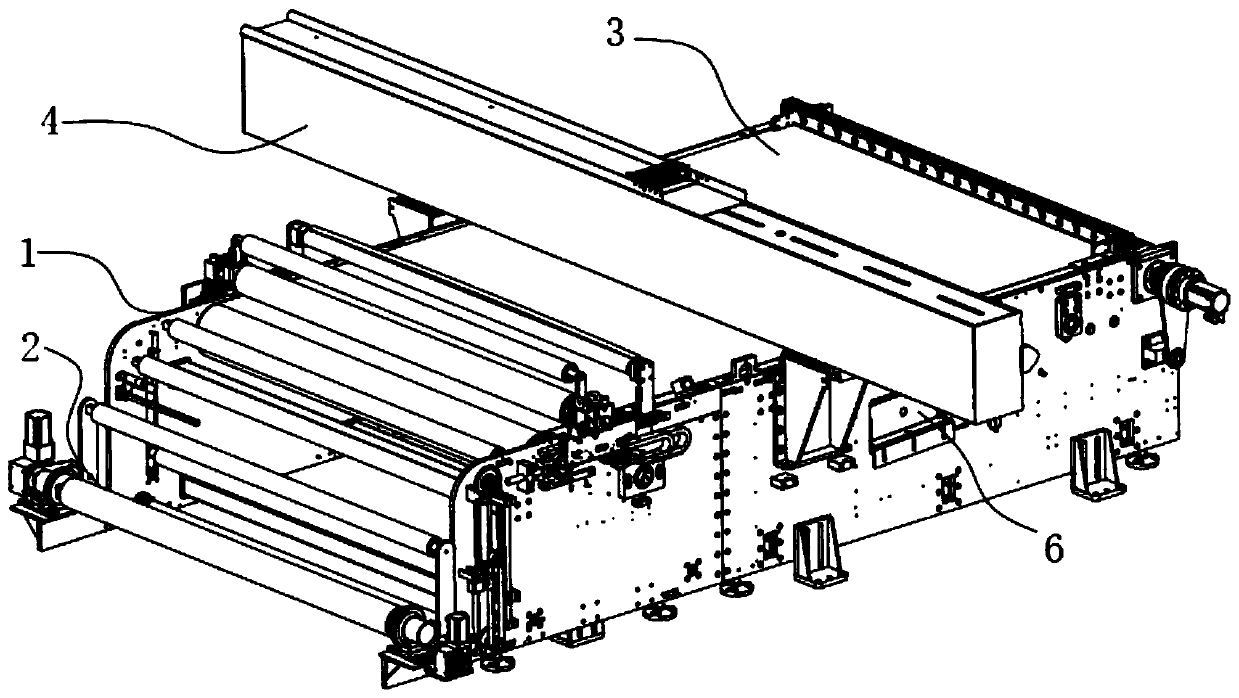

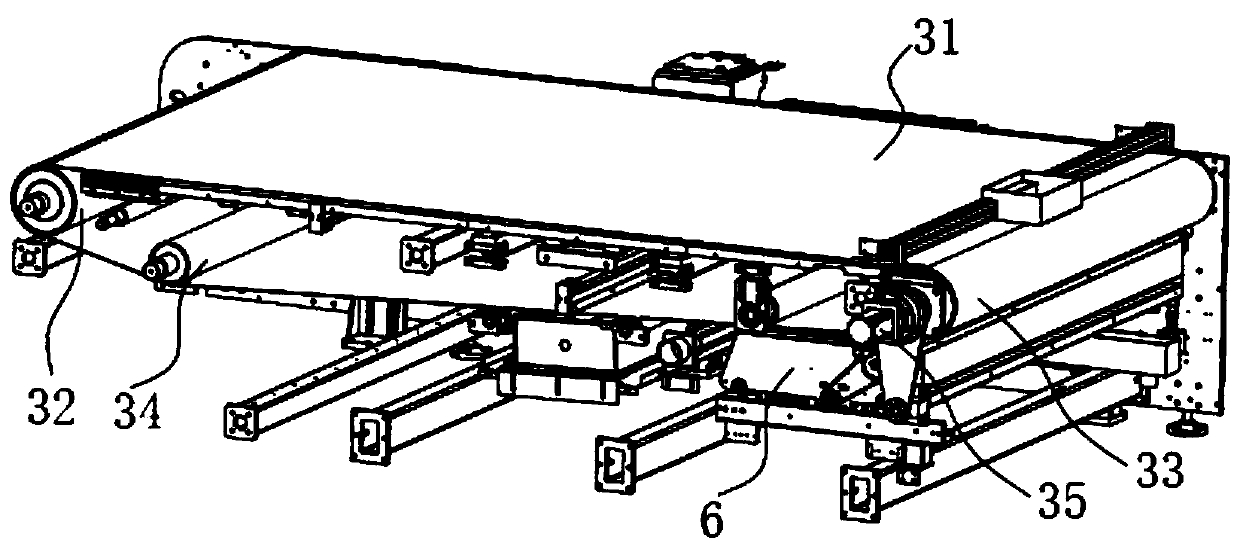

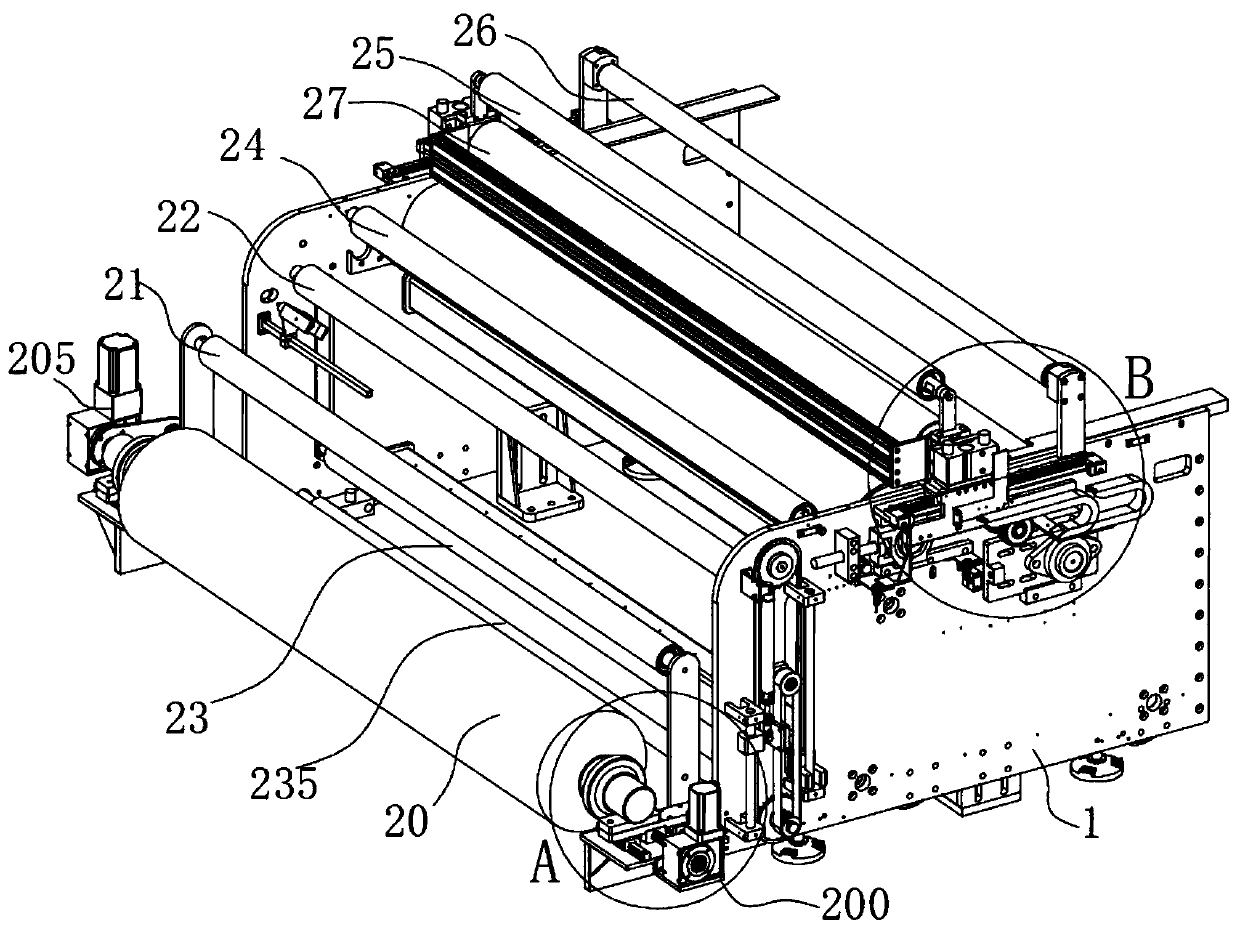

Cloth feeding mechanism of digital printing machine

The invention discloses a cloth feeding mechanism of a digital printing machine. The cloth feeding mechanism of the digital printing machine comprises a machine frame, an air expansion shaft, a largeroll corner wrapping roller, a cloth passing roller a, a constant-tension floating roller, a cloth passing roller b, a cloth passing roller c, a moving roller and a width increase corner wrapping roller. The air expansion shaft, the large roll corner wrapping roller, the cloth passing roller a, the constant-tension floating roller, the cloth passing roller b, the cloth passing roller c, the movingroller and the width increase corner wrapping roller are arranged on the machine frame. An unwinding driving device is arranged at one end of the air expansion shaft. Lifting guide mechanisms and a floating lifting driving device are arranged on the machine frame and drive the constant-tension floating roller to move. A horizontal movement driving device for front-and-rear sliding mechanisms which allow the moving roller to horizontally move is arranged on the machine frame. An unwinding deviation correcting system which conducts position correction on a piece of cloth is arranged on the machine frame. The cloth feeding mechanism of the digital printing machine has the advantages that the cloth feeding mechanism is matched with large rolls of cloth and small rolls of cloth, a cloth framedoes not need to be independently arranged, and the cost is saved; the cloth feeding mechanism has the function that the deviation correction and the edge alignment are automatically conducted on thecloth in real time; the cloth can be closely attached to a conveying belt, few press marks exist, no fold exists, a spray nozzle is protected, and the printing quality is improved; a single air cylinder is adopted so that the control over the value of the constant tension of the constant-tension floating roller can be achieved; and the jam phenomenon is avoided.

Owner:广东希望高科数字技术有限公司

Fabric care composition

InactiveUS20010034316A1Reduce deliveryReduce creasesCationic surface-active compoundsOrganic detergent compounding agentsCelluloseCross-link

Fabric care compositions for application to a fabric comprise a fabric softening and / or conditioning compound and a polymer, which is capable of self cross-linking and / or reacting with cellulose. The polymer is present in the composition in an amount of from 0.002% to 0.45%, preferably from 0.005% to 0.010% by weight based on the weight of the fabric. The polymers and the compositions may be used to enhance the delivery of perfume to a fabric from a fabric care composition, which comprises a perfume, and / or to enhance the softening of fabric by a fabric care composition, which comprises a fabric softening and / or conditioning compound.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Low-foam and anti-ageing wet type polyurethane resin for synthetic leather and preparation method thereof

