Rack system of digital printing machine

A technology of digital printing machine and rack, applied in printing, printing device, fixed filter element filter, etc., can solve the problem of not being able to solve the problem of not sticking tightly, merging, unfavorable energy saving and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

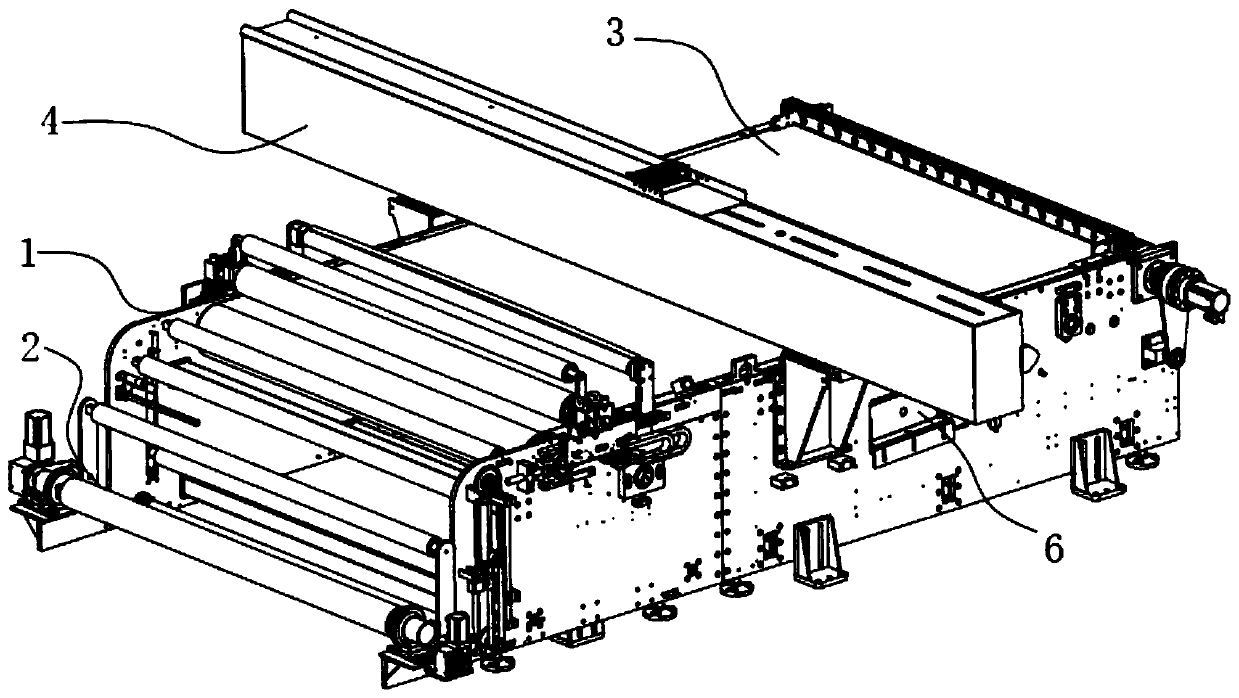

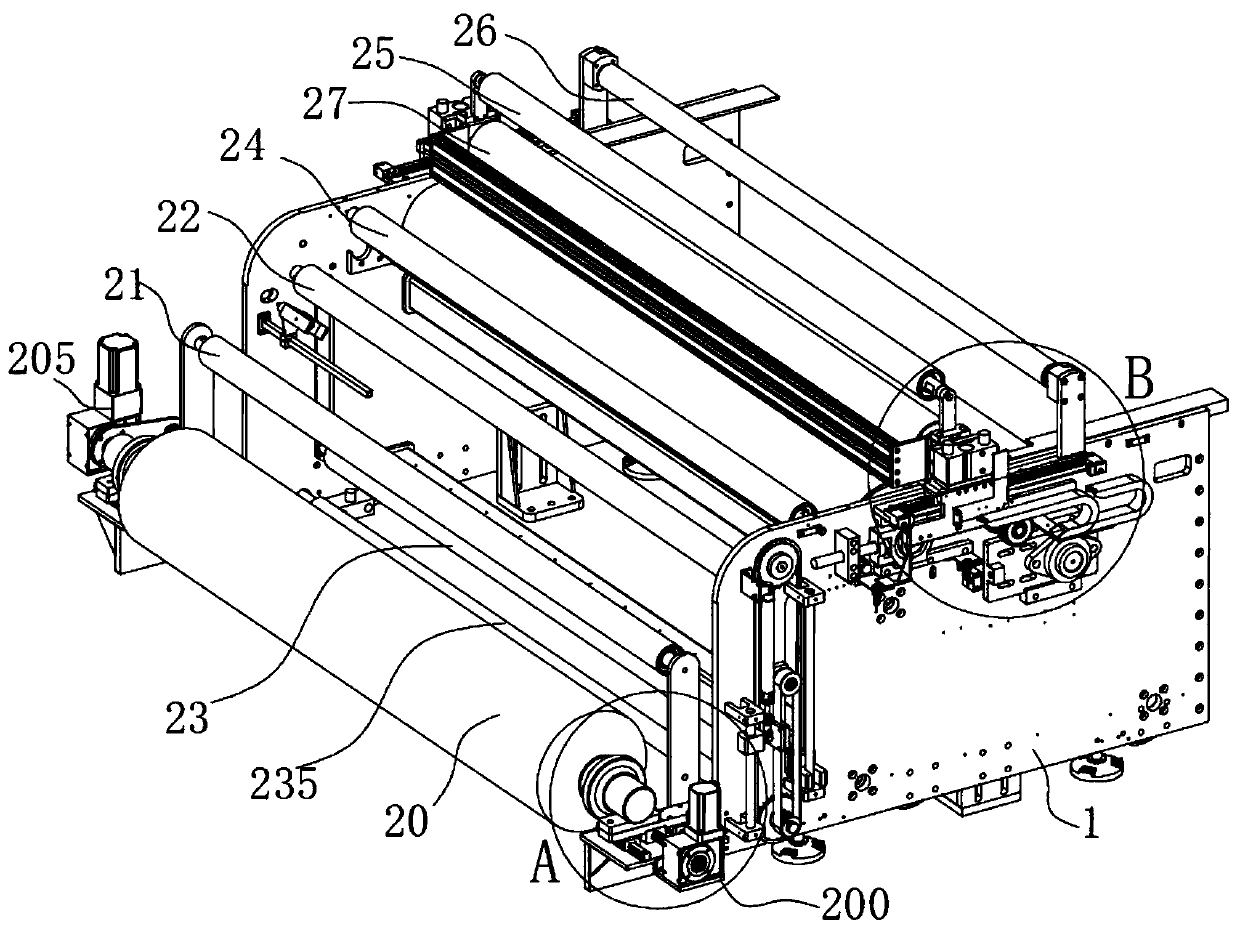

[0066] see Figure 1 ~ Figure 2 The frame system of the digital printing machine preferably implemented in the present invention comprises a frame 1 and a cloth upper mechanism 2 arranged on the frame, a printing conveying belt mechanism 