Low-foam and anti-ageing wet type polyurethane resin for synthetic leather and preparation method thereof

A wet-process polyurethane and polyurethane resin technology, applied in textiles and papermaking, can solve problems such as poor recovery, poor elasticity, and large creases, and achieve good recovery, low cost, and small creases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

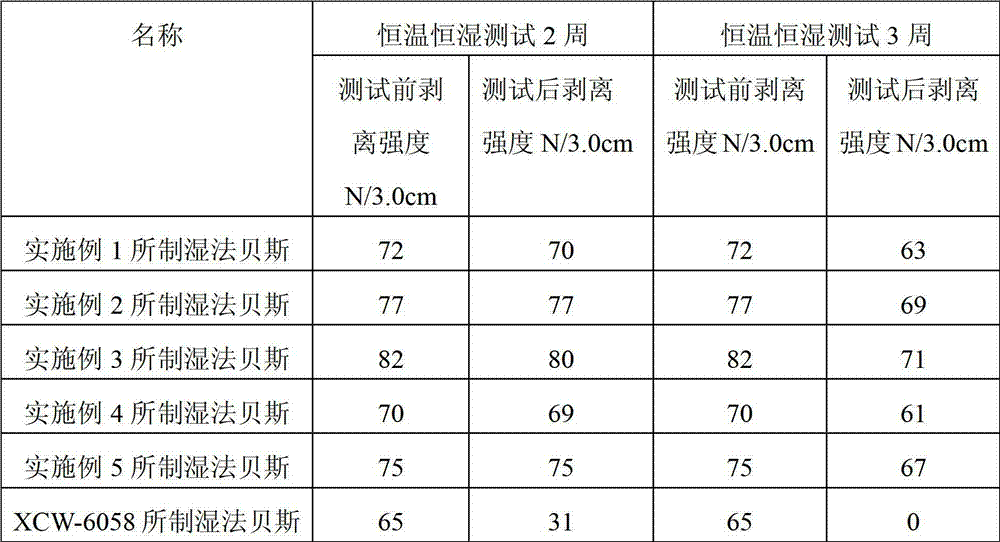

Examples

Embodiment 1

[0036] 1. Formula

[0037] Diphenylmethane-4,4'-diisocyanate 95.79kg;

[0038] Polybutylene adipate diol (number average molecular weight 3000g / mol) 150kg;

[0039] Phthalic anhydride polyester polyol (number average molecular weight 3000g / mol) 40kg;

[0040] Castor oil 10kg;

[0041] Ethylene glycol 12.46kg;

[0042] N, N-dimethylformamide 767kg;

[0043] Polyoxypropylene diol 20.49kg.

[0044] 2. Preparation method

[0045] In the reactor, drop into polybutylene adipate diol (number-average molecular weight 3000) 150kg, phthalic anhydride polyester polyol (number-average molecular weight 3000g / mol) 40kg, ethylene glycol 12.46kg, N, N-dimethyl Diphenylmethane-4,4'-diisocyanate (MDI) 280kg, stirred evenly, and reacted with 87.5kg of diphenylmethane-4,4'-diisocyanate (MDI), the reaction temperature was controlled at 75~85°C, after 2 hours of reaction, the reaction liquid was sampled and tested When the viscosity reaches 120-140Pa·s / 50°C, continue to put 10kg of castor oi...

Embodiment 2

[0047] 1. Formula

[0048] Diphenylmethane-4,4-diisocyanate 98.56kg;

[0049]Polybutylene adipate diol (number average molecular weight 2000g / mol) 60kg;

[0050] Polyethylene adipate-butylene glycol ester diol (number average molecular weight 4000g / mol) 60kg;

[0051] Phthalic anhydride polyester polyol (number average molecular weight 340) 30kg;

[0052] Castor oil 15kg;

[0053] 1,4-butanediol 21.54kg;

[0054] N, N-dimethylformamide 731.4kg;

[0055] Polyoxypropylene diol 28.37kg.

[0056] 2. Preparation method

[0057] In the reactor, drop into polybutylene adipate diol (number average molecular weight 2000) 60kg, polyethylene adipate-butylene glycol ester diol (number average molecular weight 4000g / mol) 60kg, phthalic anhydride polyester 30kg of polyol, 21.54kg of 1,4-butanediol, 210kg of N,N-dimethylformamide (DMF), mix well and add diphenylmethane-4,4-diisocyanate (MDI) 85.7 kg for the reaction, the reaction temperature is controlled at 75~85°C, after 2 hours of...

Embodiment 3

[0059] 1. Formula

[0060] Diphenylmethane-4,4‵-diisocyanate (MDI) 132.75kg;

[0061] Polybutylene adipate diol (number average molecular weight 2000g / mol) 120kg;

[0062] Phthalic anhydride polyester polyol (number average molecular weight 1000g / mol) 40kg;

[0063] Castor oil 8kg;

[0064] Ethylene glycol 6.5kg;

[0065] 1,4-butanediol 28.31kg;

[0066] N, N-dimethylformamide 814.3kg;

[0067] Polyoxypropylene diol 13.42kg.

[0068] 2. Preparation method

[0069] Put 120kg of polybutylene adipate diol (number average molecular weight 2000), 40kg of phthalic anhydride polyester polyol (number average molecular weight 1000g / mol), 6.5kg of ethylene glycol, and 1,4-butanediol into the reaction kettle. Alcohol 28.31kg, N,N-dimethylformamide (DMF) 195kg, mixed and stirred evenly, put into reaction with diphenylmethane-4,4‵-diisocyanate (MDI) 123kg, the reaction temperature is controlled at 75~85 ℃, after 2.5 hours of reaction, when the viscosity of the reaction solution rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com