The invention relates to a flow-foam and anti-ageing wet type polyurethane resin for synthetic leather and a preparation method thereof. The polyurethane resin comprises the following components in percentage by weight: 7 to 15% of diphenylmethane-4, 4'-diisocyanate, 8 to 15% of polyadipate type polyester polyol, 2 to 7% of diethylene glycol phthalic anhydride polymer, 0.5 to 3% of castor oil, 1 to 4% of chain extender, 60 to 80% of N, N-dimethylformamide, and 1 to 4% of assistant. The polyurethane resin is less and small in foam structure (low foam), high in elasticity, small in crease after being creased, and high in restorability.

Owner:SHANGHAI HUIDE TECH CO LTD

Scanning type textile digital printing equipment

ActiveCN111114130AReduce creasesAvoid wrinklesOther printing apparatusTextile printerProcess engineering

The invention discloses scanning type textile digital printing equipment. The scanning type textile digital printing equipment comprises a cloth feeding mechanism, a printing conveying belt mechanism,a gantry sliding frame, a printing scanning vehicle, a belt glue distributing and removing device, a belt cleaning device, a printing control cabinet and an ink supply system; the printing conveyingbelt mechanism is arranged at the top of the rack, the gantry sliding frame stretches across the printing conveying belt mechanism, the printing scanning vehicle is arranged on the gantry sliding frame in a sliding mode, the belt glue distributing and removing device stretches across the front portion of the printing conveying belt mechanism, and the cloth feeding mechanism is arranged behind theprinting conveying belt mechanism, and the belt cleaning device is arranged below the printing conveying belt mechanism. The printing equipment has the advantages that the cloth feeding mechanism adapts to large and small rolls of cloth; automatic online real-time deviation correction and edge alignment of the cloth are achieved; the printing quality is high; the glue distributing function and theglue removing function are integrated; the belt cleaning device adopts the combination of a composite cleaning mode and composite drying, so that the cleaning effect is improved; water consumption islow, and energy conservation and environmental protection are achieved; and the ink supply system is fast to start and high in production efficiency.

Owner:广东希望高科数字技术有限公司

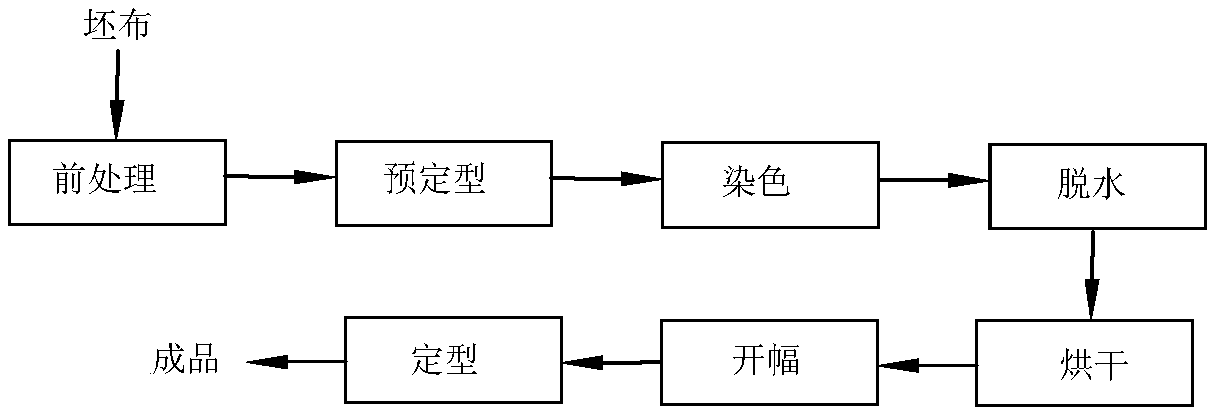

Polyester two-way-stretch fabric dyeing process

InactiveCN109403010AUniform dyeingDyeing firmDry-cleaning apparatus for textilesDyeing processDisperse dyeSewage

The invention discloses a polyester two-way-stretch fabric dyeing process including the steps of pretreatment, preshaping, dyeing, dehydration, drying, scotching and shaping to obtain a dyed polyestertwo-way-stretch fabric. In the method, under a low bath ratio condition, a dispersed dye is used for dyeing the fabric in two stages in a heat insulation manner, then the temperature is slowly decreased, sewage is discharged and the fabric is cleaned in clear water. The process is used for dyeing the polyester two-way-stretch fabric, is high in dyeing rate and good in color fastness, can reduce folds, shorten operation time and save energy, and can reduce cost.

Owner:SHAOXING COUNTY KWONG FUNG PRINTING & DYEING

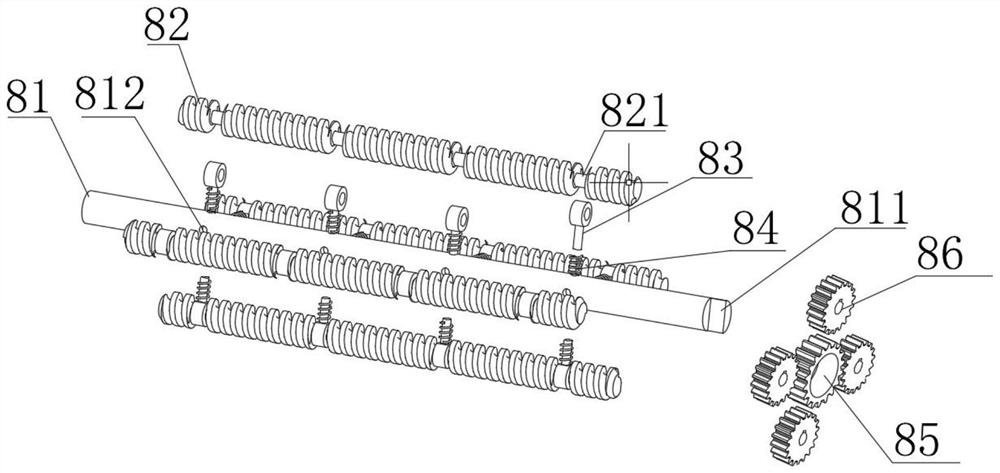

Processing technology and processing device for high-elasticity uvioresistant polyester fabric