3, a gantry carriage 4, a belt cleaning device 6; a printing conveying belt mechanism 3 It is arranged on the top of the frame, the gantry carriage 4 spans above the printing conveying belt mechanism 3, the cloth loading mechanism 2 is arranged behind the printing conveying belt mechanism 3, and the belt cleaning device 6 is arranged below the printing conveying belt mechanism 3; It is characterized in that,

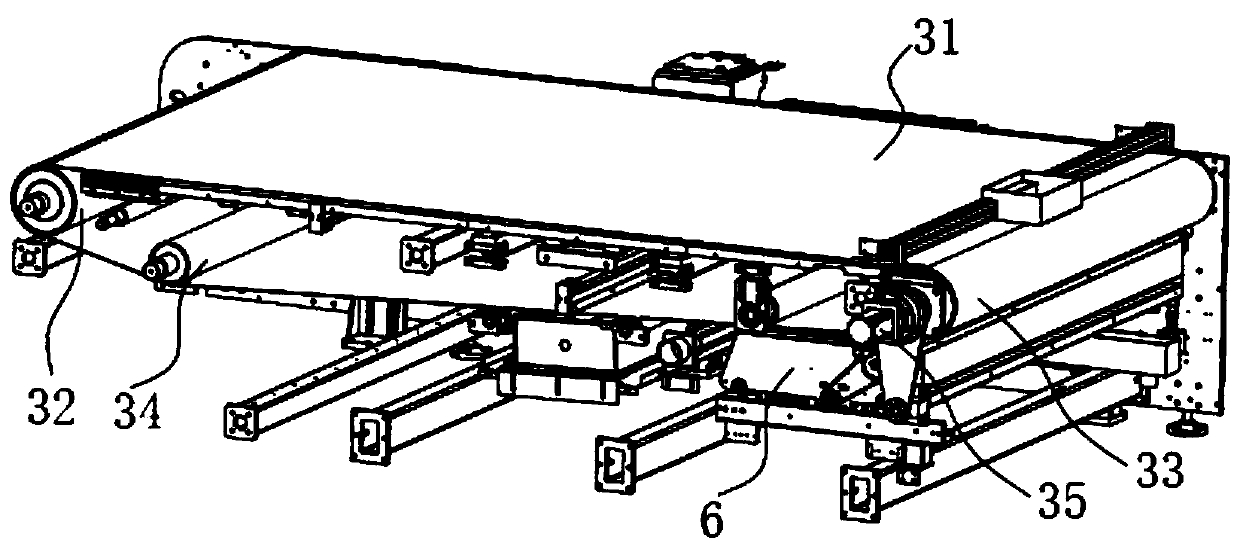

[0067] Described printing conveying belt mechanism 3 comprises transmission belt 31, driving drum 33, driven drum 32, belt deviation correction roller 34 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com