IMD mold, injection molding apparatus having such an IMD mold and method for producing a foil-decorated plastic part

A technology of plastic parts and moulds, which is applied in the field of IMD moulds, can solve the problems of high cost and achieve the effect of improving plasticity and reducing the risk of creases or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

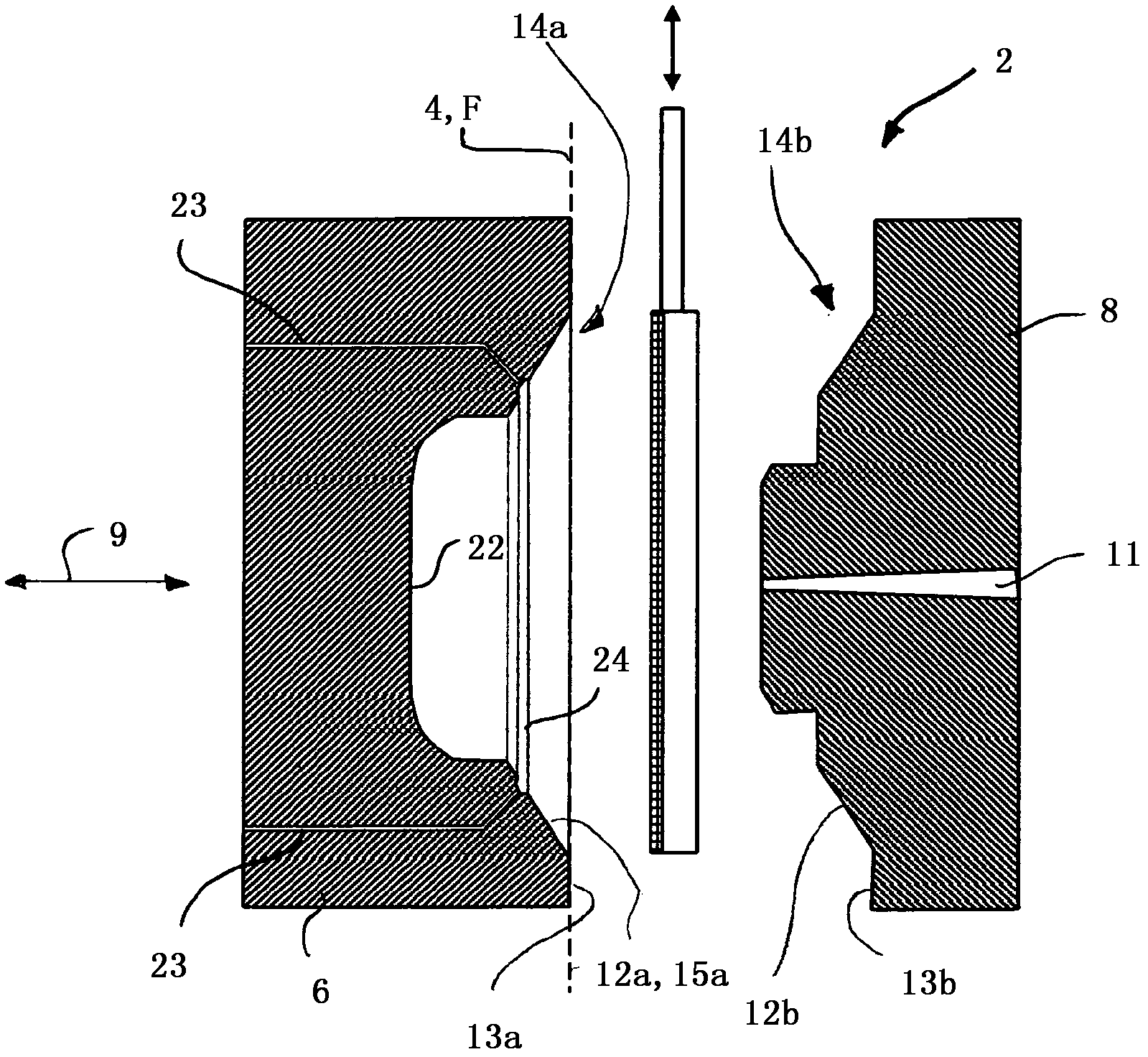

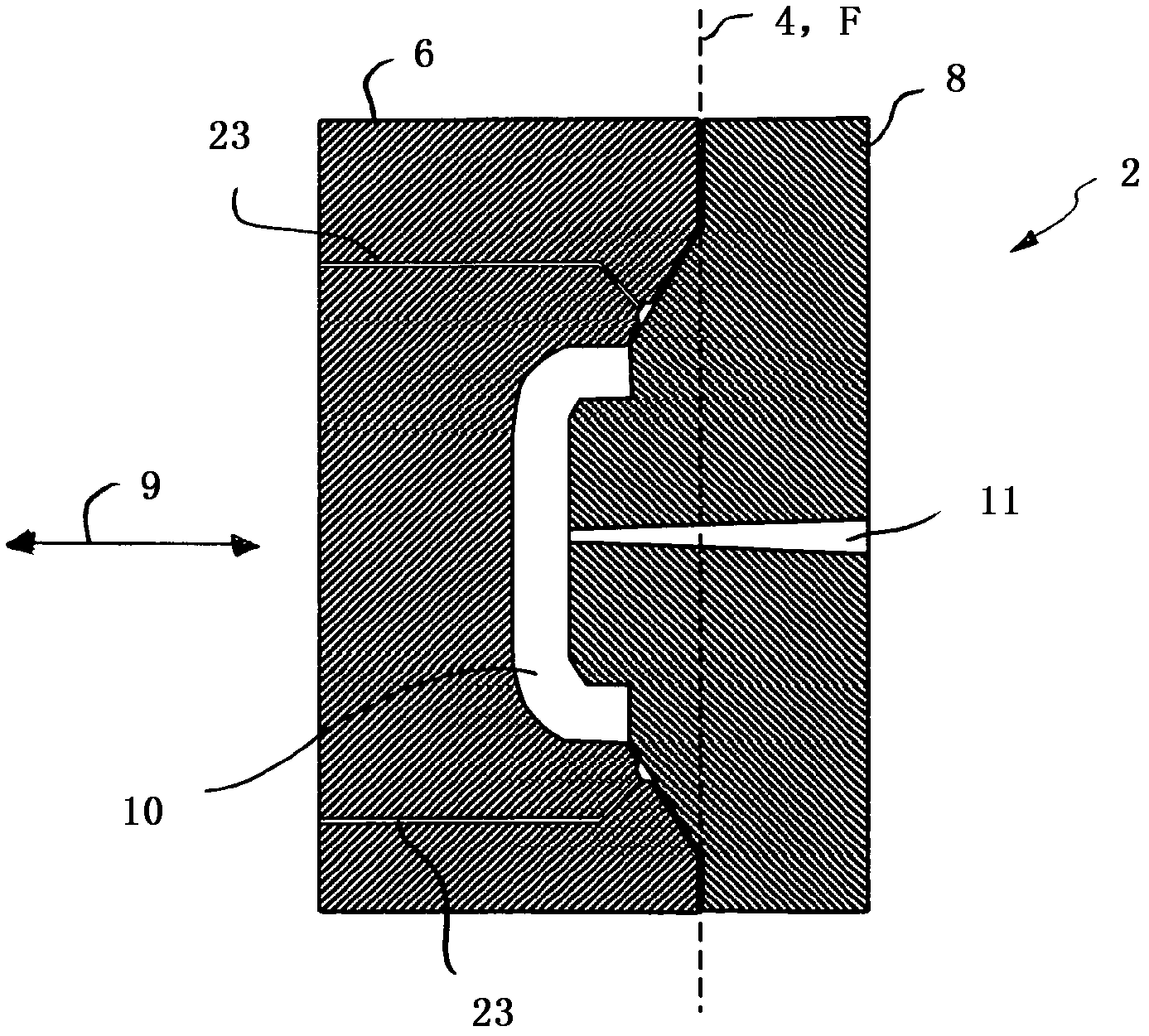

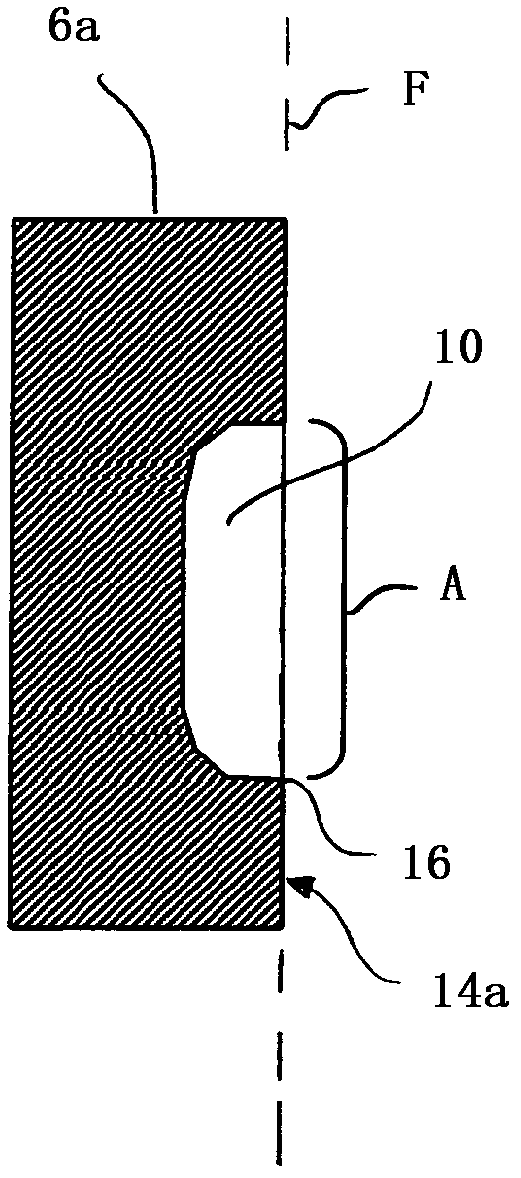

[0033] In the drawings, components with the same function are provided with the same reference signs.

[0034] in figure 1 with 2 An IMD (In-Mold Decoration) mold 2 of an injection molding device not shown in detail is shown in the open position or in the closed position. The plastic part is manufactured with the help of the IMD mold 2, and the visible surface of the plastic part is provided with a decorative paint layer. The coating of the lacquer layer is carried out by the in-mold decoration technique with the aid of a carrier film, and the lacquer layer is applied on the carrier film. The carrier film and the paint layer together form a stretchable film 4, which is placed in front of the mold half 6 of the mold 2 on the demolding side in the open position of the IMD mold 2. The film 4 in this preferred embodiment is an "endless film", that is, a rolled material, which is sequentially unrolled during a mass injection molding process. The film 4 is here guided through the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com