ActiveCN112144198AReduce creasesTextile treatment by spraying/projectingTextile treatment carriersPolyesterPolymer science

The invention discloses a processing technology and processing device for high-elasticity uvioresistant polyester fabric, and particularly relates to the field of polyester fabric production. The processing technology for the high-elasticity uvioresistant polyester fabric comprises the steps of feeding and spraying. The processing device for the high-elasticity uvioresistant polyester fabric comprises a conveyor belt, finishing mechanisms, hinge mechanisms, a guide rod, a first gear, a second gear and a first connecting rod. The finishing mechanisms are mounted on the two sides, parallel to the moving direction of the polyester fabric, of the conveyor belt to flatten the polyester fabric, and the hinge mechanisms are mounted at the two ends of the finishing mechanisms so that the finishingmechanisms can be turned over conveniently. The guide rod is mounted on first driving devices, and separation and clamping of the first driving devices and rotating shafts are achieved by operating the guide rod. The first connecting rod is mounted between the first gear and the second gear, so that a feeding mechanism and a spraying mechanism move to achieve synchronous conveying.

Owner:南通三瑞纺织科技有限公司

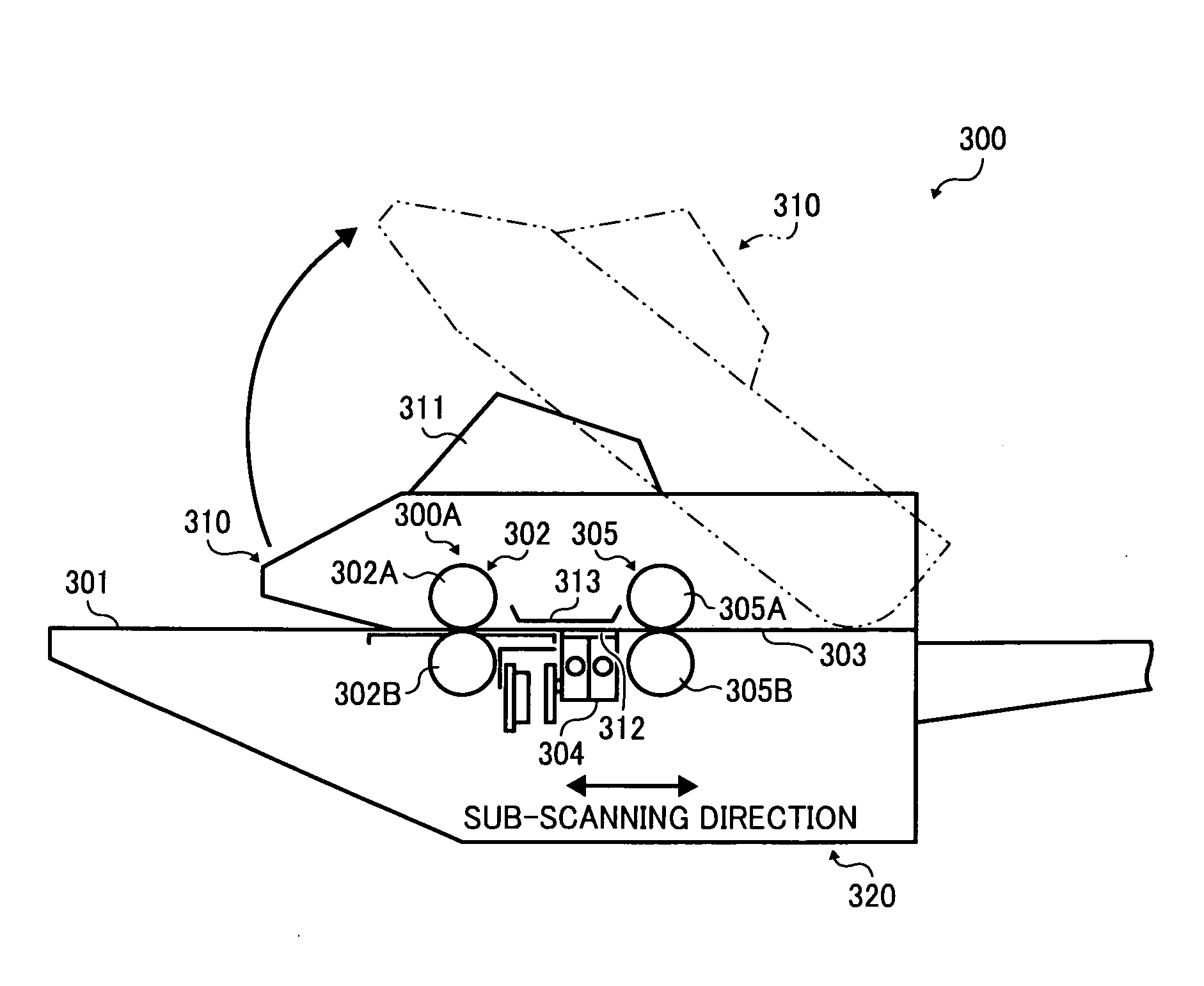

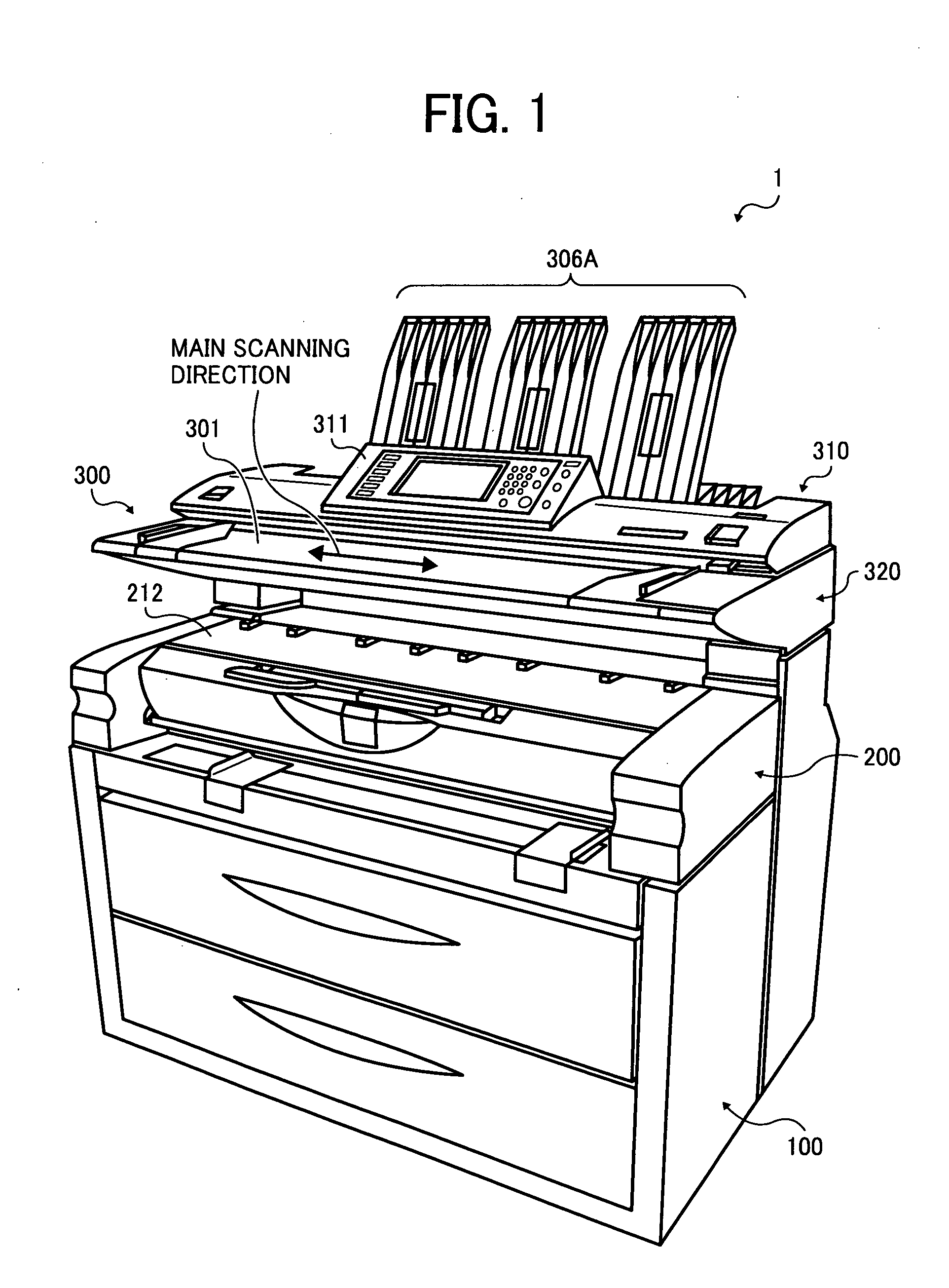

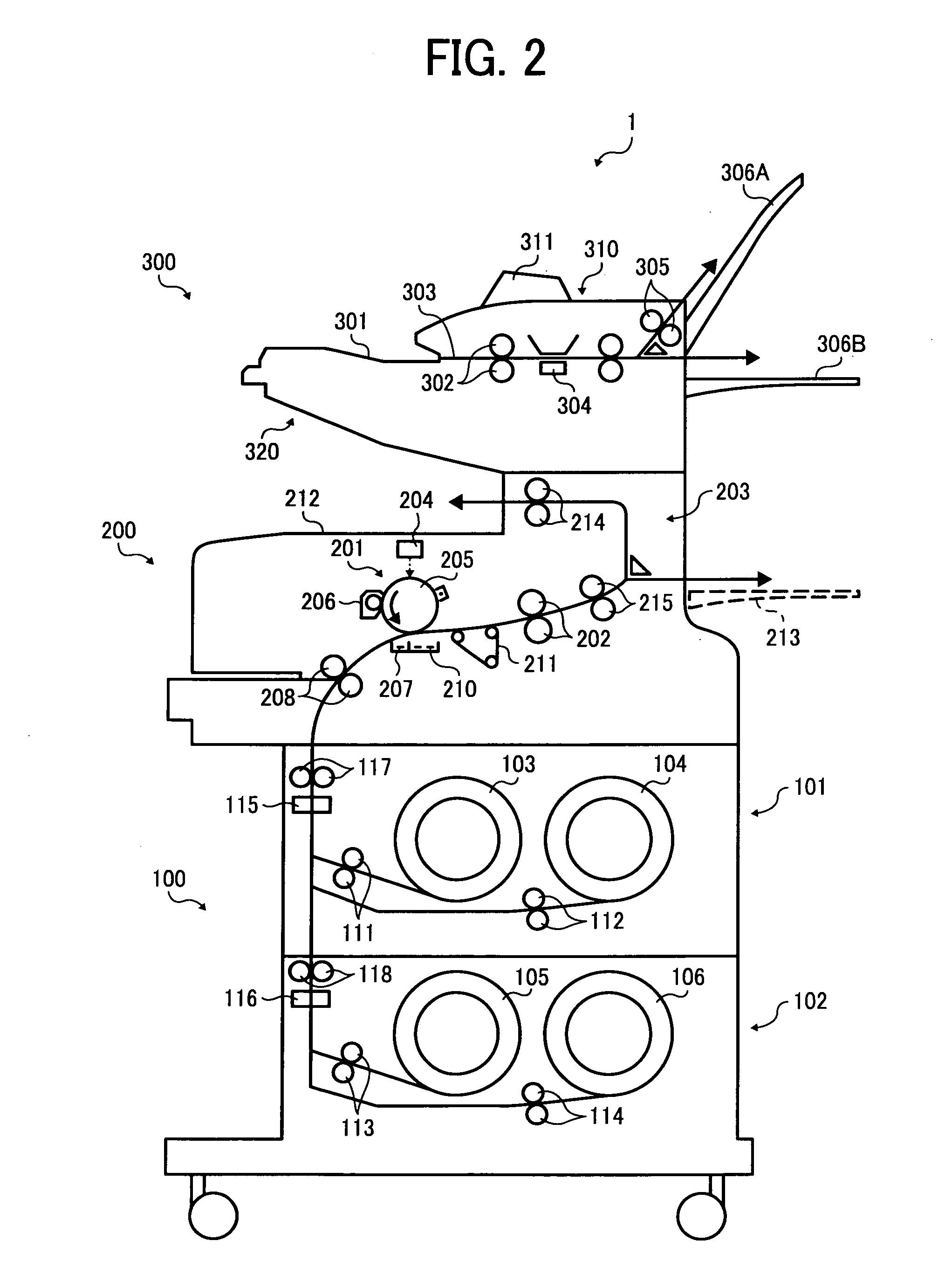

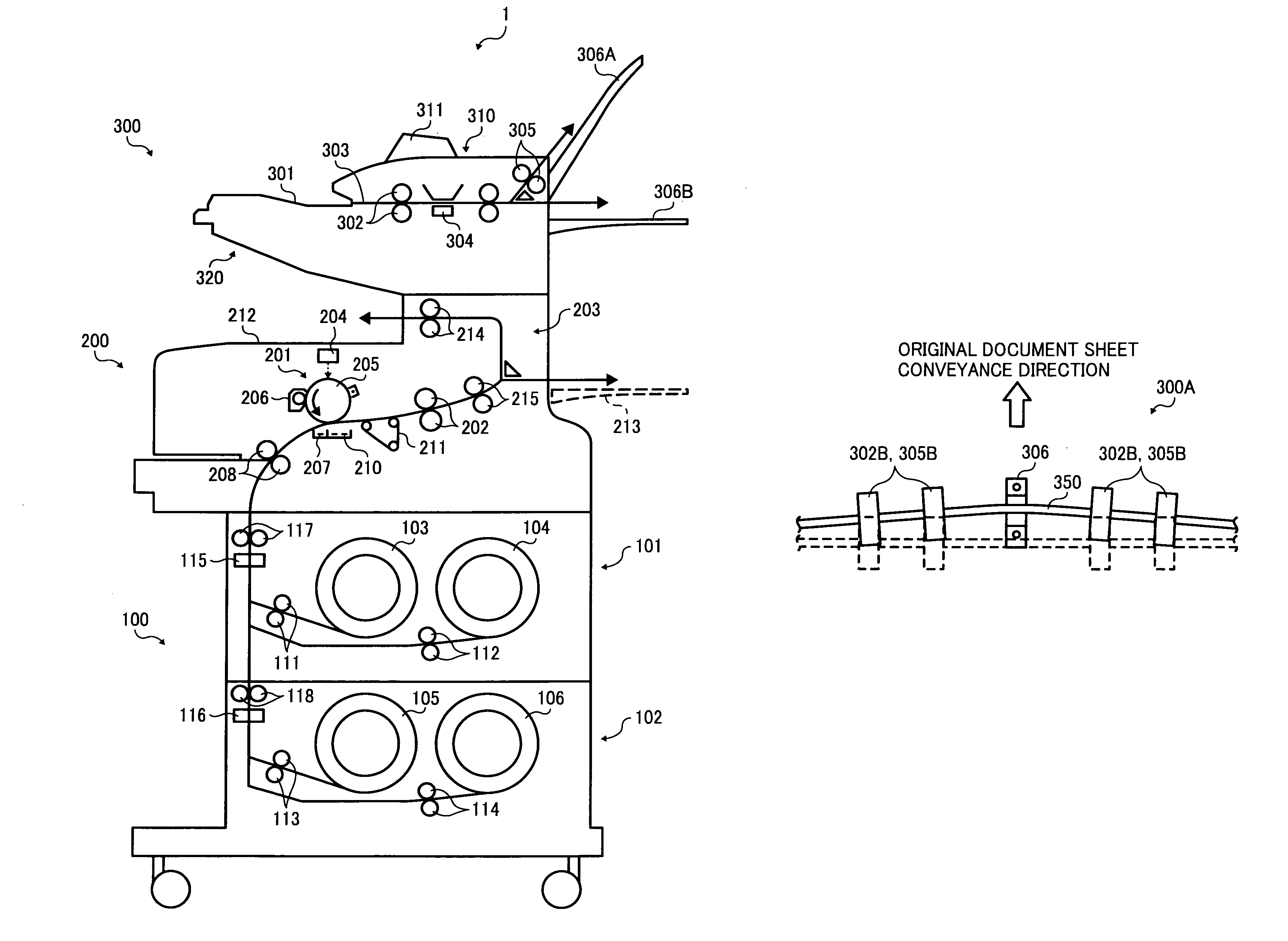

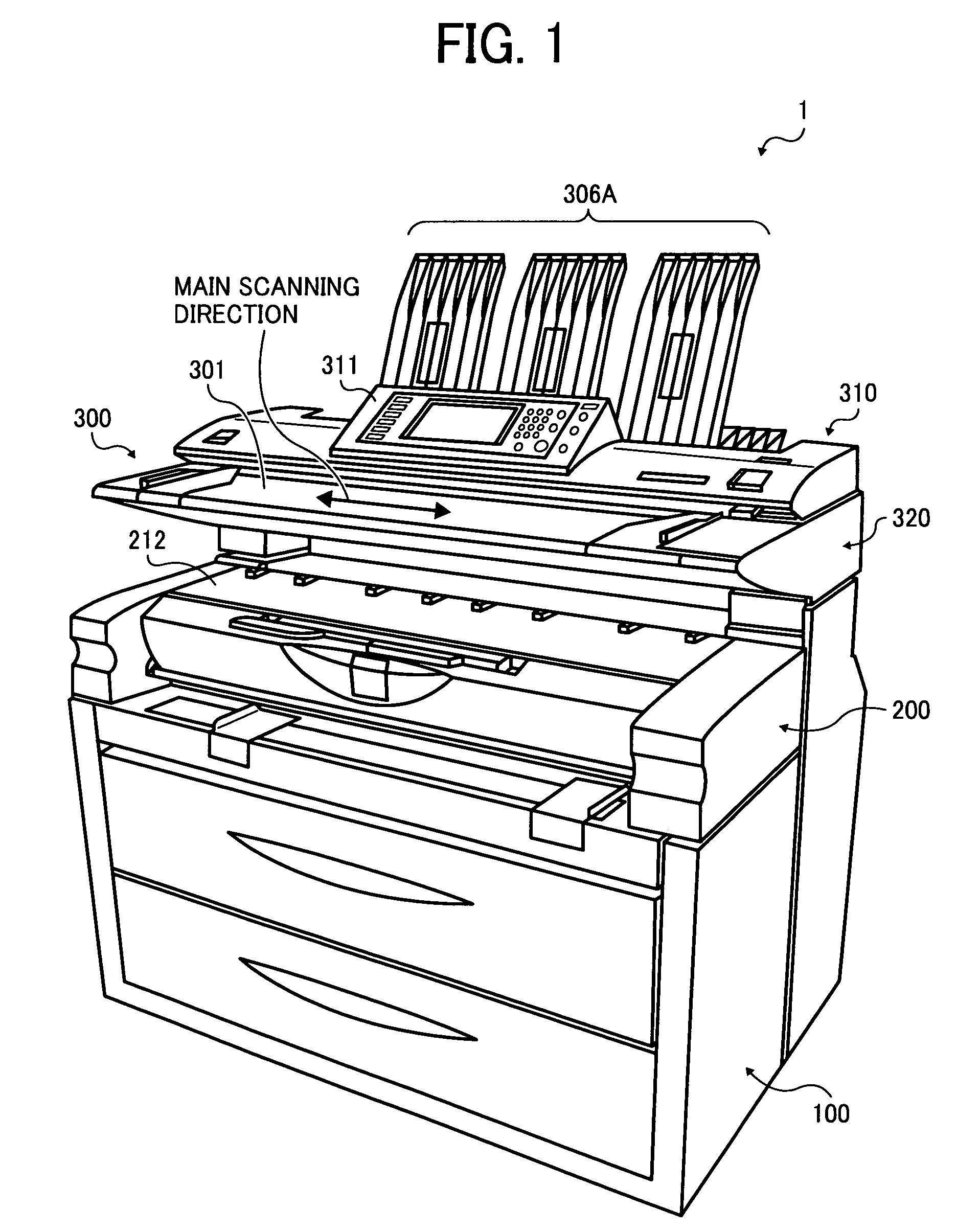

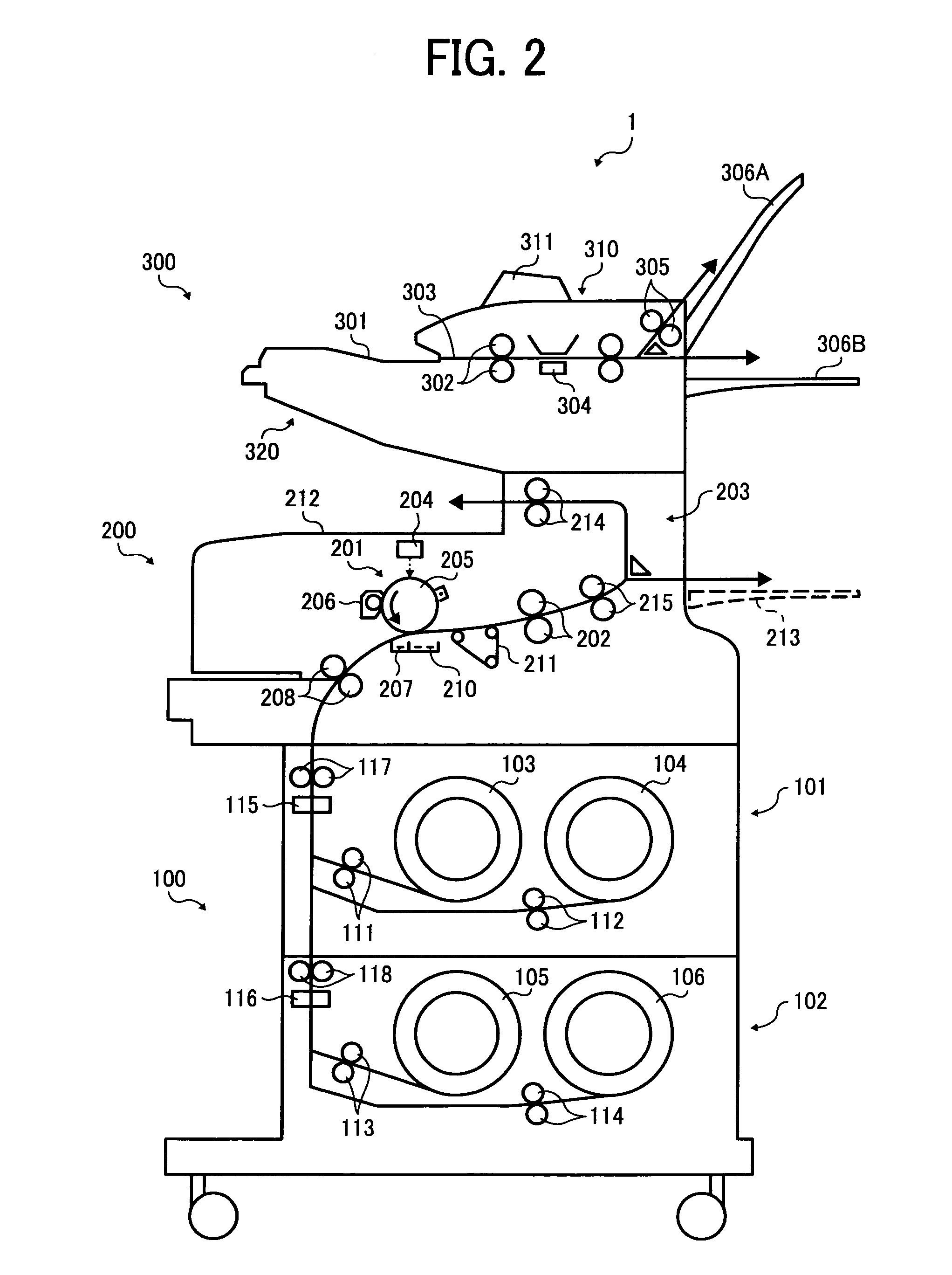

Sheet conveyance device, image reader, and image forming apparatus capable of feeding sheets effectively

ActiveUS20090212494A1Reduce creasesSmooth bootArticle feedersPictoral communicationDrive shaftEngineering

Owner:RICOH KK

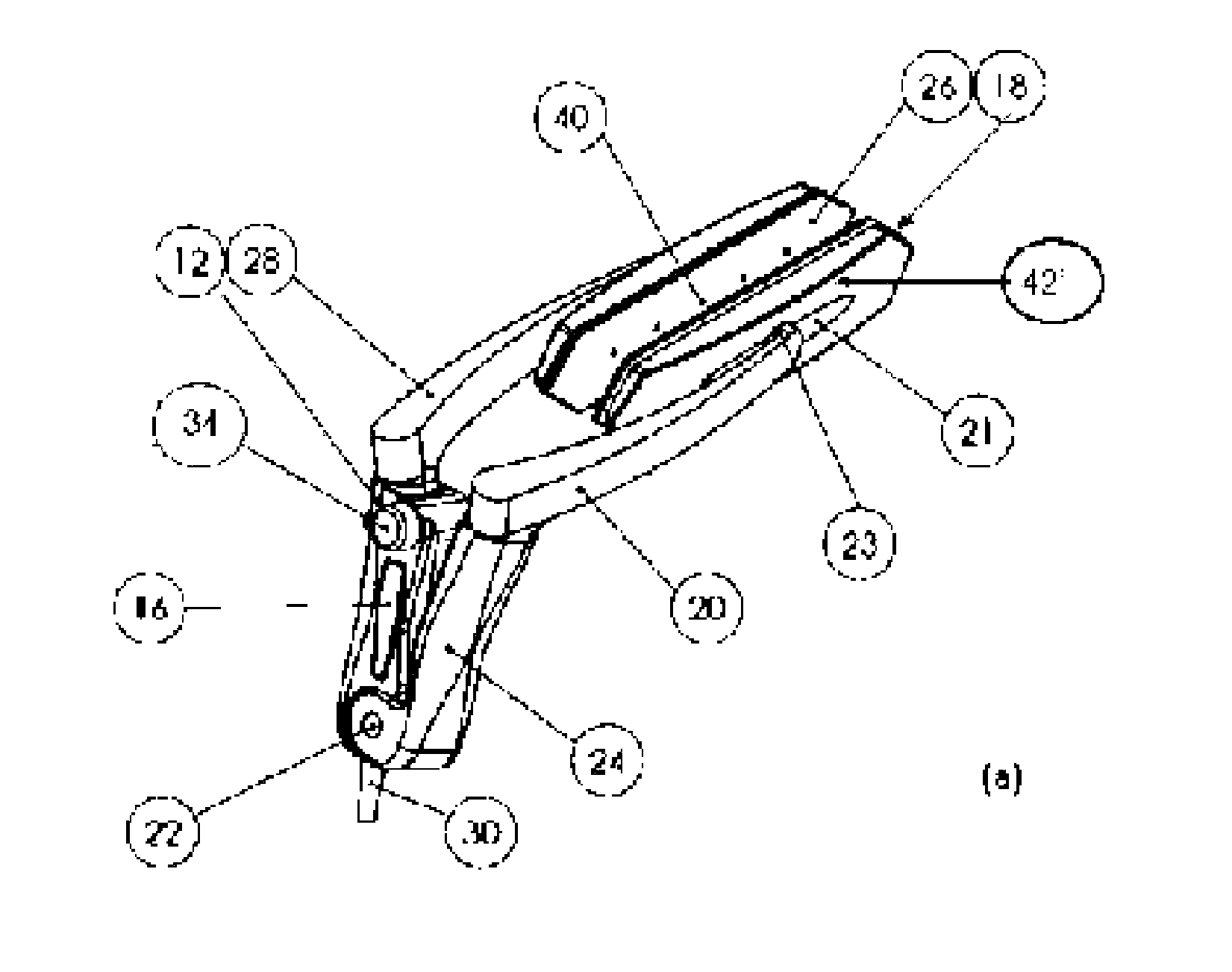

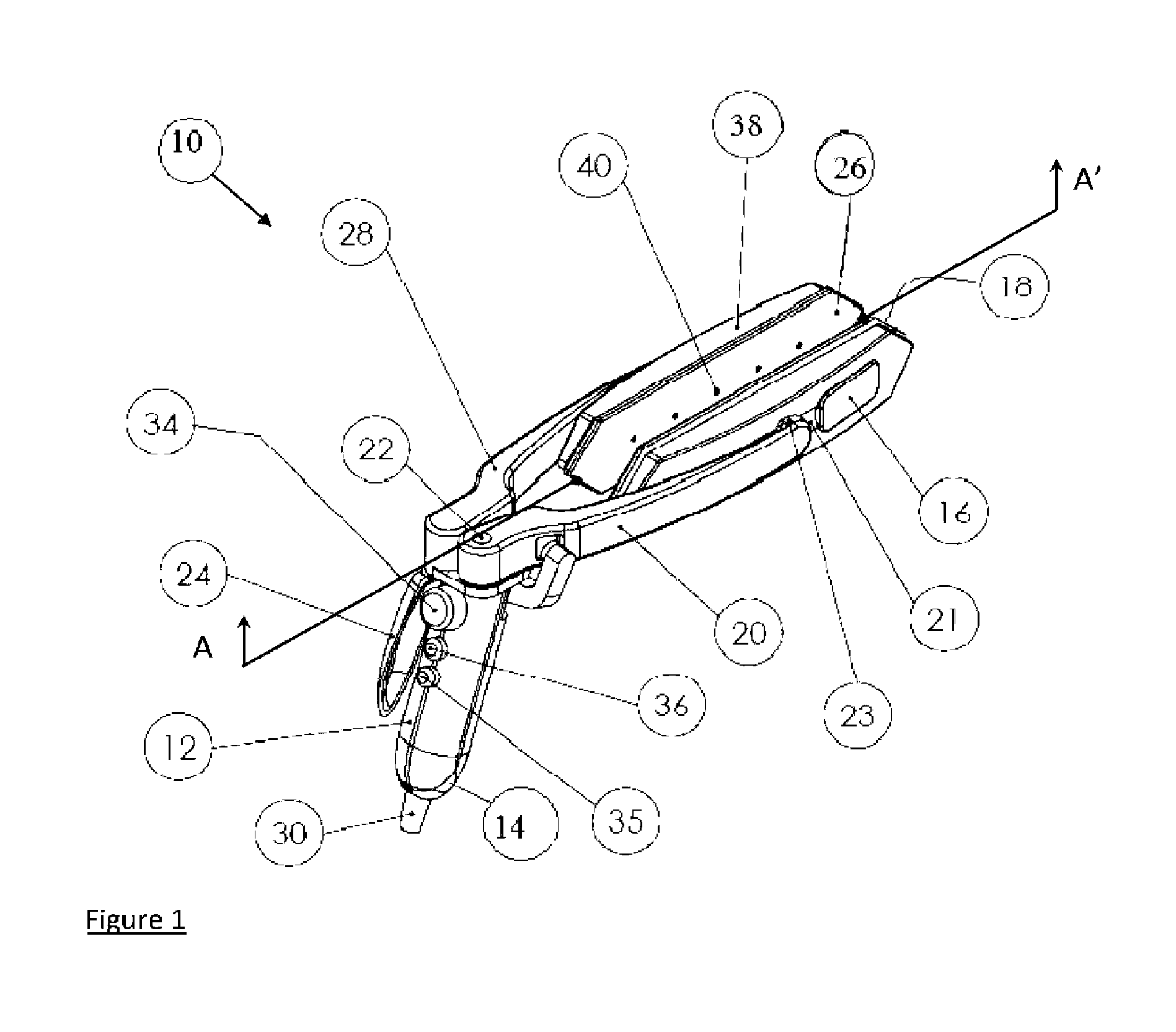

System for forming stacks of composite materials

InactiveUS9789673B2AdaptablePrevent movementLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to a system for shaping laminar composite materials, comprising a base (1) with at least one longitudinal mandrel element (2) comprising a shape to be given to a stack of composite material (3) arranged on the mandrel element (2) for obtaining a formed stack (3′) of composite material, and at least one pressure rolling forming device (4) assembled in a support carriage (5) such that it is capable of placing the pressure rolling forming device (4) in at least one position in which it rolls over the stack of composite material (3) pressing it against the mandrel element (2) for forming it and obtaining the formed stack (3′), the pressure rolling forming device (4) comprising a rolling hollow cover (4a) made of elastically flexible material with a tread (4b), and the rolling hollow cover (4a) being susceptible to containing: a fill fluid at a fill pressure and / or a plurality of particles (27) which allow the tread (4b) to elastically adapt to the shape of the mandrel element (2) and exert a chosen pressure on the stack of composite material (3).

Owner:APPLUS SERVICIOS TECHCOS

Sheet conveyance device, image reader, and image forming apparatus capable of feeding sheets effectively

ActiveUS7735828B2Reduce creasesSmooth bootArticle feedersPictoral communicationDrive shaftEngineering

Owner:RICOH KK

Photopolymer assembly

ActiveUS20100035002A1Improve accuracyConvenient lightingLayered productsNanoinformaticsPhotopolymerElectromagnetic radiation

The invention relates to an element, in particular a photopolymer unit, with a rear layer and a top layer which are joined to one another to form a sealed bag in which a precursor of a plastic which can be polymerised with electromagnetic radiation is contained, in particular a photopolymer. The top layer is made from a cast plastic. The invention further relates to the production of a printing plate from this element.

Owner:TRODAT GMBH

Thermal head

InactiveUS6972782B2Reduce creasesImprove printing qualityPrinting mechanismsRecording apparatusEngineeringHeat sensitive

In order to reduce creases of an ink film so as to offer excellent printing quality, a thermal head for use in a thermal-transfer printer includes a heat-insulating layer; a first projection serving as a part of the heat-insulating layer; a heating element formed on the first projection; common and individual electrodes connected to the heating element; a driver IC connected to these two electrodes; a sealing member sealing the driver IC; and a second projection protruding upstream, with respect to the transport route of the ink film, of the center of a section where the heating element comes into contact with a platen, so as to lie beyond a line connecting the apexes of the first projection and the sealing member.

Owner:ALPS ALPINE CO LTD

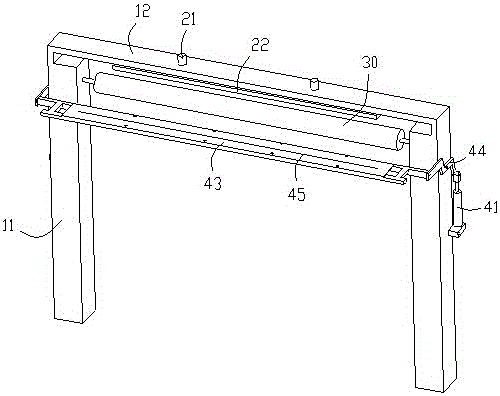

Rack system of digital printing machine

ActiveCN111055599AReduce creasesAvoid wrinklesOther printing apparatusStationary filtering element filtersTextile printerEngineering

The invention discloses a rack system of a digital printing machine. The system comprises a rack, a printing conveying belt mechanism is arranged at the top of the rack, a gantry sliding frame stretches across the upper portion of the printing conveying belt mechanism, a cloth feeding mechanism is arranged behind the printing conveying belt mechanism, and a belt cleaning device is arranged below the printing conveying belt mechanism; the cloth feeding mechanism comprises an inflatable shaft, a large roll wrap angle roller, a cloth passing roller a, a constant-tension floating roller, a cloth passing roller b, a cloth passing roller c, a moving roller and an expanding wrap angle roller which are all arranged on the rack; a lifting guide mechanism for driving the constant-tension floating roller to act is arranged; and an unwinding deviation correcting system for correcting the position of cloth is arranged. The system has the advantages that the cloth feeding mechanism simultaneously adapts to large and small rolls of cloth, so that the cost is saved; automatic online real-time deviation rectification and edge alignment of the cloth are realized; the printing quality is high; the belt cleaning device combines a composite cleaning mode and a composite drying mode, so that the cleaning effect is improved; the system is small in water consumption, energy-saving and environmentallyfriendly; and the production efficiency is improved.

Owner:广东希望高科数字技术有限公司

IMD mold, injection molding apparatus having such an IMD mold and method for producing a foil-decorated plastic part

Owner:HBW-GUBESCH塑胶工程有限公司

Coating paper for printing

A coated paper for print purpose and its making method are disclosed. Said coated paper features that a PVA-series resin composition composed of polyvinyl alcohol with 90 mole% of saponified degree and the polyacrylic acid (or its salt) and / or cellulose derivative (or its salt) in wt ratio of 100:(0.1-10) is coated on both surfaces of basic paper and the mixture of pigment and adhesive is coated on at least one surface of basic paper to obtain 500-1000 g / sq.m.24hr of moisture permeability. When it is in friction with offset print roller, the wrinkles and air bubble can not be generated.

Owner:OJI PAPER CO LTD

Film connecting device for polarizer cutting machine

The invention provides a film connecting device for a polarizer cutting machine. The film connecting device comprises a machine frame composed of two side supports and a crossbeam. A pressing device is arranged on the crossbeam. A machine board roller and a telescopic flat support are horizontally connected to the two side supports. The machine board roller is located under the pressing device. The telescopic flat support is located below the machine board roller. By the adoption of the film connecting device, the last coiled material and the next coiled material can be connected, the next coiled material can be made to penetrate through all rollers of a machine board in the automatic cutting process of the cutting machine board, the process that a workers pulls the coiled material to penetrate through the rollers is omitted, folding marks generated in the coiled material pulling process can be reduced, and meanwhile the time for replacing the coiled material is greatly shortened.

Owner:HANBO HIGH TECH MATERIALS HEFEI CO LTD

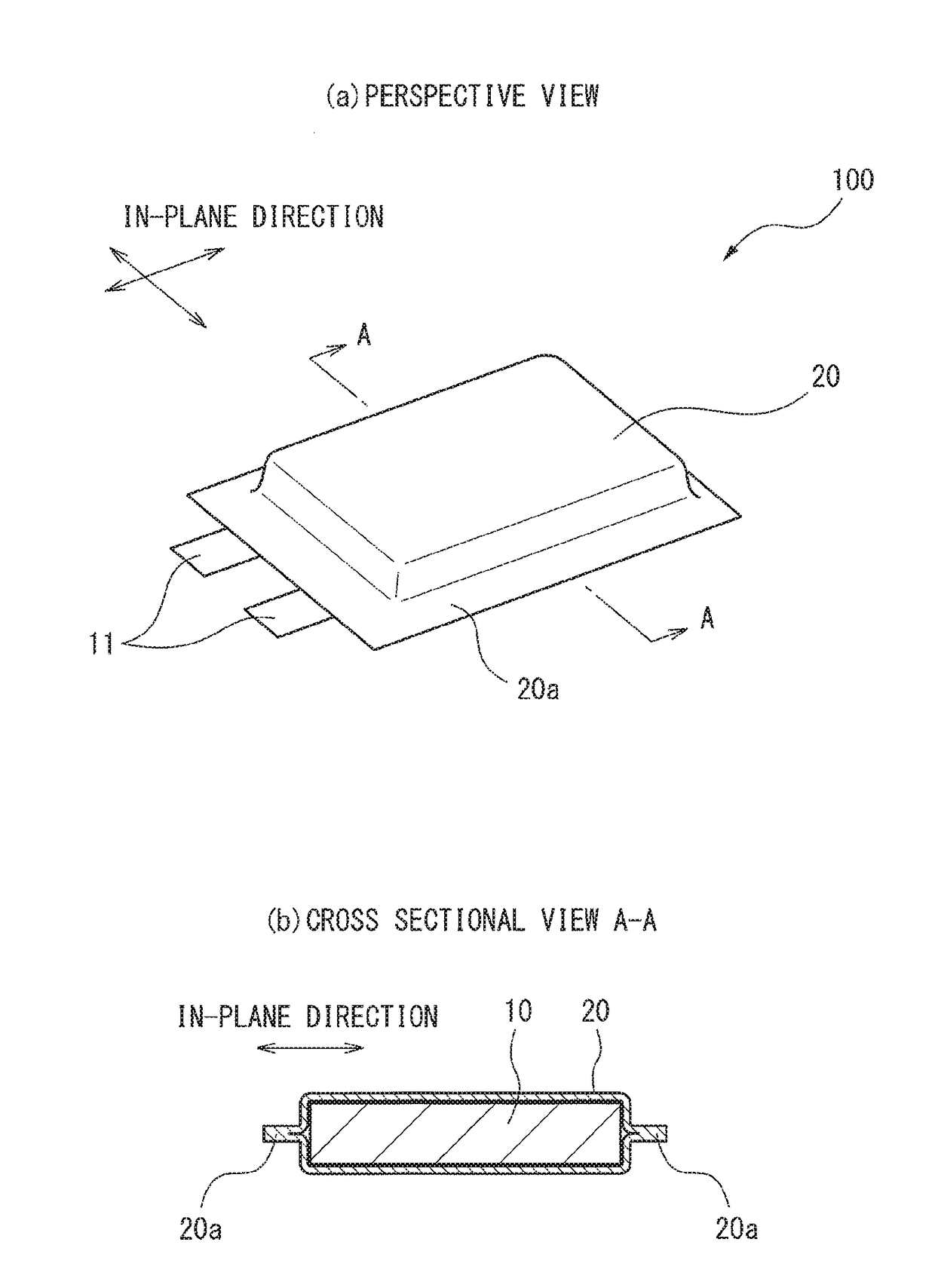

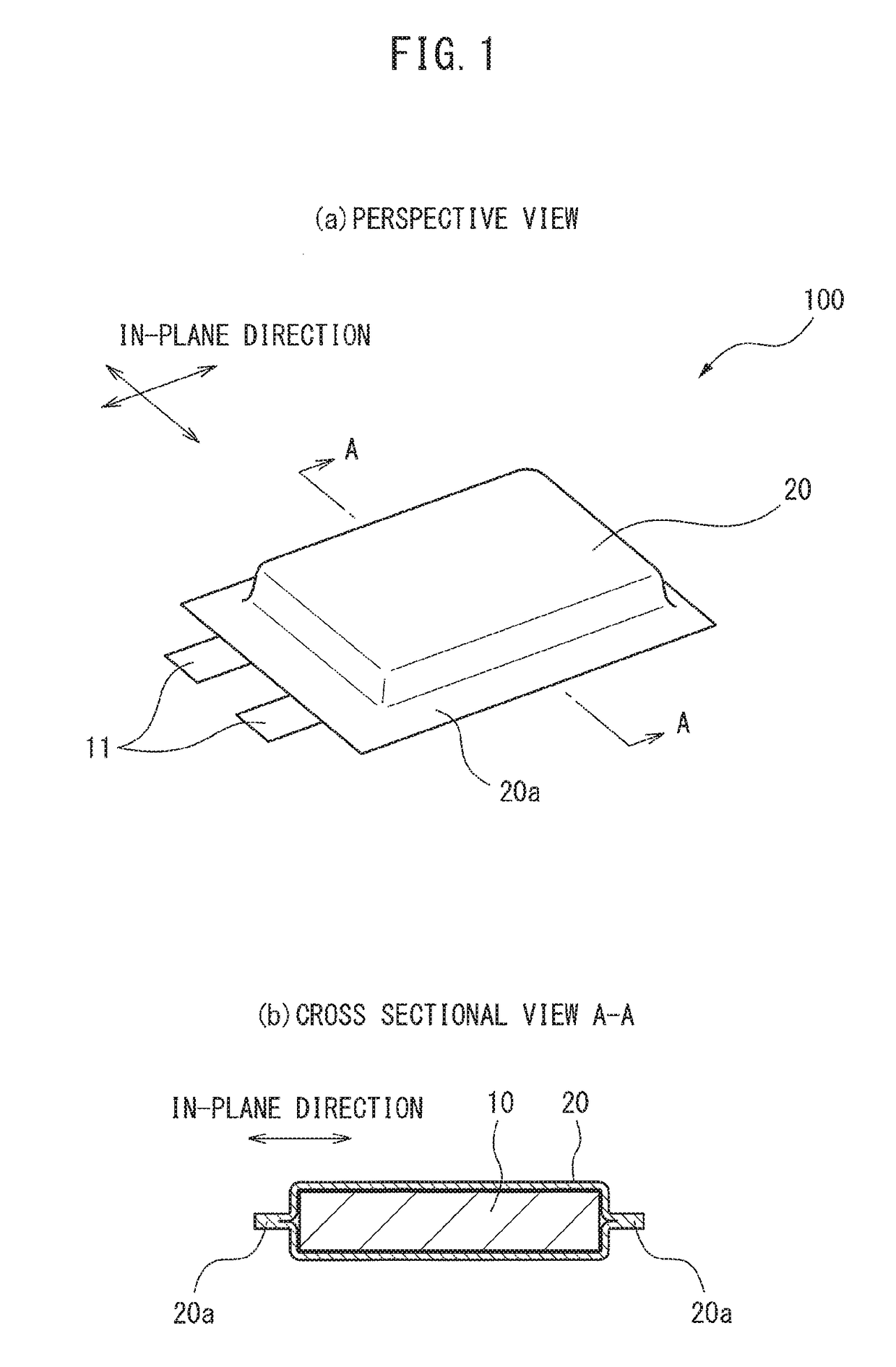

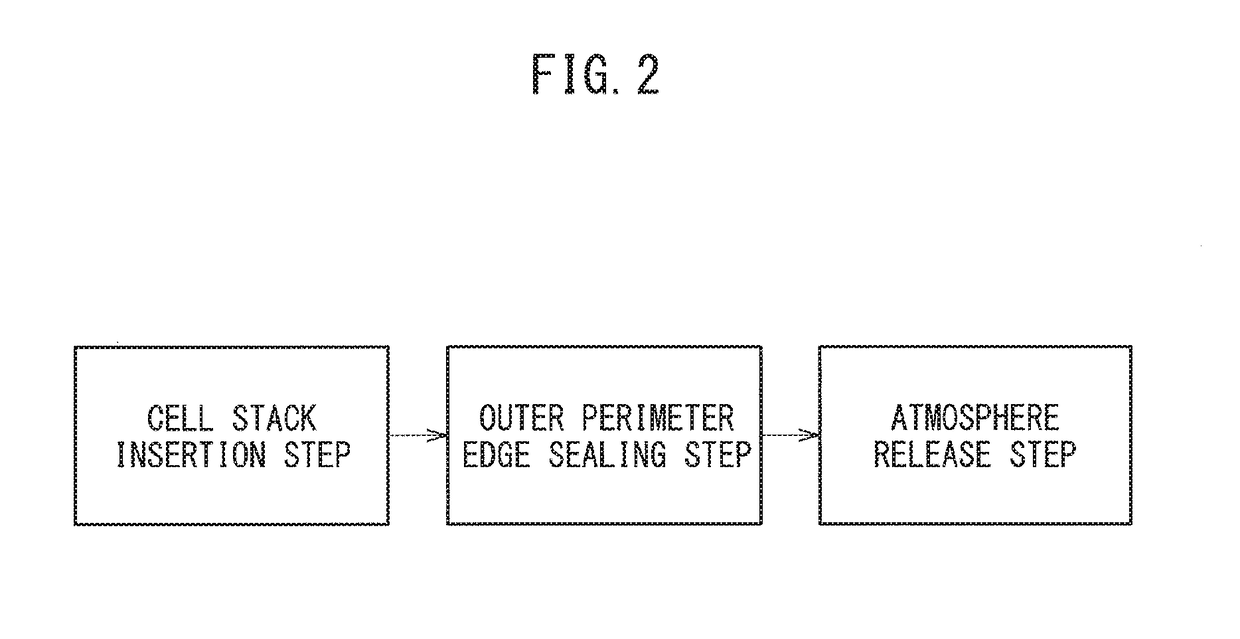

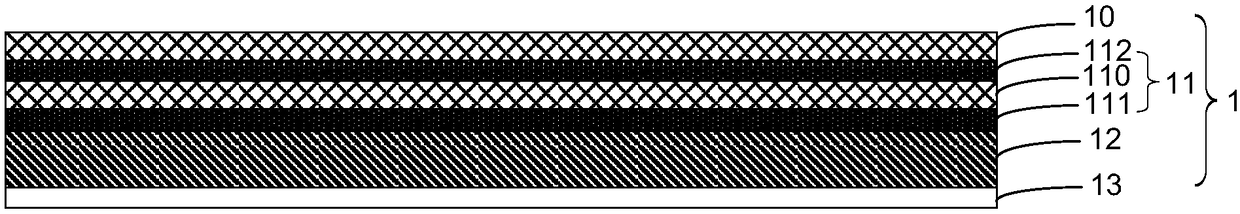

Method for producing pouch battery

ActiveUS20180309092A1Reduce formationReduce creasesAssembling battery machinesFinal product manufactureIn planeEngineering

[PURPOSE]To provide a method for producing a pouch battery that can reduce formation of creases on the main sides and the lateral sides of the laminate film exterior body.[SOLUTION MEANS]A method for producing a pouch battery that comprises a cell stack insertion step in which a cell stack is inserted in a laminate film exterior body, an outer perimeter edge sealing step in which the outer perimeter edges of the laminate film exterior body in which the cell stack has been inserted are sealed in an airtight chamber in a state of reduced pressure, a tensile force applying step in which tensile force is applied to the outer sides in the in-plane direction at two facing locations in the in-plane direction on the outer perimeter edges of the laminate film exterior body, and a tensile force-maintained air release step, in which application of tensile force to the outer sides of the laminate film exterior body in the in-plane direction is maintained while the pressure in the airtight chamber is raised to atmospheric pressure.

Owner:TOYOTA JIDOSHA KK

Polarized light plate and display device

ActiveCN108873141AReduce liftReduce creasesPolarising elementsIdentification meansDisplay devicePolarizer

The invention, which relates to the technical field of display, discloses a polarized light plate and a display device so that a problem of warping or folding caused by bending of the polarized lightplate included by the display device can be solved. The polarized light plate comprises a polarized light plate base body and a deformation control layer for suppressing deformation of the polarized light plate base body; the deformation control layer is arranged on the surface of the polarized light plate base body. In addition, the display device includes the polarized light plate. The polarizedlight plate and the display device are applied to display.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com